Additive for producing high-performance methanol gasoline

A technology for methanol gasoline and additives, applied in the field of oil additives, can solve the problems of poor combustion effect, low methanol content, easy stratification, etc., and achieve the effects of solving water stratification, reducing corrosion degree and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with specific embodiment content of the present invention is described in further detail:

[0009] The preparation method and steps of the additive are as follows: 1. Measure 18mL of isobutanol, 12mL of 2.4-di-tert-butyl-4-cresol, 26mL of isoamyl alcohol, and mix well. 2. Under the state of mechanical stirring, add o- Dioctyl phthalate 10mL, dioctyl alcohol 5mL, methylcyclopentadiene manganese tricarbonyl 0.005mL, dicyclohexylamine nitrite 1.0mL, glycerin triacetate 1.5mL, 0.5mL mixture of aldehyde condensates . 3. Stir until it is evenly mixed.

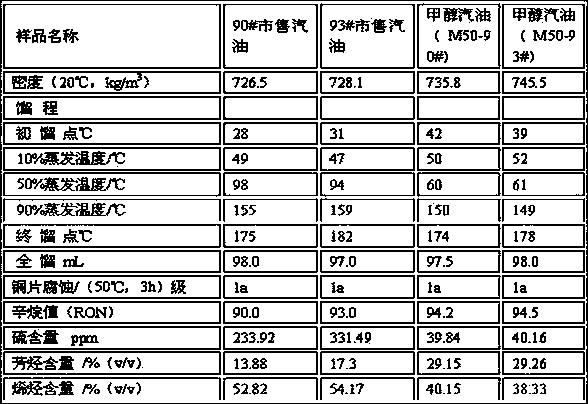

[0010] Methanol-gasoline blending: Take 5 mL of the prepared additive and add it to 495 mL of methanol, stir until fully shaken, add it to 1L 93# gasoline, shake it 100 times, and you can get it, which is recorded as M50-93#. The methanol gasoline of 90# gasoline can be obtained by the same method deployment, which is recorded as M50-90#.

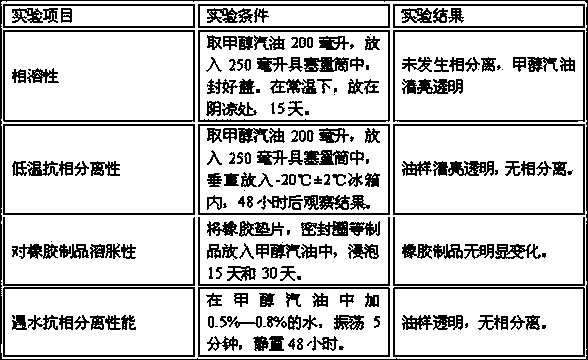

[0011] The gasoline formulated by this method can not only achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com