Cast steel material for chain wheel of marine diesel engine and casting method of chain wheel

A marine diesel engine, diesel engine technology, applied in belt/chain/gear, mechanical equipment, components with teeth, etc., can solve the problems of long-term use fatigue, local wear, casting defects of sprocket teeth, etc., to achieve surface hardness and mechanical Improved performance, increased strength and surface hardness, uniform hardness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

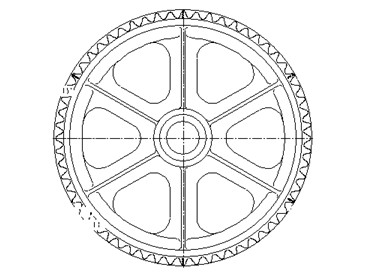

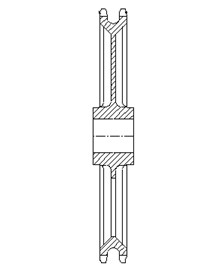

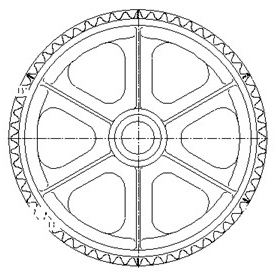

Image

Examples

Embodiment Construction

[0038] Below we will further elaborate the manufacturing material and sprocket casting method of the sprocket on the marine diesel engine of the present invention in conjunction with specific embodiments, in order to understand the present invention more clearly, but can not limit the scope of the present invention with this protected range.

[0039] The cast steel material that is used for marine diesel engine sprocket among the present invention comprises following composition:

[0040] Chemical element mass percentage (%)

[0041] C 0.18~0.21

[0042] Mn 0.85~1.00

[0043] Si 0.35~0.55

[0044] S≤0.020

[0045] P≤0.020

[0046] Cr≤0.30

[0047] Ni≤0.30

[0048] Mo≤0.080

[0049] V≤0.10

[0050] Al≤0.080

[0051] Nb≤0.060

[0052] Cu≤0.40

[0053] The rest is Fe element and other unavoidable impurities;

[0054] Among the above element ratios, the following carbon equivalent requirements are met:

[0055] CEV≤0.39%, CEV is calculated according to the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com