Evaporating pipe with narrow-gap steam exhaust opening

A discharge port and evaporating tube technology, applied in the field of evaporating tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

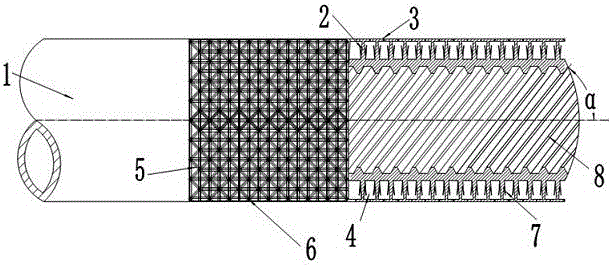

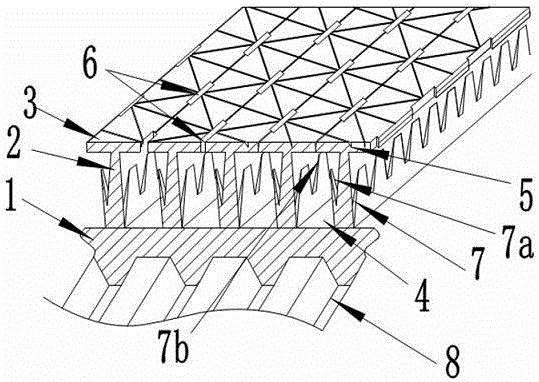

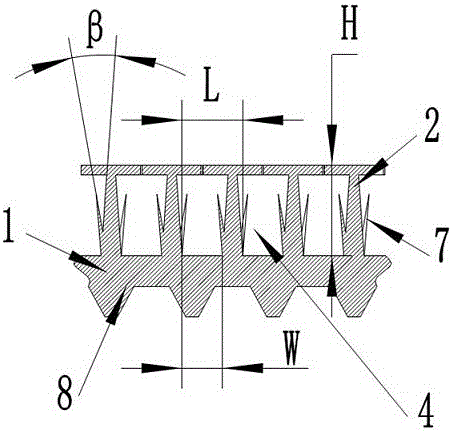

[0024] Embodiment: a kind of evaporating tube with slit-shaped steam outlet (see Figure 1-Figure 5 ), which includes a tube body 1, the outer surface of the tube body 1 is provided with T-shaped fins, the T-shaped fins are composed of fins 2 and platforms 3 extending from the top of the fins 2 to both sides, and the outer surface of the T-shaped fins is provided with Extend triangular micro-grooves 5 in various directions, including triangular micro-grooves extending in the axial and radial directions and at angles of 45° and 135° to the axis, and the intersection points of the grooves extending in various directions form a "m" shape , the intersection point is the steam outlet 6 generated in the cavity, and the shape of the steam outlet 6 is a narrow slit; the side of the fin 2 is provided with a triangular protrusion 7, each side of the triangular protrusion 7 is straight, and faces the fin. The surface of the protrusion on the side wall of sheet 2 is flat and as close as p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com