System and method for metal card clothing quenching treatment adopting YAG laser

A YAG laser and metal card clothing technology, applied in the field of quenching system, can solve the problems of inability to accurately locate the heating position of the tooth, uneven heating degree of the tooth tip, unstable quenching quality of the tooth, etc., and achieve significant economic benefits. Good toughness and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

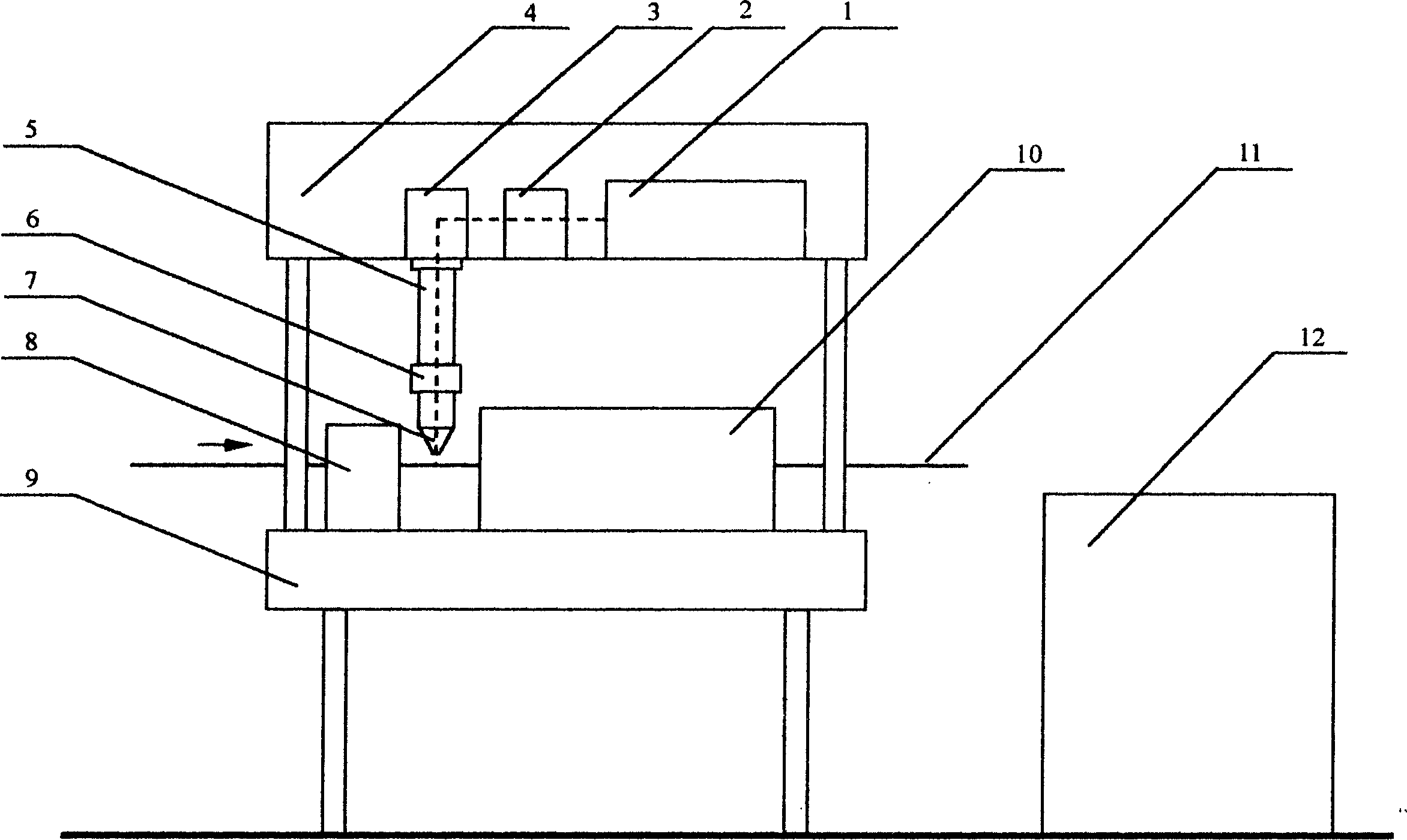

[0047] refer to figure 1 : In conjunction with this embodiment, the structure of the whole system consisting of three parts, such as an optical system, a positioning cooling system and a control cabinet, is described in detail.

[0048] The YAG laser 1 of this embodiment is purchased on the market, adopts a lamp-pumped structure, and the laser output power is continuously adjustable from 0 to 200W, including a full reflection mirror and an adjustment frame, a light collecting cavity, an output mirror and an adjustment frame, and a light gate. And laser power measuring head, etc. The YAG laser 1 is electrically connected with the laser power supply in the control cabinet to generate YAG laser light under the excitation of the laser power supply; the shutter of the laser 1 is used to control the switch of the laser; the laser power measuring head is used for real-time laser power monitoring. Described optical path comprises: the output optical path front of YAG laser 1 sequent...

Embodiment 2

[0055] This embodiment is a method for processing the 20 series cylinder card clothings whose model is AC2030×01550 in the YAG laser quenching metal card clothing system of embodiment 1, including the following steps:

[0056] Will figure 1 The system (of embodiment 1) that adopts YAG laser quenching processing metal card clothing shown in the above is installed on the production line; The metal card clothing that is determined to be processed is installed on the movable mechanism of the positioning device 8 of the system;

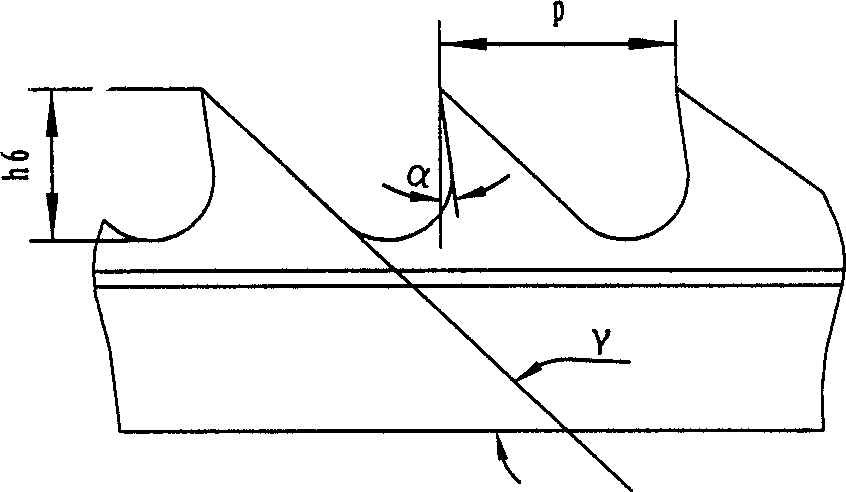

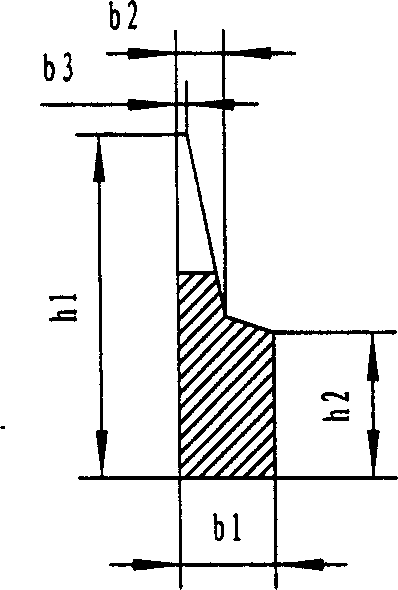

[0057] 2. According to the process parameters of the metal card clothing to be processed, determine the current I of the laser power supply (corresponding to the power P of the spot), the scale L of the adjustment ring 6 (corresponding to the diameter of the spot φ), the moving speed v of the metal card clothing and the positioning device 8 the scale S;

[0058] 3. Start the feeding device on the metal card clothing production line, so that the metal car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com