Vacuum circulating drying machine for grain

A grain vacuum, circulating technology, applied in dryers, dryers for static materials, drying, etc., can solve the problems of poor quality and high hot air temperature, achieve fast drying speed, increase drying temperature, and reduce boiling point. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

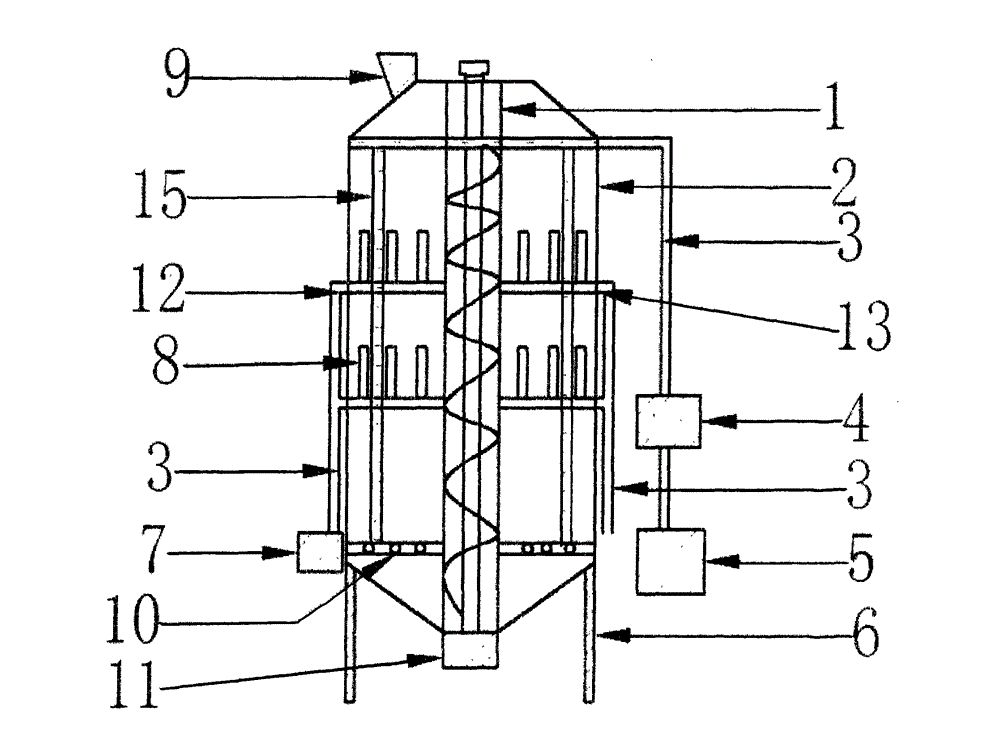

[0032] Such as figure 1 Shown: a grain vacuum circulation dryer consists of a lifting device (1), a drying bin (2), a condenser (4), a vacuum pump (5), a heating device (7), a heat exchange device (8), It consists of a feed valve (9), a discharge valve (11), a grain discharge device (10), a support (6), and an air duct (3).

[0033] The lower end of the drying bin (2) is fixedly supported by a bracket (6).

[0034] The drying bin (2) is a metal bin made of metal plates, the upper and lower ends of the drying bin (2) are tapered; the section of the drying bin (2) is square.

[0035] A discharge valve (11) is installed on the lower end of the drying bin (2); a feed valve (9) is installed on the side of the upper end of the drying bin (2); A lifting device (1) is installed in the center.

[0036] The feed valve (9) and the discharge valve (11) are high airtight discharge valves.

[0037] The lifting device (1) is installed in the drying bin (2), and the connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com