Heat exchanger tube used for evaporator

A technology of heat exchange tubes and evaporators, applied in heat exchange equipment, tubular elements, heat transfer modification, etc., can solve problems such as the inability to guarantee the cavity structure, achieve reduced strength, increase activity, and increase boiling heat transfer coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

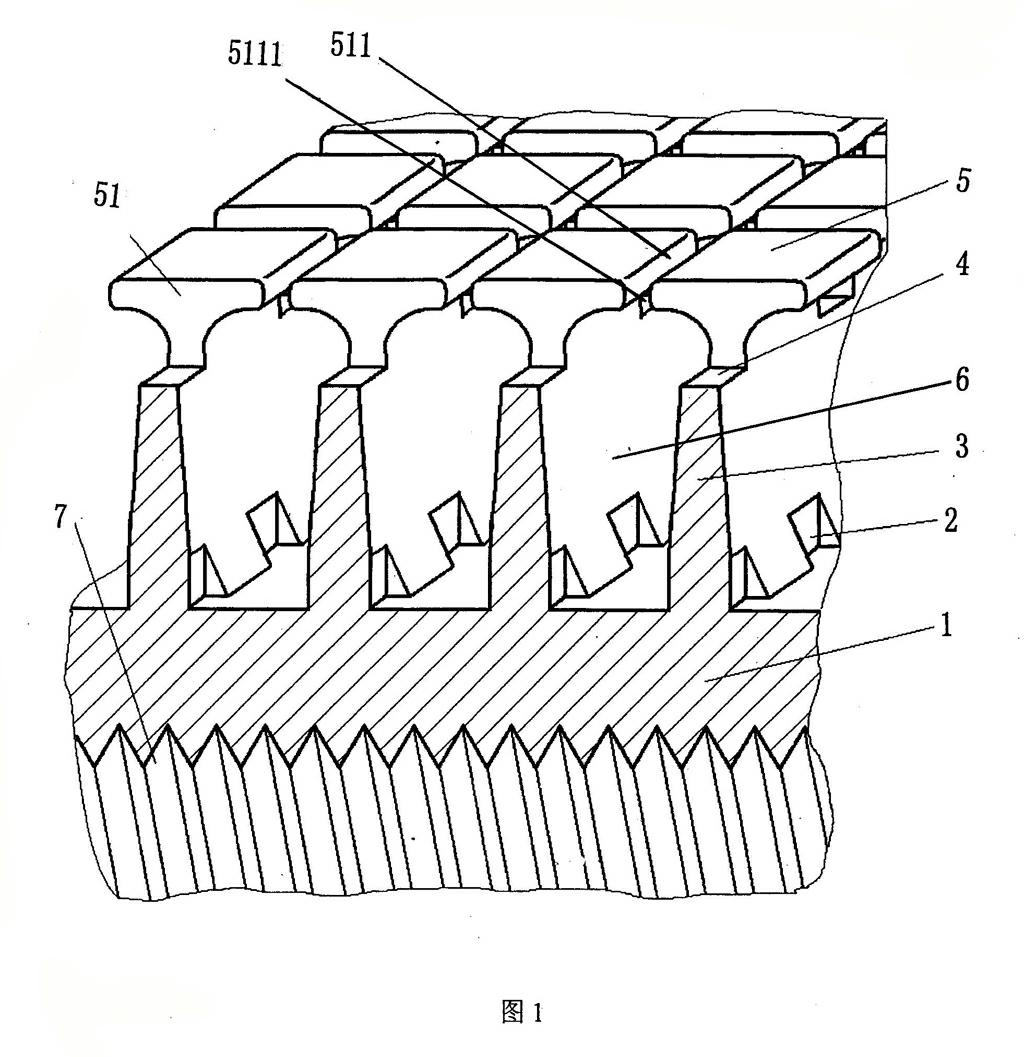

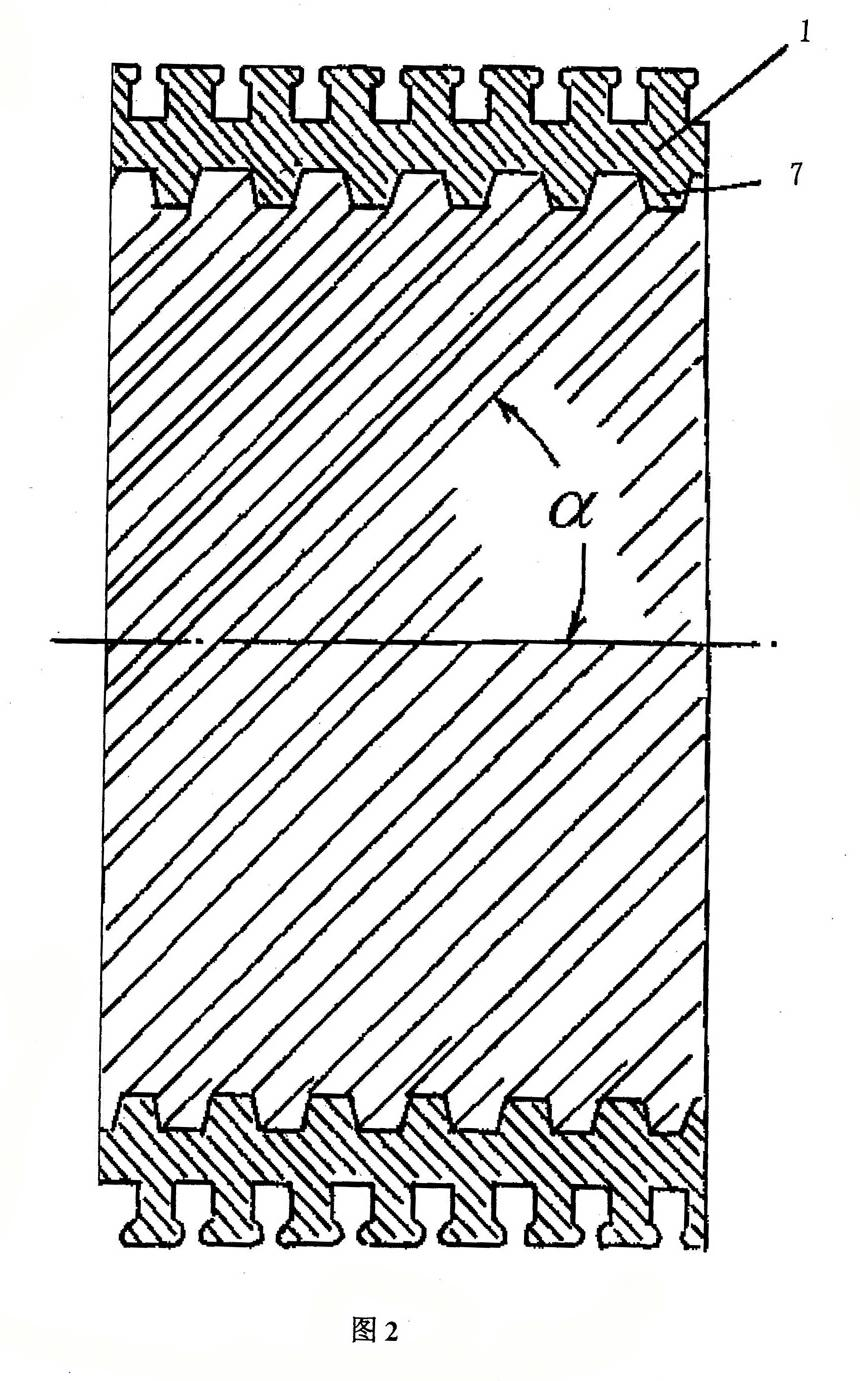

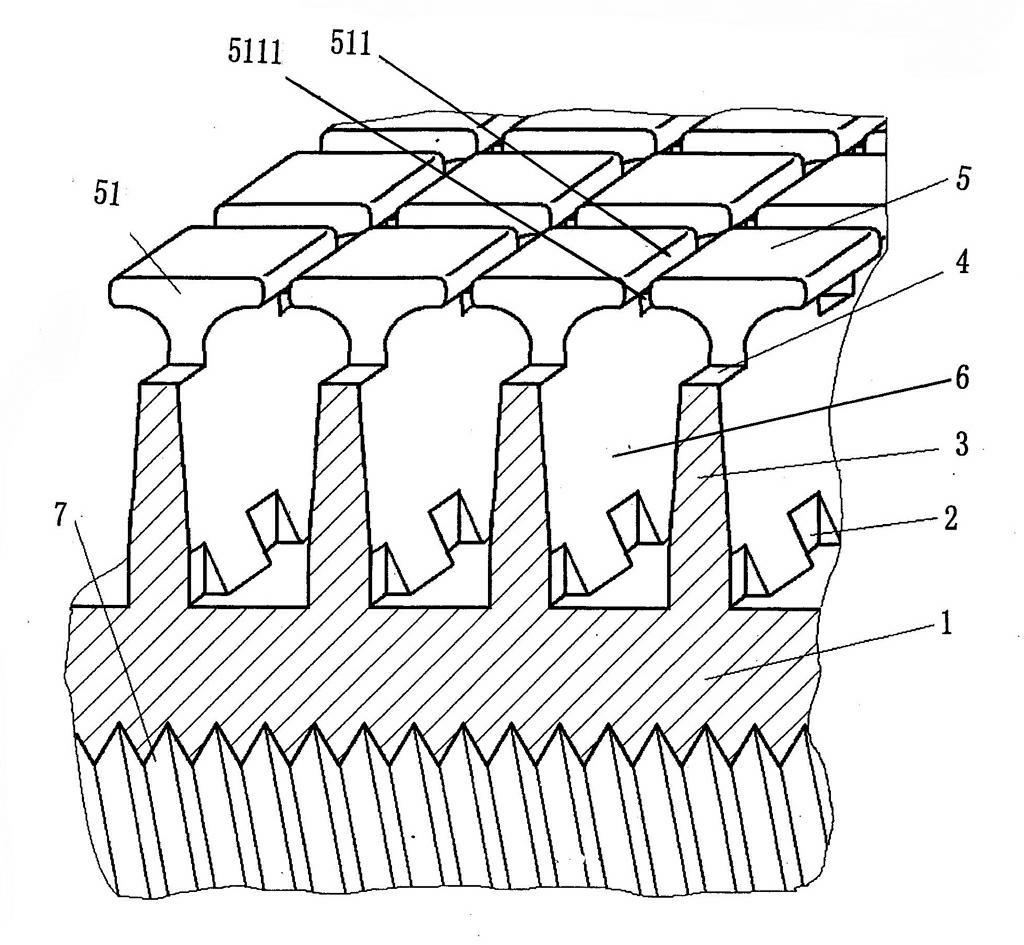

[0024] please see figure 1 and figure 2 The outer fins 3 formed on the outer wall of the tube body 1 according to the present invention can extend around the length direction of the tube body 1 in the form of a helix, or extend around the length direction of the tube body 1 in a ring shape. A plurality of annular outer fins are formed on the outer surface of the tube body 1 , and a plurality of straight fins are formed on the outer surface of the tube body 1 along the axial extension of the tube body 1 . Among them, the tube shape with spiral outer fins is most suitable to be manufactured by adding a tool for cutting the groove 2 with a small-scale cavity structure on the basis of the prior art.

[0025] The outer fin 3 is the basis for forming a cavity structure on the outer surface of the tube body 1. The fin height and fin distance of the outer fin 3 have an appropriate range. If the value is too small, the number of vaporization cores can be greatly increased, but ...

Embodiment 2

[0031] The figure is omitted, and the difference from Embodiment 1 is that a fin stage edge gap 5111 is maintained between the fin stage edge 511 of the T-shaped fin stage 51 on the outer fin top 5 on the adjacent outer fin 3, and the fin stage edge gap 5111 is less than half of the height of the gap between adjacent outer fins 3, for example: when the height of the gap between adjacent outer fins 3 is 2.5 mm, then the edge gap 5111 of the fin platform is less than 1.25 mm. The cavity 6 with the large-scale cavity structure also contains the groove 2 with the small-scale cavity structure inside by the edge gap 5111 of the fin platform. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com