Hydraulic control self-propelled road surface cutter

A self-propelled cutting machine technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems affecting the quality and efficiency of cutting operations, labor-intensive operations of workers, and inability to guarantee stable cutting, etc., to achieve simple structure and operation. The effect of fast response and reduced maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

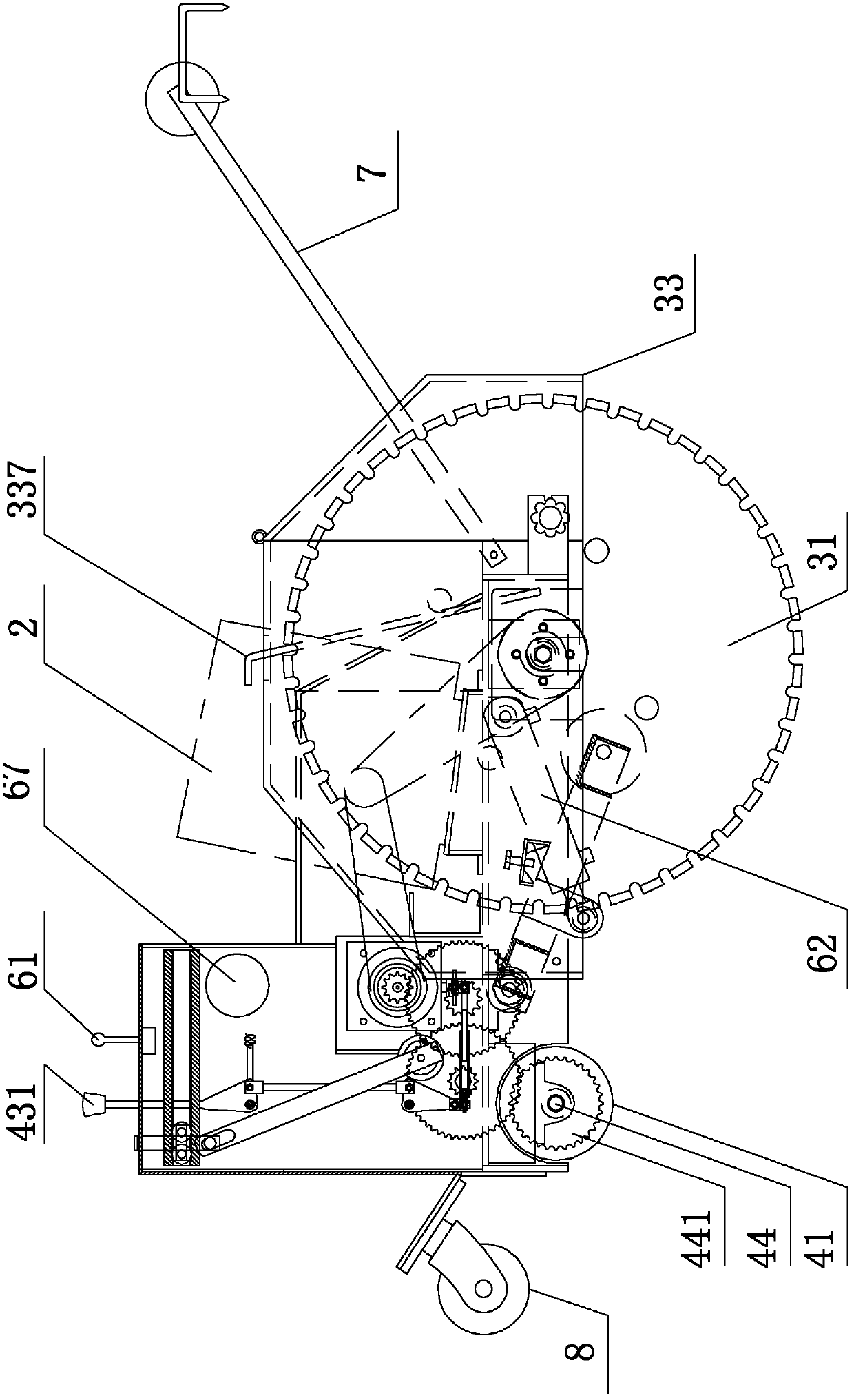

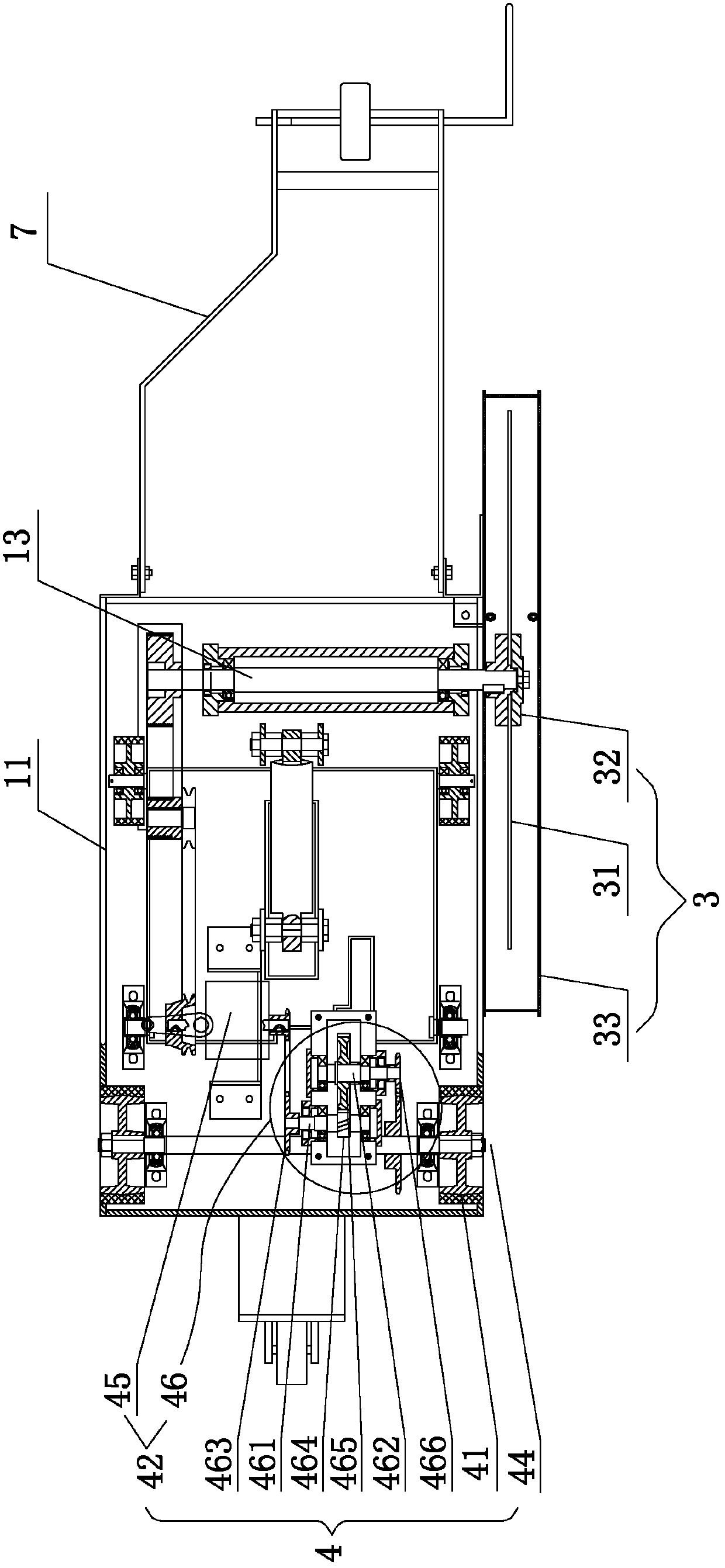

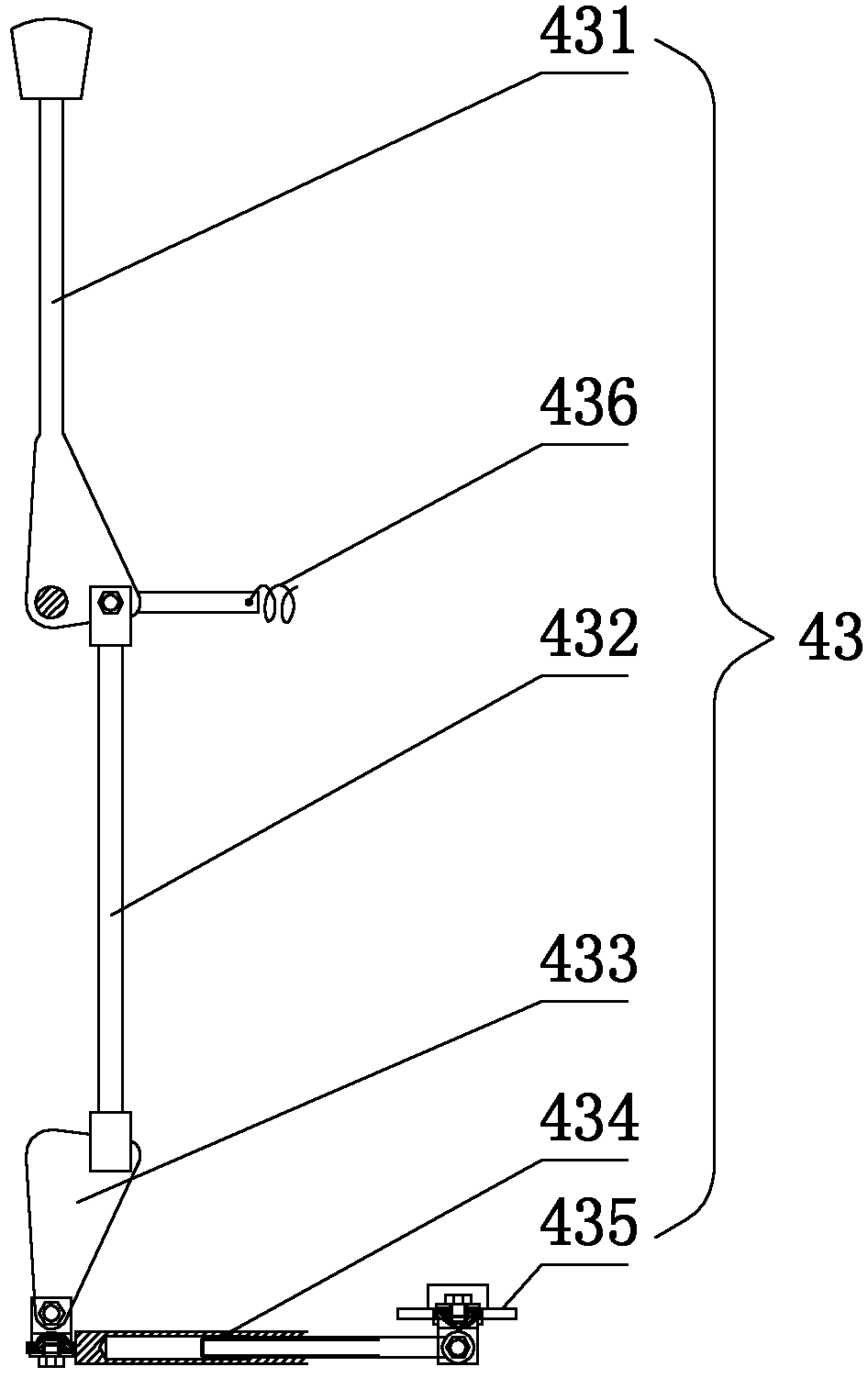

[0033] See Figure 1-7 , the present invention has vehicle frame 1, engine 2, cutting device 3, traveling device 4 and supporting device 9; Vehicle frame 1 has chassis 11 and support 12; Support 12 is fixedly arranged on the left end of chassis 11; On the chassis 11 of support 12 right sides; Cutting device 3, walking device 4 and supporting device 9 are fixedly installed on the vehicle frame 1; Cutting device 3 has blade 31; Blade 31 is installed on the right side of chassis 11 by blade pressure plate 32. On the blade shaft 13 at the lower end; the running gear 4 has a driving wheel 41, a transmission mechanism 42 and a walking control mechanism 43; the driving wheel 41 is installed on the left end of the chassis 11 by the rear wheel shaft 44; the transmission mechanism 42 has a hydrostatic transmission 45 and a speed reduction device 46; the input wheel of the hydrostatic transmission 45 is connected to the output shaft of the engine 2 by a transmission belt or a transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com