Al*O*-SiC-C system waterless taphole mix containing ferrosilicon nitride

A technology of ferrosilicon nitride and anhydrous taphole mud, which is applied to blast furnace parts, blast furnaces, furnace types, etc., can solve problems such as slow sintering and difficulty in opening holes, and achieve reduced tapping times, reduced labor intensity, and corrosion resistance Good performance and ease of hole opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

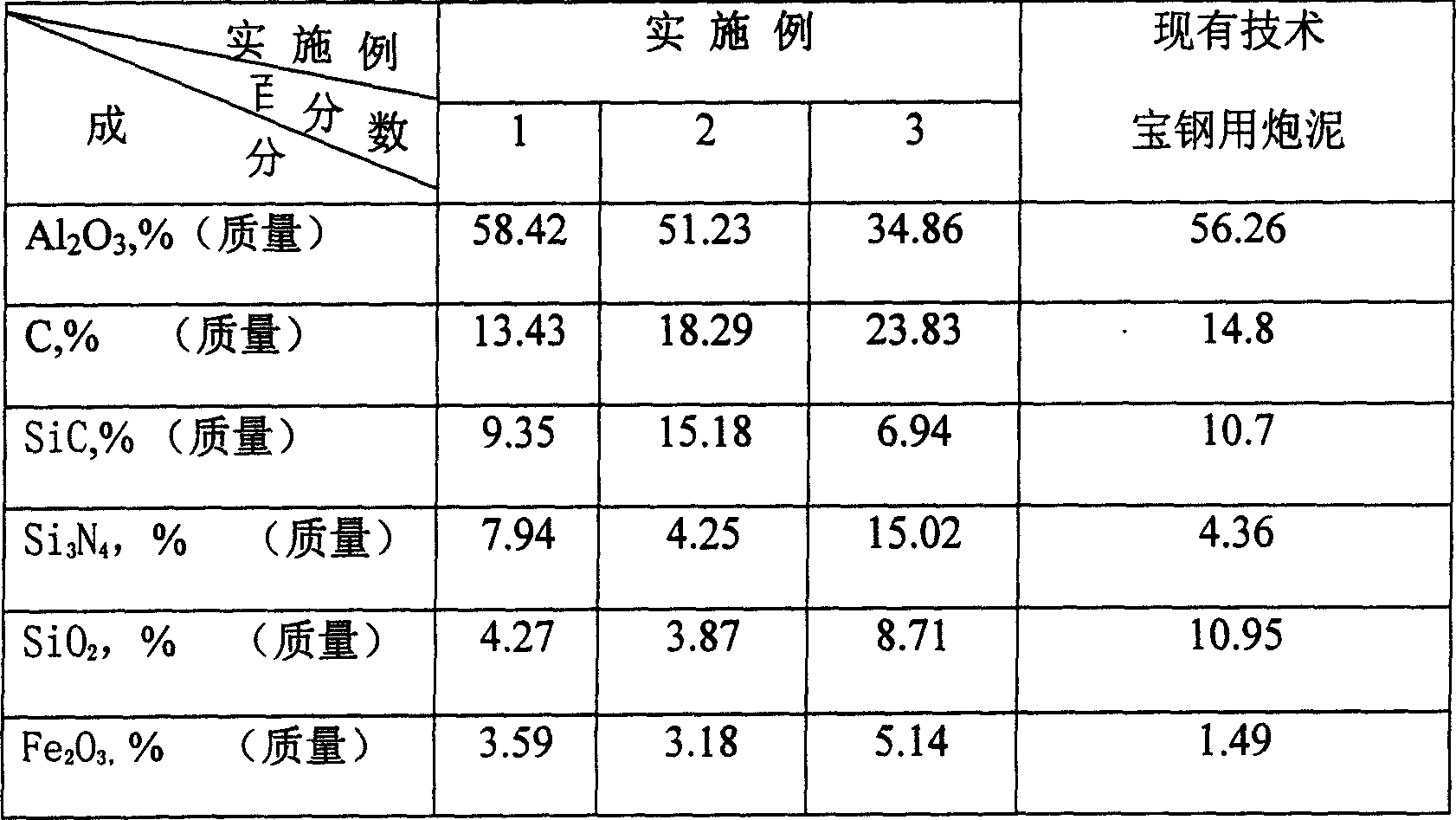

[0018] Specific embodiments of the present invention are shown in Table 2

[0019] Table 2 Embodiments of the present invention

[0020] Other ingredients, % (mass)

3

4

5.5

1.5

Slag corrosion resistance (mm)

it is good

it is good

it is good

it is good

Medium temperature strength

it is good

it is good

it is good

better

Difficulty of opening

better

it is good

it is good

Difference

[0021] Note: The corrosion resistance of slag is to make the taphole mud into Φ50×50mm, the slag hole is Φ25×25mm, and do the high temperature slag invasion test under the reduction condition of 1500℃×3h; blast furnace slag is: SiO 2 34.29%, Al 2 O 3 14.37%, CaO4 3.58, MgO 5.79, FeO 0.9%.

[0022] The chemical composition of the present invention is the detection result of the taphole clay after being treated in a reducing atmosphere at 1000° C.×3h.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com