Heat exchange assembly for looped heat pipe

A heat exchange device and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as inconsistency in economy, reduced temperature uniformity, reduced heat transfer, etc., to achieve good heat transfer, manufacturing Low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings.

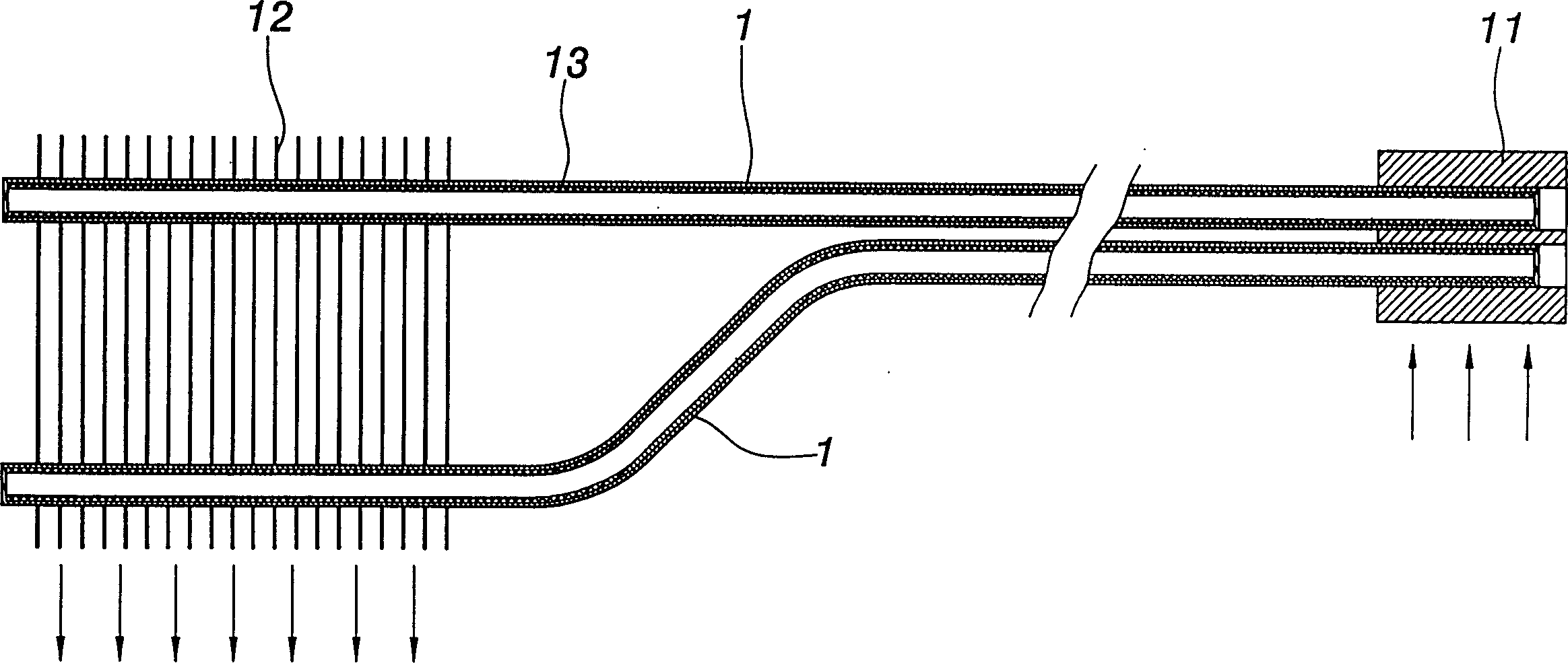

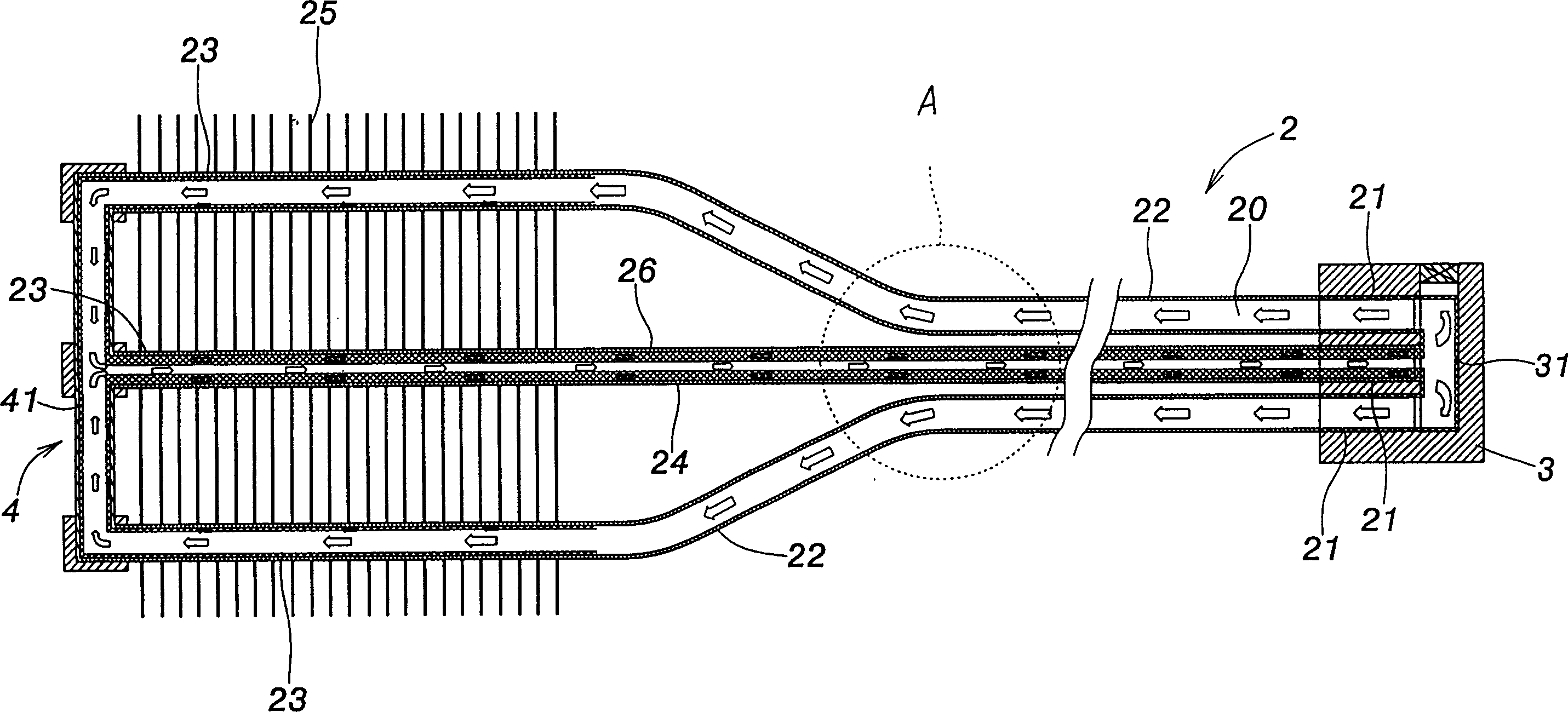

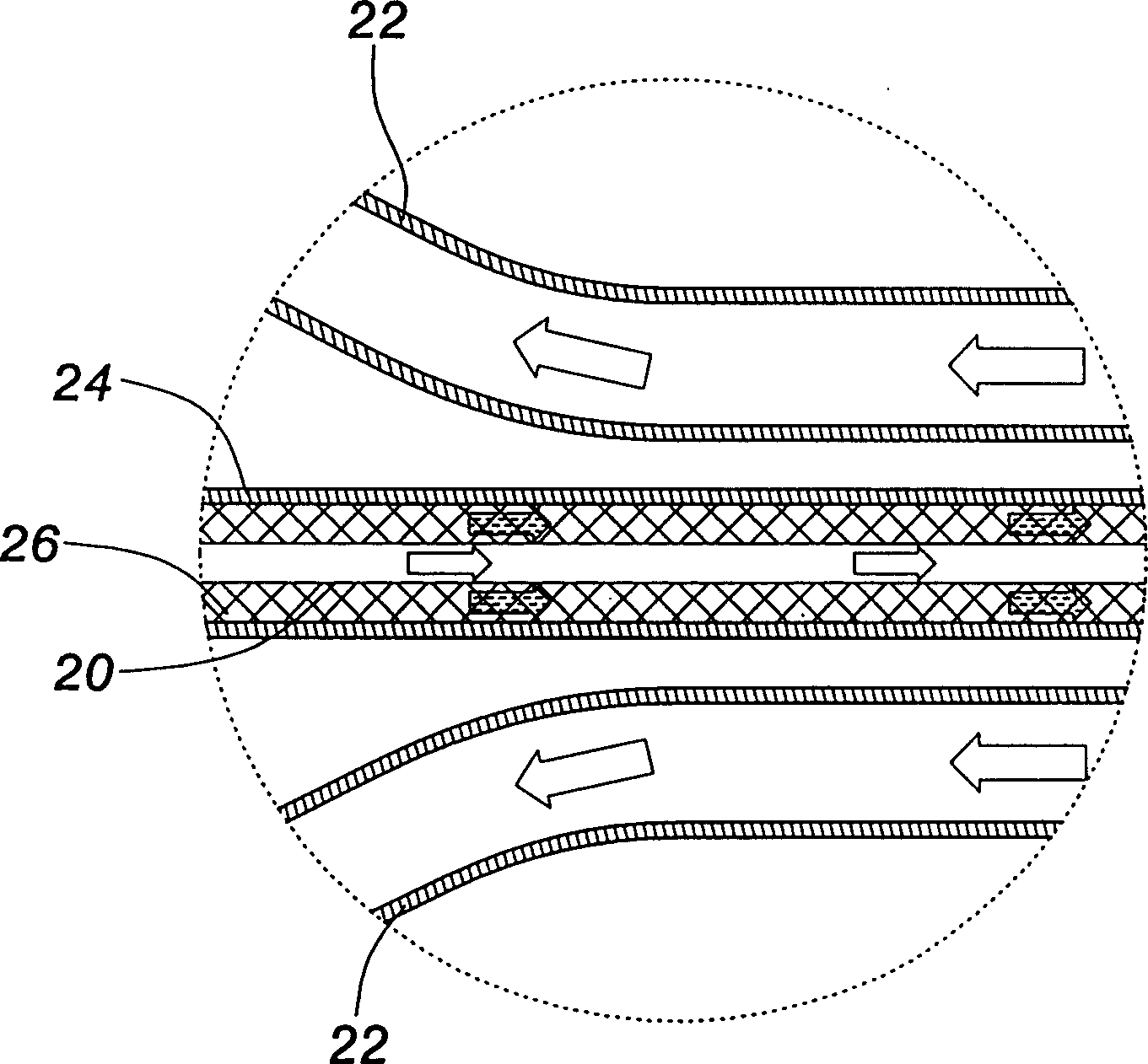

[0027] Such as figure 2 , image 3 , Figure 4 As shown, the present invention includes a closed circuit 2 , an evaporation part 21 , a steam channel 22 , a condensation part 23 , a fluid return channel 24 , a heat transfer block 3 and a connection block 4 connected in series on the closed circuit 2 in sequence.

[0028] An appropriate amount of liquid is filled in the closed circuit 2, and the filling amount of the liquid refers to the volume from filling the capillary tissue to filling the circuit to 90%.

[0029] The fluid return channel 24 and the steam channel 22 are not shared pipelines, that is, the steam channel 22 and the fluid return channel 24 are independent pipelines.

[0030] The flow resistance of the fluid in the fluid return channel 24 is greater than the flow resistance of the fluid in the steam channel 22, resulting in an unbalanced heat flow in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com