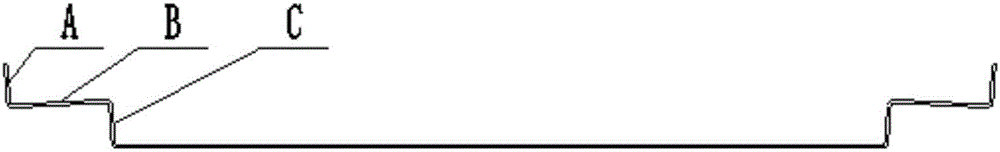

Bending die for safe case door frame plate and using and machining method thereof

A technology of bending molds and processing methods, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult processing, low processing precision, poor efficiency, etc., and achieve convenient operation, good quality of finished products, and no cumulative error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

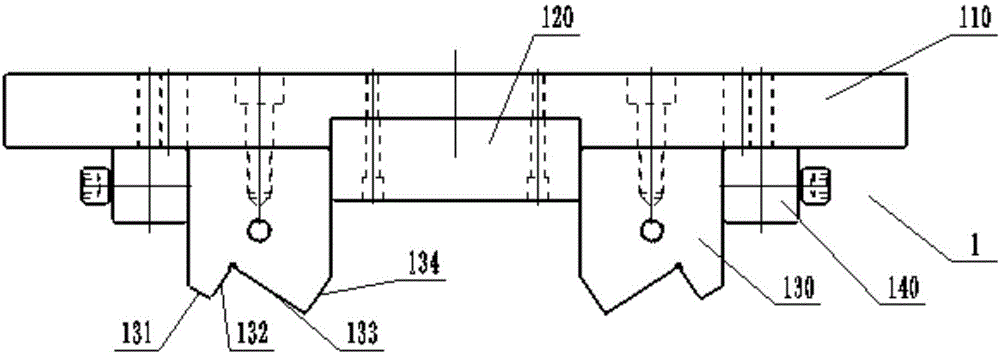

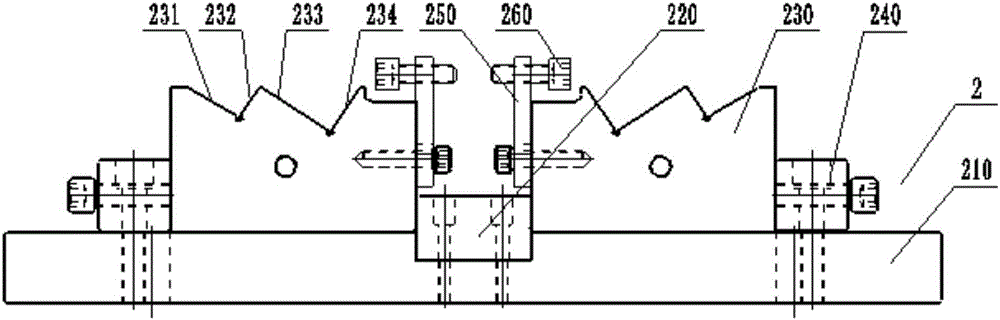

[0058] Such as figure 2 , image 3 As shown, a special bending mold for a safe door frame plate in this embodiment includes an upper mold assembly 1 and a lower mold assembly 2;

[0059] Wherein, the upper mold assembly 1 includes an upper mold 130, the lower end surface of the upper mold 130 is a stamping surface, and the first slope 131, the second slope 132, and the third slope 133 are formed from one side to the other. and the fourth bevel 134 are sequentially connected, the angle between the first bevel 131 and the side of the upper mold 130 is 240°, the angle between the first bevel 131 and the second bevel 132 is 266°, the second bevel 132 and the The included angle between the third slope 133 is 91°, the fourth slope 134 is parallel to the second slope 132, and the intersection position between the first slope 131 and the second slope 132 is higher than the intersection position between the third slope 133 and the fourth slope 134 .

[0060] The lower mold assembly...

Embodiment 2

[0079] Although adopting the special mold and method in embodiment 1 can well complete the bending process of the safe door frame plate, there is a problem, that is, the number of times of use is too many, and the working parts of the upper mold 130 and the lower mold 230 are more stressed due to It is large and easy to damage, which leads to the need to replace the mold after a period of use. It has been proved by practice that the upper mold made of ordinary materials and heat treatment process will easily appear the first slope 131 and the second slope of the upper mold 130 when it is used for about 1600 times. The edges and corners at the junction of the inclined plane 132 and the corners at the junction of the third inclined plane 133 and the fourth inclined plane 134 appear cracking and wear. Similarly, the corners at the junction of the second groove surface 232 and the third groove surface 233 of the lower mold 230 also appear cracking abrasion etc. Although the above ...

Embodiment 3

[0096] A kind of processing method of special bending mold for safe door frame plate of the present embodiment, lower mold 230 is processed, and its steps are:

[0097] (1) Raw material preparation for rough

[0098] It is made by forging blank. The composition and mass percentage of the forging blank are: C 0.4%, Si 0.3%, Mn0.65%, S≤0.023%, P≤0.021%, Cr 1.4%, Mo 0.42%, ZrO 2 0.1%, the balance is Fe;

[0099] (2) Annealing treatment of forging blank

[0100] Annealing the forged blank obtained in step (1) through an annealing furnace, the annealing temperature is 830°C, the annealing time is 4.2h, cooled to 250°C in the annealing furnace, held for 0.8h, and then air-cooled to normal temperature;

[0101] (3) Initial processing of forging blanks

[0102] The forging blank in step (2) is processed into the primary shape of the mold on the lathe, and each side retains a margin of 1.5mm;

[0103] (4) Heat treatment of the mold

[0104]The mold obtained by machining in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com