A kind of solidification/stabilization method for high-concentration water-soluble manganese in manganese slag

A stabilization treatment, water-soluble manganese technology, applied in the direction of solid waste removal, etc., can solve the problem of not considering the impact, and achieve the effect of reducing the leaching concentration and being conducive to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

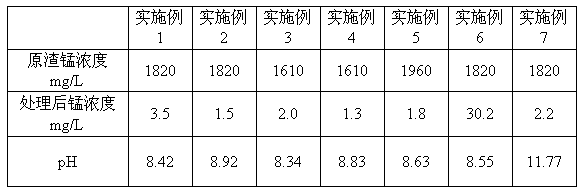

Embodiment 1

[0033] Fresh electrolytic manganese slag 20kg

[0034] Add water to the active silica to form an active silica dispersion, the amount of active silica is 1% of the manganese slag, and the amount of water is 1% of the manganese slag; add active silica dispersion to the manganese slag , stirred for 1 minute; added magnesium oxide, stirred for 30 minutes, the amount of magnesium oxide was 5% of the manganese slag; after mixing evenly, aged for 14 days. According to the GB5086.1-1997 solid waste leaching method, the manganese concentration and pH in the leachate were determined by the inversion method.

Embodiment 2

[0036] Fresh electrolytic manganese slag 20kg

[0037]Add water to the active silica to form an active silica dispersion, the amount of active silica is 5% of the manganese slag, and the amount of water is 1% of the manganese slag; add active silica dispersion to the manganese slag , stirred for 3 minutes; added magnesium oxide, stirred for 40 minutes, the amount of magnesium oxide was 10% of the manganese slag; after mixing evenly, aged for 7 days. According to the GB5086.1-1997 solid waste leaching method, the manganese concentration and pH in the leachate were determined by the inversion method.

Embodiment 3

[0039] Old electrolytic manganese slag 20kg

[0040] Add water to the active silica to form an active silica dispersion, the amount of active silica is 3% of the manganese slag, and the amount of water is 5% of the manganese slag; add active silica dispersion to the manganese slag , stirred for 2 minutes; added magnesium oxide, stirred for 35 minutes, the amount of magnesium oxide was 9% of the manganese slag; after mixing evenly, let it stand for 10 days. According to the GB5086.1-1997 solid waste leaching method, the manganese concentration and pH in the leachate were determined by the inversion method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com