Electric pressure cooker air leakage protection control method and device and electric pressure cooker

An electric pressure cooker, protection and control technology, applied in the field of control, can solve problems such as circuit short circuit, controller control failure, plastic shell deformation, etc., to achieve the effect of avoiding safety accidents and protecting from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

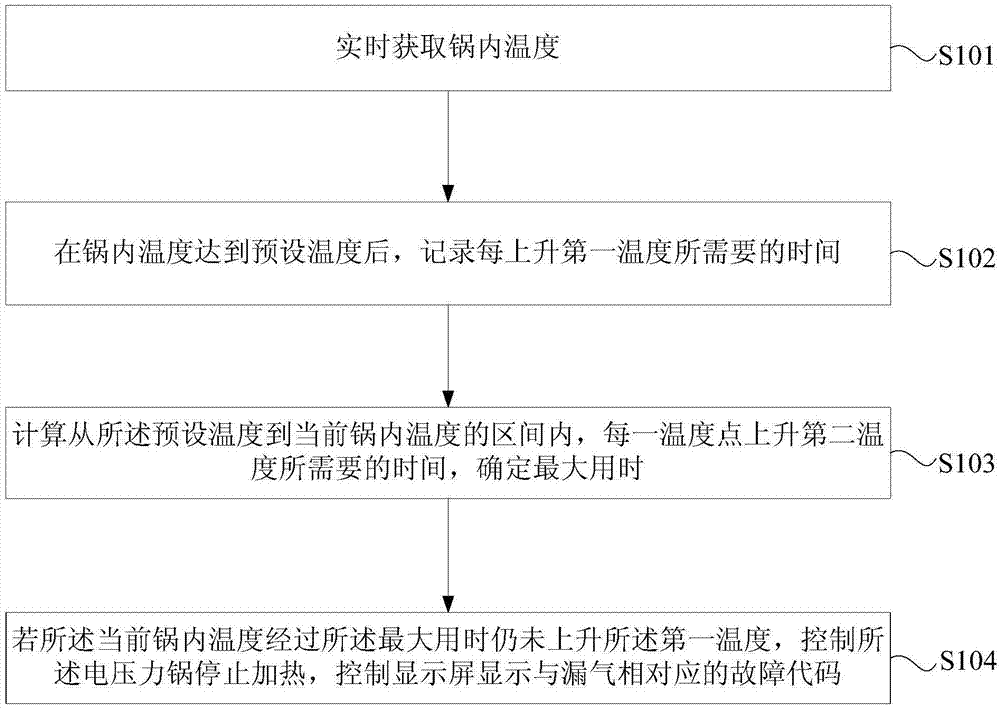

[0046] see figure 1 , figure 1 It is a flowchart of a gas leakage protection control method for an electric pressure cooker provided by an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0047] Step S101, obtaining the temperature in the pot in real time;

[0048] Specifically, the temperature in the pot is obtained in real time through a temperature sensing package arranged inside the upper cover of the electric pressure cooker.

[0049] Step S102, after the temperature in the pot reaches the preset temperature, record the time required for each increase of the first temperature;

[0050] Specifically, the preset temperature is lower than the boiling point temperature of water at the current altitude, that is to say, the preset temperature is a certain temperature before the electric pressure cooker enters the boosting phase. If the boiling temperature of water at the current altitude is 100 degrees Celsius, the preset temperature m...

Embodiment 2

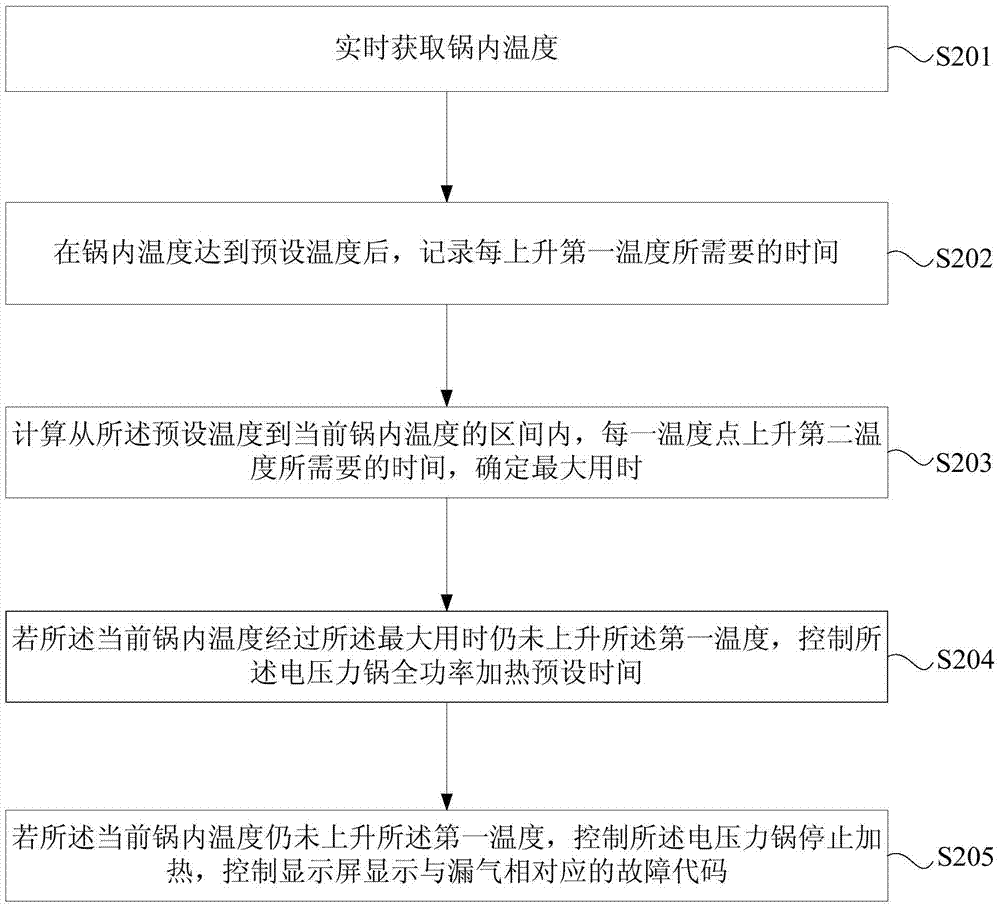

[0059] see figure 2 , figure 2 It is a flow chart of another electric pressure cooker air leakage protection control method provided by the embodiment of the present invention. Such as figure 2 As shown, the method includes:

[0060] Step S201, obtaining the temperature in the pot in real time;

[0061] Step S202, after the temperature in the pot reaches the preset temperature, record the time required for each increase of the first temperature;

[0062] Specifically, the preset temperature is lower than the boiling temperature of water at the current altitude.

[0063] Step S203, calculating the time required for each temperature point to rise to the second temperature within the interval from the preset temperature to the current temperature in the pot, and determining the maximum time;

[0064] Specifically, the second temperature is greater than the first temperature.

[0065] Step S204, if the current temperature in the pot has not risen to the first temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com