A medium and low temperature waste heat driven flash-injection-absorption combined cooling, heating and power system

A technology of combined cooling, heating and power, low-temperature waste heat, applied in refrigerators, steam engine installations, refrigeration and liquefaction, etc., can solve the problems of complex generator structure, high power consumption of solution pump, low steam intake of turbine, etc. Achieve maximum utilization of energy, save heat transfer area, and increase cycle efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

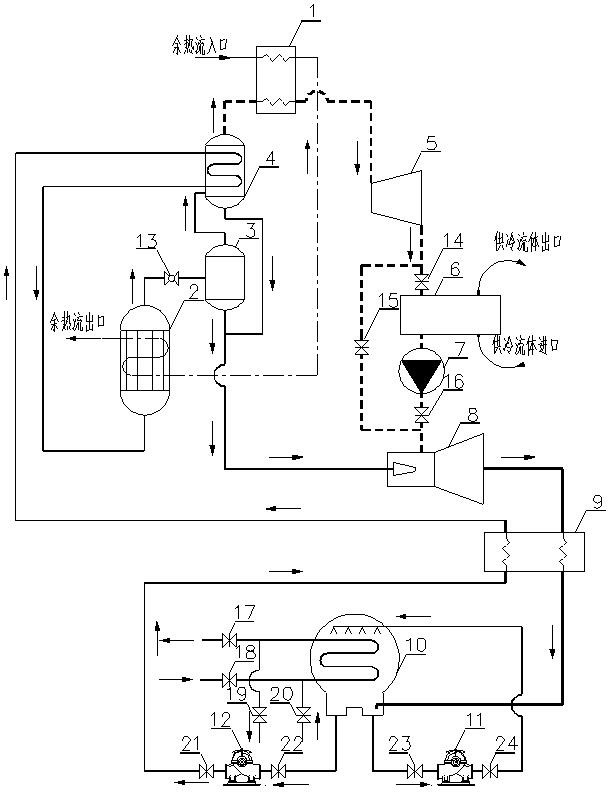

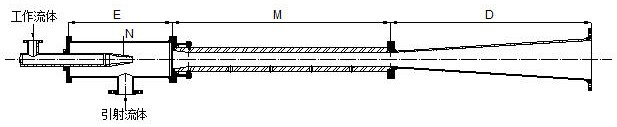

[0030] like figure 1 and 3 As shown, the medium and low temperature waste heat-driven flash evaporation-injection-absorption combined cooling, heating and power system includes superheater 1, waste heat heater 2, flash evaporator 3, rectifier 4, expander 5, cooling and heat exchange 6, booster compressor 7, jet ejector 8, regenerator 9, absorber 10, absorption pump 11, solution pump 12, throttle valve 13 and stop valve, the concentration of circulating working medium in the absorber 10 is relatively high The high working fluid is pumped into the regenerator 9 and the rectifier 4 through the solution pump 12 to the outlet of the solution to be preheated, and then flows into the waste heat heater 2, and the waste heat flows into the waste heat heater after being overheated by the superheater 1 The waste heat inlet of 2 heats the working fluid with a high concentration of circulating working fluid to heat the solution, and the high-temperature working fluid on the top of the was...

Embodiment 2

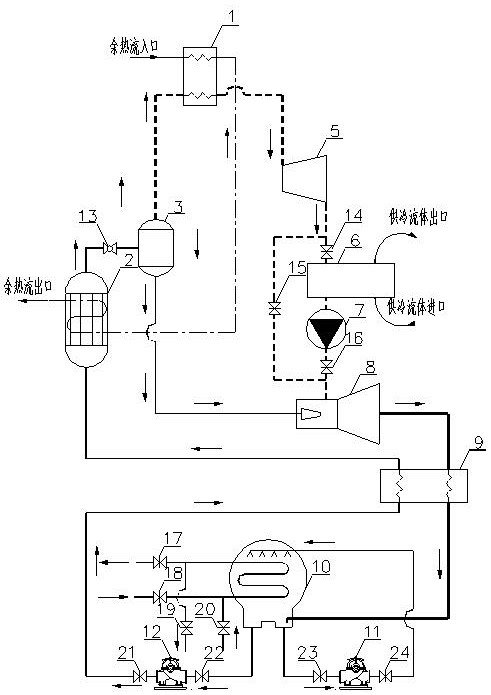

[0034] like figure 2 and 3 As shown, the medium and low temperature waste heat-driven flash evaporation-injection-absorption combined cooling, heating and power system includes a superheater 1, a waste heat heater 2, a flash evaporator 3, an expander 5, a cooling heat exchanger 6, a booster Compressor 7, jet ejector 8, regenerator 9, absorber 10, absorption pump 11, solution pump 12, throttle valve 13 and stop valve, absorber 10 contains circulating working medium concentration The solution outlet is pumped into the regenerator 9 by the solution pump 12 to be preheated, and then flows into the waste heat heater 2, and the waste heat flow passes through the superheater 1 and enters the waste heat inlet of the waste heat heater 2 to control the concentration of circulating working fluid. The higher working fluid heats the solution, and the high-temperature working fluid on the top of the waste heat heater 2 is connected to the flash evaporator 3 through the throttling valve 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com