A kind of metal alloy material and its use

A metal alloy and multi-purpose technology, applied in metal processing equipment, damage protection, pipeline anticorrosion/rust protection, etc., can solve the problems of high brittleness of porous layer, poor corrosion resistance, and failure to meet the performance requirements of pipe materials, etc., and achieve high boiling transmission Excellent thermal coefficient and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

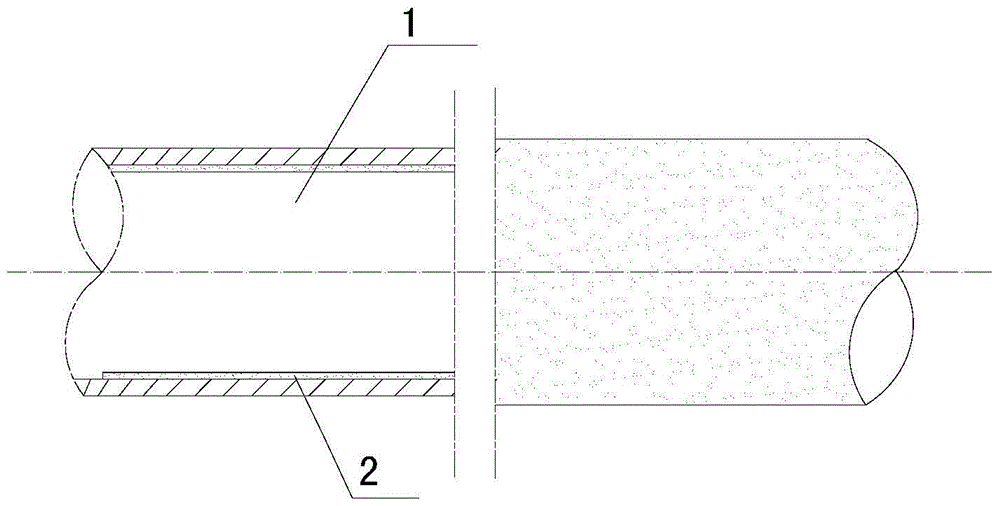

[0036] Example 1 A copper-nickel alloy surface porous tube with a porosity of the inner porous layer of 45% and a thickness of 0.2 mm was prepared.

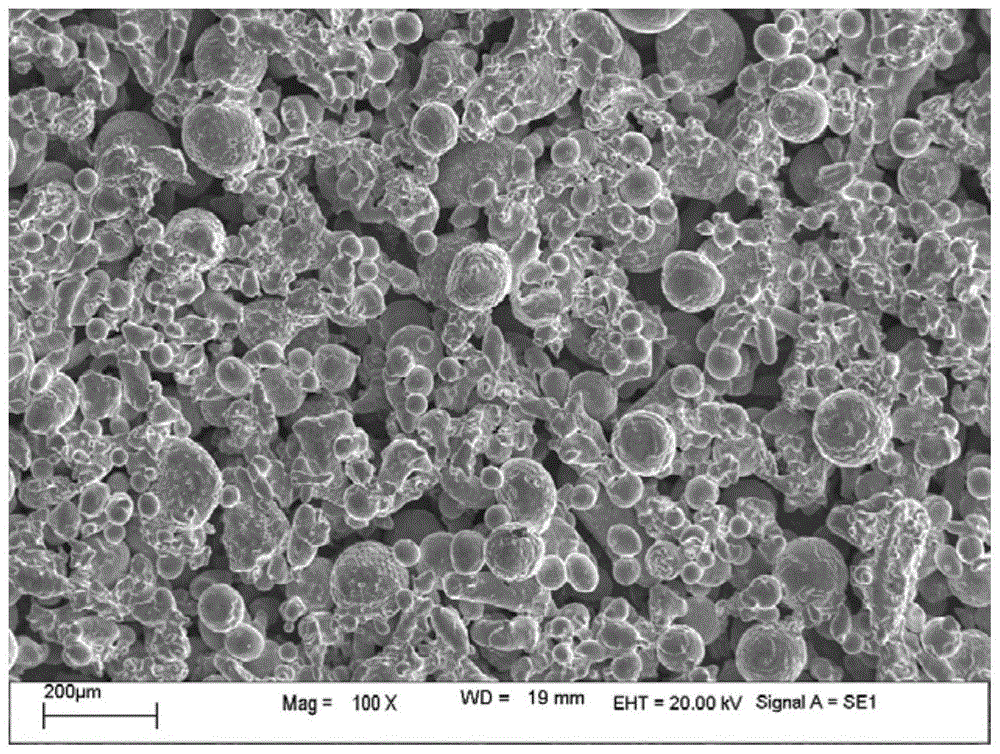

[0037] (1) a metal alloy material of CuNi10Zn20Sn10, which is prepared into 100~400 mesh copper alloy metal powder by gas atomization;

[0038] (2) The binder that the powder obtained in step (1) is mixed with 17wt% polyvinyl alcohol particles and 83wt% toluene solution is mixed with a volume ratio of 49% to form a uniform paste coating; Cladding to φ32×2, 150mm long copper-nickel tube 1;

[0039] (3) After the highly volatile substances in it are completely removed, place the pipe in the first section of the continuous sintering furnace filled with hydrogen atmosphere and the furnace temperature is stable at 380°C, and keep it warm for about 30 minutes to remove all the bonding Then, it is sent to the second section of the continuous sintering furnace with a furnace temperature of 900°C by a conveyor belt, and it is kept for ab...

Embodiment 2

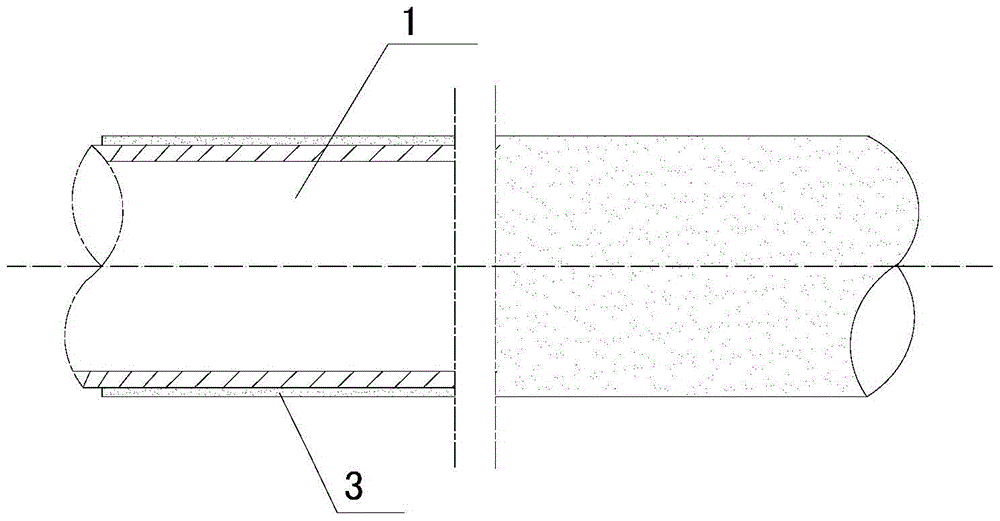

[0042] Example 2 Prepare a copper-nickel alloy surface porous tube with a porosity of 40% in the outer porous layer and a thickness of 0.3mm

[0043] (1) a metal alloy material of CuNi5Zn15Sn8, which is prepared into 200~500 mesh copper alloy metal powders by gas atomization;

[0044] (2) The binder that the powder obtained in step (1) is mixed with 29wt% polystyrene particles and 71wt% xylene solution is mixed with a volume ratio of 60% to form a uniform paste coating; then at 200 ° C by spraying Coat it on the outer surface of φ32×3, 300mm long copper-nickel tube;

[0045] (3) After the highly volatile substances in it are completely removed, place the pipe in the first section of the continuous sintering furnace filled with hydrogen atmosphere and the furnace temperature is stable at 350°C, and keep it warm for about 40 minutes to remove all the bonding Then, it is sent to the second section of the continuous sintering furnace with a furnace temperature of 870°C by a conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com