Dry-type hot water heating floor

A hot water and dry technology, applied to floors, building components, buildings, etc., can solve the problems of large downward heat transfer ratio, small floor area heat dissipation, small heating pipe diameter, etc., to achieve small temperature changes, Effect of increasing heat transfer and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

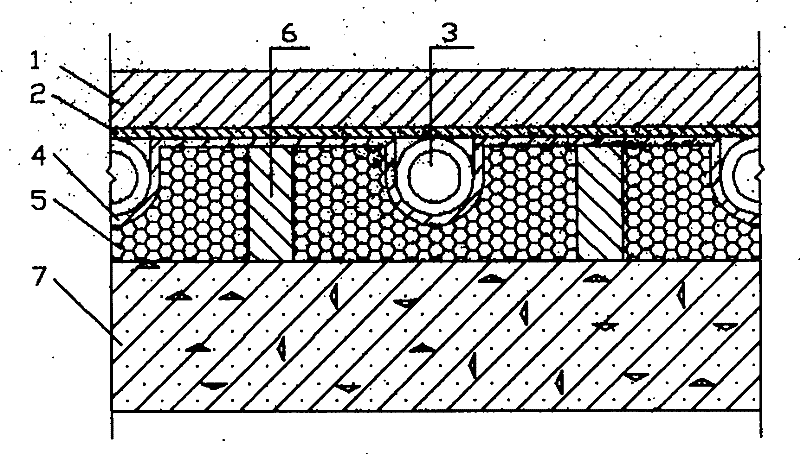

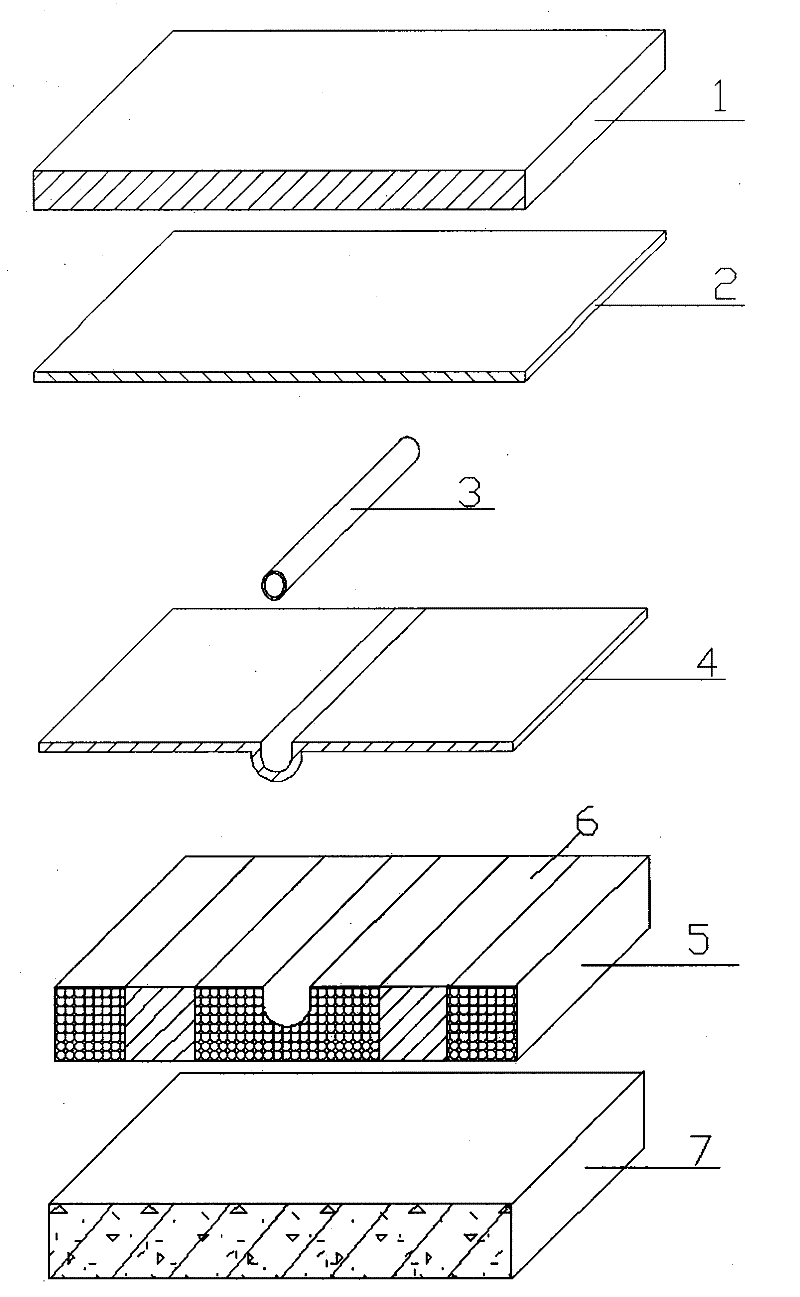

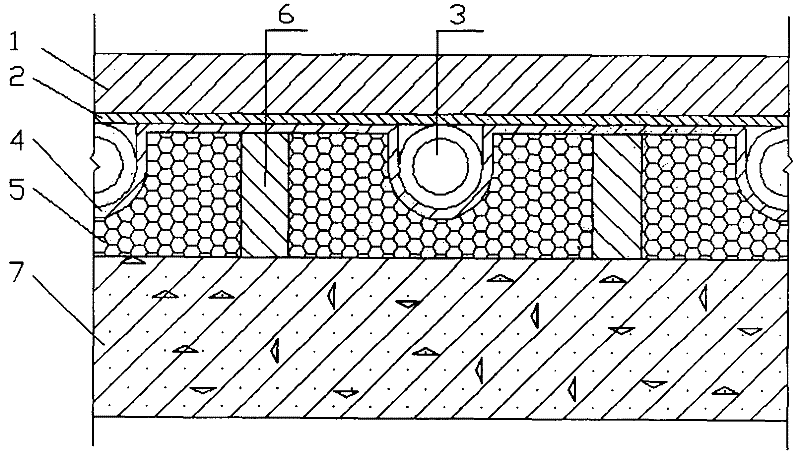

Embodiment 1

[0026] The floor structure is 110mm from bottom to top, the insulation layer is 25mm, the heating pipe is polybutene (PB) pipe, the outer diameter of the heating pipe is 12mm, the upper and lower heat conduction films are made of aluminum foil, the thickness is 0.1mm, and the wooden floor is 9mm. The heating tube spacing is 150mm. When the indoor design temperature is 18°C and the average temperature of hot water in the heating pipe is 45°C, the average floor surface temperature is 27.9°C, the maximum temperature difference on the floor surface is 3.7°C, and the heat dissipation per unit floor area is 63W / m 2 .

Embodiment 2

[0028] The floor structure is 110mm from bottom to top, the insulation layer is 25mm, the heating pipe is polybutene (PB) pipe, the outer diameter of the heating pipe is 12mm, the thickness of the upper and lower heat conducting films is 0.2mm, and the wooden floor is 9mm. The heating tube spacing is 200mm. When the indoor design temperature is 20°C and the average temperature of hot water in the heating pipe is 50°C, the average floor surface temperature is 25.6°C, the maximum temperature difference on the floor surface is 2.6°C, and the heat dissipation per unit floor area is 59W / m 2 .

Embodiment 3

[0030] The floor structure is 110mm from bottom to top, the insulation layer is 40mm, the heating pipe is polybutene (PB) pipe, the outer diameter of the heating pipe is 20mm, the thickness of the upper and lower heat conduction films is 0.6mm, and the wooden floor is 9mm. The heating tube spacing is 200mm. When the indoor design temperature is 22°C and the average temperature of hot water in the heating pipe is 35°C, the average floor surface temperature is 26.2°C, the maximum temperature difference on the floor surface is 0.8°C, and the heat dissipation per unit floor area is 65W / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com