Movable hot rolling thermal insulation heat treatment device

A heat treatment device and mobile technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of disrupted production line production rhythm, long interval time, long coil air cooling time, etc., to improve the level of automatic operation , reduce heat loss, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

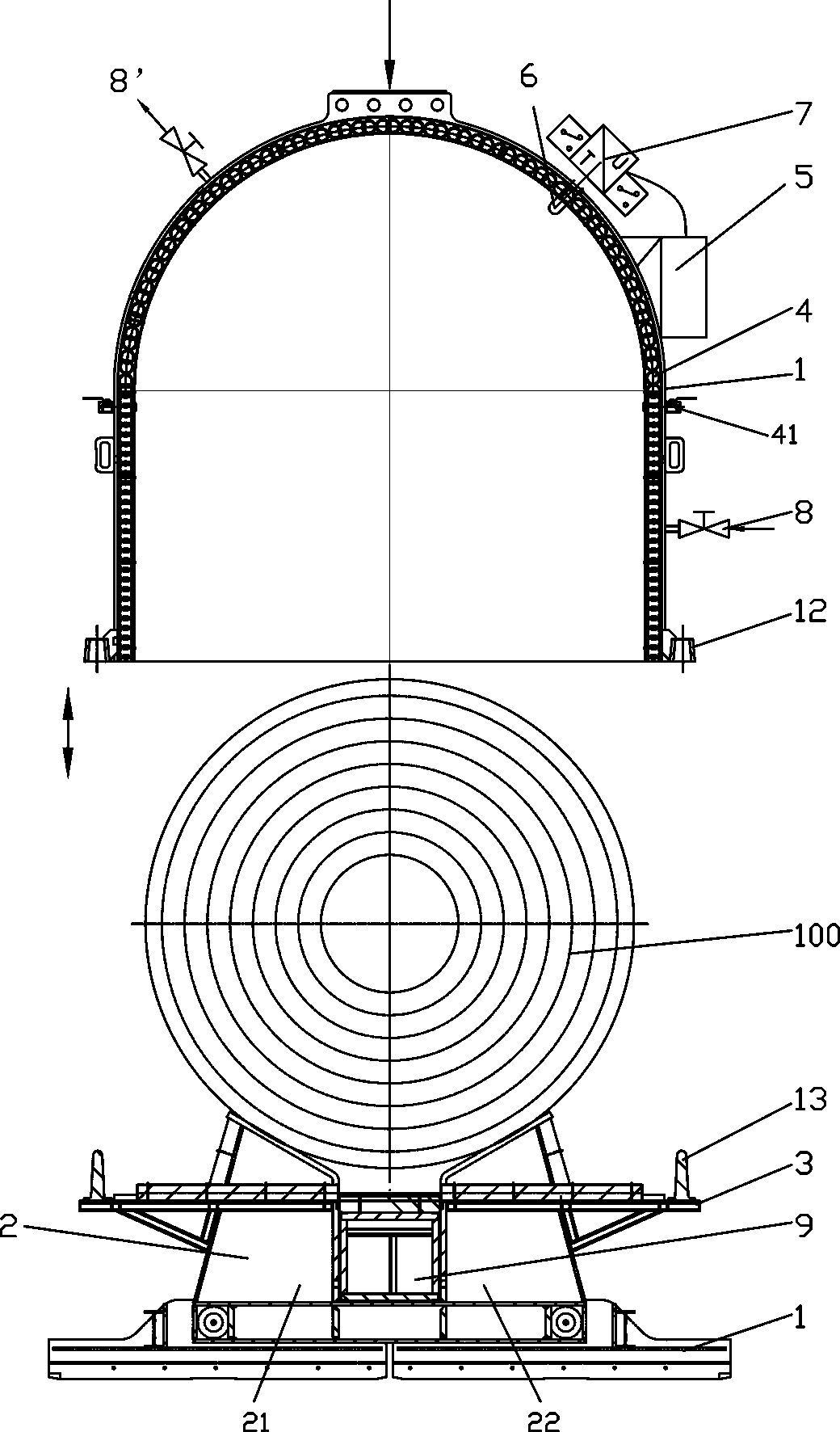

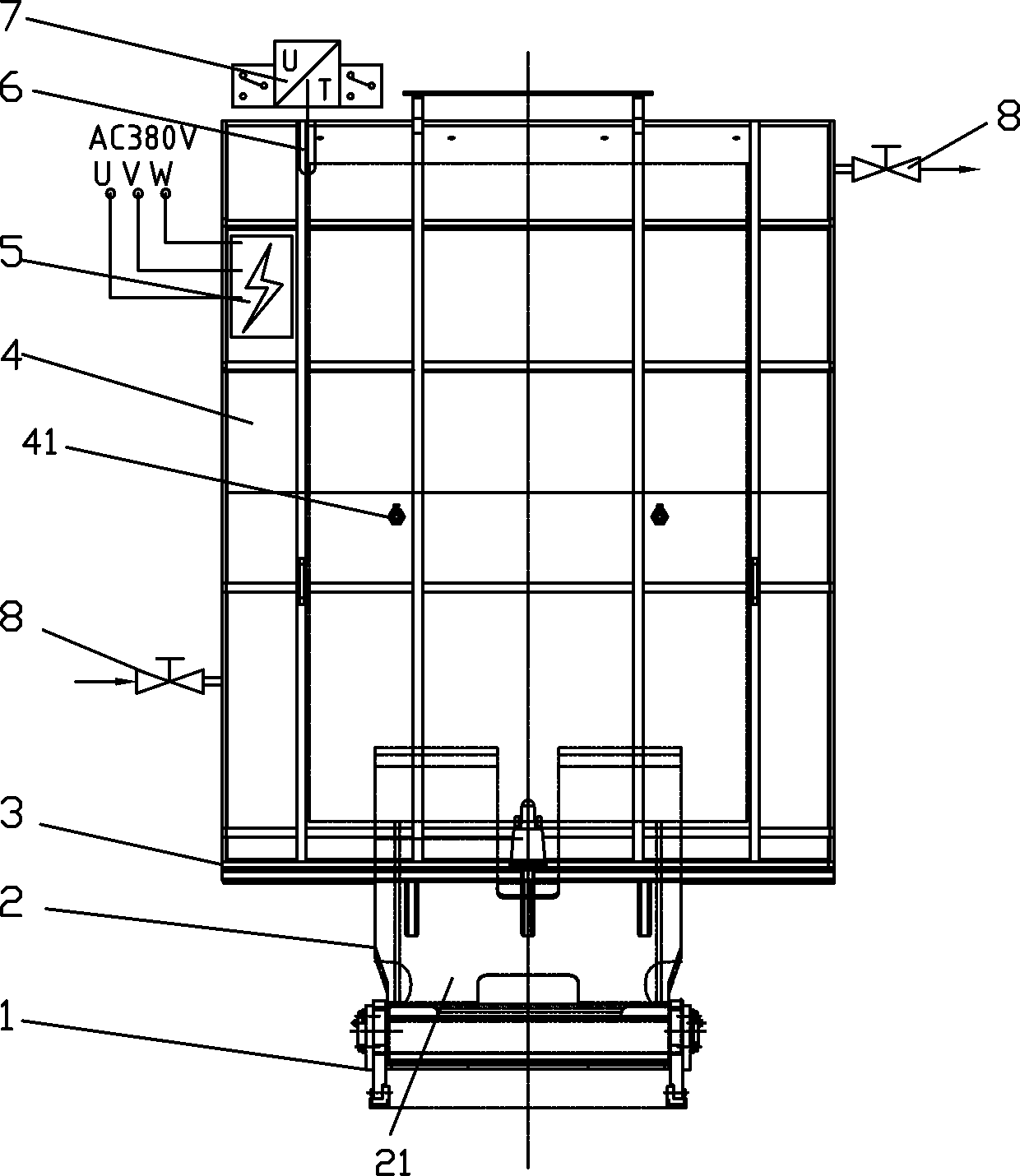

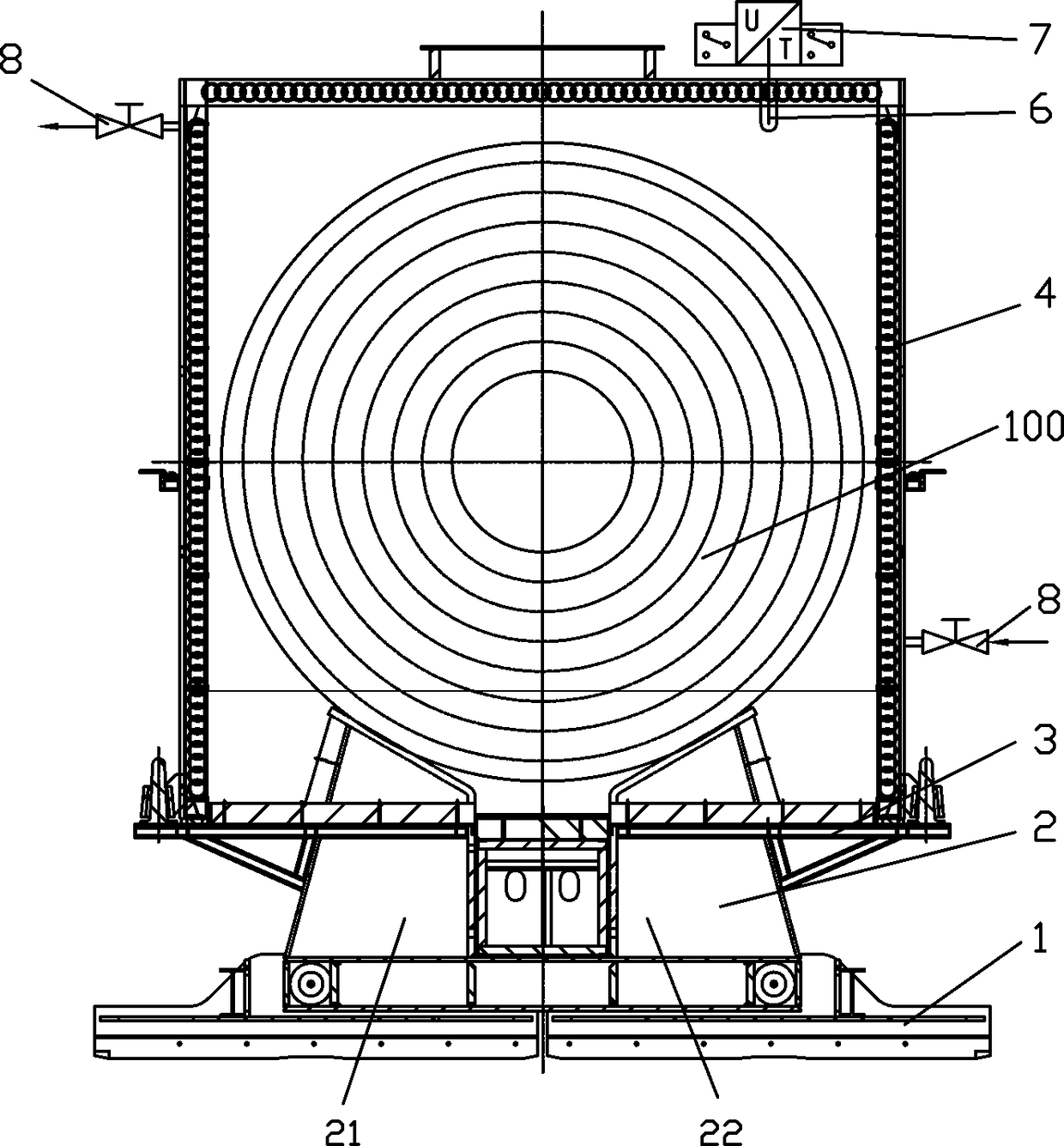

[0062] see Figure 1 to Figure 12 , a mobile hot coil insulation heat treatment device of the present invention, which includes,

[0063] bottom plate 1;

[0064] The steel coil fixing seat 2 is arranged on the center of the bottom plate 1;

[0065] The tray 3 has an annular structure and is horizontally sleeved in the middle of the steel coil fixing seat 2;

[0066] The heat preservation cover 4 is open at the lower end, and the cover is set on the tray 3, and its inner cavity volume is larger than the steel coil 100;

[0067] The electric heating device 5 is arranged on the inner wall of the heat preservation cover 4;

[0068] A temperature sensor 6 is arranged in the heat preservation cover 4;

[0069] An information collection control module 7 , the electric heating device 5 and the temperature sensor 6 are electrically connected to the information collection control module 7 .

[0070] Further, a gas protection device and gas sensors 8, 8' are also included, and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com