Mixed refrigeration system and quick freezing method thereof

A technology of mixed refrigeration and freezing chambers, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve the problems of high operating costs and poor freezing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

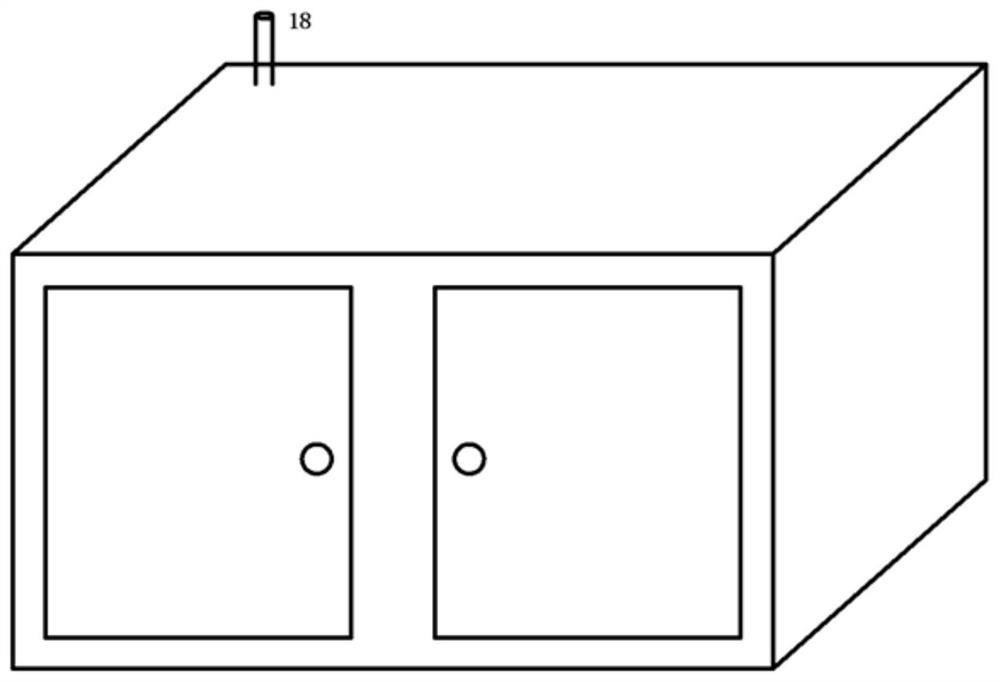

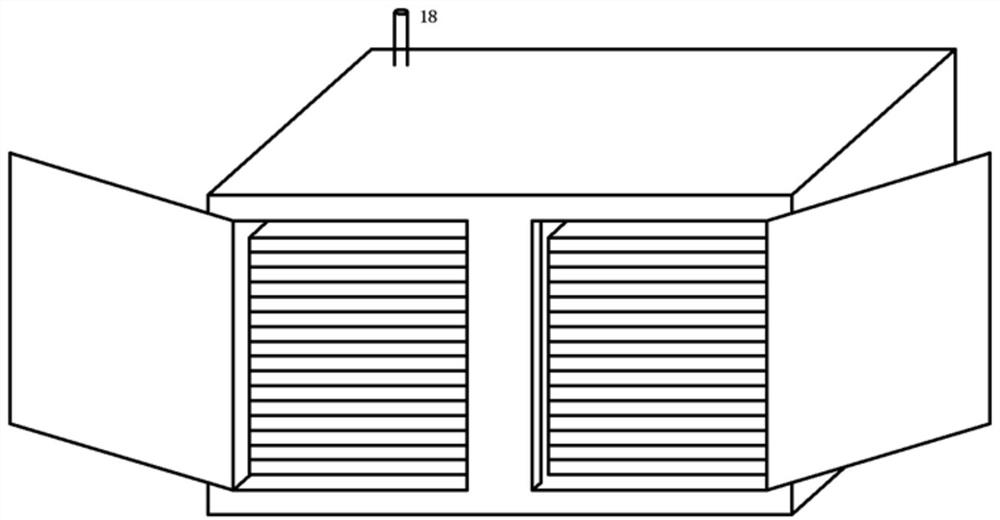

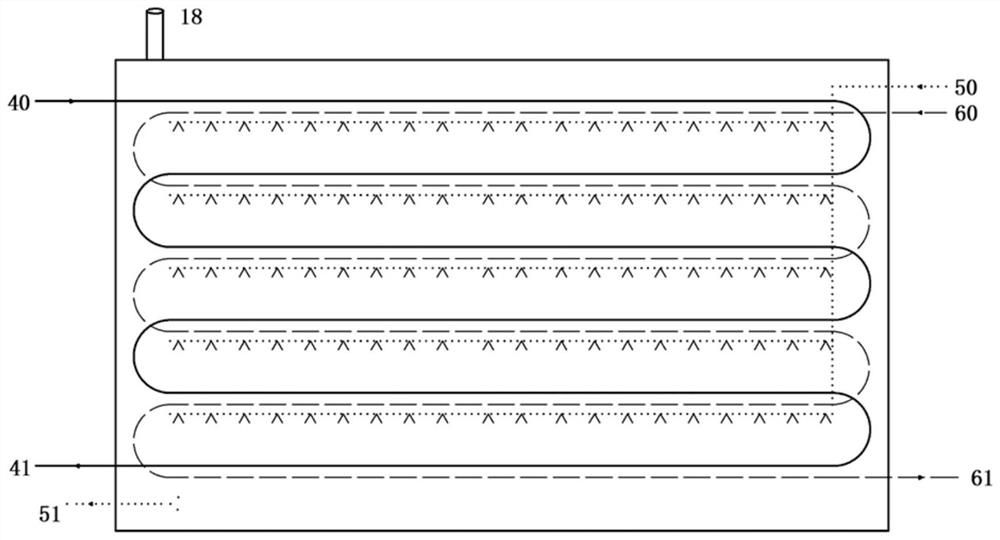

[0093] One object of the present invention is to propose a hybrid refrigeration system (hereinafter referred to as the hybrid quick-freezing system) that combines the contact quick-freezing method and the circulating spraying method.

[0094] The hybrid refrigeration system system of the present invention comprises: a freezing chamber, a carbon dioxide gas supply tank, a contact cascade heat exchanger, a freezing chamber, a regulating valve, an infusion pump, a exhaust gas recovery device, an exhaust port, a spray pipe rack, Food trays, carbon dioxide quick-freezing circulation system, contact quick-freezing system, wherein the contact quick-freezing system includes: the first compressor, the oil separator, the first pipeline of the three-way condenser, the regenerator, the solenoid valve, the contact cascade The heat exchanger (evaporator pipeline), the condenser of the carbon dioxide quick freezing cycle and the evaporator of the contact quick freezing system are cascaded to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com