A surface treatment method for improving heat transfer coefficient of heat exchanger

A technology of surface treatment and heat transfer coefficient, applied in metal material coating process, coating, liquid chemical plating, etc., can solve the problems of decreased material strength, decreased strengthening effect, difficult to accurately control structural parameters, etc., to achieve critical heat flow The density increases, the boiling heat transfer coefficient increases, and it is beneficial to the effect of boiling heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of surface treatment method that improves heat transfer coefficient of heat exchanger, concrete steps are:

[0027] (1) Add copper salt (copper nitrate) to water to prepare a copper salt solution; the concentration of copper ions in the copper salt solution is 0.002mol / L;

[0028] (2) Add the nitric acid in step (1) to the copper salt solution in step (1) to obtain a copper salt-acid surface treatment solution; wherein H in the copper salt-acid surface treatment solution + The concentration is 1mol / L;

[0029] (3) At a temperature of 90°C, place the iron surface heat exchanger in the copper salt-acid surface treatment solution in step (2) for 30 minutes to obtain the porous surface of the iron surface heat exchanger;

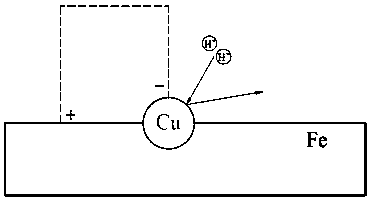

[0030] The principle schematic diagram of this embodiment is as follows figure 1 As shown, the copper ions in the copper salt-acid surface treatment solution undergo a substitution reaction with the metal element to form copper nano...

Embodiment 2

[0033] Embodiment 2: a kind of surface treatment method that improves heat exchanger heat transfer coefficient, concrete steps are:

[0034] (1) Add copper salt (copper chloride) to water to prepare a copper salt solution; the concentration of copper ions in the copper salt solution is 0.004mol / L;

[0035] (2) adding the sulfuric acid of step (1) to the copper salt solution of step (1) to obtain a copper salt-acid surface treatment solution; wherein H in the copper salt-acid surface treatment solution+ The concentration is 2mol / L;

[0036] (3) At a temperature of 60°C, place the iron surface heat exchanger in the copper salt-acid surface treatment solution in step (2) for 1.5 hours to obtain the porous surface of the iron surface heat exchanger;

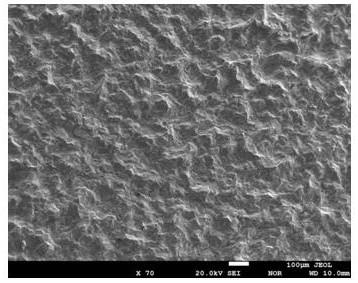

[0037] The SEM of the iron surface heat exchanger porous surface of the present embodiment is as image 3 shown, from image 3 It can be seen that complex pores appear on the surface of the heat exchanger, and the average depth of ...

Embodiment 3

[0039] Embodiment 3: a kind of surface treatment method that improves heat exchanger heat transfer coefficient, concrete steps are:

[0040] (1) Add silver salt (silver nitrate) to water to prepare a silver salt solution; the concentration of silver ions in the silver salt solution is 0.006mol / L;

[0041] (2) Add the nitric acid of step (1) to the silver salt solution of step (1) to obtain a silver salt-acid surface treatment solution; wherein H in the silver salt-acid surface treatment solution + The concentration is 3mol / L;

[0042] (3) At a temperature of 40°C, place the iron surface heat exchanger in the silver salt-acid surface treatment solution in step (2) for 6 hours to obtain the porous surface of the iron surface heat exchanger;

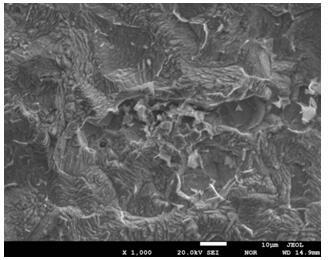

[0043] The SEM of the iron surface heat exchanger porous surface of the present embodiment is as Figure 4 shown, from Figure 4 It can be seen that complex pores appear on the surface of the heat exchanger, and the average depth of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com