Novel flooded type evaporating heat exchange tube

A heat exchange tube, flooded technology, used in evaporators/condensers, tubular elements, heat transfer modification, etc. The effect of increasing the growth and improving the boiling heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

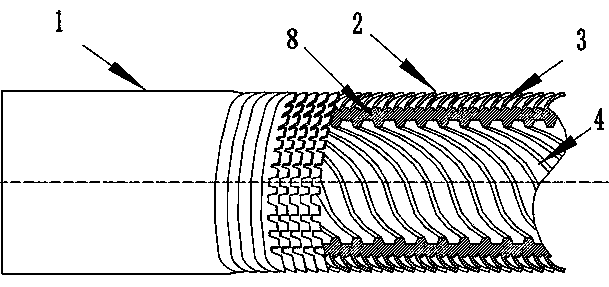

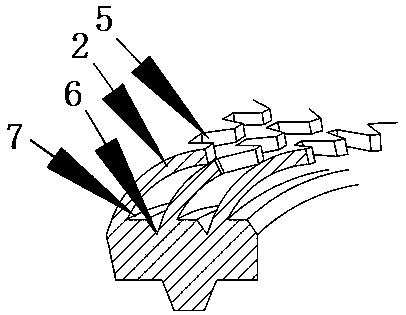

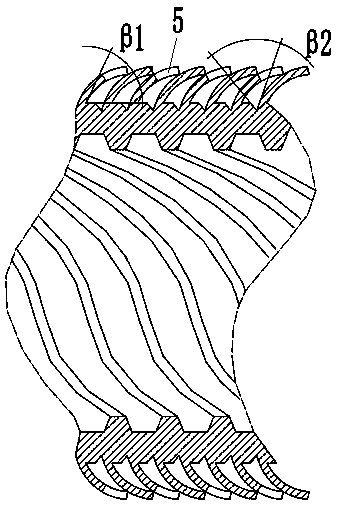

[0026] Embodiment: a new flooded evaporative heat exchange tube (see Figure 1-Figure 3), which includes light segment 1 and evaporation surface segment. Optical section 1 is used for fixing with the end plate of the heat exchanger, and its outer diameter is 19mm. The evaporation surface section is the heat exchange surface, and the evaporation surface section includes the heat exchange tube body 8, and the outer surface of the heat exchange tube body 8 is provided with inclined and curved fins 2 distributed in a spiral shape along the axis of the heat exchange tube, and the surface of the fins 2 is Curved surface shape, and the fins are inclined in the same direction. The tops of adjacent fins 2 are in close contact with each other without gaps. The length of fins 2 is 0.8-1.1mm, and the thickness of fins 2 is 0.08-0.25mm. The root spacing is 0.3-0.8mm. The fins 2 cover the channels between the fins to form a triangular cavity 3, the height of the cavity 3 is 0.3-0.5mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com