Nozzle device for smoke injection system

A technology of nozzle device and spray system, which is applied in the directions of spray device, spray device, dispersed particle separation, etc., to achieve the effect of improving operation reliability, reducing investment cost and reducing mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

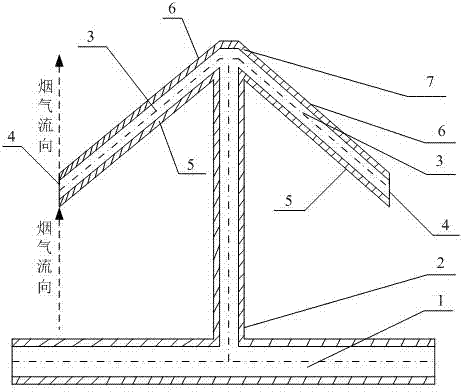

[0017] For ease of understanding, the present invention will be described in detail below with reference to the accompanying drawings, taking a selective catalytic reduction (SCR) flue gas denitrification system as an example. In the selective catalytic reduction (SCR) flue gas denitrification system, what is injected from the injection port 4 of the injection chamber 3 and mixed with the flue gas is a reducing agent gas, such as a mixed gas of ammonia and air; The connected "main pipe" can be called "reductant main pipe"; the "main pipe" that supplies reductant gas to the injection chamber or the reducing agent main pipe can be called "reductant main pipe".

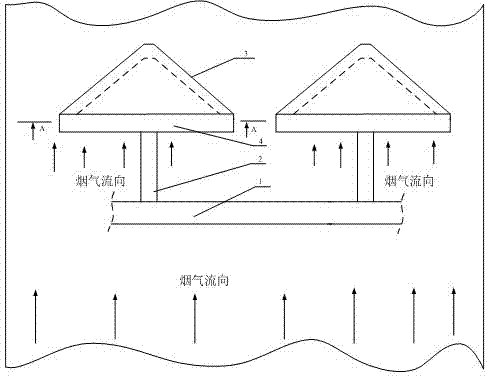

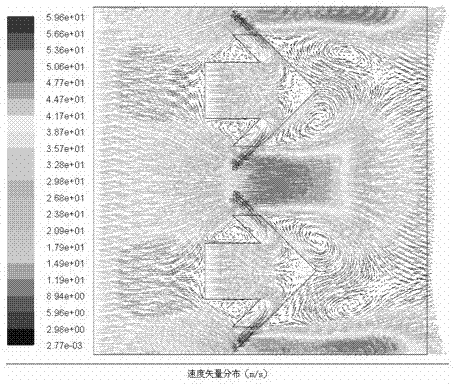

[0018] exist Figure 1 to Figure 3 The shown nozzle arrangement for a flue gas injection system consists essentially of an injection body 7 . The injection body 7 is provided with an injection chamber 3, and the injection chamber 3 communicates with the reducing agent main pipe 1. The reducing agent gas from the reducin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com