Preparation method for water erosion resistant coating of last-stage long blade

A manufacturing method and technology of long blades, which are applied to the supporting elements, coatings, metal material coating processes of blades, etc., can solve the problems of low dilution rate and small deformation, avoid overheating, improve stability, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

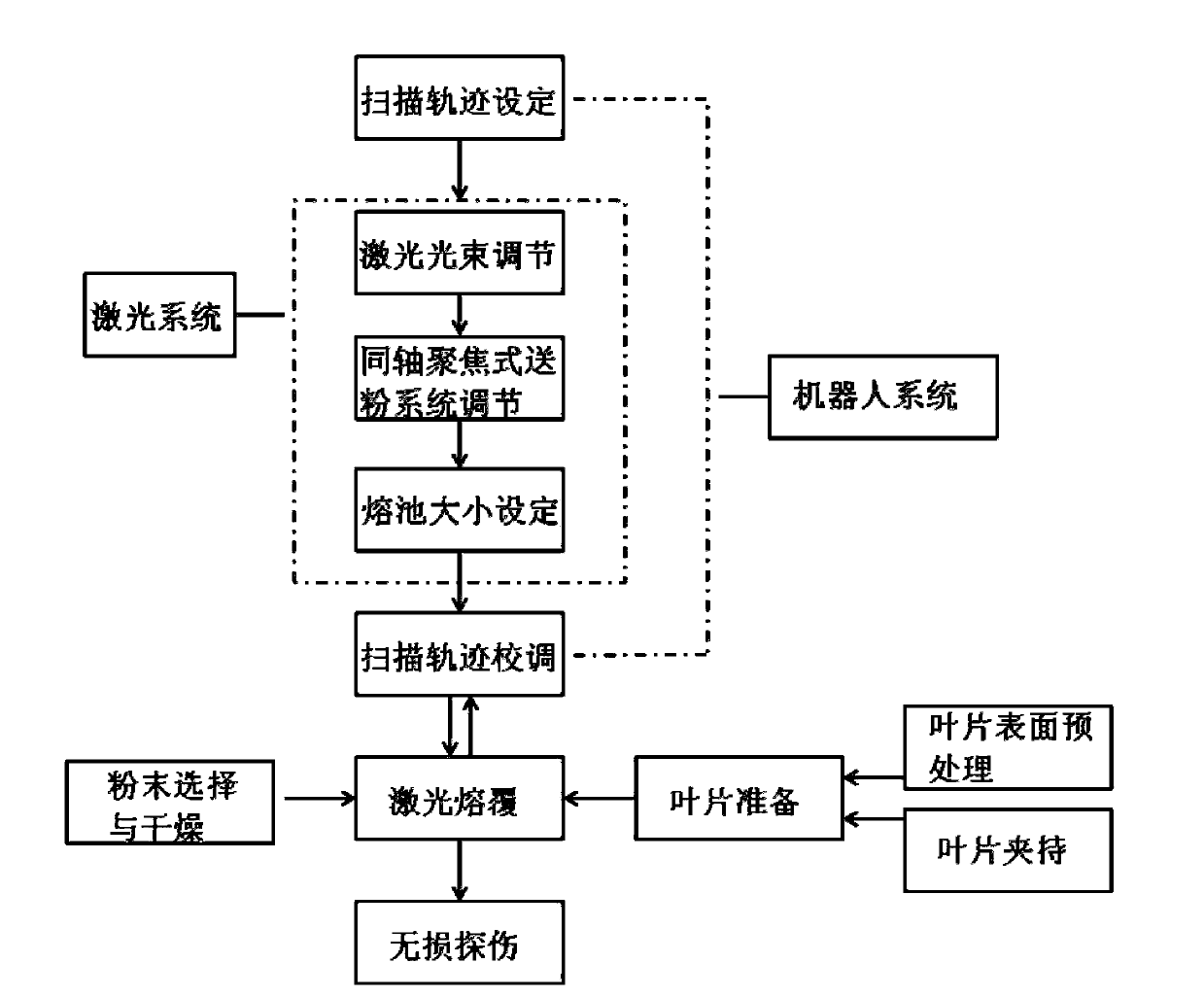

Method used

Image

Examples

Embodiment 1

[0041] The invention is used for the manufacture of the water corrosion-resistant coating of the long blade of the low-pressure last stage of a large-scale nuclear power steam turbine. The process proceeds in the following steps:

[0042] Alloy powder selection and powder drying: select Stellite No. 6 cobalt-based alloy powder, ball mill the powder for 1 hour and dry at 150° C. for 1 hour.

[0043] Blade surface pretreatment: Degrease and derust the blade surface, and clean it with acetone. It is required that the blade surface has no defects such as cracks, pores, and inclusions.

[0044] Clamp the blade: clamp the blade on a specific mobile platform so that the blade is in a horizontal position.

[0045] Scanning trajectory setting: use Fanuc trajectory planning and control robot system to set the scanning trajectory of the laser.

[0046] Laser beam adjustment: adjust the defocus amount to make the focused laser spot a rectangle, and the spot size: length×width=3.2mm×2.0m...

Embodiment 2

[0058] The invention is used for the manufacture of the water corrosion-resistant coating of the long blade of the low-pressure last stage of a large-scale nuclear power steam turbine. The process proceeds in the following steps:

[0059] Alloy powder selection and powder drying: select Stellite No. 6 cobalt-based alloy powder, ball mill the powder for 1 hour and dry at 150° C. for 1 hour.

[0060] Blade surface pretreatment: Degrease and derust the blade surface, and clean it with acetone. It is required that the blade surface has no defects such as cracks, pores, and inclusions.

[0061] Clamp the blade: clamp the blade on a specific mobile platform so that the blade is in a horizontal position.

[0062] Scanning trajectory setting: use Fanuc trajectory planning and control robot system to set the scanning trajectory of the laser.

[0063] Laser beam adjustment: adjust the defocus amount to make the focused laser spot a rectangle, and the spot size: length×width=3.3mm×2.0m...

Embodiment 3

[0075] The invention is used for the manufacture of the water corrosion-resistant coating of the long blade of the low-pressure last stage of a large-scale nuclear power steam turbine. The process proceeds in the following steps:

[0076] Alloy powder selection and powder drying: select Stellite No. 6 cobalt-based alloy powder, ball mill the powder for 1 hour and dry at 150° C. for 1 hour.

[0077] Blade surface pretreatment: Degrease and derust the blade surface, and clean it with acetone. It is required that the blade surface has no defects such as cracks, pores, and inclusions.

[0078] Clamp the blade: clamp the blade on a specific mobile platform so that the blade is in a horizontal position.

[0079] Scanning trajectory setting: use Fanuc trajectory planning and control robot system to set the scanning trajectory of the laser.

[0080] Laser beam adjustment: adjust the defocus amount to make the focused laser spot a rectangle, and the spot size: length×width=3.3mm×2.0m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com