Novel stemming at tap hole

A technology of taphole and taphole mud, which is applied in the field of refractory materials and taphole mud, which can solve the problems of not being able to guarantee the depth of the taphole, poor compressive and thermal shock resistance, and excessive smoke generation, and achieve opening performance Good effect of prolonging tapping time and reducing tapping times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

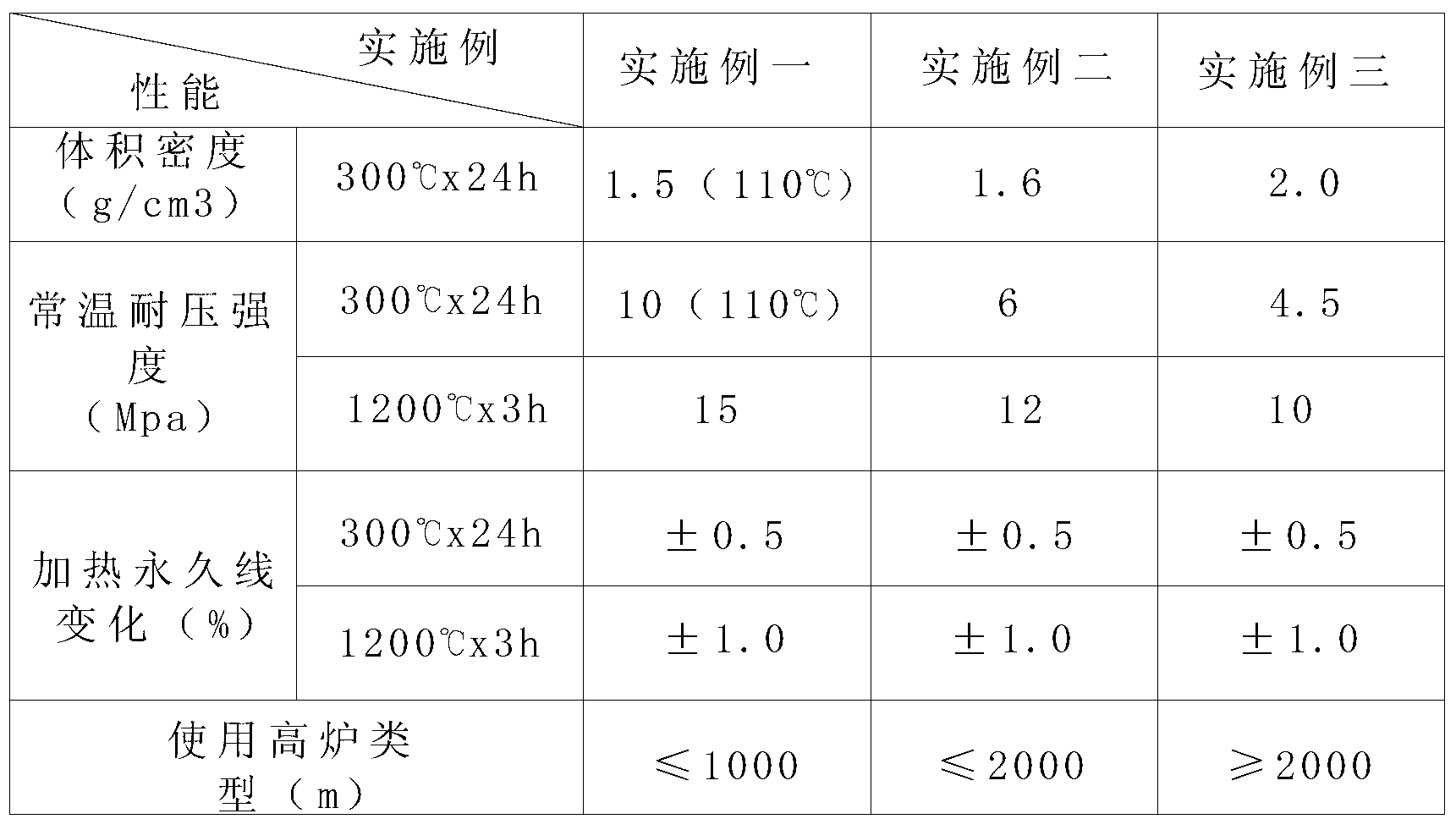

Examples

Embodiment 1

[0022] The new type of taphole clay includes the following components and the mass ratio of each component is: 8 parts of corundum, 9 parts of high alumina aggregate, 20 parts of silicon nitride bonded silicon carbide, 3 parts of ferrosilicon nitride, and 12 parts of coke powder , 16 parts of clay, 2 parts of flake graphite, 8 parts of pyrophyllite, 5 parts of sericite, 10 parts of aluminum-magnesium spinel, 4 parts of activated alumina micropowder, 3 parts of metal powder, plus 15 parts of composite binder, including 3 parts of tar , 9 parts of silicone modified phenolic resin, 3 parts of organic solvent acetone, and the metal powder is metal silicon powder. The above-mentioned gun mud adopts the following preparation method: After uniformly mixing the dry raw materials, adding a composite binder, rolling and stirring together with the dry raw materials in a roller compactor, and mixing and milling at a temperature of 50°C for 30 Minutes, put the mixed and milled gun mud into...

Embodiment 2

[0024] The new type of taphole clay includes the following components and the mass ratio of each component is: 17 parts of corundum, 12 parts of high alumina aggregate, 21 parts of silicon nitride bonded silicon carbide, 2 parts of ferrosilicon nitride, and 6 parts of coke powder , 12 parts of clay, 2 parts of flake graphite, 6 parts of pyrophyllite, 4 parts of sericite, 8 parts of aluminum-magnesium spinel, 3 parts of activated alumina micropowder, 2 parts of metal powder, plus 18 parts of composite binder, including 3.6 parts of tar , 10.8 parts of silicone modified phenolic resin, 3.6 parts of organic solvent acetone, and metal powder is metal aluminum powder. The above-mentioned gun mud adopts the following preparation method: After uniformly mixing the dry raw materials, adding a composite binder, rolling and stirring together with the dry raw materials in a roller compactor, and mixing and milling at a temperature of 55°C for 40 Minutes, put the mixed and milled gun mud ...

Embodiment 3

[0026] The new type of taphole clay includes the following components and the mass ratio of each component is: 20 parts of corundum, 18 parts of high alumina aggregate, 24 parts of silicon nitride bonded silicon carbide, 3 parts of ferrosilicon nitride, and 5 parts of coke powder , 12 parts of clay, 2 parts of flake graphite, 2 parts of pyrophyllite, 4 parts of sericite, 6 parts of aluminum-magnesium spinel, 2 parts of activated alumina micropowder, 2 parts of metal powder, plus 20 parts of composite binder, including 4 parts of tar , 12 parts of silicone modified phenolic resin, 4 parts of organic solvent acetone, metal powder is metal silicon powder and metal aluminum powder, the ratio of the two is 1:1. The above-mentioned gun mud adopts the following preparation method: after uniformly mixing the dry raw materials, adding a composite binder, rolling and stirring together with the dry raw materials in a roller compactor, and mixing and rolling at a temperature of 60°C for 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com