Multi-layer shell-core structure CoxCuyPbz alloy particle and preparation method thereof

A technology of alloy particles and core structure, which is applied in the field of immiscible alloy particles, can solve the problems of difficult operation, complicated process, high cost of preparation, etc., and achieve the effect of simple operation process, simple precipitated phase and anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

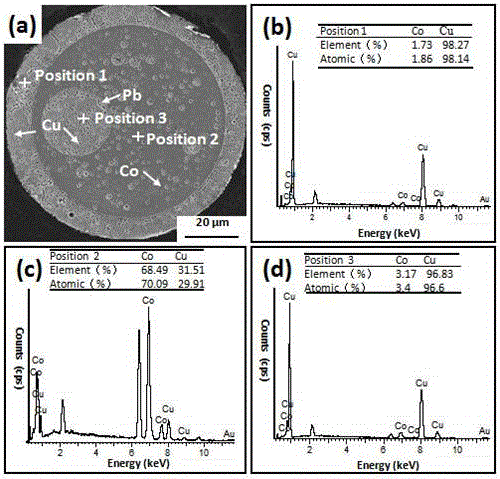

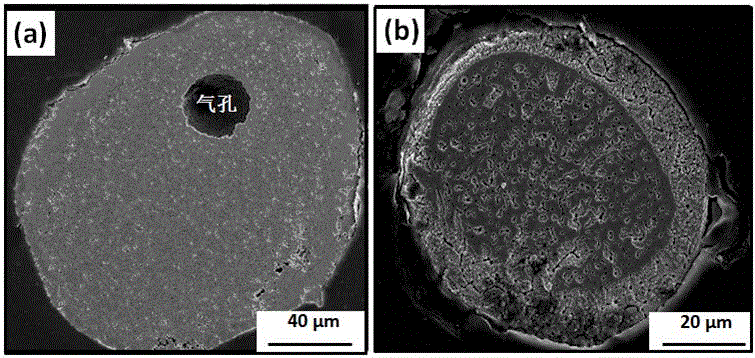

Examples

Embodiment 1

[0027] A multilayer core-shell structure Co 47.5 Cu 47.5 Pb 5 The preparation method of alloy particles is special in that:

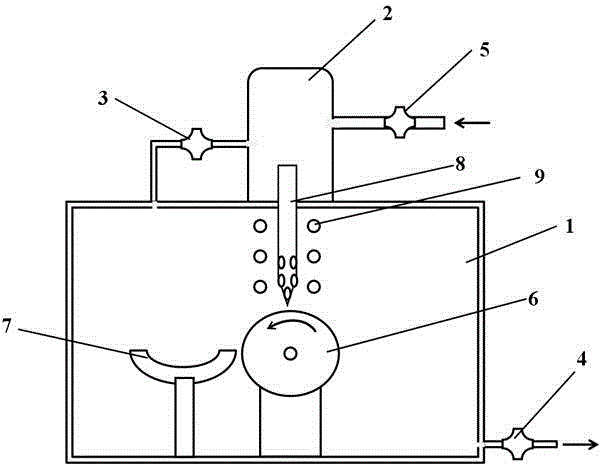

[0028] The method utilizes a solidification forming device such as figure 1As shown, the device includes a first vacuum chamber 1 and a second vacuum chamber 2 at its top. The first vacuum chamber 1 and the second vacuum chamber 2 are fully transparent vacuum chambers made of plexiglass material. The first vacuum chamber 1 The volume is greater than the volume of the second vacuum chamber 2, the first vacuum chamber 1 and the second vacuum chamber 2 are communicated through the vacuum chamber conduction valve 3, and the first vacuum chamber 1 is connected to the external vacuum pump (not connected) through the vacuum conduction valve 4 shown), the second vacuum chamber 2 is connected to the external Ar gas tank (not shown) through the Ar gas conduction valve 5; the first vacuum chamber 1 is provided with a motor (not shown), Cu rollers 6, Y Type rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com