A self-generated potential-excited microbubble-enhanced evaporative heat transfer tube

A heat exchange tube and micro-bubble technology, applied in electrical components, electrical components, electromechanical devices, etc., can solve the problems of increased exergy loss, heat transfer area and heat transfer temperature difference cannot be changed at will, high heat transfer temperature difference, etc. The effect of superheat, lowering onset of boiling, increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

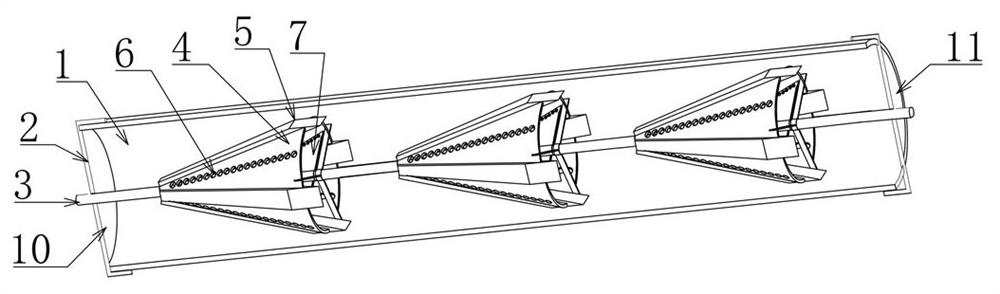

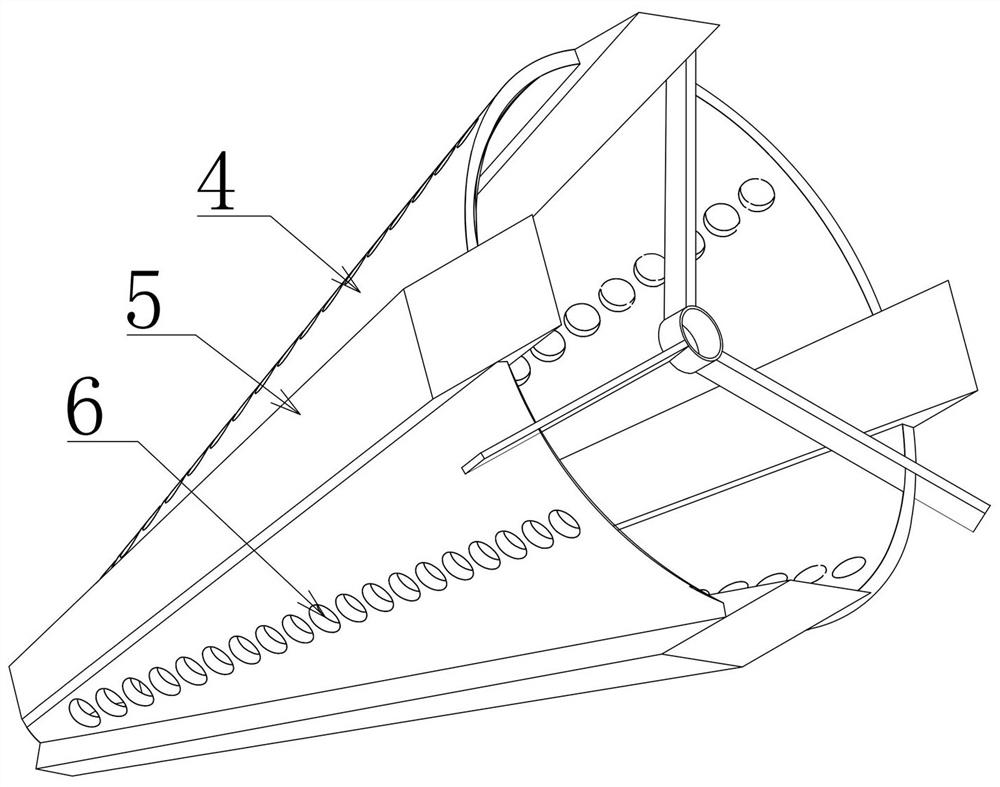

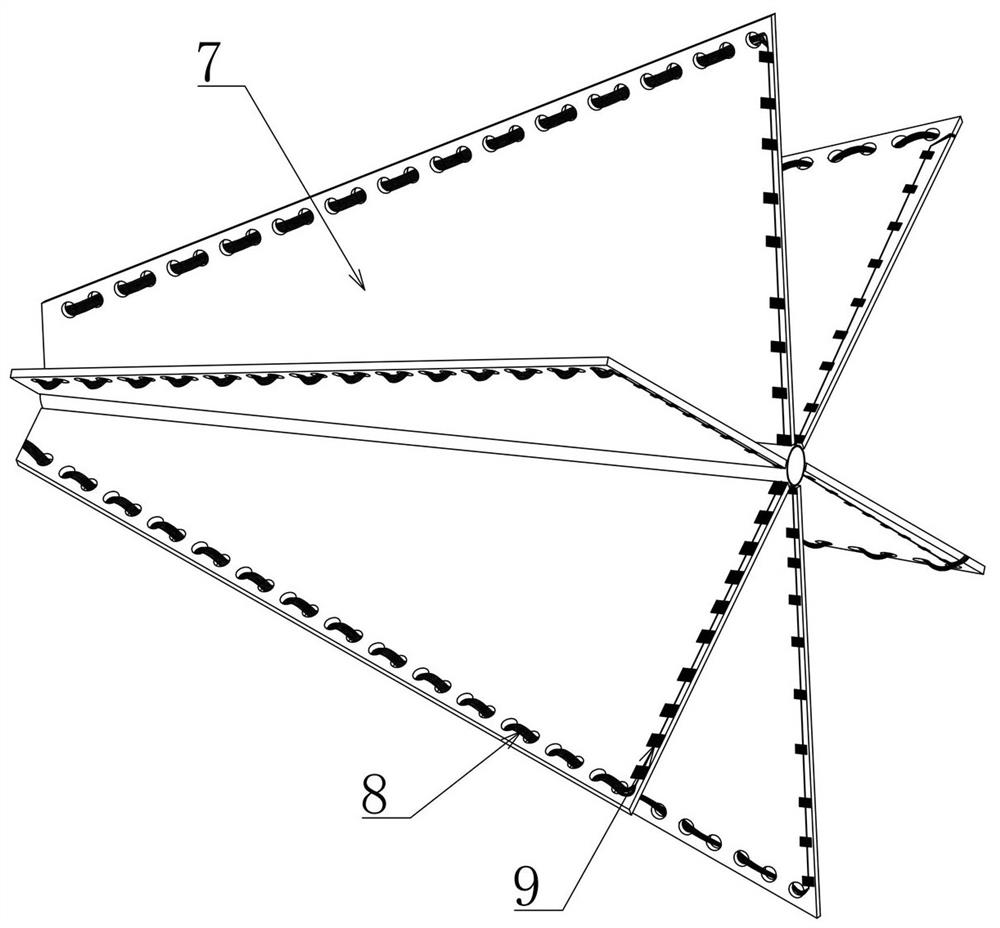

[0030] Embodiment 1, a self-generated potential-excited microbubble-enhanced evaporation heat exchange tube, including a heat exchange tube 1, characterized in that the left and right ends of the heat exchange tube 1 are respectively fixedly connected with an axially fixed shaft 2, and two sets of A central fixed shaft 3 placed in the heat exchange tube 1 is fixedly connected between the axially fixed shafts 2, and three groups of conical rings 4 are fixedly connected at horizontal intervals on the central fixed shaft 3. 4 is fixedly connected with an array of permanent magnets 5 along the circumferential direction. The ring 4 is rotatably connected with a rotating blade 7 sleeved on the central fixed shaft 3, the rotating blade 7 is provided with a coil 8, and the bottom of the rotating blade 7 is fixedly connected with a micro heater 9 connected with the coil 8. .

[0031] When this embodiment is in use, the left and right ends of the heat exchange tube 1 are respectively f...

Embodiment 2

[0033] Embodiment 2, on the basis of Embodiment 1, the permanent magnets 5 are distributed between the circumferential array micro-holes 6 and the number is even and distributed in pairs, and each pair of permanent magnets 5 is 180 degrees symmetrical, The number of blades of the rotating blades 7 is even and distributed in pairs, and each pair of rotating blades 7 is 180 degrees symmetrical.

[0034] When this embodiment is used, the number of rotating blades 7 is six, and the distance between each group is one hundred and eighty degrees. The number of blades of the rotating blades 7 is even and distributed in pairs, and each pair of rotating blades 7 is one hundred and eighty degrees. Symmetrical, the rotating blade 7 is in the shape of a right-angled trapezoid and the gradient of the oblique waist of the blade is consistent with the gradient of the outer surface of the tapered ring 4. The length of the lower bottom of the rotating blade 7 is greater than the length of the up...

Embodiment 3

[0035] Embodiment 3, on the basis of Embodiment 1, the tapered ring 4 is made of polymer heat-resistant insulating material, its outer surface is coated with a layer of high thermal conductivity material, and the coil 8 is coated with a Layer enameled wire.

[0036] When this embodiment is used, the conical ring 4 is made of polytetrafluoroethylene, which is coated with graphene high thermal conductivity material, which can increase the heat transfer on the surface of the conical ring 4, improve the superheat of the surface, and increase the effective nucleation. point density, thereby enhancing the heat transfer effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com