A preparation method of porous Cu surface for heat exchange

A technology of hydrothermal reaction kettle and substrate, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of serious equipment dependence, unevenness, small porous aperture, etc., and achieve excellent boiling heat transfer The effect of improving the boiling heat transfer coefficient and the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1. Cut the dense Cu substrate into 50mm×5mm×1mm slices, place them in ethanol for ultrasonic degreasing, then place them in 1mol / L HCl solution for ultrasonic etching for 15 minutes, then wash them with deionized water and then naturally dry;

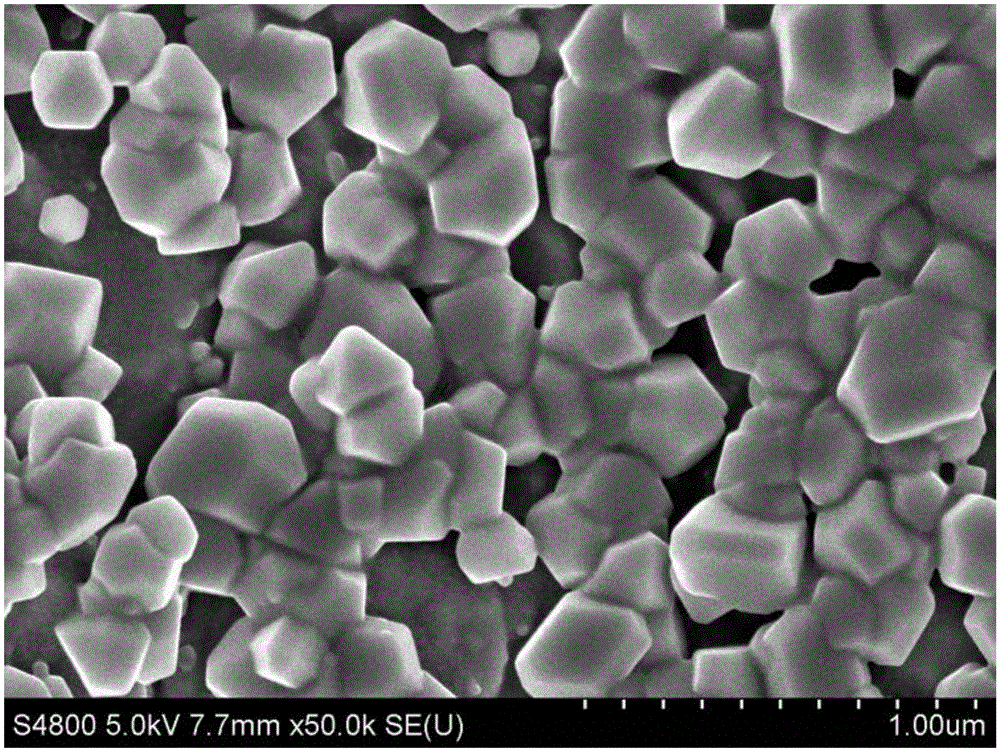

[0025] Step 2. Place the Cu substrate after natural air-drying in step 1 flatly on the polytetrafluoroethylene platform, and then place it together in a hydrothermal reaction kettle with a tetrafluoroethylene liner with a volume of 500mL. Add 20mL of absolute ethanol to the gap between the PTFE platforms, and finally seal the hydrothermal reactor and place it in an oven, and use steam to steam heat the Cu substrate for 6 hours at a temperature of 160°C to obtain Cu-based porous CuO film;

[0026] Step 3. Perform reduction heat treatment on the Cu-based porous CuO film described in step 2 in a hydrogen atmosphere with a volume purity of not less than 99.999%, to obtain a Cu-based porous Cu surface for heat exchange; the temp...

Embodiment 2

[0029] Step 1. Cut the dense Cu substrate into 20mm×10mm×0.1mm sheets, place them in ethanol for ultrasonic degreasing, then place them in 0.5mol / L HCl solution for ultrasonic etching for 30min, and then clean them with deionized water After natural air drying;

[0030] Step 2. Place the Cu substrate after natural air-drying in step 1 on a polytetrafluoroethylene platform, and then place it together in a hydrothermal reaction kettle with a tetrafluoroethylene liner with a volume of 800mL. Add 40mL of absolute ethanol to the gap between the PTFE platforms, and finally seal the hydrothermal reactor and place it in an oven, and steam heat the Cu substrate with steam for 8 hours at a temperature of 150°C to obtain Cu-based porous CuO film;

[0031] Step 3. Perform reduction heat treatment on the Cu-based porous CuO film described in step 2 in a hydrogen atmosphere with a volume purity of not less than 99.999%, to obtain a Cu-based porous Cu surface for heat exchange; the temperat...

Embodiment 3

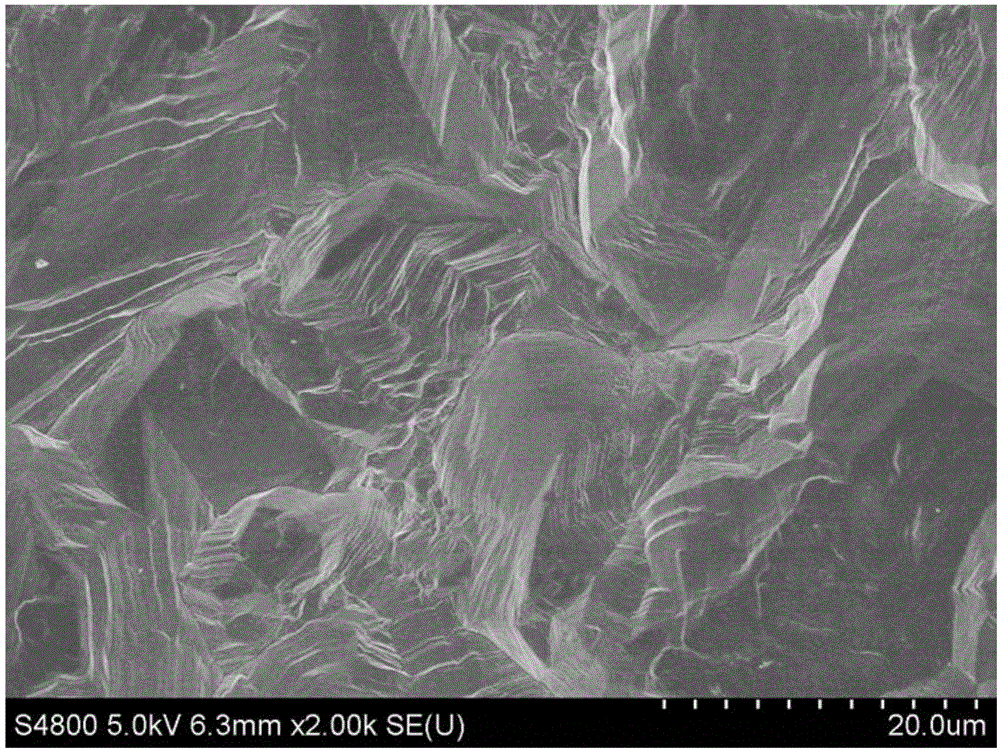

[0034] Step 1. Cut the powder metallurgy sintered porous Cu substrate into a sheet of 60mm×25mm×0.1mm, place it in ethanol for ultrasonic degreasing, then place it in 1.5mol / L HCl solution for ultrasonic etching for 15min, and then use Naturally air-dry after washing with ionized water;

[0035] Step 2. Place the Cu substrate after natural air-drying in step 1 on a polytetrafluoroethylene platform, and then place it together in a hydrothermal reaction kettle with a tetrafluoroethylene liner with a volume of 800mL. Add 30mL of absolute ethanol to the gap between the PTFE platforms, and finally seal the hydrothermal reactor and place it in an oven, and steam heat-treat the Cu substrate with steam for 4 hours at a temperature of 180°C to obtain Cu-based porous CuO film;

[0036] Step 3. Perform reduction heat treatment on the Cu-based porous CuO film described in step 2 in a hydrogen atmosphere with a volume purity of not less than 99.999%, to obtain a Cu-based porous Cu surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com