Free particle/porous medium composite enhanced boiling structure and preparation method thereof

A technology to strengthen boiling and porous media, applied in heat exchange equipment, lighting and heating equipment, heat transfer modification and other directions, can solve the problems of increasing wall thermal resistance, strengthening the long-term effect of boiling, and speeding up the liquid reflux rate. , delayed critical heat flux, flexible operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the particle / porous medium composite enhanced boiling structure specifically includes the following steps:

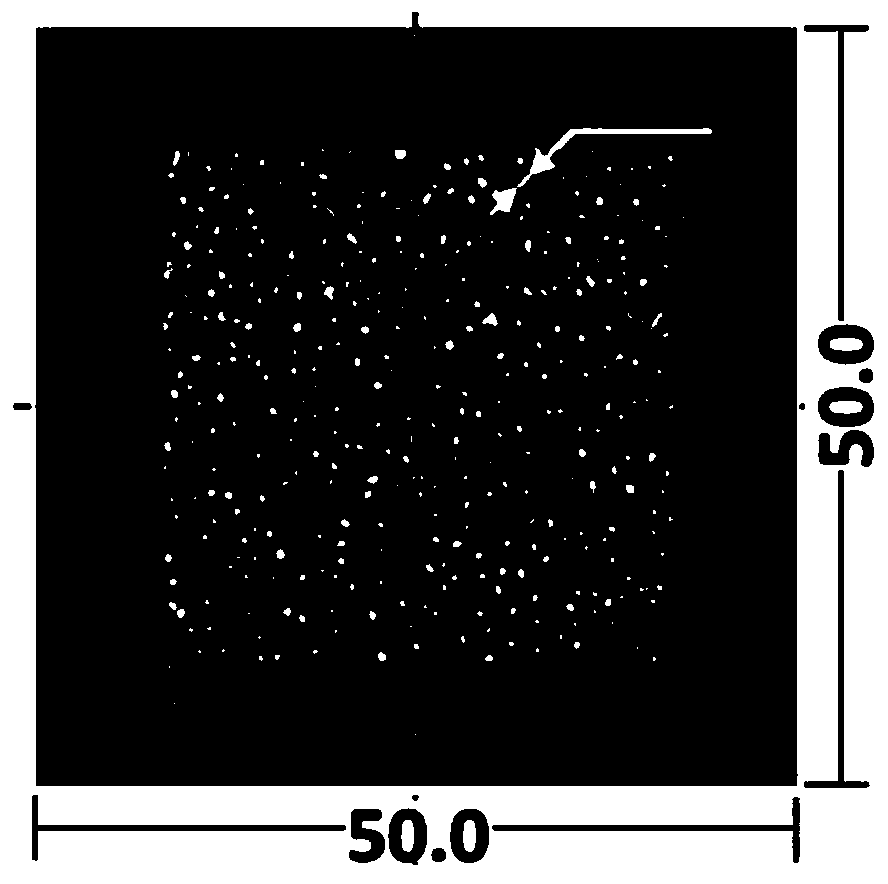

[0048] (1) Heating the substrate (50mm×50mm), and using 800 mesh, 1200 mesh, 1500 mesh, 2000 mesh, and 3000 mesh sandpaper to polish the substrate in sequence;

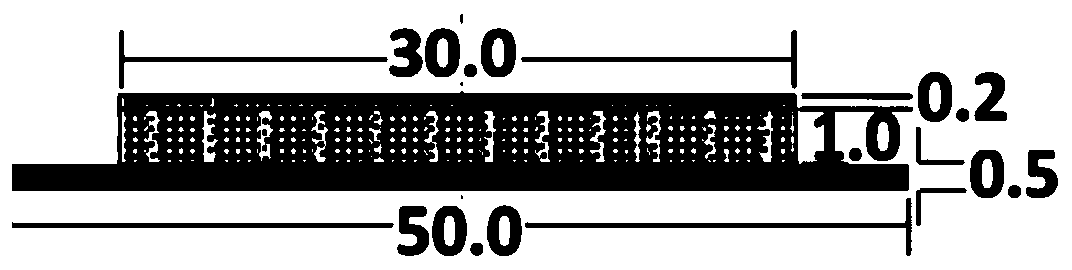

[0049] (2) Copper particle and barium chloride are mixed by volume ratio 4:1, and add the ethanol of mixing particle volume 5% to make it bond in the mixed particle, the mixture is packed in the diamond mold (30mm * 30mm), Put it on the polished surface of red copper, apply a pressure of 16MPa to compact the mixture to obtain a porous layer with a thickness of 1mm; sinter at about 870°C for 40min in a hydrogen atmosphere, cool naturally, remove the pore-forming agent by ultrasonic cleaning, and dry in vacuum to obtain Porous matrix;

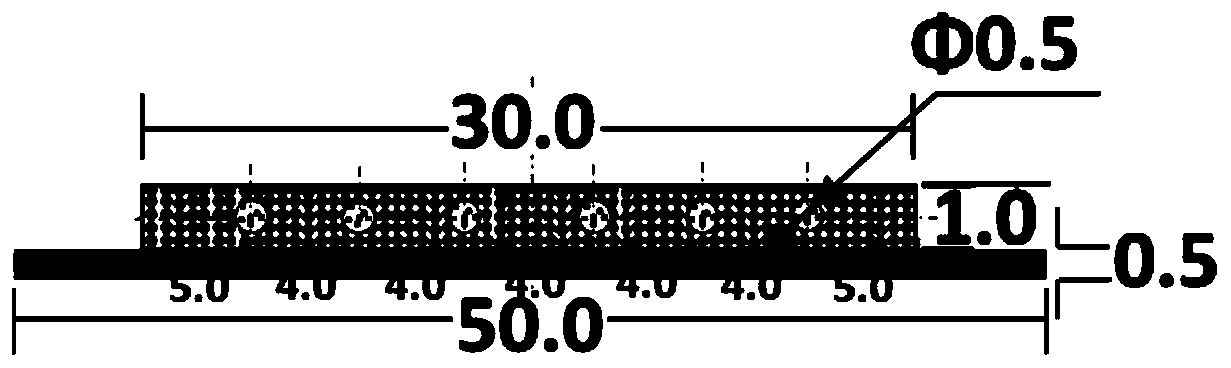

[0050] (3) Mechanically perforate the porous substrate to form a cavity with a diameter of 0.5mm, a hole spacing of 1.5mm, and a hole array of 12...

Embodiment 2

[0054] The preparation method of the particle / porous medium composite enhanced boiling structure specifically includes the following steps:

[0055] (1) Heating the substrate (50mm×50mm), and using 800 mesh, 1200 mesh, 1500 mesh, 2000 mesh, and 3000 mesh sandpaper to polish the substrate in sequence;

[0056] (2) Copper particle and barium chloride are mixed by volume ratio 4:1, and add the ethanol of mixing particle volume 5% to make it bond in the mixed particle, the mixture is packed in the diamond mold (30mm * 30mm), Put it on the polished surface of red copper, apply a pressure of 16MPa to compact the mixture, and obtain a porous layer with a thickness of 1mm; sinter at about 870°C for 40min in a hydrogen atmosphere, cool naturally for 12h, remove the pore-forming agent by ultrasonic cleaning, and dry in vacuum. Porous matrix;

[0057] (3) Holes are formed by laser perforation in the cross-section of the porous substrate, with a diameter of 0.5mm and a hole spacing of 4m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com