An evaporation tube with a slit-shaped steam outlet

A technology of discharge port and evaporating tube, applied in the field of evaporating tube, can solve the problems of inapplicability of low-pressure refrigerant, reduction of the number of steam bubbles, reduction of the frequency of debodying of steam bubbles, etc., so as to improve the effect of boiling heat transfer and increase the heat transfer of boiling. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

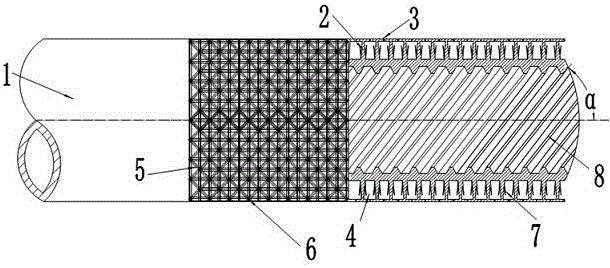

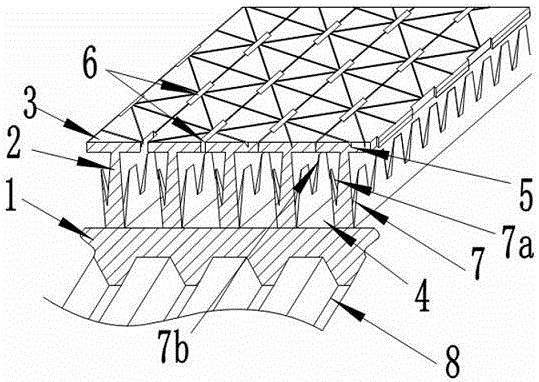

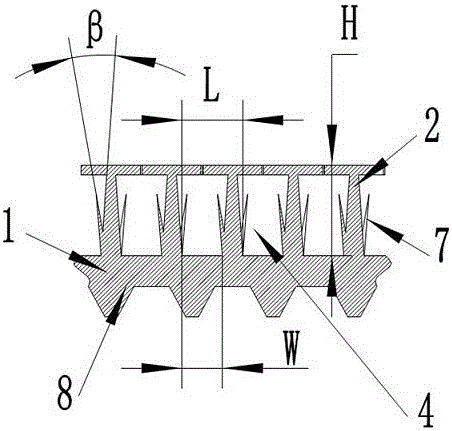

[0027] Embodiment: a kind of evaporating tube with slit-shaped steam outlet (see Figure 1-Figure 5 ), which includes a tube body 1, the outer surface of the tube body 1 is provided with T-shaped fins, the T-shaped fins are composed of fins 2 and platforms 3 extending from the top of the fins 2 to both sides, and the outer surface of the T-shaped fins is provided with Extend triangular micro-grooves 5 in various directions, including triangular micro-grooves extending in the axial and radial directions and at angles of 45° and 135° to the axis, and the intersection points of the grooves extending in various directions form a "m" shape , the intersection point is the steam discharge port 6 generated in the cavity, and the shape of the steam discharge port 6 is a narrow slit; the side of the fin 2 is provided with a triangular protrusion 7, and each side of the triangular protrusion 7 is straight and faces the fin. The surface of the protrusion on the side wall of sheet 2 is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Helix angle α | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com