High-hole-density through hole metal foam electronic element heat-dissipation device based on impact jet flow

A metal foam, impinging jet technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problem that the heat exchange performance of through-hole metal foam through-hole metal foam cannot be fully utilized, the specific heat capacity of the refrigerant is small, and the refrigerant is easy to leak. and other problems, to achieve the effect of increasing the heat transfer coefficient, increasing the heat transfer coefficient, and enhancing the pulverization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

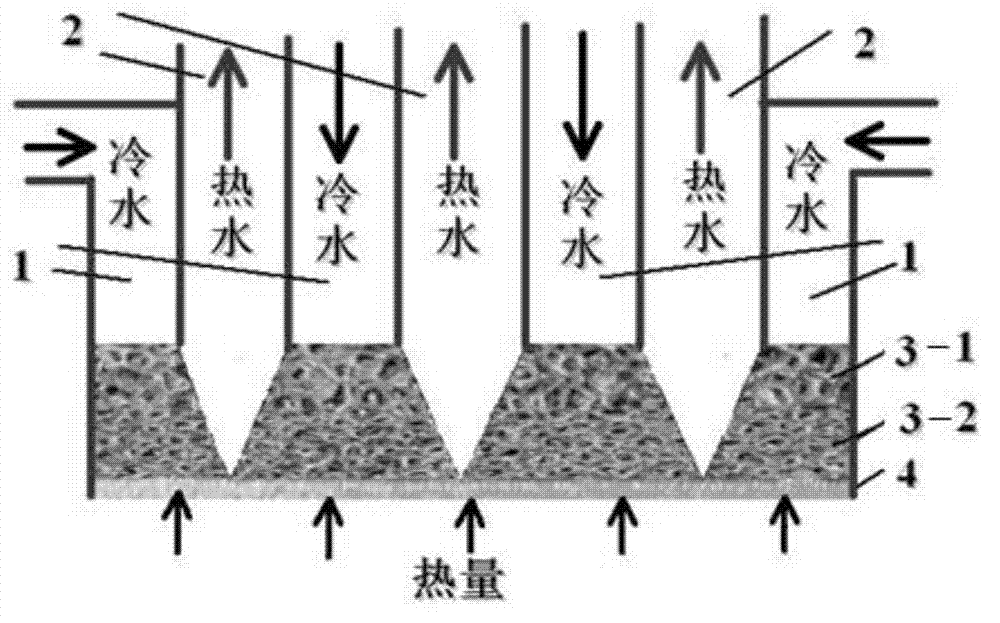

[0027] Such as figure 1 As shown, this embodiment includes: a heat exchange substrate 4, a through-hole metal foam 3 sintered on the heat exchange substrate 4, a cooling water inlet pipe 1 and a drain pipe 2, wherein: the main bodies of the cooling water inlet pipe 1 and the drain pipe 2 are vertical Arranged at straight intervals, the heat exchange part at the bottom of the two water pipes is provided with a through-hole metal foam 3, and the through-hole metal foam 3 has a heat exchange structure at the position where it connects with the drain pipe 2;

[0028] The internal through-holes of the through-hole metal foam 3 have a gradually changing density structure, specifically referring to: the porosity is the same, and the pore density increases or decreases along the vertical direction of the wall; or the pore density is the same, the porosity increases or decreases. decrease; or the hole density and porosity are the same, but the materials constituting the through-hole me...

Embodiment 2

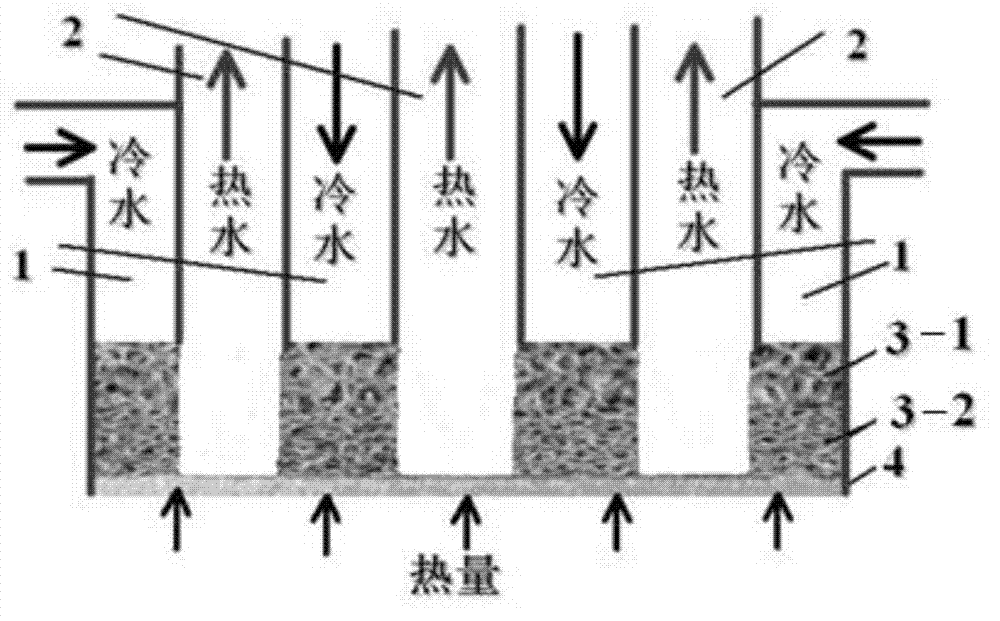

[0044] The same settings as in Example 1, but as figure 2 As shown, the heat exchange structure is a U-shaped symmetrical groove.

Embodiment 3

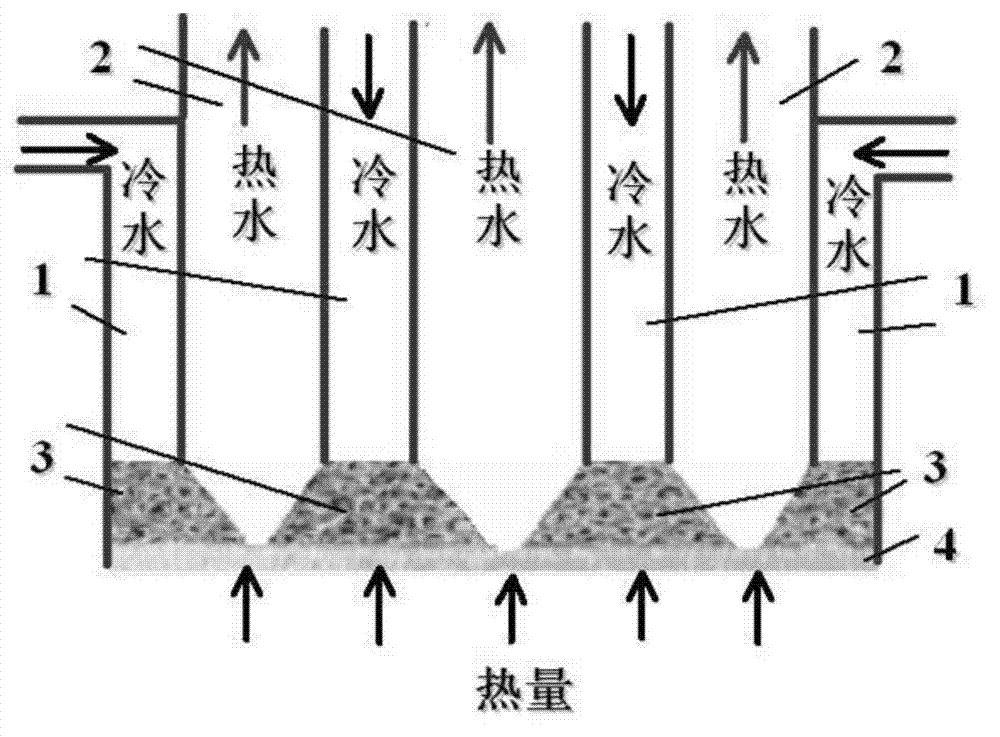

[0046] The same settings as in Example 1, but as image 3 As shown, the through-hole metal foam 3 of this embodiment is a single-layer structure with a simplified structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com