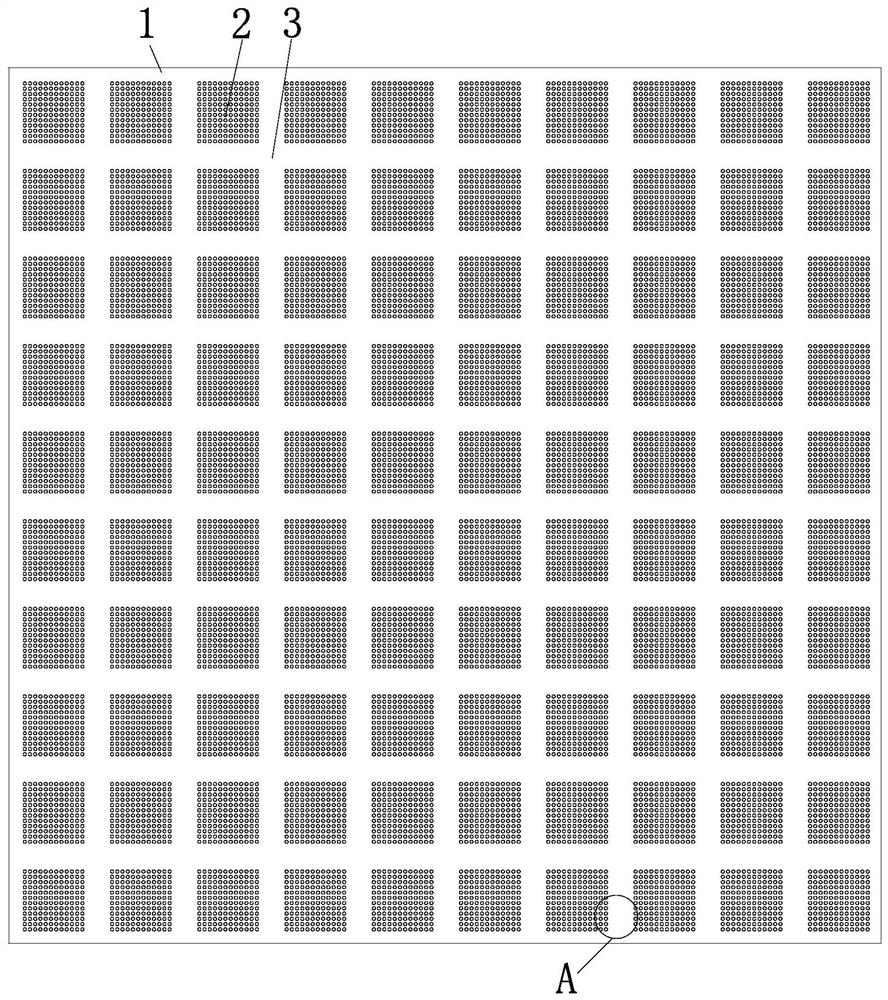

Mixed wettability micro-nano composite enhanced heat exchange structure and preparation method thereof

A micro-nano composite and enhanced heat transfer technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of limited heat transfer performance of high heat flux pool boiling and no consideration of hydrophilic and hydrophobic wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

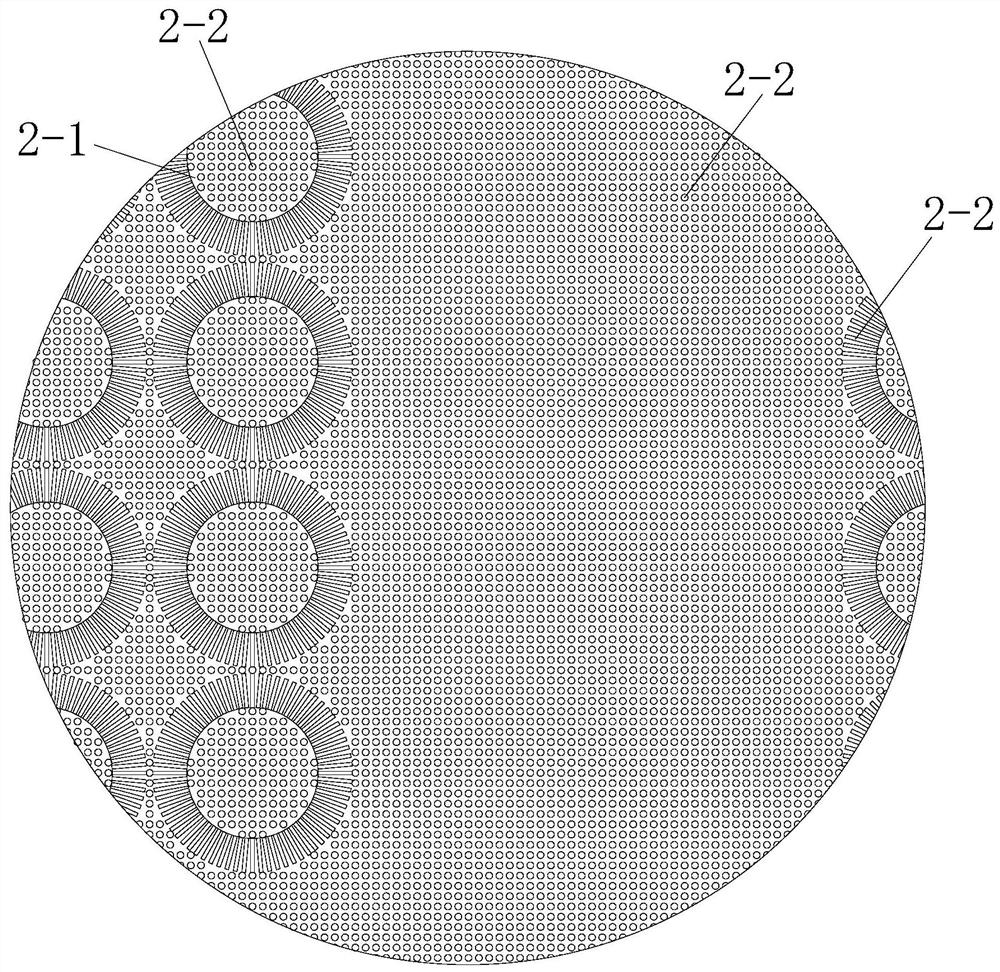

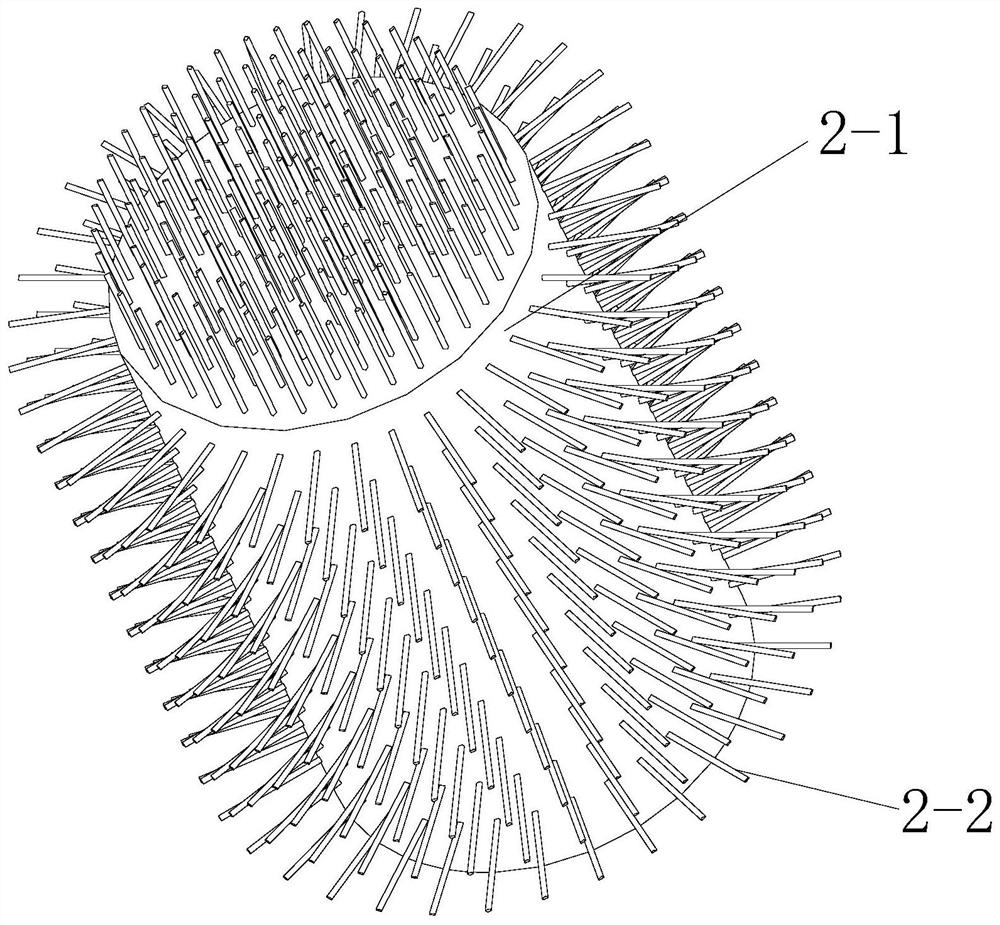

[0036] Embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although certain embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be construed as limited to the embodiments set forth herein; A more thorough and complete understanding of the present invention. It should be understood that the drawings and embodiments of the present invention are for exemplary purposes only, and are not intended to limit the protection scope of the present invention.

[0037] It should be noted that concepts such as "first" and "second" mentioned in the present invention are only used to distinguish different devices, modules or units, and are not used to limit the sequence of functions performed by these devices, modules or units or interdependence.

[0038] It should be noted that the modifications of "one" and "multiple" mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com