Patents

Literature

122results about How to "Self-learning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

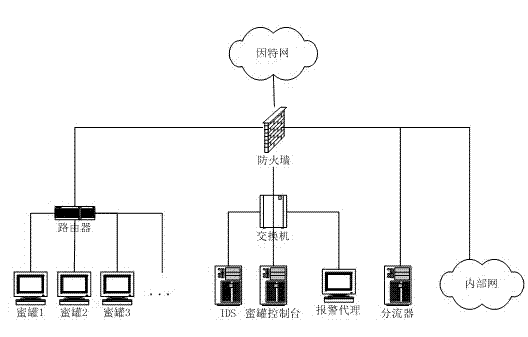

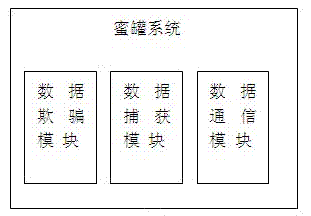

DDos (distributed denial of service) attack defensive system based on network trap

InactiveCN102790778ARespond to attacks in a timely mannerRespond quicklyData switching networksTraffic volumeComputer security

The invention discloses a DDos (distributed denial of service) attack defensive system based on a network trap. The system comprises a honey pot console, a plurality of honey pot systems, an alarm agent and a data shunt, wherein the honey pot system is a cheat host with the same operating system and host operating system; the external characteristics of the cheat host can be used for attracting intrusion of a attacker; and the attack data can be introduced to the data shunt by the honey pot console for protecting the network. With the aadoption of the system, known DDos attack can be defended and the attacker is attracted to enter the trap system, thereby the harm to other systems in the network by the attacker is reduced, and shunting process is simultaneously carried out on the data flow in the network to separate normal flow from DDos attack flow and filter DDos attack flow, so that the normal flow visits a target host according to a source route.

Owner:CHANGZHOU UNIV

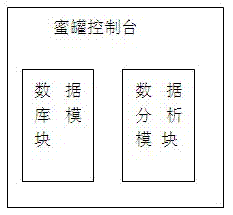

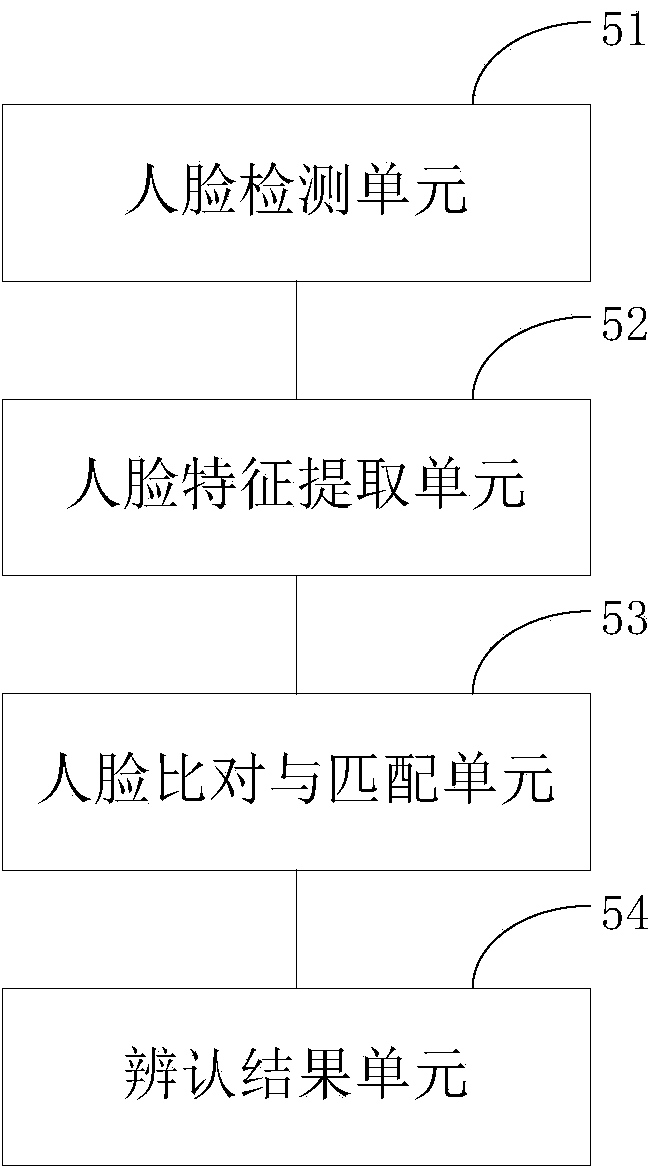

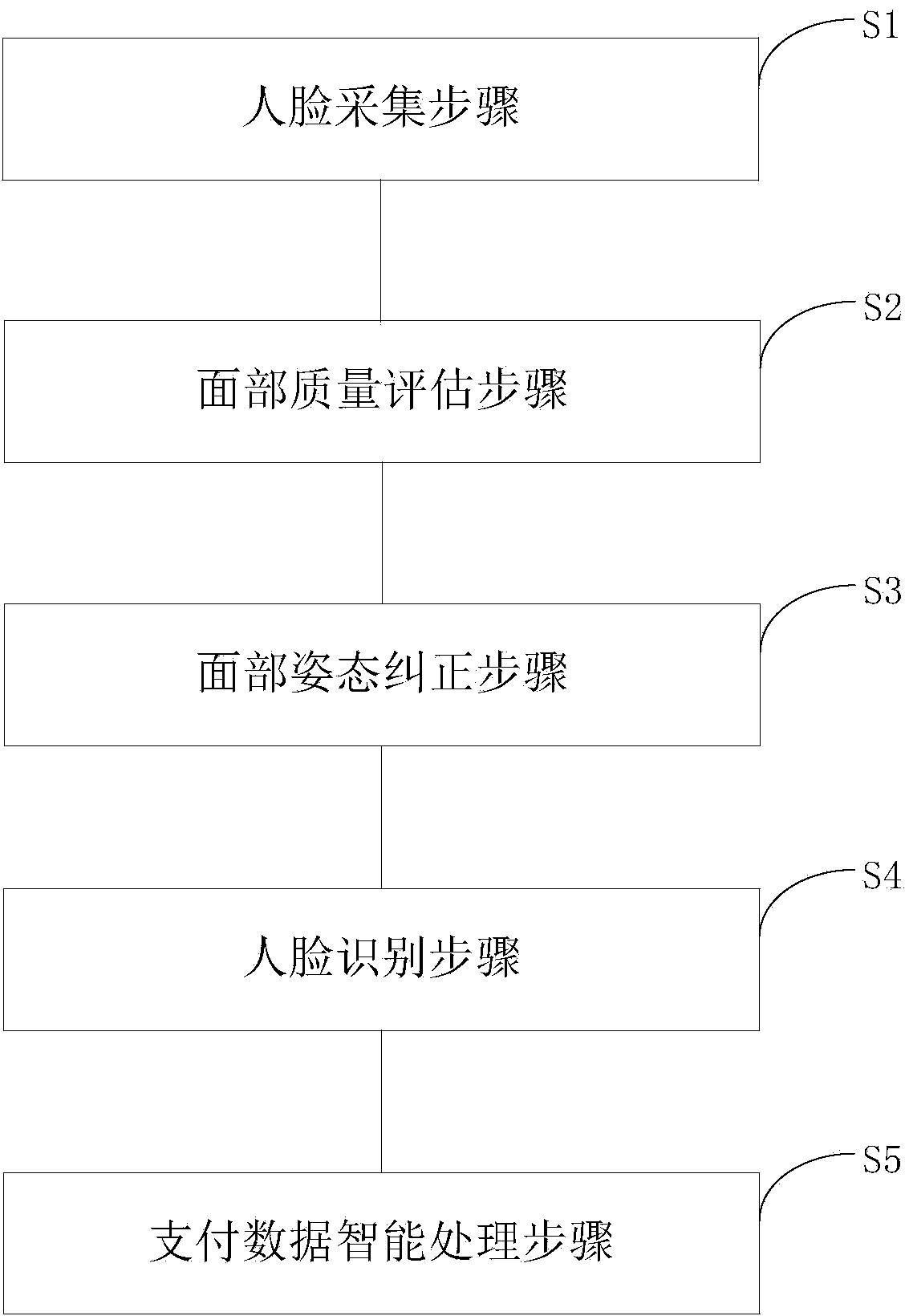

Human face payment authentication system and method

ActiveCN103824068ASelf-learningIntelligent managementCharacter and pattern recognitionDigital data authenticationPaymentOriginal data

The invention discloses a human face payment authentication system and method. The human face payment authentication system comprises a human face original data binding module, a face quality evaluation module, a face posture correction module, a human face recognition module and a payment data intelligent treatment module, wherein the human face original data binding module uses standard user face information as original binding data; the face quality evaluation module is used for performing comprehensive quality evaluation of data collection faces and screening comparison data; the face posture correction module is used for correcting deviated postures on the premise that the face data is not lost; the human face recognition module is used for collecting information of human faces needing to be compared, extracting face feature information and comparing the face feature information with corresponding face feature information in a database so as to judge whether the feature information belongs to the same person; the payment data intelligent treatment module is used for performing comprehensive evaluation and judgment on human face information after human face payment authentication transaction is successful. The human face payment authentication system and method provided by the invention can be used for improving the safety and convenience of payment, and meanwhile, the recognition accuracy of the system is improved.

Owner:SHANGHAI KANKAN INTELLIGENT TECH CO LTD

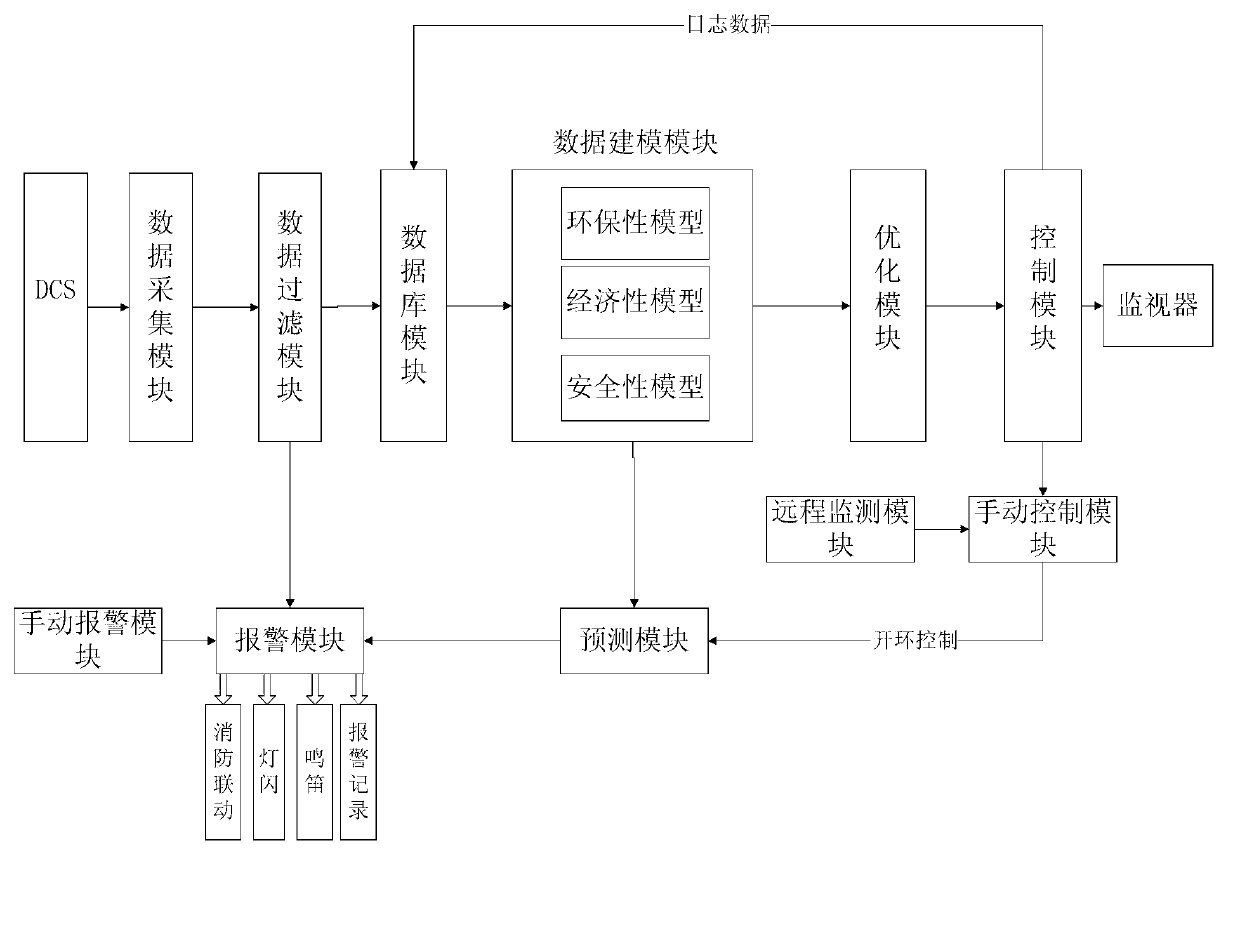

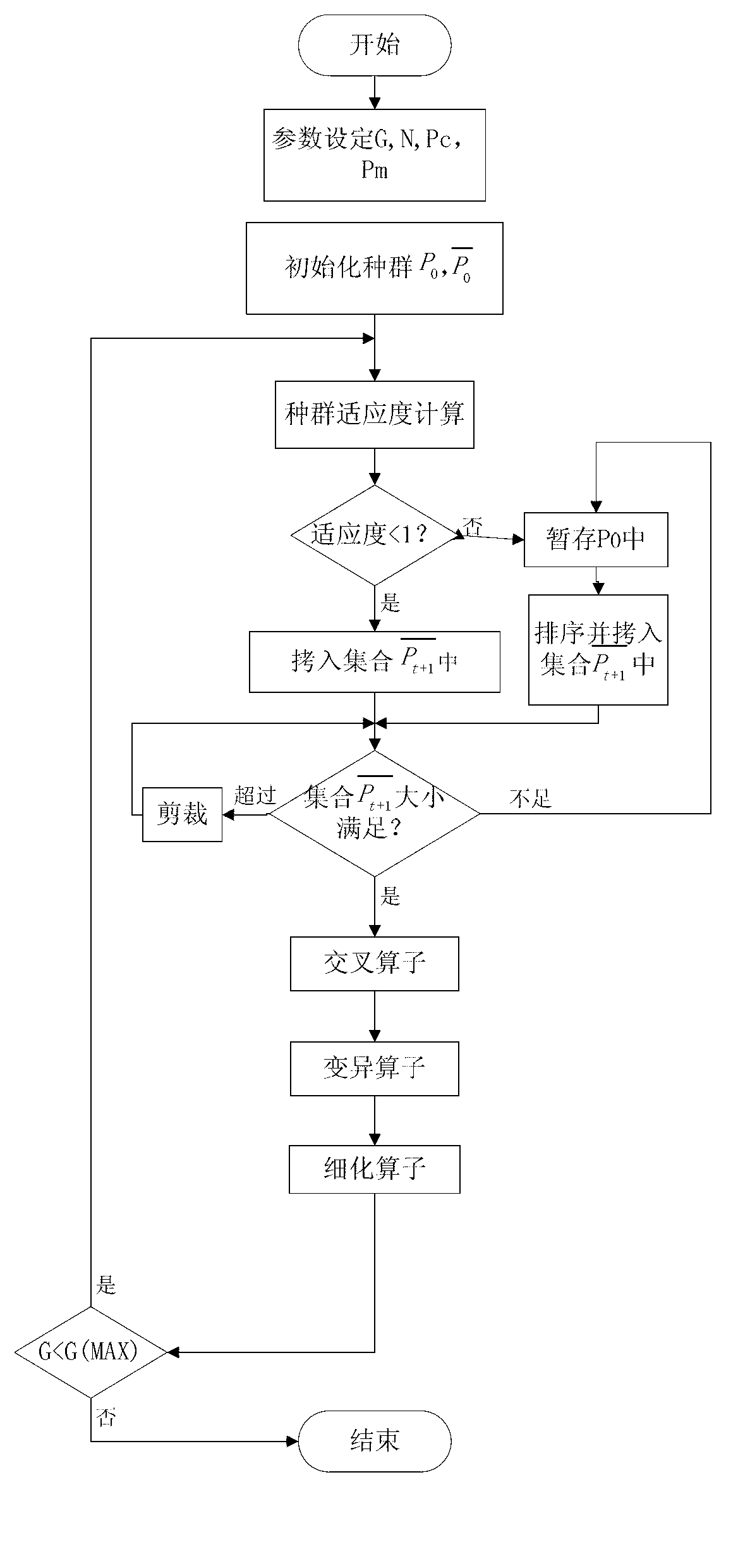

Multiple-target operation optimizing and coordinating control method and device of garbage power generator

The invention provides a multiple-target operation optimizing and coordinating control method and a device of a garbage power generator. The multiple-target operation optimizing and coordinating control method includes the following steps. Operational parameters are downloaded from a data communication system (DCS), data judged as reasonable based on a threshold value are transmitted to a database. In terms of environmental protection, economy and safety of the power generator, three models are respectively set up by means of a support vector machine and a fuzzy neural network. A modified strength PARETO genetic algorithm is used for comprehensively optimizing multiple targets and then optimum operation parameters under the present working condition are worked out. Operational staff can adjust operation of corresponding parts based on the optimum operation parameters. The device comprises a data collecting module, a data filtering module, a database module, a data modeling module, an optimizing module, a forecasting module, a remote monitoring module, a monitor, an alarming module and a manual alarming module. The multiple-target operation optimizing and coordinating control method and the device of the garbage power generator achieve multiple functions of real-time forecasting, offline simulation, dynamic optimizing and the like and have the advantages of being strong in adaptability, good in self-learning ability, high in fitting precision, obvious in optimizing effect and the like.

Owner:SOUTH CHINA UNIV OF TECH

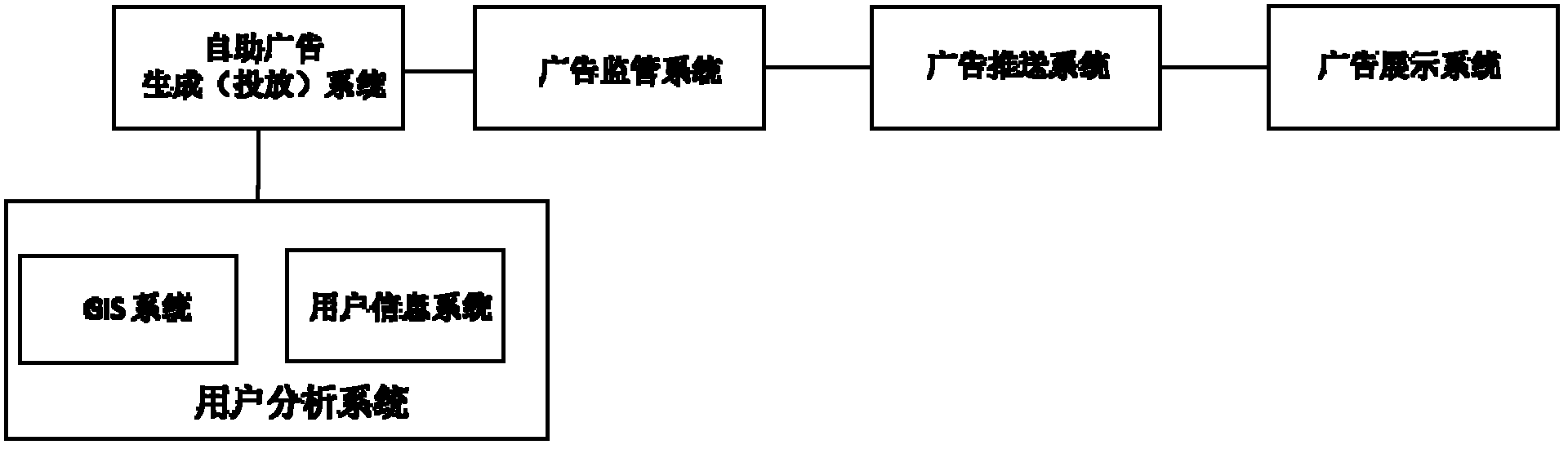

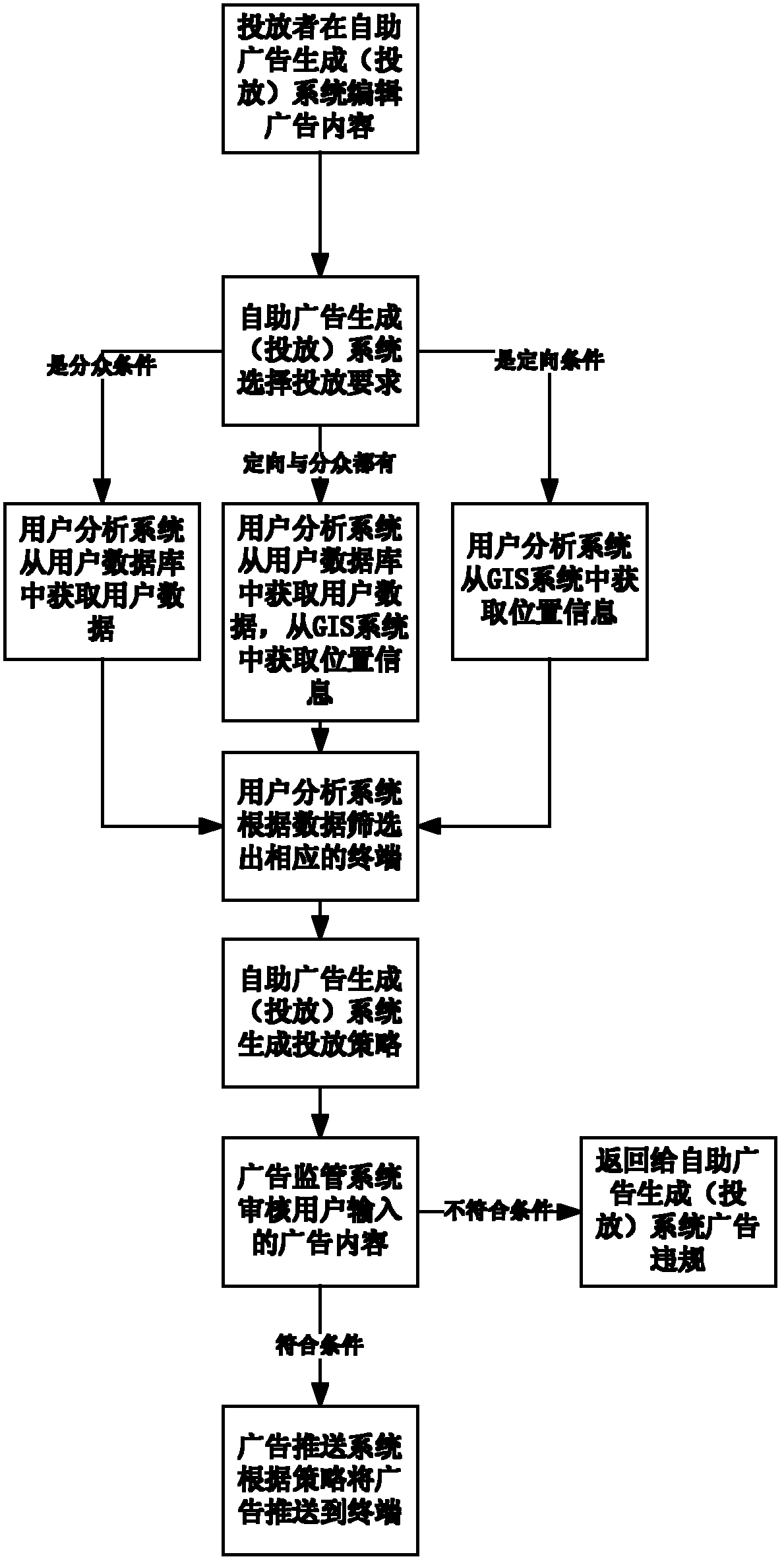

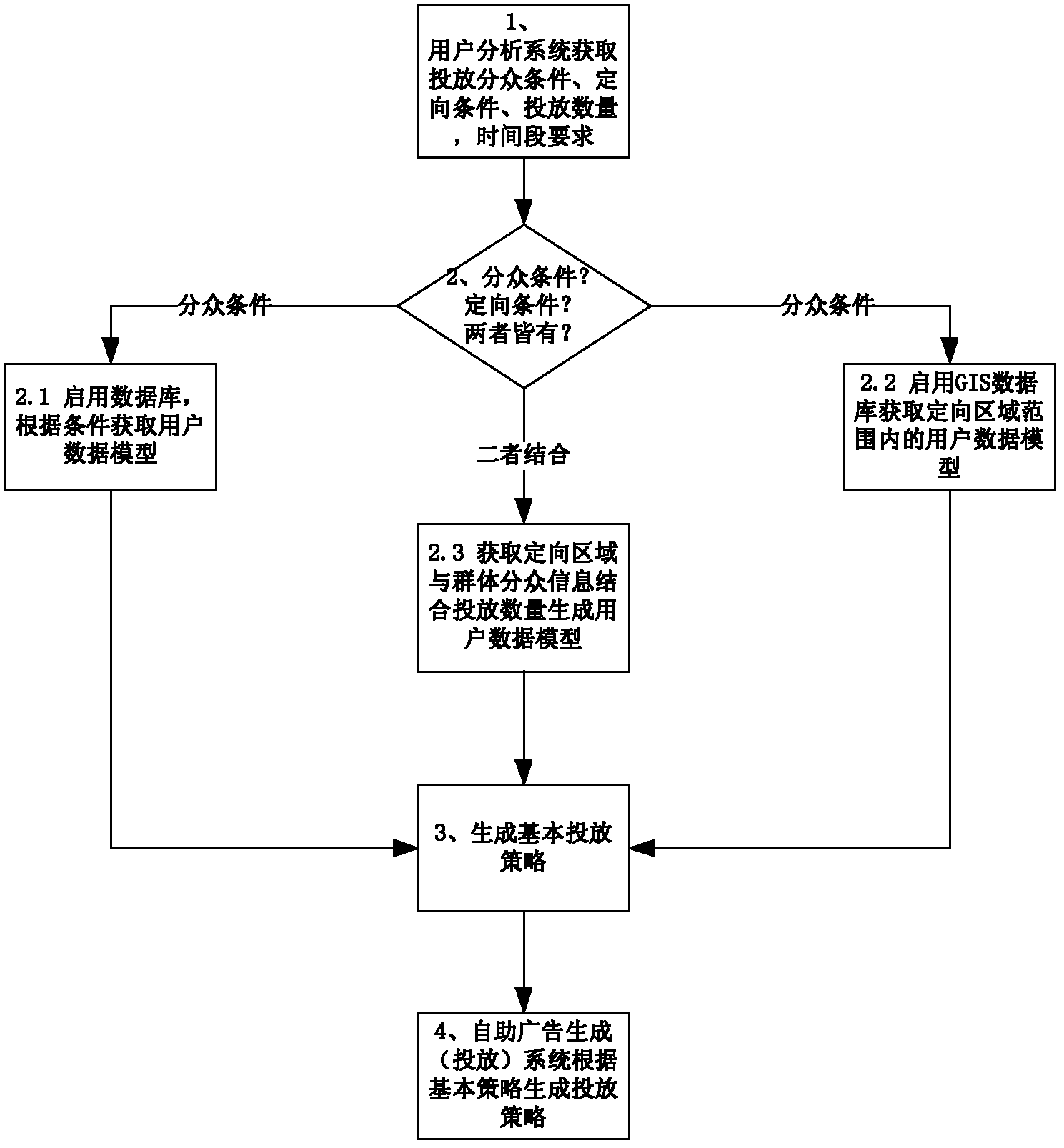

System and method for mass-decentralized and targeted delivery of advertising

InactiveCN102622701AImprove accuracySelf-learningMarketingUser analysisGeographic information system

The invention discloses a system and a method for mass-decentralized and targeted delivery of advertising. The system comprises a user analysis system, a self-help advertising generation delivery system, an advertising supervision system, an advertising pushing system and an advertising display system. A deliverer edits advertising through the advertising generation delivery system, and different mass-decentralized conditions or a targeted condition concluding the range of geographical location is selected. The user analysis system extracts corresponding data from a user information system and a GIS (Geographic Information System) according to the conditions given by an advertiser, selects a corresponding terminal according to the extracted data, and generates a basic delivery strategy. The information required by the advertiser, such as delivery time and the like is combined to generate a delivery strategy. The advertising supervision system is used for examining, verifying and supervising the content of advertising delivered by a user, and the approved advertising is sent to the advertising display system. The invention provides an advertising delivery system which obtains the user consumption behavior, living standard and geographical location information according to the living community condition of the user, and the mass-decentralized and targeted accuracy is increased.

Owner:江苏运赢物联网产业发展有限公司

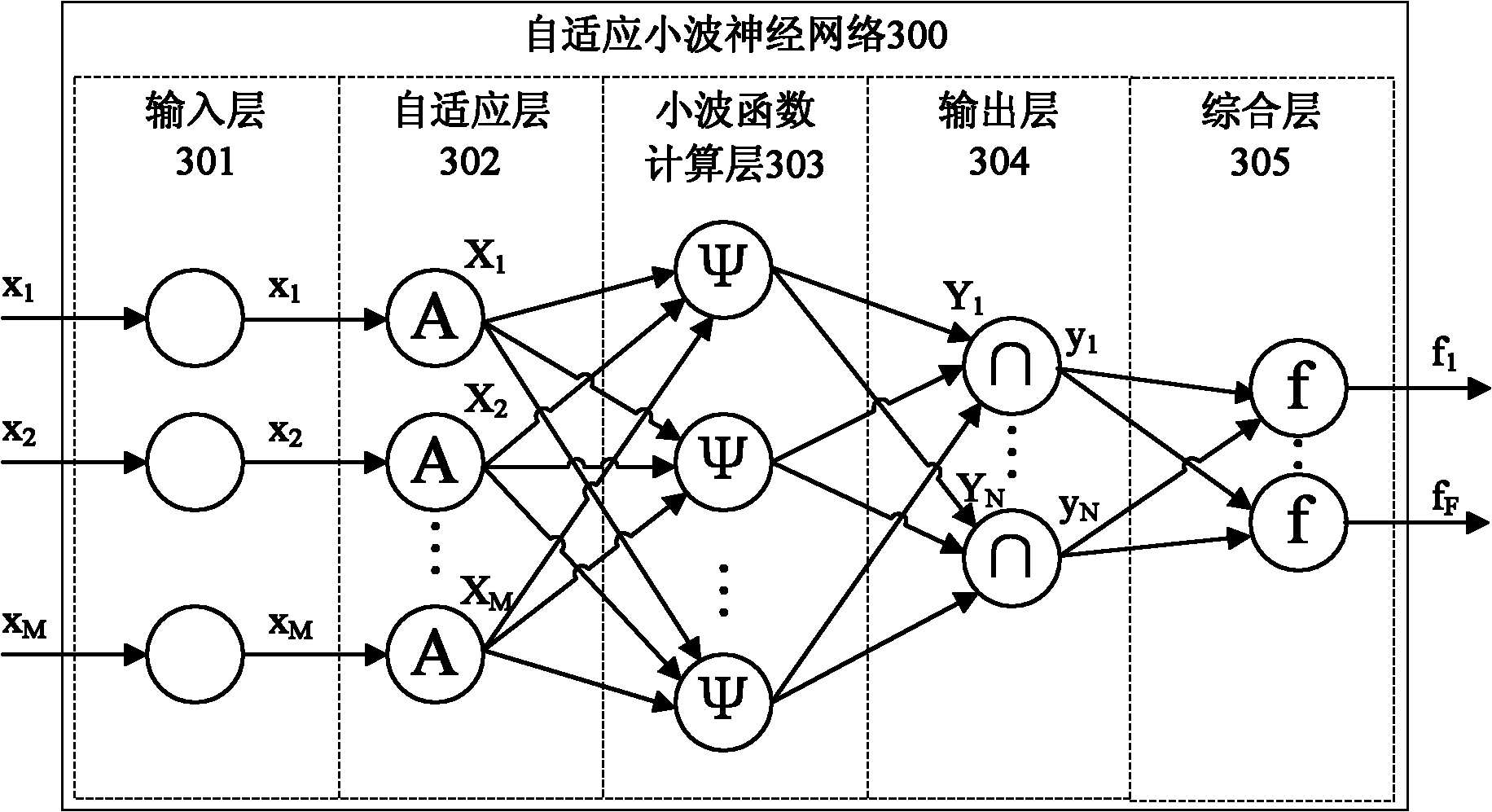

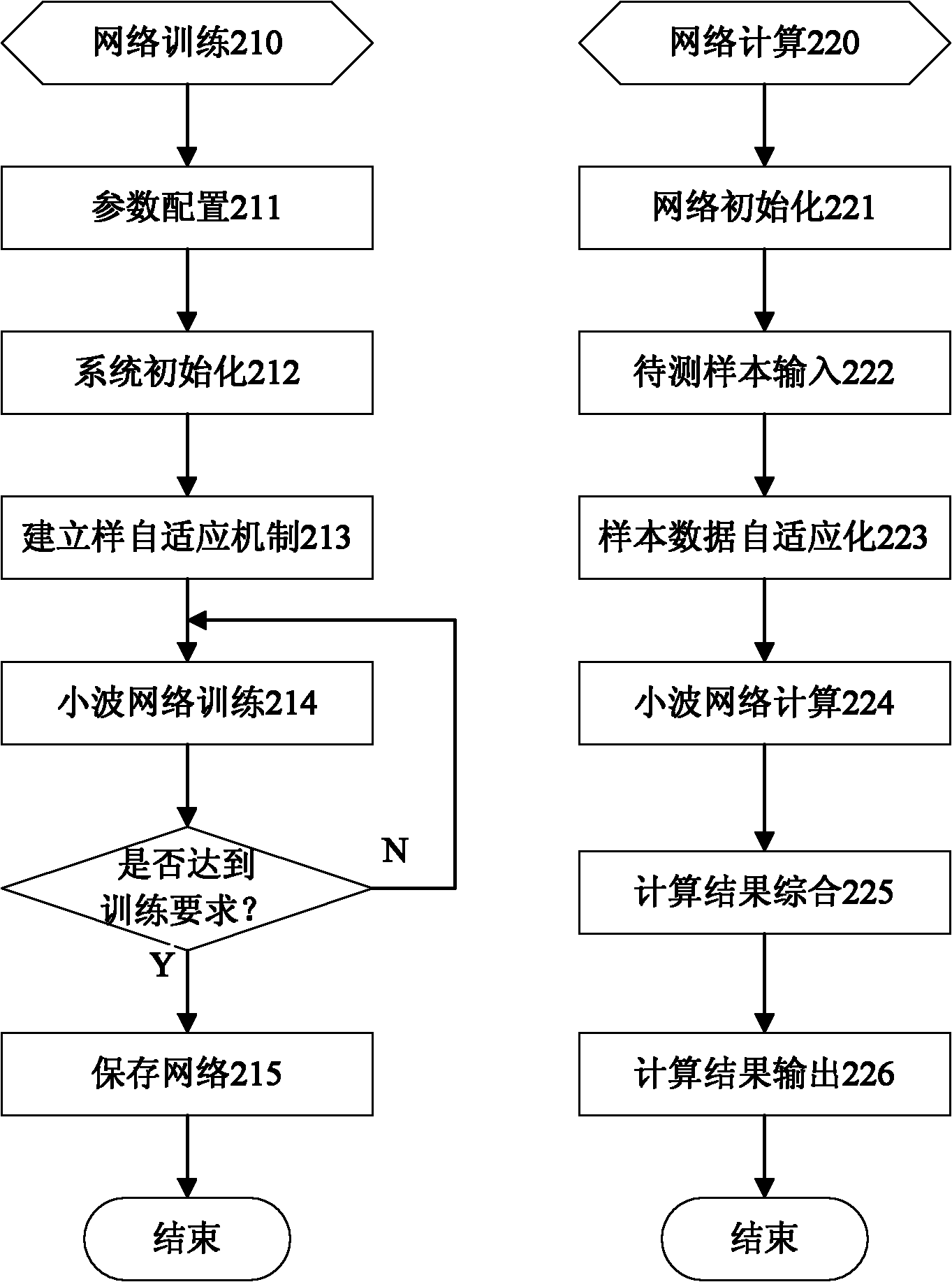

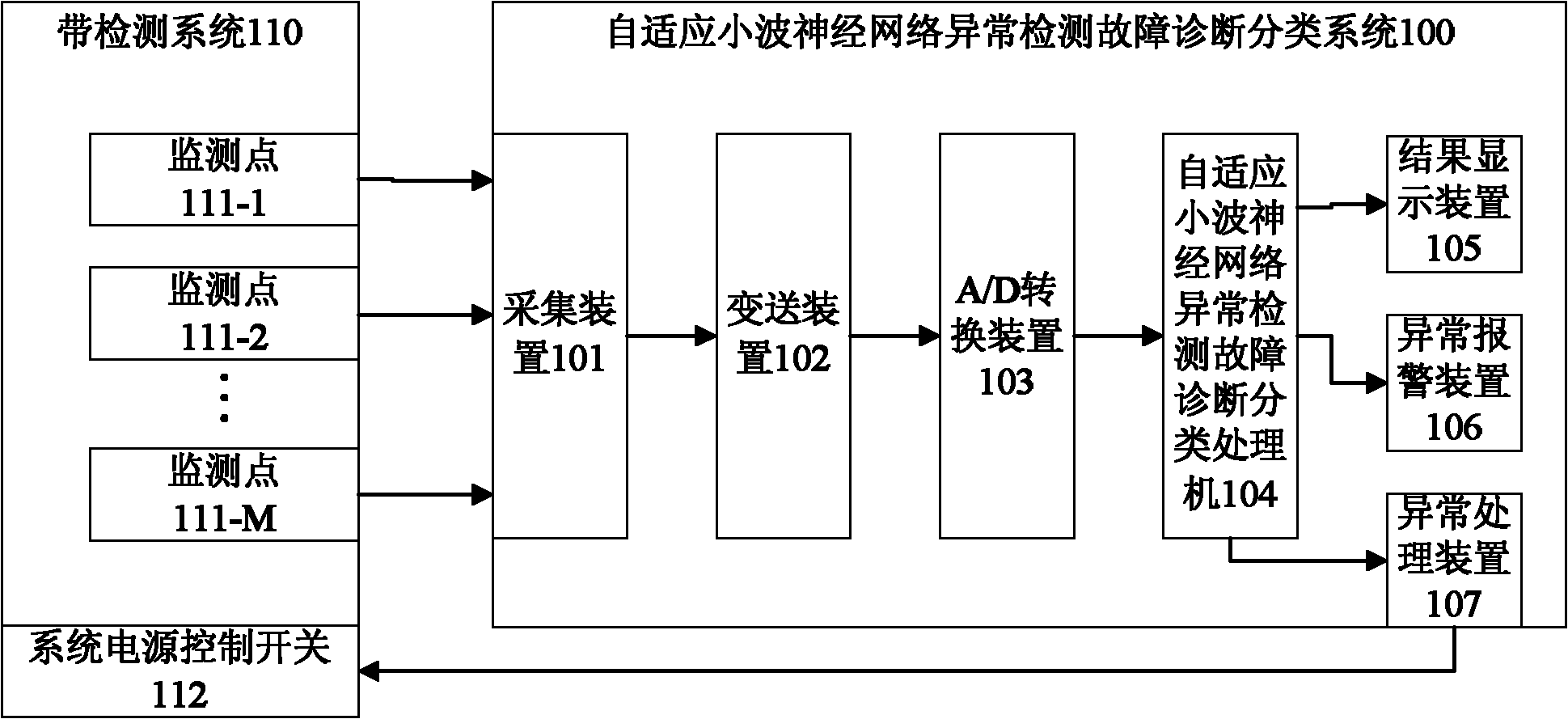

Self-adaption wavelet neural network abnormity detection and fault diagnosis classification system and method

The invention relates to a self-adaption wavelet neural network abnormity detection and fault diagnosis classification system and method, which can be applied to the fields, such as economic management abnormity detection, image recognition analysis, video retrieval, audio retrieval, signal abnormity detection, safety detection, and the like. The system comprises the following seven parts: an acquisition device, a transmitter device, an A / D (Analog / Digital) conversion device, a self-adaption wavelet neural network abnormity detection and fault diagnosis classification processor, a display interaction device, an abnormity alarm device and an abnormity processing device. The abnormity detection and fault diagnosis classification object of the self-adaption wavelet neural network abnormity detection and fault diagnosis classification system is acquired from samples for which a self-adaption mechanism is automatically established by the self-adaption wavelet neural network of a system to be detected, the characteristic information of a signal can be effectively extracted through wavelet transform multi-scale analysis, and a more accurate abnormity detection and fault diagnosis locating result can be obtained. The device adopting the method has the advantages of generalization, high accuracy in the application field, capability of real-time monitoring and low cost.

Owner:BEIJING UNIV OF TECH

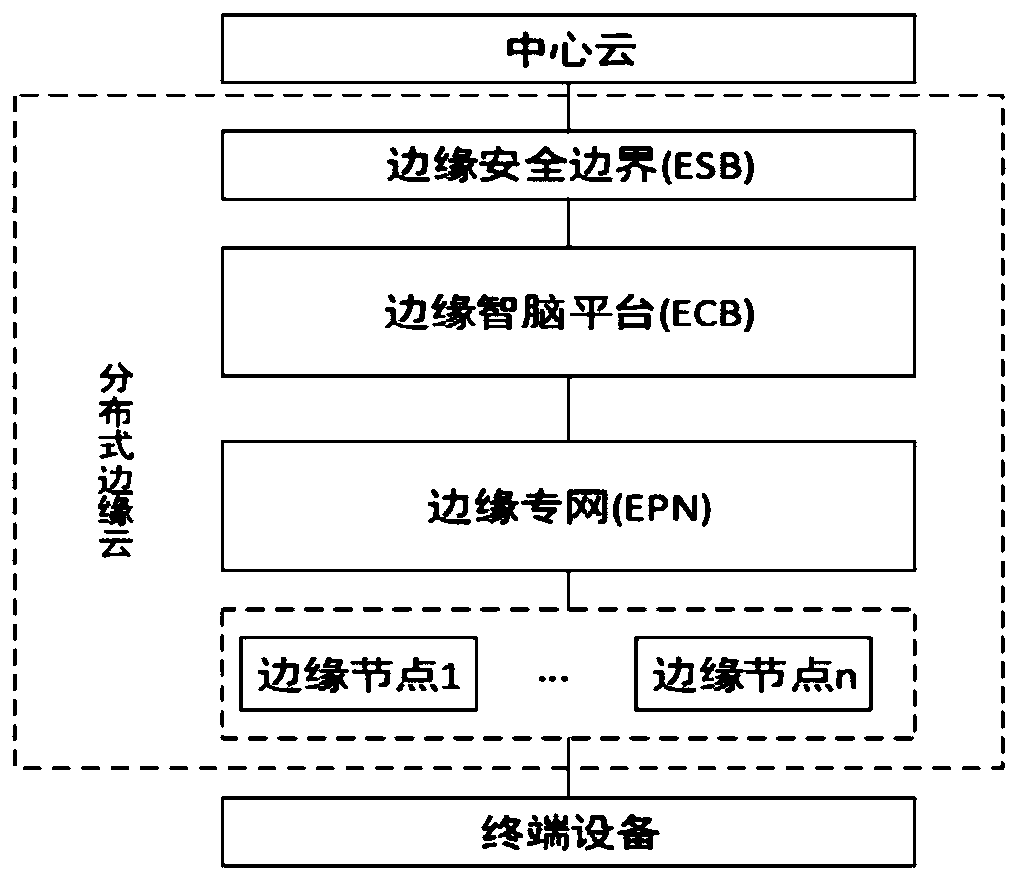

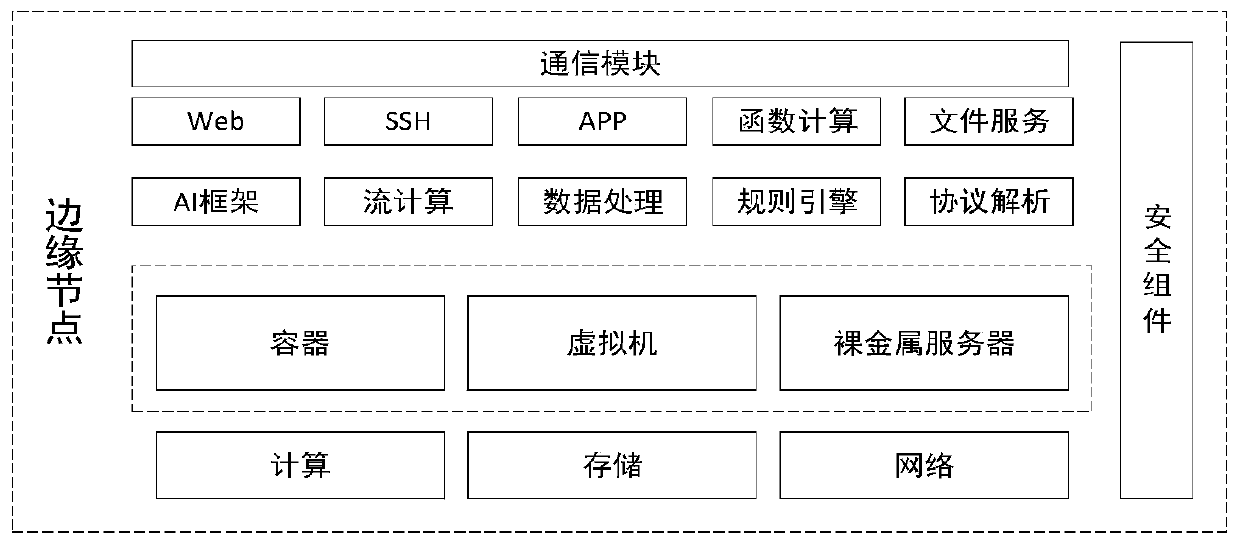

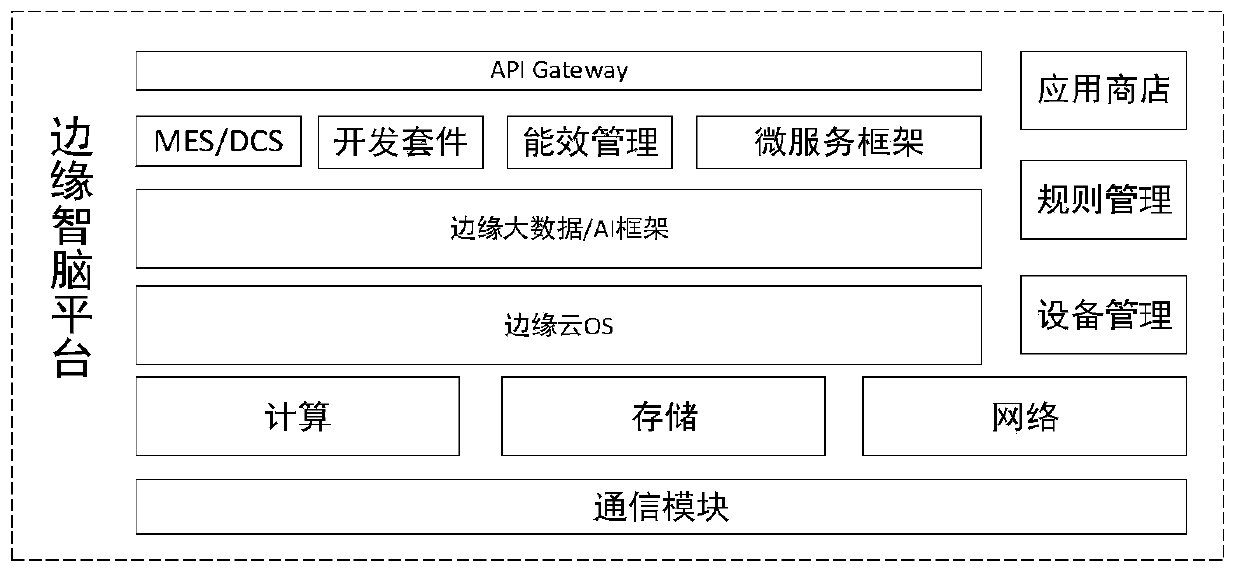

A distributed edge cloud system architecture

ActiveCN110572448AReduce interactionAchieve decouplingTransmissionCommunications securityTime delays

The invention belongs to the technical field of edge cloud computing systems, and discloses a distributed edge cloud system architecture. The architecture comprises an edge node, an edge computing intelligent brain platform layer and an edge security boundary layer, wherein the edge node communicates with the edge computing intelligent brain platform layer through an edge private network; an intelligent brain platform of the edge computing intelligent brain platform layer is in butt joint with a plurality of different edge nodes to realize distributed deployment; data are acquired through external terminal equipment accessed by the edge node and uploading the data to the edge node for processing; the edge computing intelligent brain platform layer communicates with the center cloud or theindustry cloud through the edge security boundary layer; the edge security boundary layer serves as an interface for communication between the edge cloud system and the center cloud or the industry cloud and is used for guaranteeing the communication security between the edge cloud and the center cloud or the industry cloud; the system architecture has the characteristics of low time delay and high security, and meets the requirements of agile connection, real-time service, data optimization, intelligent application, security and privacy protection.

Owner:FENGHUO COMM SCI & TECH CO LTD

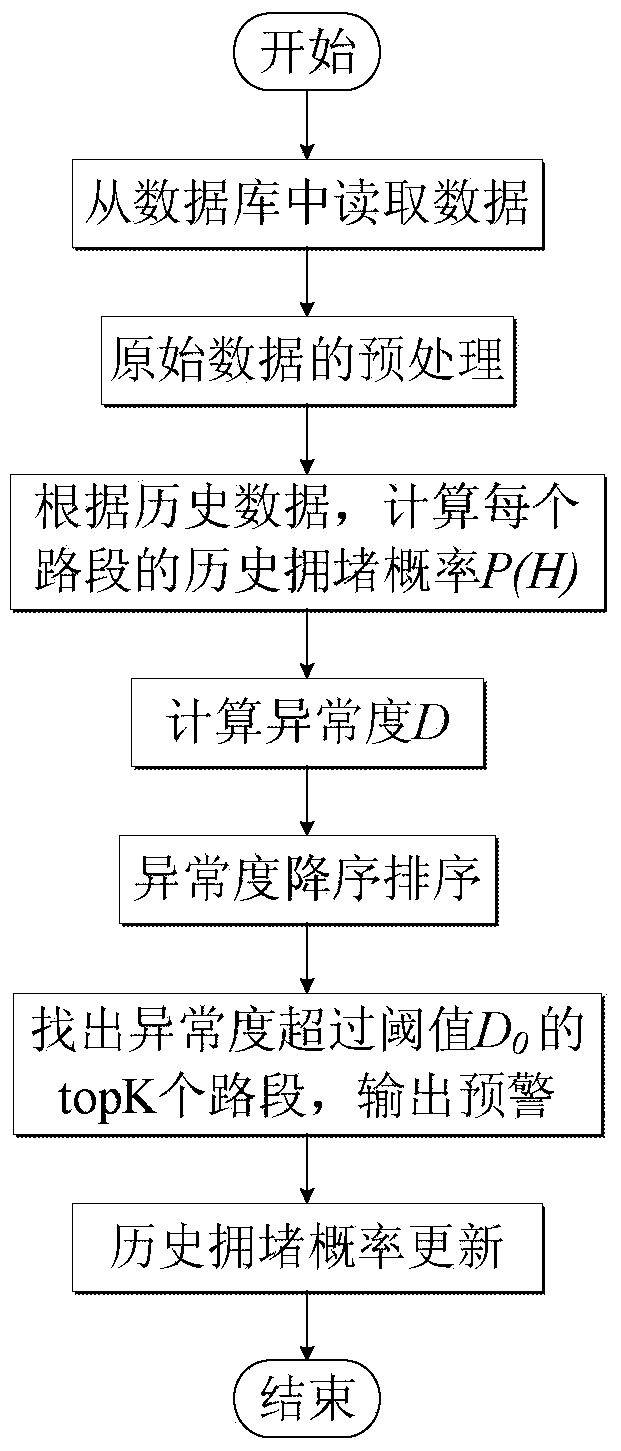

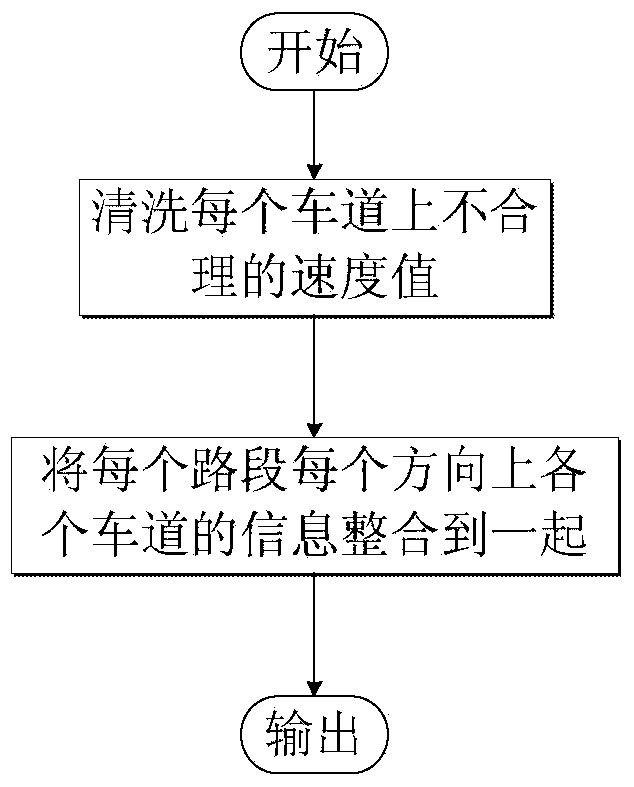

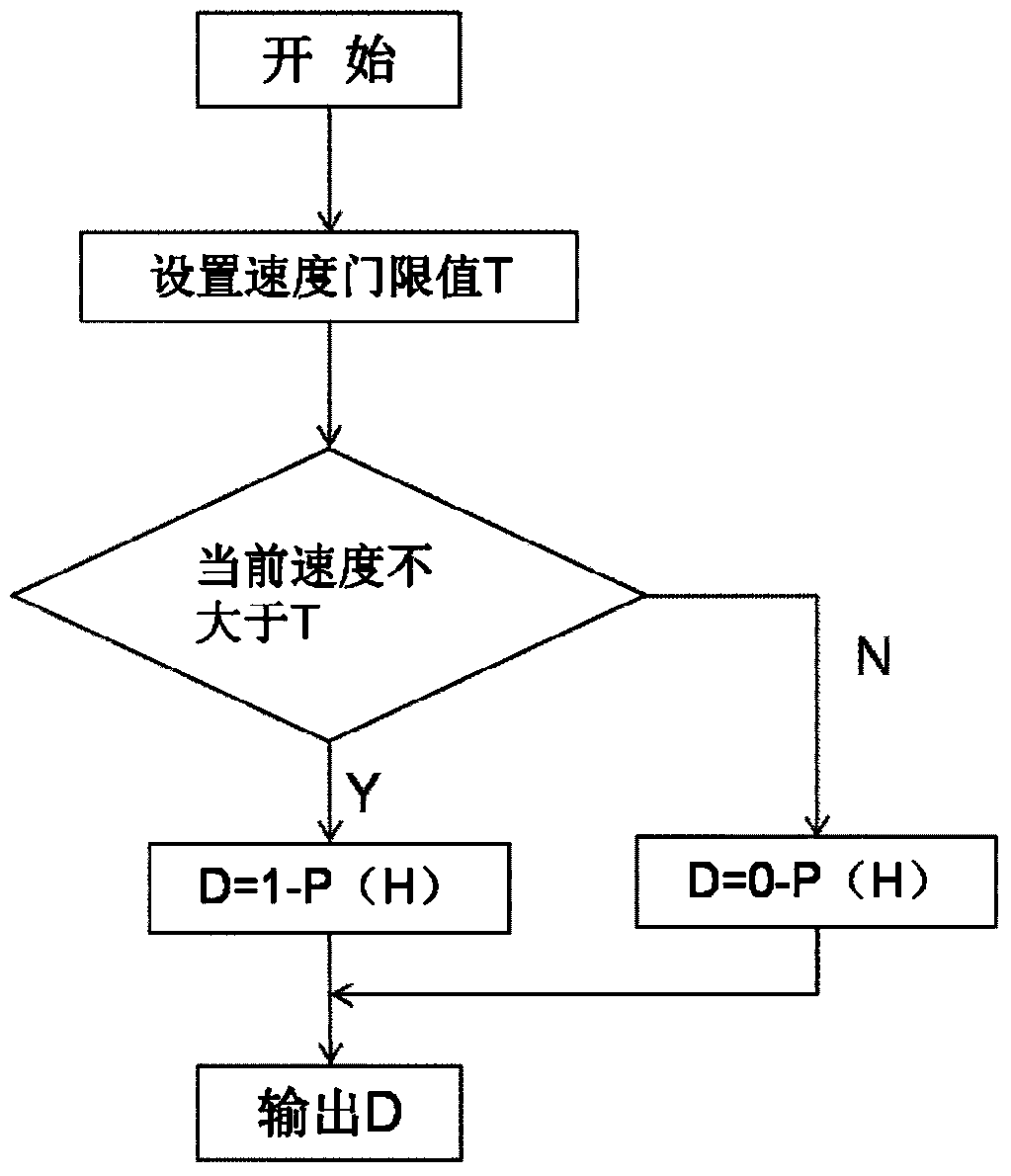

Abnormal congestion point judgment method based on microwave data

ActiveCN104240499AImprove accuracyWill not affect the suitabilityDetection of traffic movementMicrowaveRoad networks

The invention provides an abnormal congestion point judgment method based on microwave data. The method comprises the steps that firstly, historical data of microwave points are read from a database; secondly, original microwave data are preprocessed; thirdly, a historical congestion probability P (H) of each road segment in each time slot is calculated; fourthly, the abnormal degree D of each road segment in the current time slot is calculated in real time; fifthly, the abnormal degrees of a whole road network in the current time slot are ranked; sixthly, time anomaly judgments are accumulated, wherein if an anomaly happens to a current microwave point in a first set time period, the anomaly grade is set to be yellow, if an anomaly happens to the current microwave point in a second time period, the anomaly grade is set to be orange, and if anomalies continuously happen to the current microwave point in three set time periods, the anomaly grade is set to be red, namely the most abnormal state; seventhly, the historical congestion probability is updated. The abnormal congestion point judgment method based on the microwave data can effectively detect abnormal traffic congestion points and improve the accuracy of a real-time early warning.

Owner:ENJOYOR COMPANY LIMITED

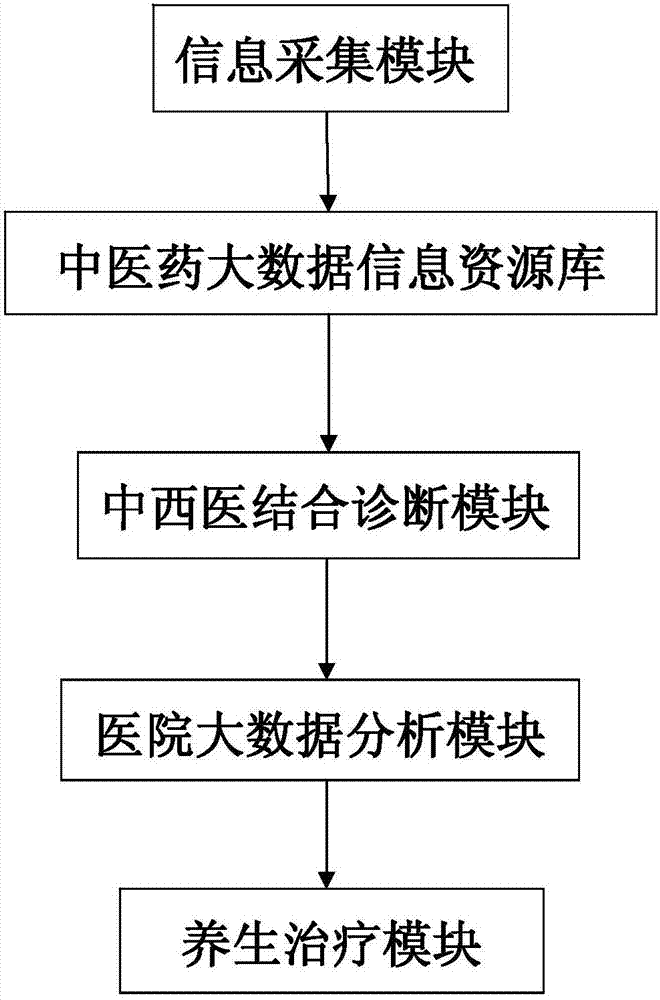

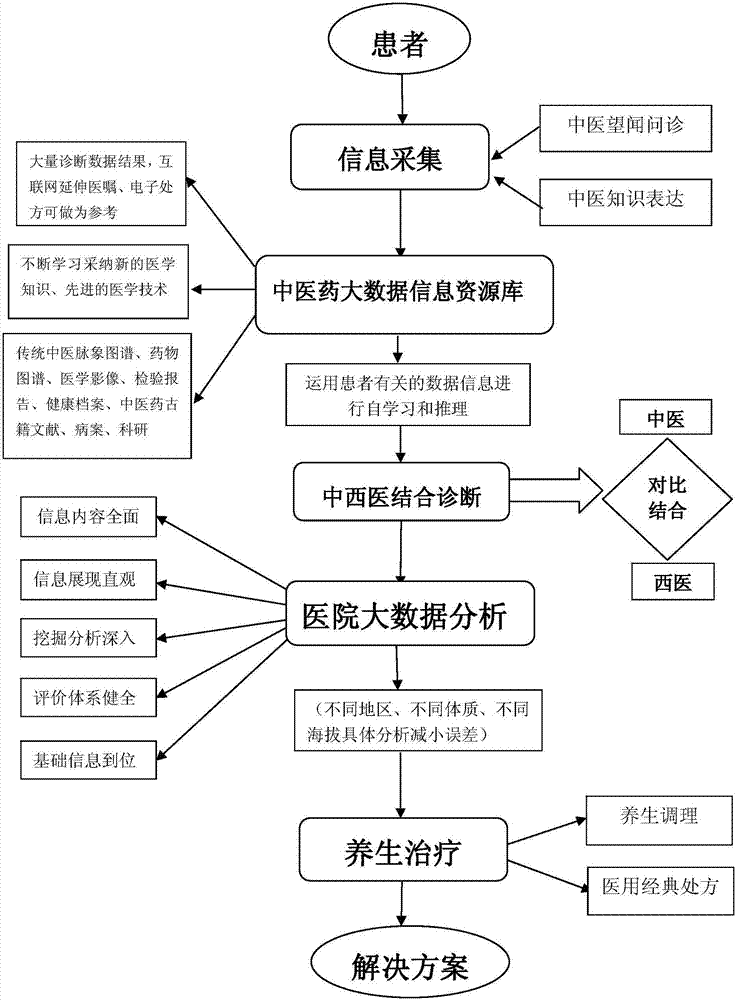

Four-diagnostic method cooperation-based traditional Chinese medicine intelligent aided diagnosis system

InactiveCN107066814AGood for healthRealize informatizationMedical automated diagnosisSpecial data processing applicationsInformation repositoryWestern medicine

The invention discloses a four-diagnostic method cooperation-based traditional Chinese medicine intelligent aided diagnosis system and belongs to the technical field of big data application. The system comprises five modules including an information collection module, a traditional Chinese medicine big data information library module, a traditional Chinese medicine and western medicine combined diagnosis module, a hospital big data analysis module and a health preserving treatment module. The core contents of the system are that intelligentization and informationization of traditional Chinese medicine are realized based on a big data platform. A computer collects information of a patient and then finds out data information corresponding to the patient by using the platform through a traditional Chinese medicine big data information resource library; by adopting a traditional Chinese medicine and western medicine comparative combination mode, the operation of taking the essence and discarding the dregs is performed according to the information of the patient; further explanation is performed through hospital big data analysis; and finally a treatment scheme suitable for the patient is obtained. According to the system, all information communications between the patient and a doctor adopt a wireless or wired communication form. For the patient and the doctor, the traditional Chinese medicine intelligent aided diagnosis system is very helpful in life.

Owner:NANJING UNIV OF POSTS & TELECOMM

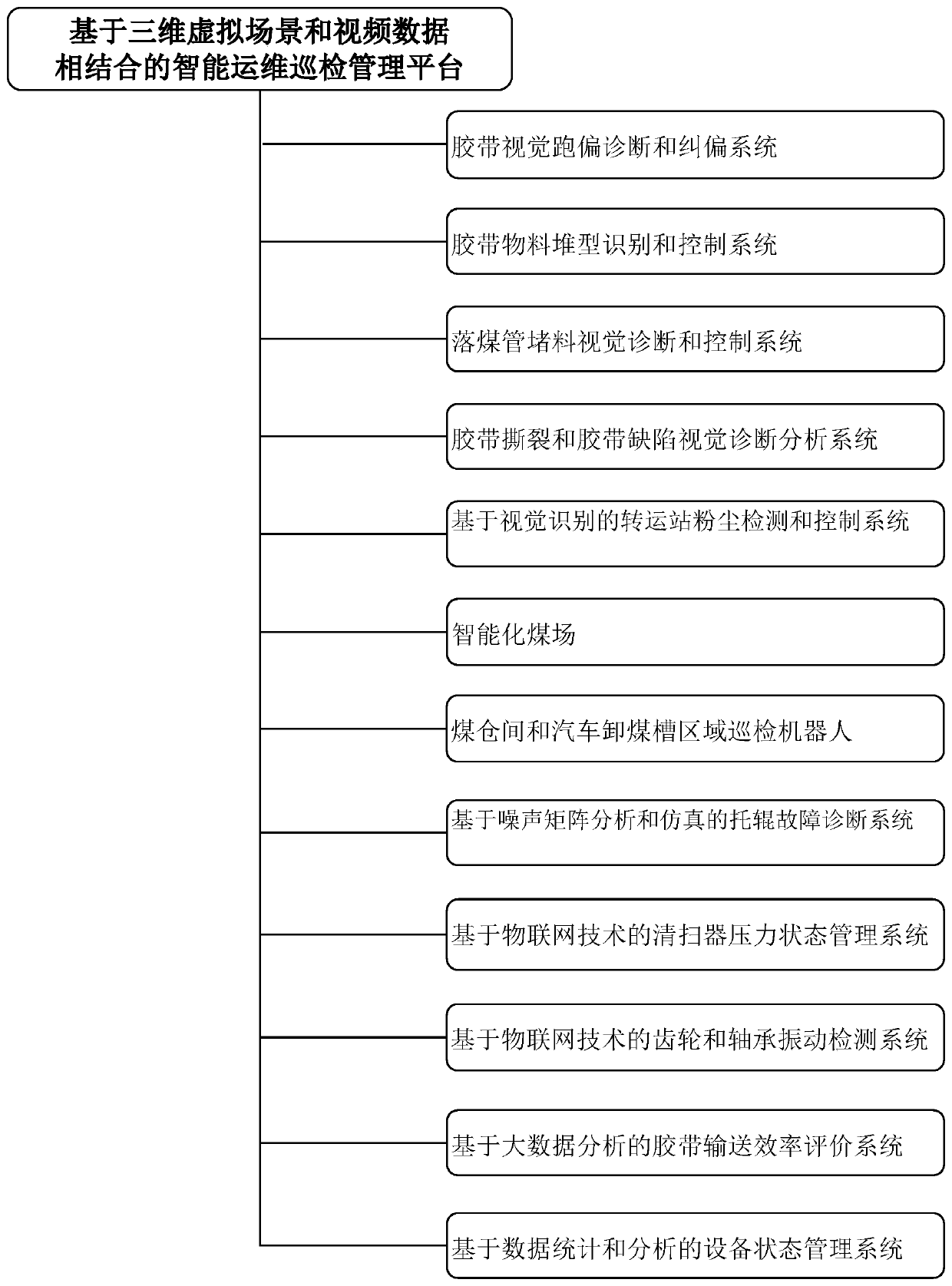

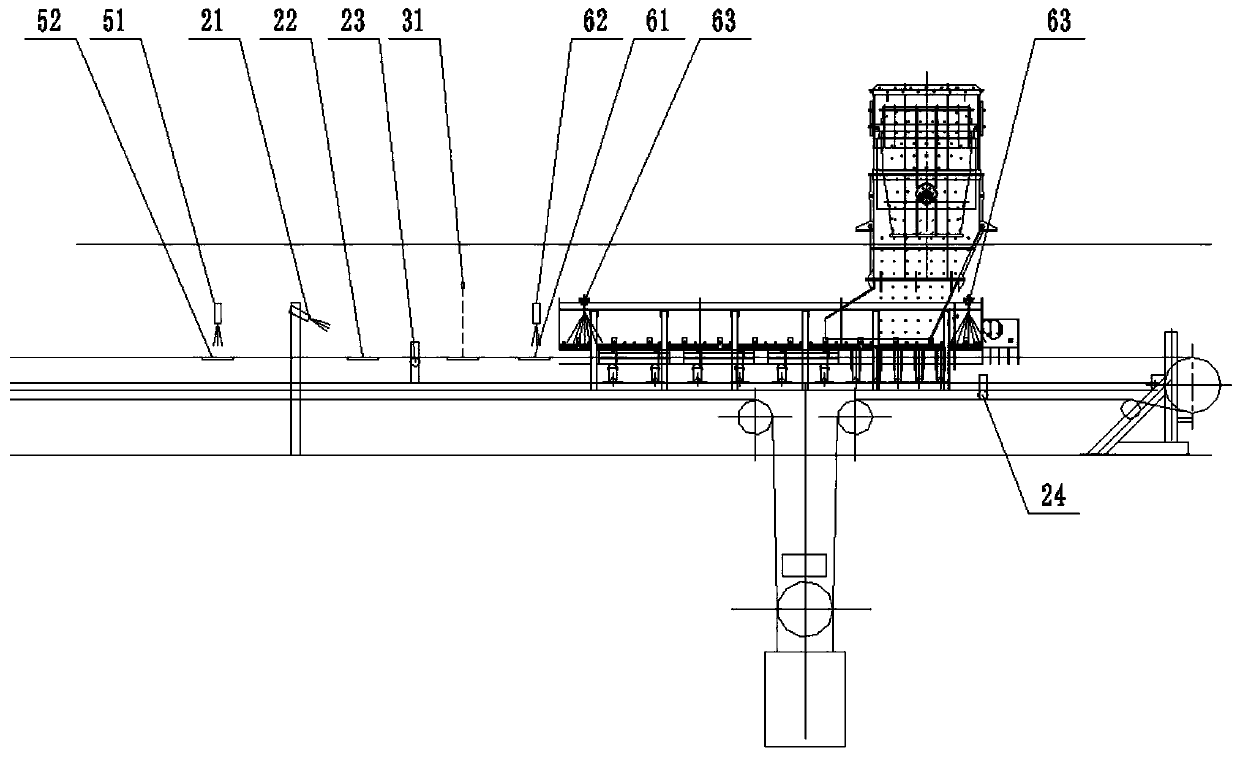

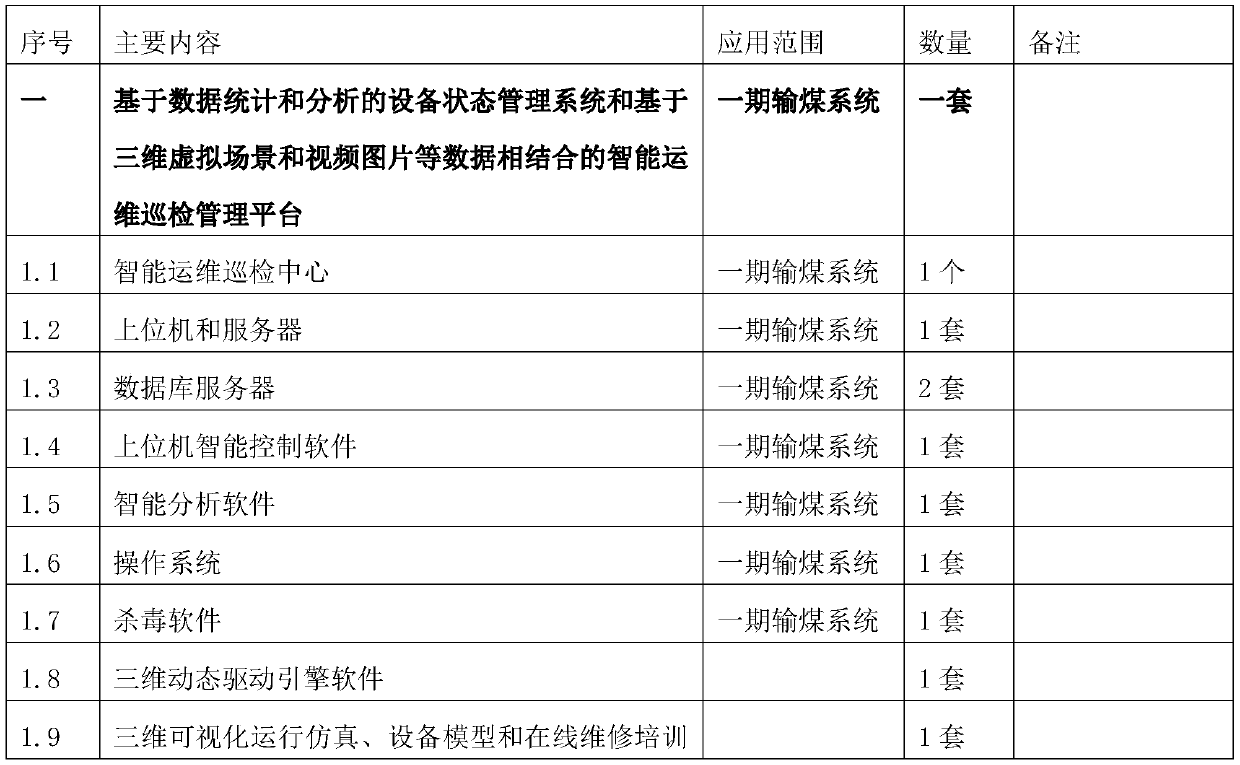

Intelligent unmanned inspection system of coal conveying system

ActiveCN109941700ASave electricityReduce labor costsConveyorsCleaningAutomotive engineeringState management

The invention discloses an intelligent unmanned inspection system of a coal conveying system. The intelligent unmanned inspection system of the coal conveying system comprises an intelligent operationand maintenance inspection management platform based on a three-dimensional virtual scene and combined with video data, an adhesive tape visual deviation diagnosing and correcting system, an adhesivetape material stacking identification and control system, a coal falling pipe material blocking visual diagnosis and control system, an adhesive tape tearing and adhesive tape defect visual diagnosisanalysis system, a visual identification based forwarding station dust detection and control system, an intelligent coal yard, a bunker bay and automobile coal unloading tank area inspection robot, anoise matrix analysis and simulation based carrier roller fault diagnosis system, the internet of things technology based sweeper pressure state management system, the internet of things technology based gear and bearing vibration detection system, a big data analysis based adhesive tape conveying efficiency evaluation system and a data statistics and analysis based device state management system, wherein the adhesive tape visual deviation diagnosing and correcting system, the adhesive tape material stacking identification and control system, the coal falling pipe material blocking visual diagnosis and control system, the adhesive tape tearing and adhesive tape defect visual diagnosis analysis system, the visual identification based forwarding station dust detection and control system, the intelligent coal yard, the bunker bay and automobile coal unloading tank area inspection robot, the noise matrix analysis and simulation based carrier roller fault diagnosis system, the internet ofthings technology based sweeper pressure state management system, the internet of things technology based gear and bearing vibration detection system, the big data analysis based adhesive tape conveying efficiency evaluation system and the data statistics and the analysis based device state management system are connected with the intelligent operation and maintenance inspection management platform. According to the system, a whole coal conveying system is monitored and controlled in real time, self-accumulation and learning capability is achieved, and the unmanned and intelligent inspection system is realized.

Owner:湖北凯瑞知行智能装备有限公司

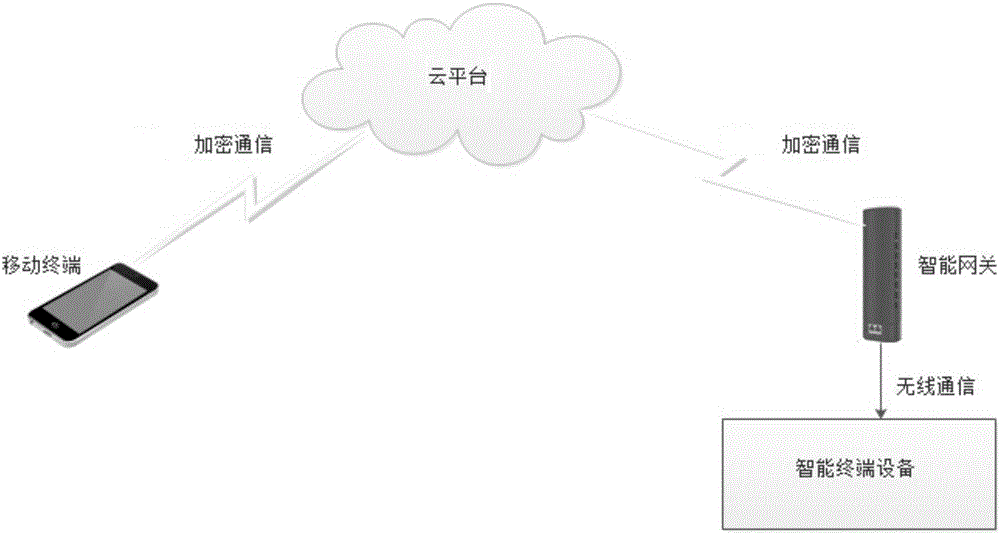

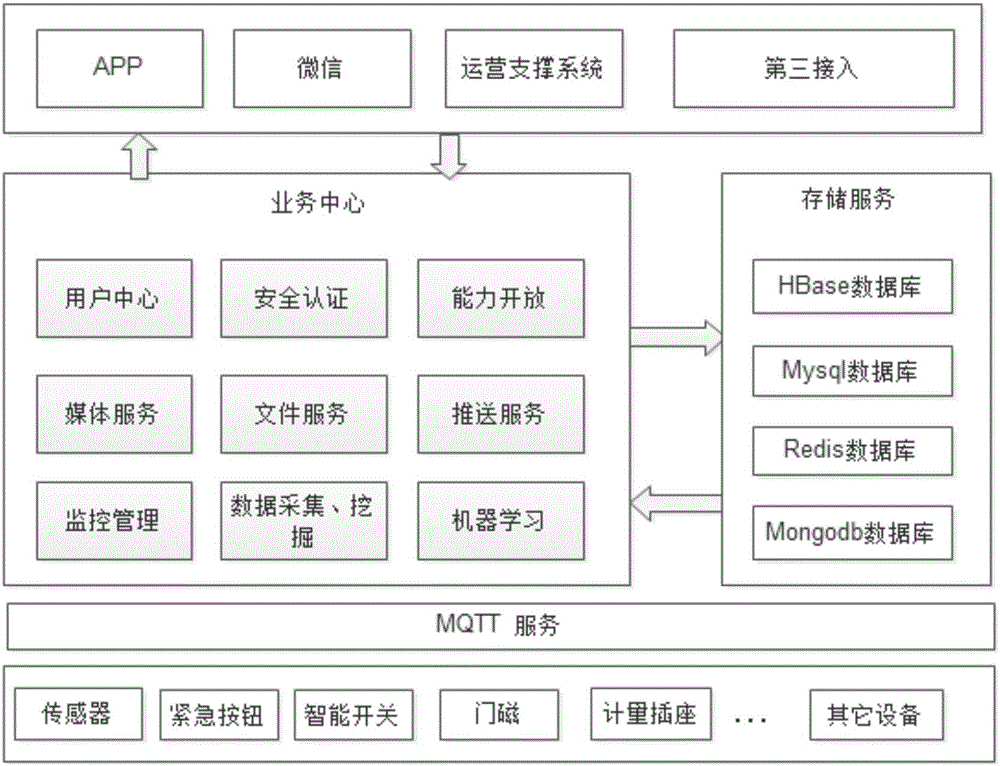

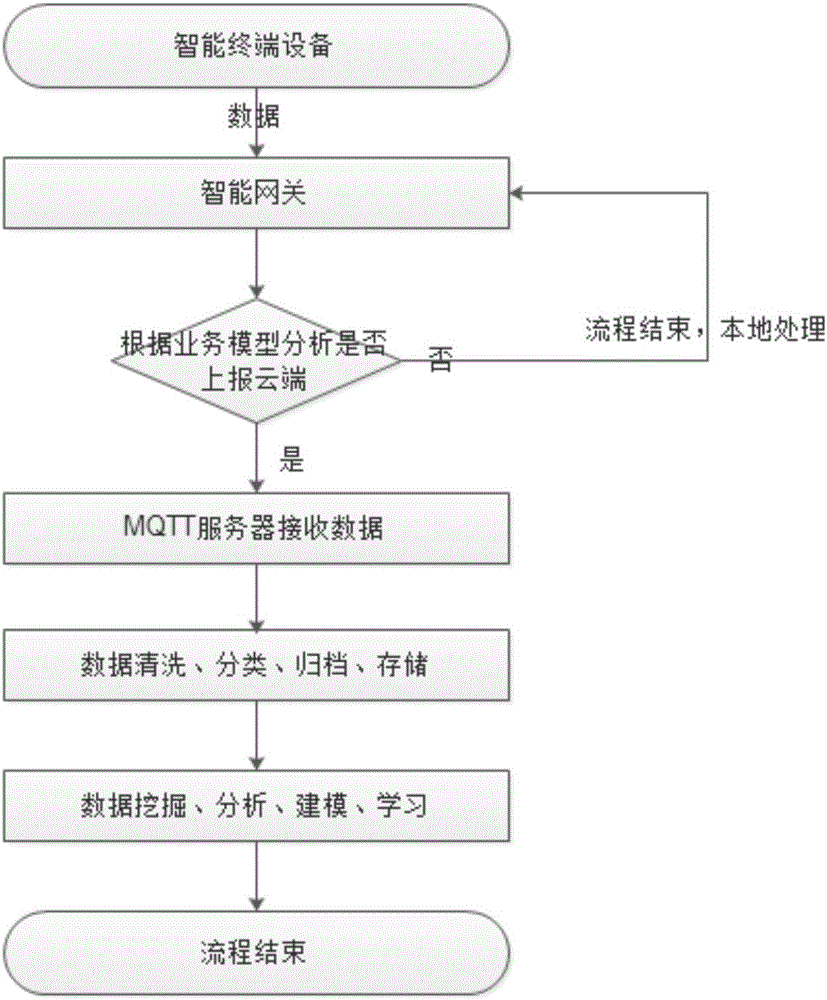

Cloud-based whole house intelligent system

The invention discloses a cloud-based whole house intelligent system, which comprises a mobile terminal, a cloud platform, an intelligent gateway and intelligent terminal equipment, wherein the cloud platform is connected with the mobile terminal and the intelligent gateway in an encrypted communication mode, and the intelligent terminal equipment is connected with the intelligent gateway in a wireless communication mode. The cloud-based whole house intelligent system relates to the relevant technologies of sensor, intelligent gateway, cloud computing and data mining, and establishes a service model by utilizing big data mining and analysis at the cloud side, so that domestic intelligent hardware can have the self-learning, self-triggering, self-adjustment functions and the like.

Owner:NANJING IOT SENSOR TECH

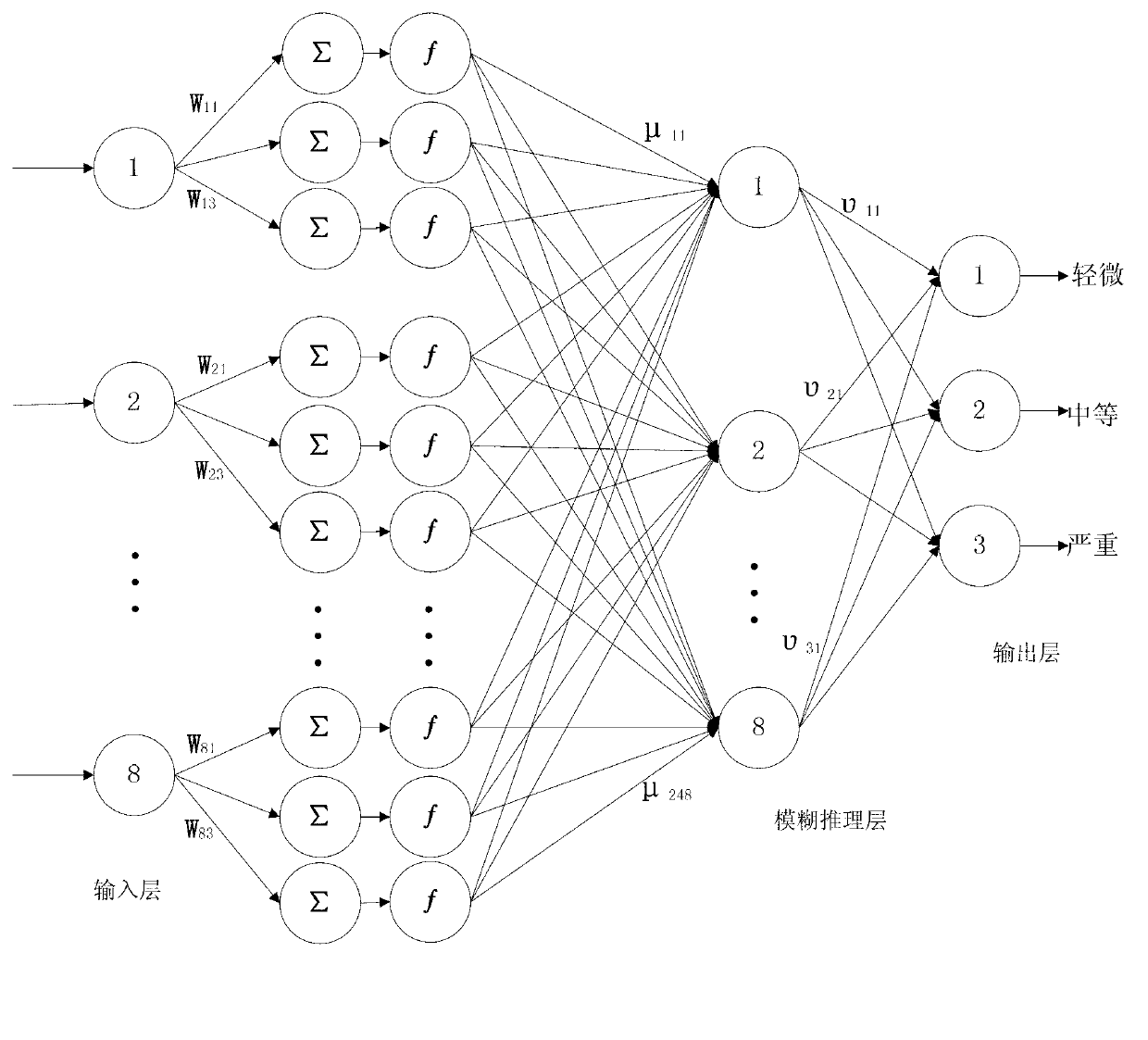

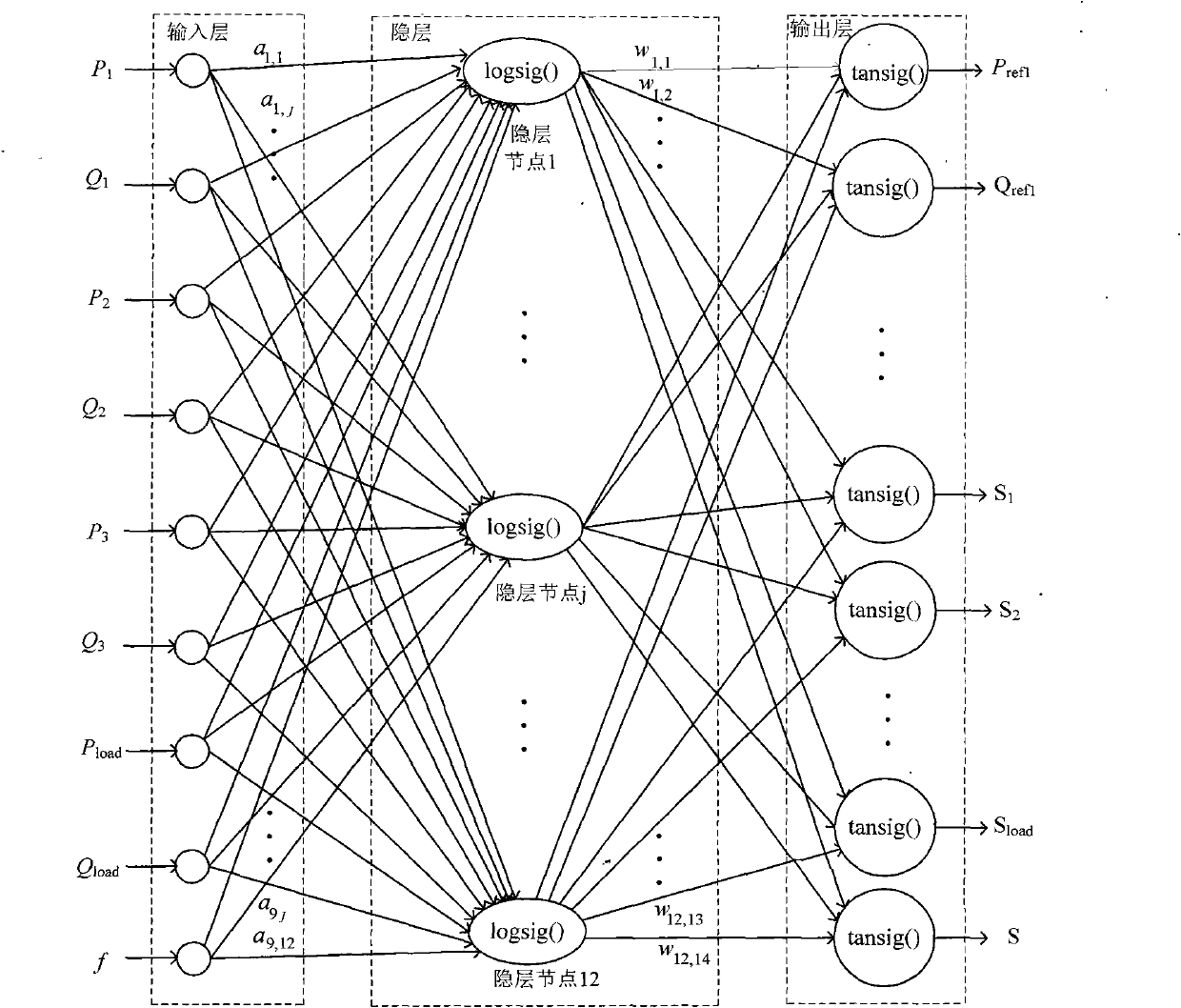

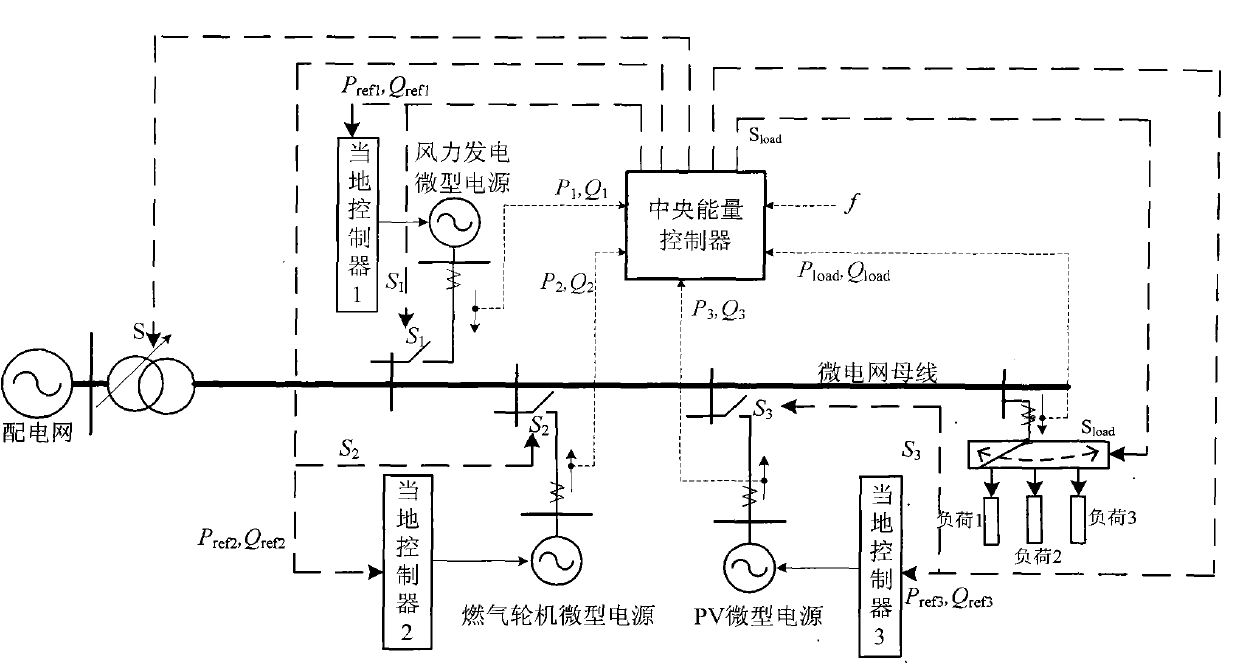

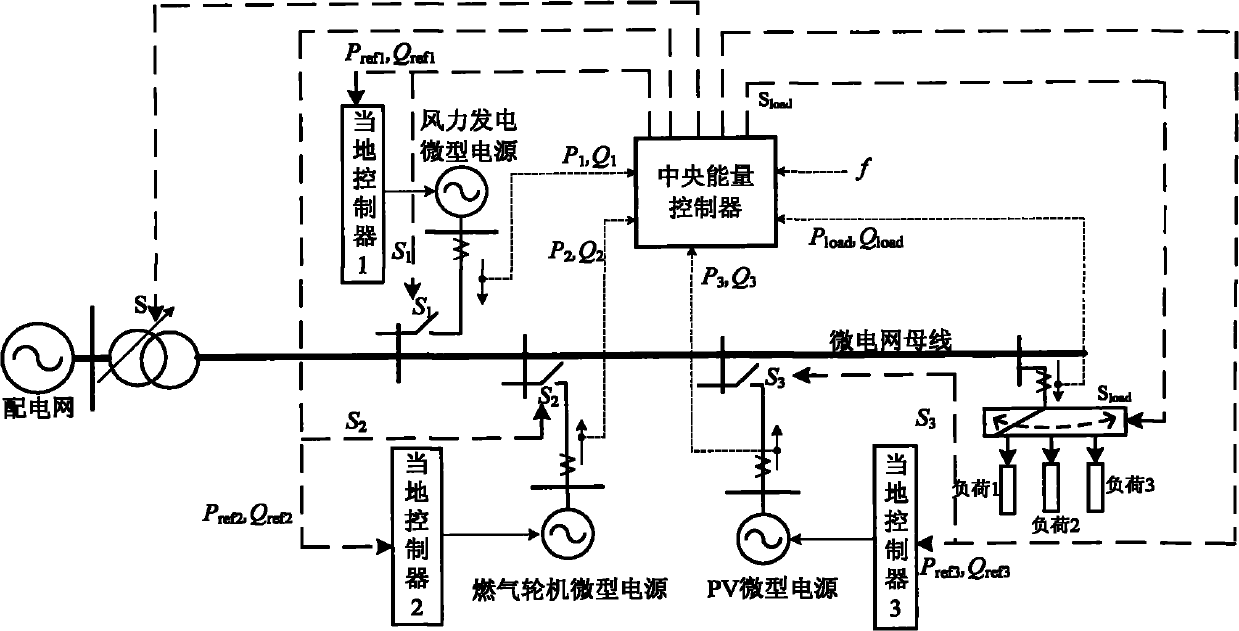

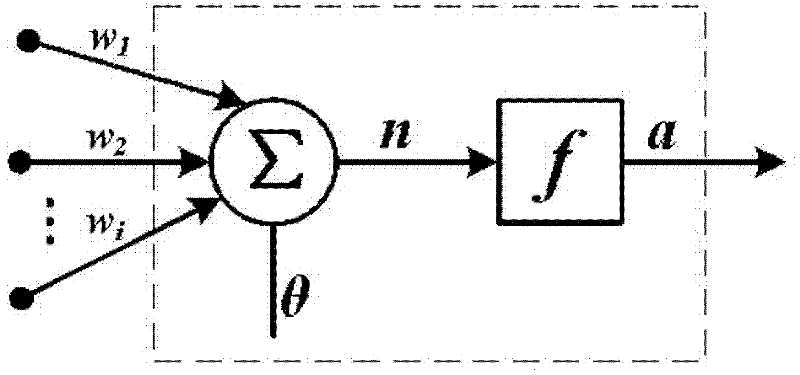

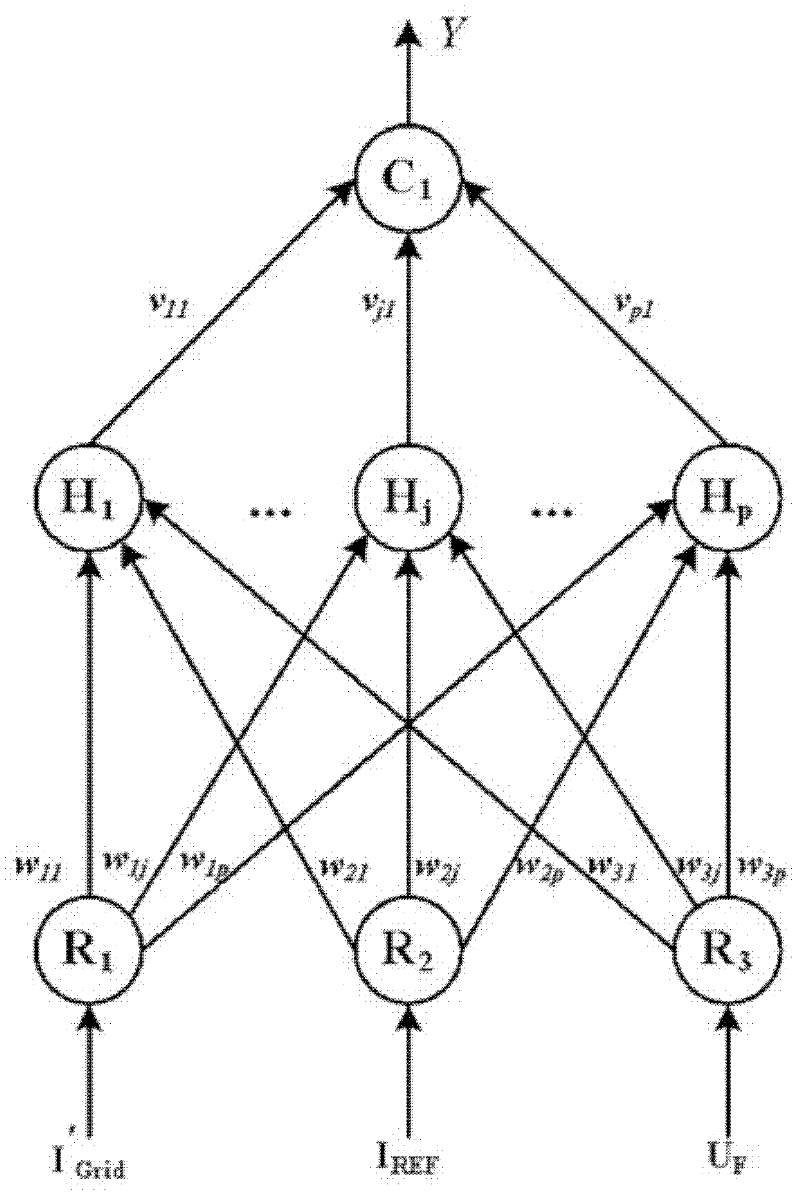

Neural network energy coordinated controller for microgrid

InactiveCN102135760AWith adaptive adjustment reasoning functionSelf-learningAdaptive controlMicrogridTransformer

The invention belongs to the field of distributed power generation and smart power grid control, relates to a neural network-based microgrid energy coordination central processor, and particularly provides a smart energy central controller which can utilize a BP (Back Propagation) neural network to control a microgrid comprising a wind power generation unit, a gas turbine generation unit, a PV (photovoltaic) generation unit, a load tap changing transformer, various loads and other units. In the implementing process, actual power of each micro-power supply, loaded actual power and system frequency are utilized as 9 input nodes of the neural network controller; and a network mapping relationship between the 9 input nodes and 11 output nodes is constructed by using a single hidden layer BP neural network containing 12 hidden layer nodes, so that energy balance management of a microgrid system is controlled, and self-adaptive connection between the microgrid and large grids is realized.

Owner:TIANJIN POLYTECHNIC UNIV

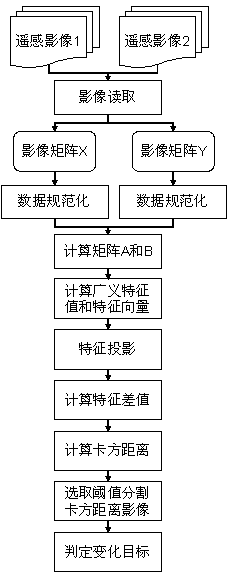

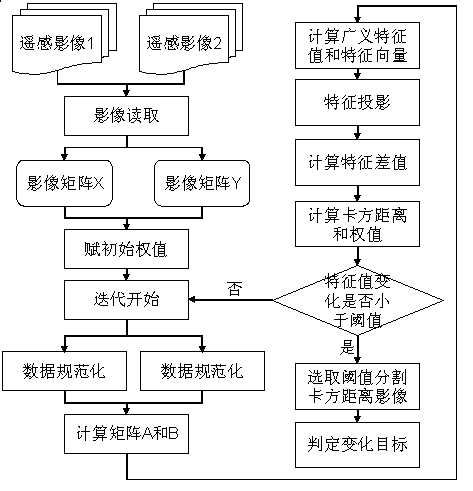

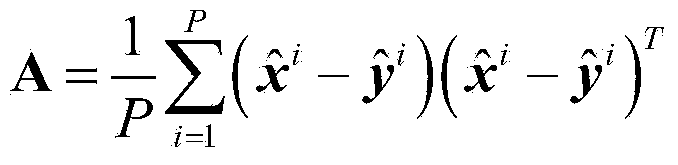

Remote-sensing image variation detecting method based on slow characteristic analysis

ActiveCN103632155ASuppression of spectral differencesHighlight real changesCharacter and pattern recognitionState variationData set

The invention discloses a remote-sensing image variation detecting method based on slow characteristic analysis. A slow characteristic analysis approach is introduced in the detection of multi-temporal remote-sensing image variations; in the slow characteristic analysis approach, the space corresponding relation between the multi-temporal remote-sensing images is completely taken into account, and the original theory aiming at continuous signal analysis is developed into a variation detecting algorithm based on a discrete data set. By utilizing the slow characteristic analysis approach, invariant characteristics can be extracted from a multi-temporal remote-sensing image data set to serve as a characteristic space; in the characteristic space, the spectrum difference between the multi-temporal remote-sensing images is restrained, and true variation is highlighted, so that the variation detection accuracy can be enhanced. The slow characteristic analysis approach is simple to perform and high in arithmetic speed.

Owner:WUHAN UNIV

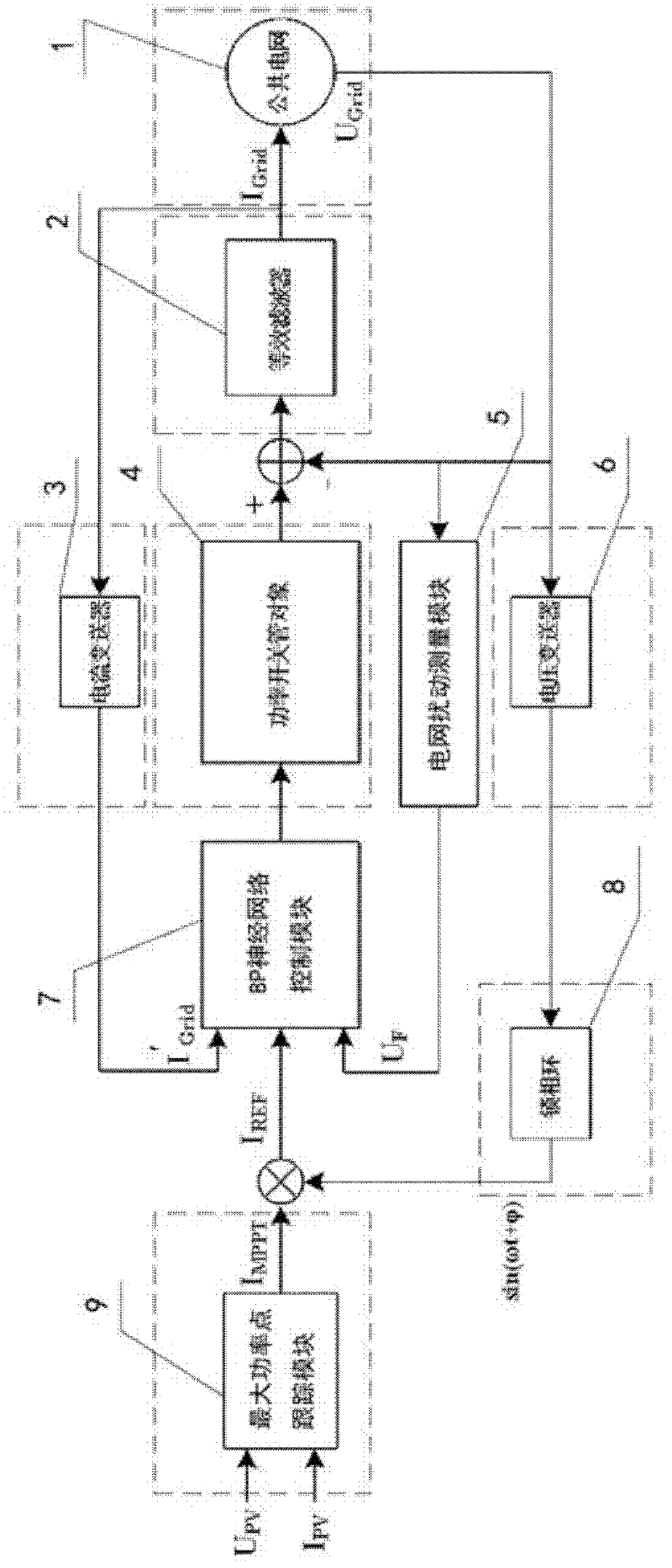

Photovoltaic grid-connected inverter and control method thereof

InactiveCN102593862ARealize intelligent synchronous controlImprove output accuracySingle network parallel feeding arrangementsPhotovoltaic energy generationCurrent transducerNerve network

The invention discloses a photovoltaic grid-connected inverter and a control method of the photovoltaic grid-connected inverter. The photovoltaic grid-connected inverter comprises a maximum power point tracking module, a power switch tube object, an equivalent filter, a phase-locked loop, an electric grid disturbance measurement module, a current transducer, a voltage transducer and a BP (Back Propagation) nerve network control module, wherein the output end of the voltage transducer is connected to the input end of the phase-locked loop; the BP nerve network control module is respectively connected with the output end of the maximum power point tracking module and the phase-locked loop, the output end of the electric grid disturbance measurement module and the output end of the current transducer, which are used as three input ends of the BP nerve network control module; the output end of the BP nerve network control module is connected with the input end of the power switch tube object; and the output end of the power switch tube object is connected with the input end of the equivalent filter. The photovoltaic grid-connected inverter is higher in intelligent and output precision and is capable of adapting various electric grid environments and improving the stability and the reliability of a photovoltaic grid-connected power generation system.

Owner:GUANGXI NORMAL UNIV

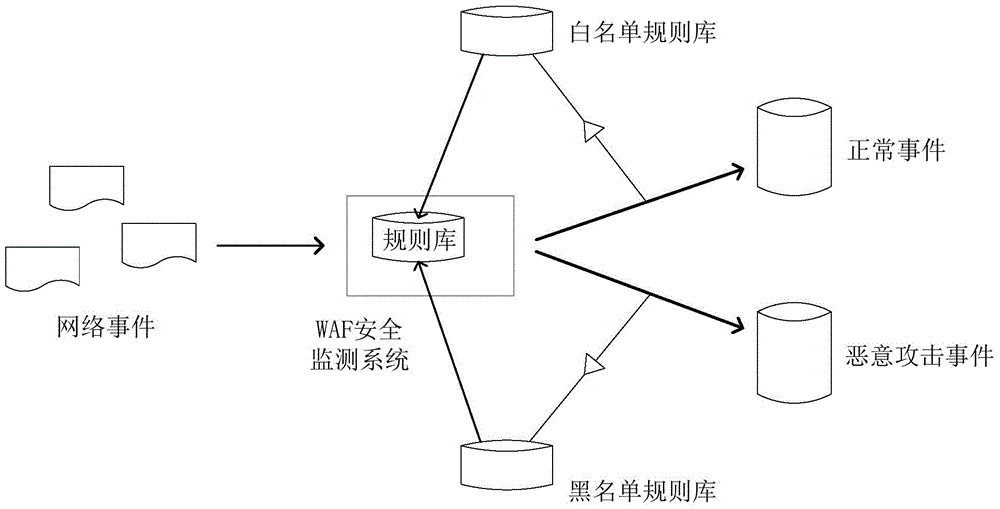

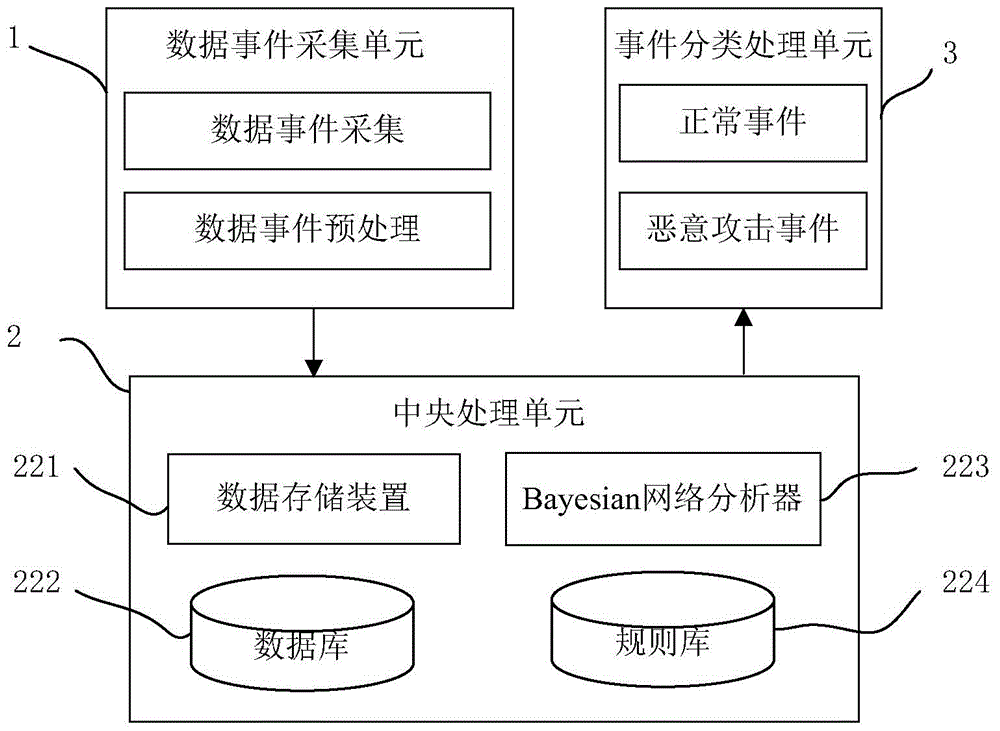

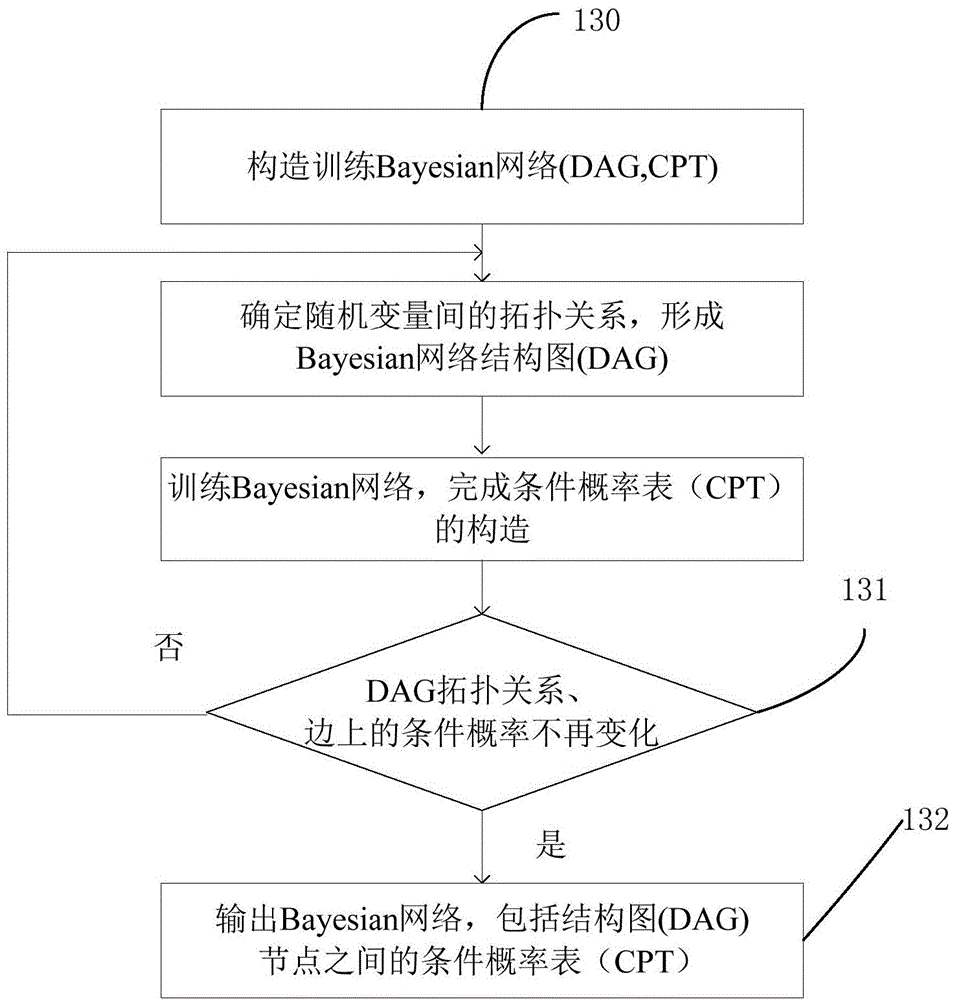

WAF safety monitoring system based on intelligent algorithm

The invention discloses a WAF safety monitoring system based on an intelligent algorithm. The WAF safety monitoring system works according to the steps of (1) obtaining network events according to a data event collecting unit, conducting preprocessing on the network events, and enabling the network events to serve as system input, (2) connecting system output to an event classification processing unit to process the classified events, (3) conducting concrete analysis on event information with a central processing unit for connecting the data event collecting unit and the event classification processing unit, (4) storing the event information into a database through a data storage device in the central processing unit, and (5) enabling a rule base to be used as a training set by the central processing unit, building a Bayesian network analyzer, and analyzing the event information. By means of the WAF safety monitoring system, information in network access events is automatically monitored, the security of the network access events is automatically identified, and the network access events are automatically processed. By means of the WAF safety monitoring system, the network access events are continuously sampled, an accurate safety monitoring mechanism is provided, and APT attacks are effectively and accordingly prevented.

Owner:NANJING UNIV OF SCI & TECH +1

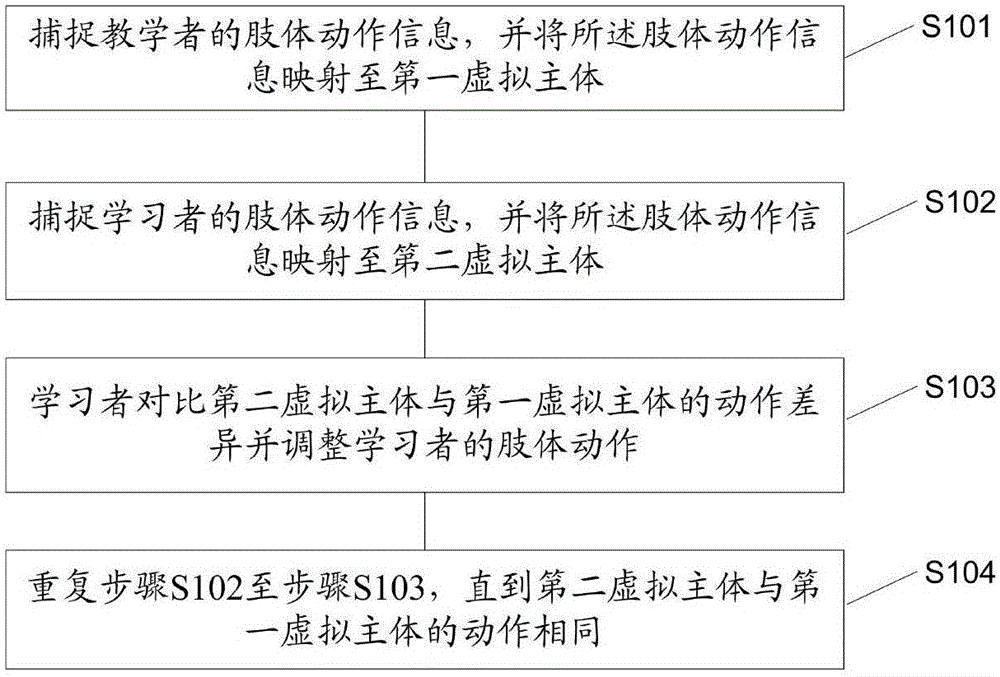

Body teaching method and body teaching system based on virtual reality

InactiveCN106097787ASelf-learningWay imageInput/output for user-computer interactionGraph readingBody movementVirtual reality

The invention discloses a body teaching method based on virtual reality, which comprises the steps of a, capturing body movement information of a teacher, and mapping the body movement information to a first virtual subject; b, capturing body movement information of a learner, and mapping the body movement information to a second virtual subject; c, comparing movement differences between the second virtual subject and the first virtual subject by the learner, and adjusting body movements of the learner; and d, repeating the step b to the step c until the second virtual subject and the first virtual subject are identical in movement. According to the scheme disclosed by the invention, the learner is enabled to learn adjustment in a virtual scene through self comparison, and body movements of the teacher can be perfectly matched without supervision or guidance of the teacher. The body teaching method is more visual and simpler and is popularized more easily. Correspondingly, the invention further discloses a body teaching system based on the virtual reality.

Owner:四川以太原力科技有限公司

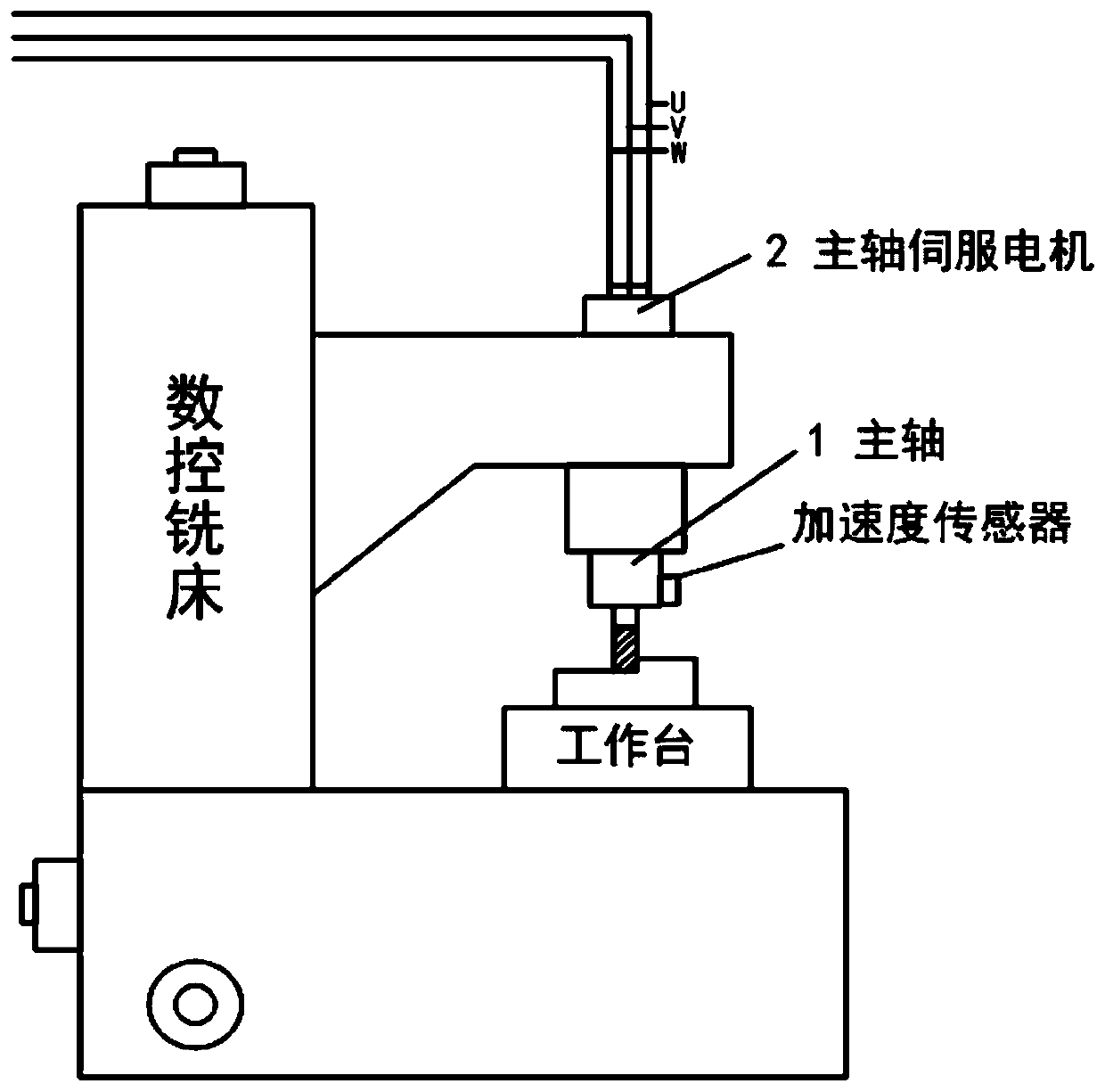

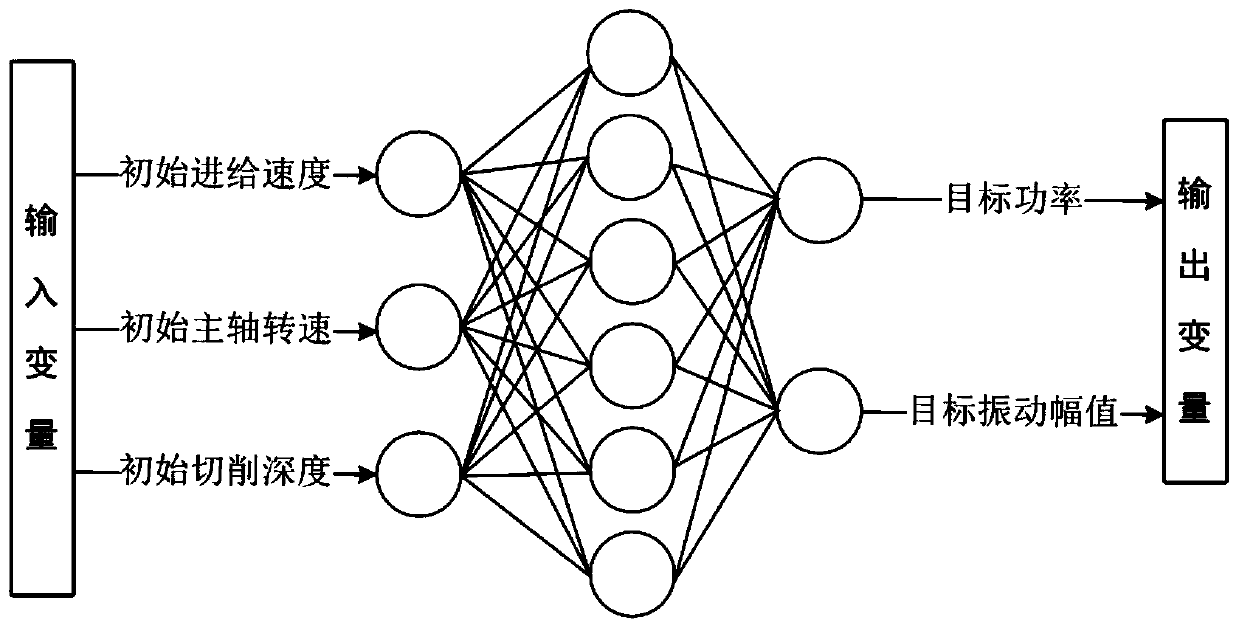

Adaptive machine tool control method based on GA-BP neural network algorithm

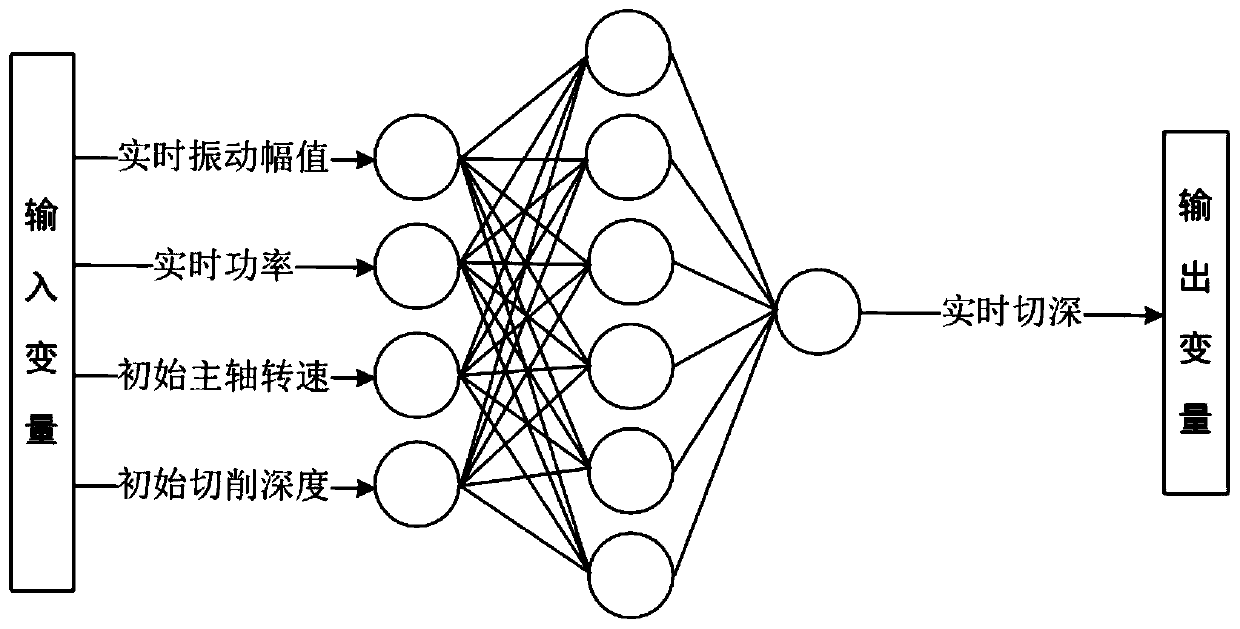

ActiveCN110488754AImprove processing efficiencySave production time and costProgramme controlComputer controlNumerical controlMachine tool control

The invention discloses a machine tool self-adaptive control method based on a GA-BP neural network algorithm, and belongs to the technical field of numerical control machining. The method comprises the steps that a spindle motor power signal and a spindle vibration signal in the workpiece numerical control machining process are monitored in real time, and the feeding speed and the spindle rotating speed are optimized in real time and adjusted adaptively based on the spindle power signal and the spindle vibration signal; and the whole signal acquisition process does not influence normal processing. The machine tool self-adaptive control method based on the neural network algorithm can be used to effectively improve the machining efficiency and the machining quality, prolong the service life of a cutter and a machine tool and reduce the cost.

Owner:DALIAN UNIV OF TECH

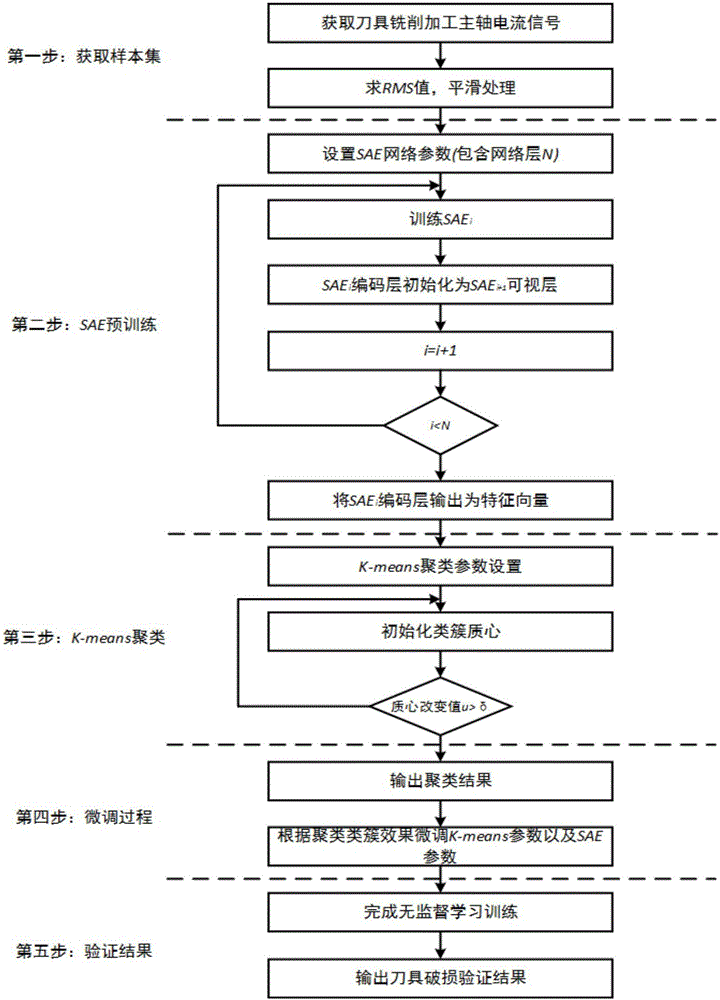

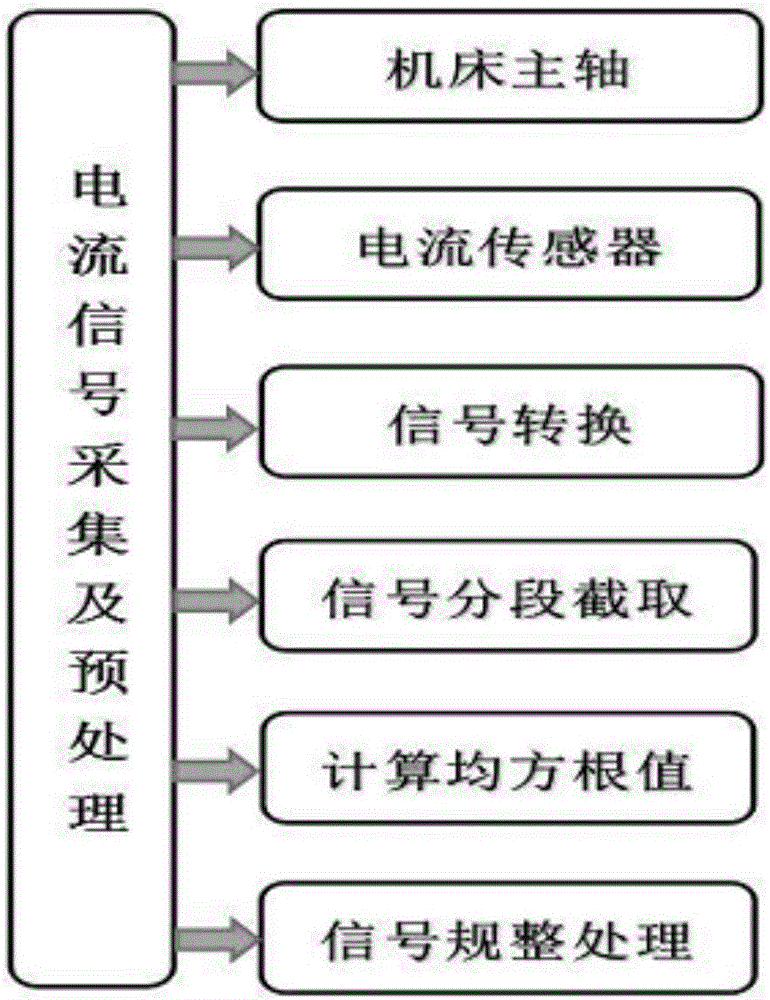

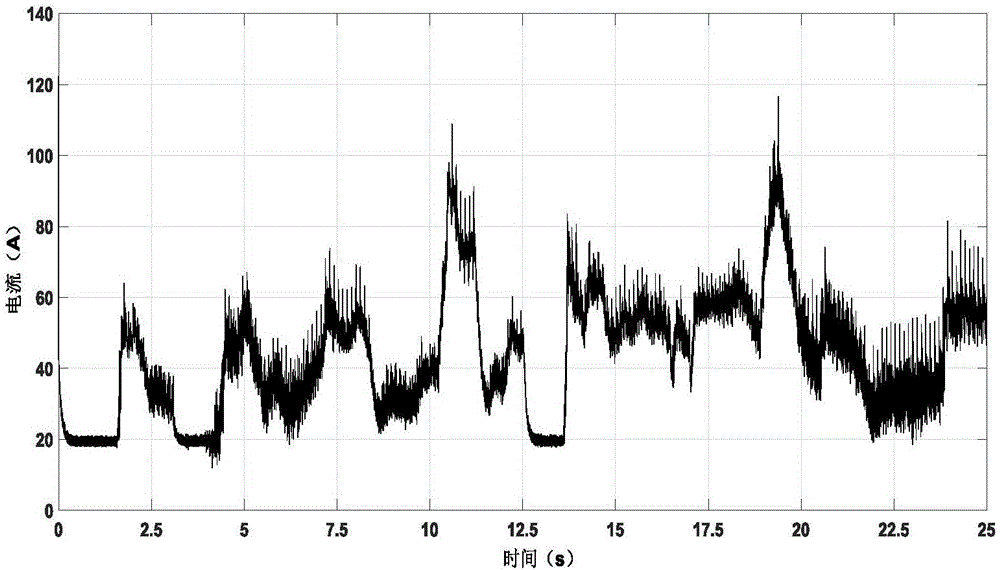

Tool breakage monitoring method based on SAEs and K-means

ActiveCN106271881AAchieve forecastImprove reliabilityMeasurement/indication equipmentsFeature vectorPower flow

The invention discloses a tool breakage monitoring method based on an SAEs and K-means. The method comprises the following steps: 1, collecting a current signal sample set; 2, inputting current signals subjected to arrangement treatment into the SAEs as an input sample set, reconstructing and extracting features of original current signals, and outputting an encoding vector which is last obtained through SAEs training as a feature vector; 3, treating the feature vector as an input layer of K-means clustering, and classifying all input data; 4, outputting a sample clustering result, and conducting fine adjustment on K-means parameters and SAEs parameters according to a clustering effect; and 5, outputting the clustering effect, and judging whether a tool is broken or not according to the clustering effect.

Owner:WUHAN HENGLI HUAZHEN TECH CO LTD

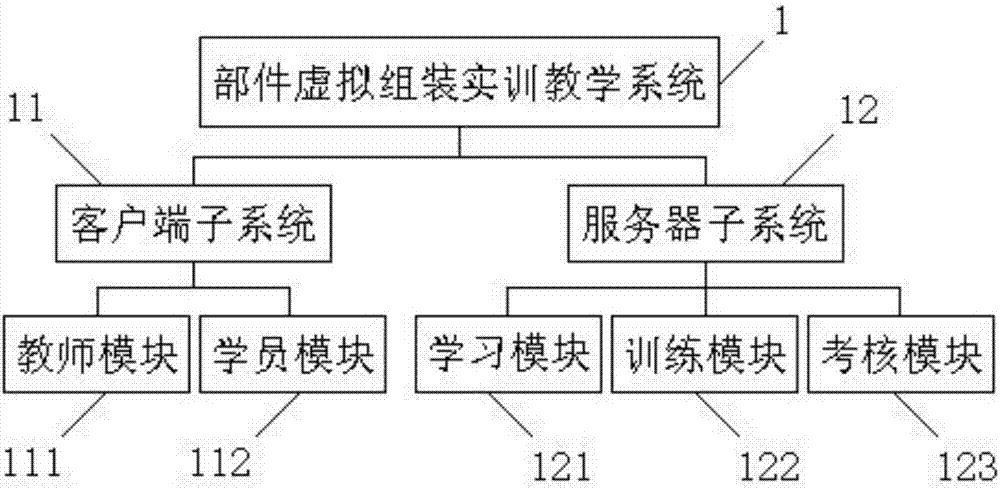

Component virtual assembly training teaching system

PendingCN107393404ASelf-learningEfficient learning processEducational modelsElectrical appliancesSolid componentEvaluation result

The invention provides a component virtual assembly training teaching system. The system is characterized in that the system comprises a client subsystem and a server subsystem. The client subsystem comprises a teacher module and a student module. The server subsystem comprises a learning module, a training module and an evaluation module. The client subsystem and the server subsystem are communicated through a network. The teacher module is used by a teacher to send learning instructions, upload teaching cases and training projects, and review evaluation results. The student module is used by a student to receive task instruction from the teacher and complete learning, training and evaluation. The component virtual assembly training teaching system provided by the invention is in virtuality and reality combination with solid component assembly training teaching, coexists with solid component assembly training teaching, and has complementary advantages. Under the condition that low training teaching cost is maintained, practical teaching planning can be well completed to improve the quality of student training.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

Battery life prediction method based on combination of data driving and battery characteristics

The invention discloses a battery life prediction method based on combination of data driving and battery characteristics. The battery life prediction method comprises the steps of battery aging and residual life factor test analysis and weight comparison, battery and user portrait algorithm establishment, data cleaning, extraction and analysis, SOH algorithm design and the like. The invention hasthe advantages that the method not only can be applied to estimation and prediction of vehicles or battery products with historical use data, but also can be applied to estimation of the battery SOHwithout historical operation or test data but with only the battery portrait and the user portrait, the application range is wide, the algorithm design has self-learning performance, and the estimation accuracy can be continuously improved along with increase of the data volume.

Owner:蓝谷智慧(北京)能源科技有限公司

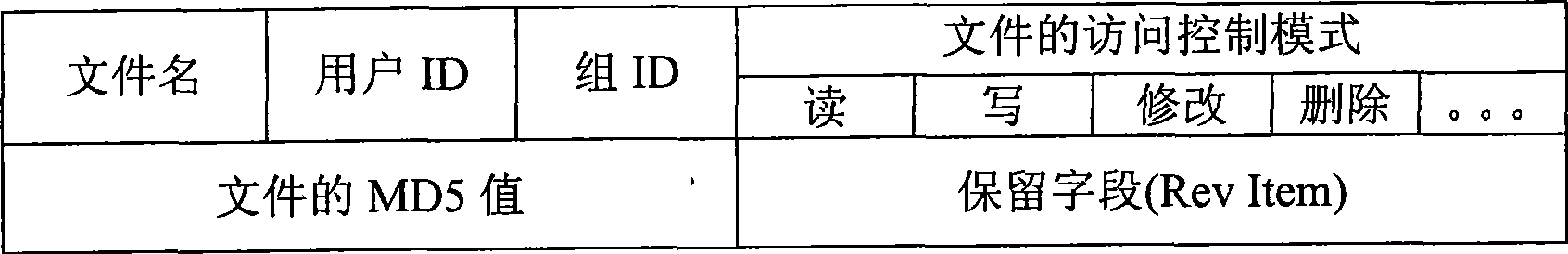

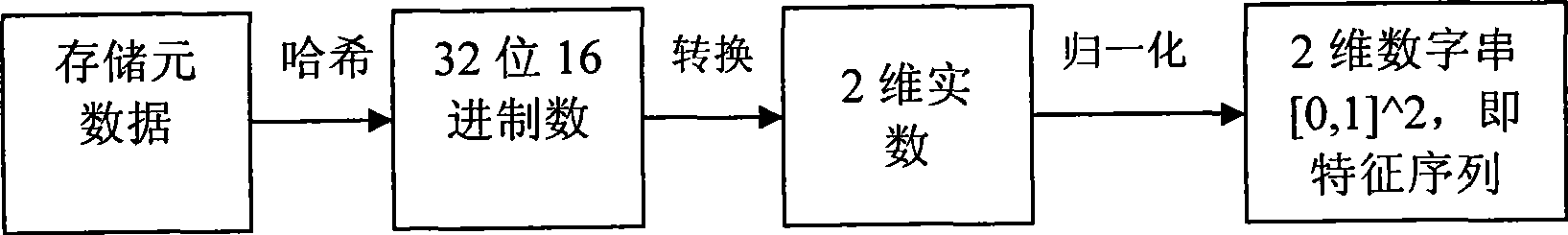

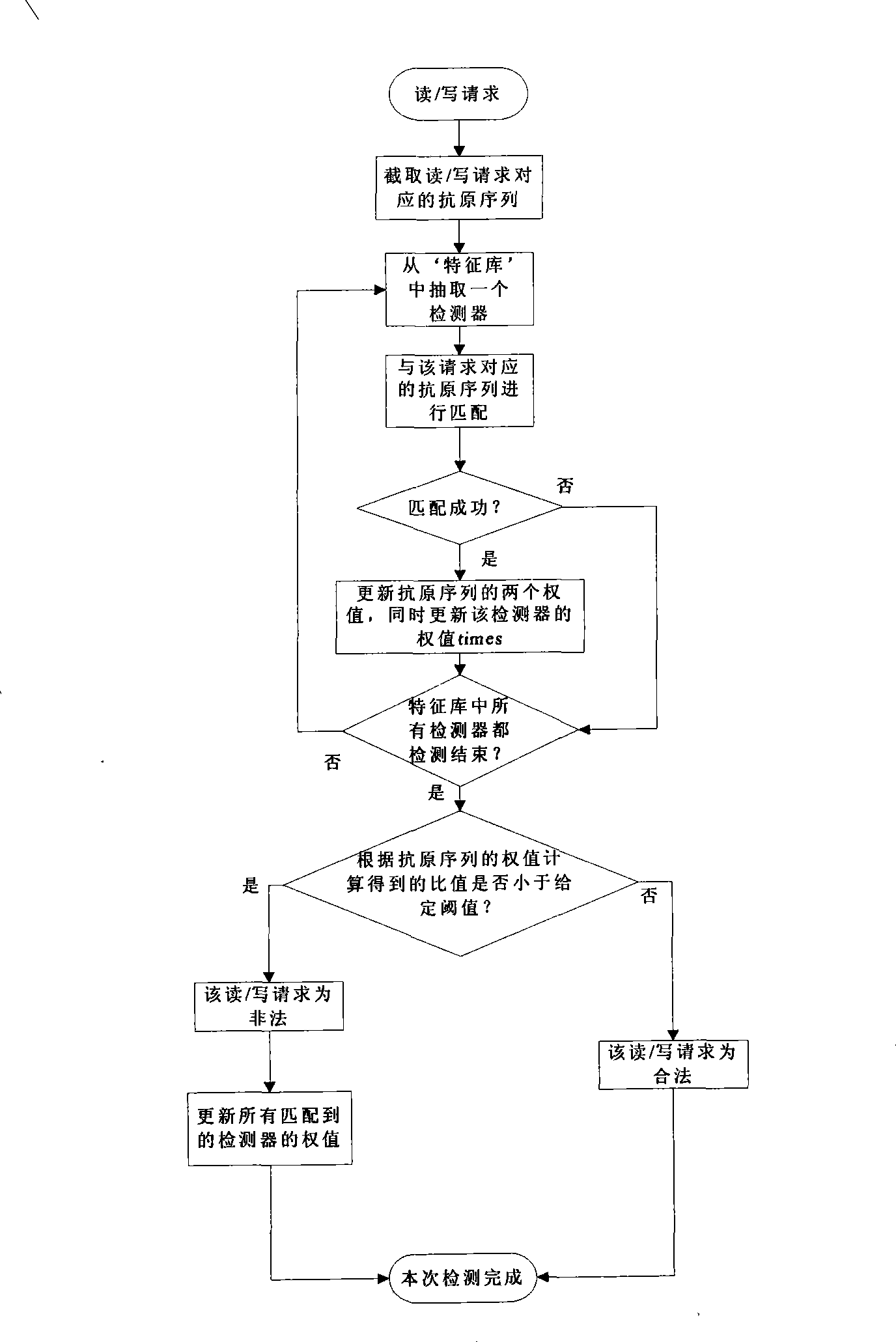

Storage abnormal detecting method based on artificial immunity

InactiveCN101458751AEnabling Immune Abnormality DetectionGuaranteed detection rateInternal/peripheral component protectionSpecial data processing applicationsAnomaly detectionNatural immune system

The invention discloses a storage abnormality detection method based on artificial immunity, which adopts non-self detection mechanism of natural immunity system to judge the legality of data read / write request, realizes immunity abnormality detection on the data of storage element via monitoring the data of storage element formed by data read / write request, induces self learning and forgetting mechanism and the like in natural immunity system to refresh the weight value of a detector after each detection on user's read / write request and periodically eliminate or rebuild the detector according to the weight value, to adapt new non-self ones continuously appearing in storage system. Via the detector refresh mechanism, the method is different from prior storage abnormality detection technology, to realize actual intelligent abnormality detection, and the method has artificial intelligence as self learning and self adaptive characteristics, to effectively recognize new appeared abnormalities.

Owner:HUAZHONG UNIV OF SCI & TECH

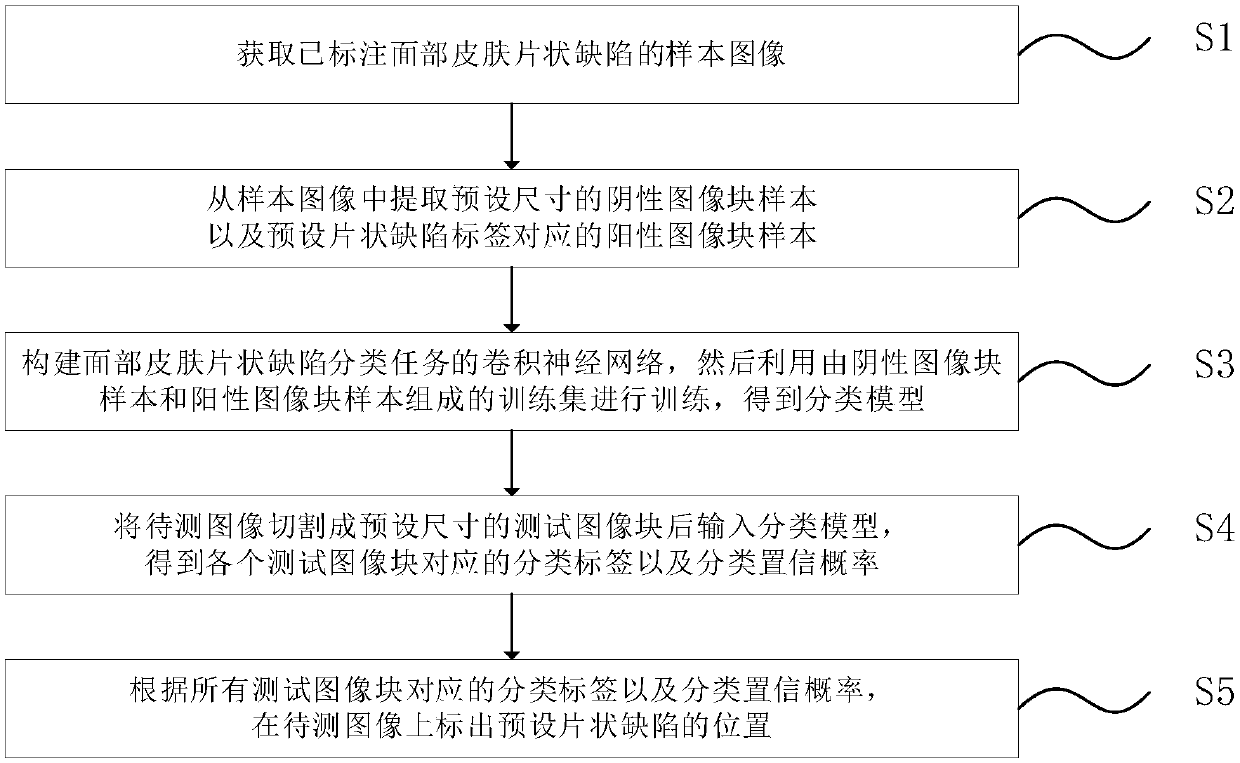

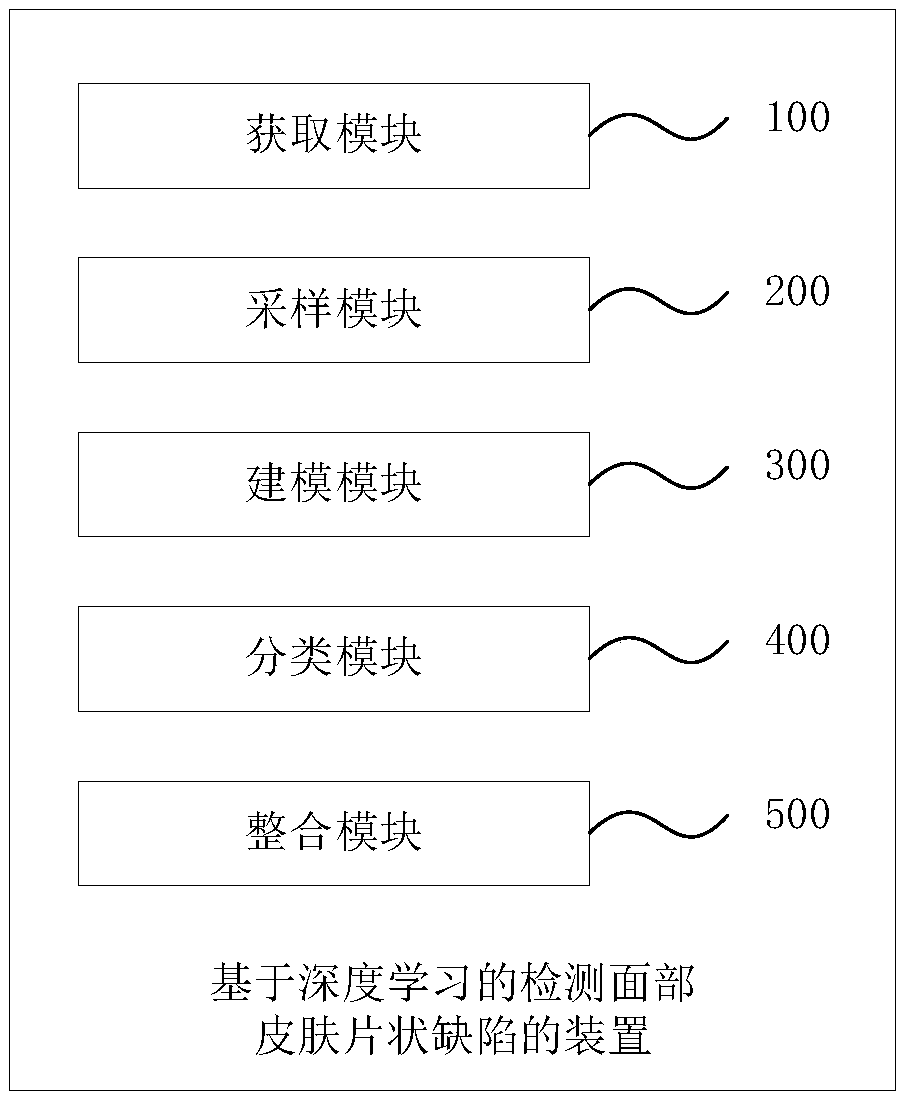

Method and device for detecting facial skin flake defect based on deep learning

InactiveCN108846311AImprove accuracySelf-learningImage enhancementImage analysisFacial skinSample image

The present invention provides a method and device for detecting a facial skin flake defect based on deep learning. The method comprises a step of acquiring a sample image of a marked facial skin flake defect, a step of extracting a negative image block sample of a preset size and a positive image block sample corresponding to a preset flake defect label from the sample image, a step of constructing a convolutional neural network of a facial skin flake defect classification task and then training by using a training set formed by the negative image block sample and the positive image block sample to obtain a classification model, a step of cutting an image to be tested into test image blocks of a preset size and inputting the test image blocks into the classification model to obtain a classification label and a classification confidence probability corresponding to each test image block, and a step of marking the position of a preset flake defect on the image to be tested according toclassification labels and classification confidence probabilities corresponding to all test image blocks.

Owner:北京羽医甘蓝信息技术有限公司

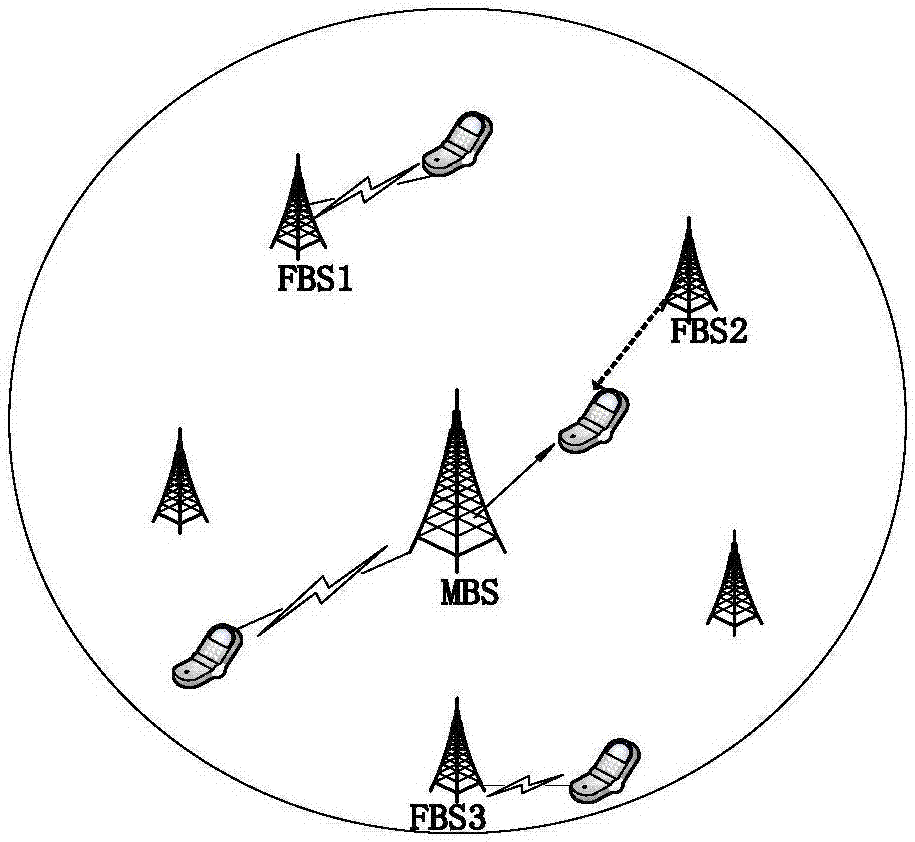

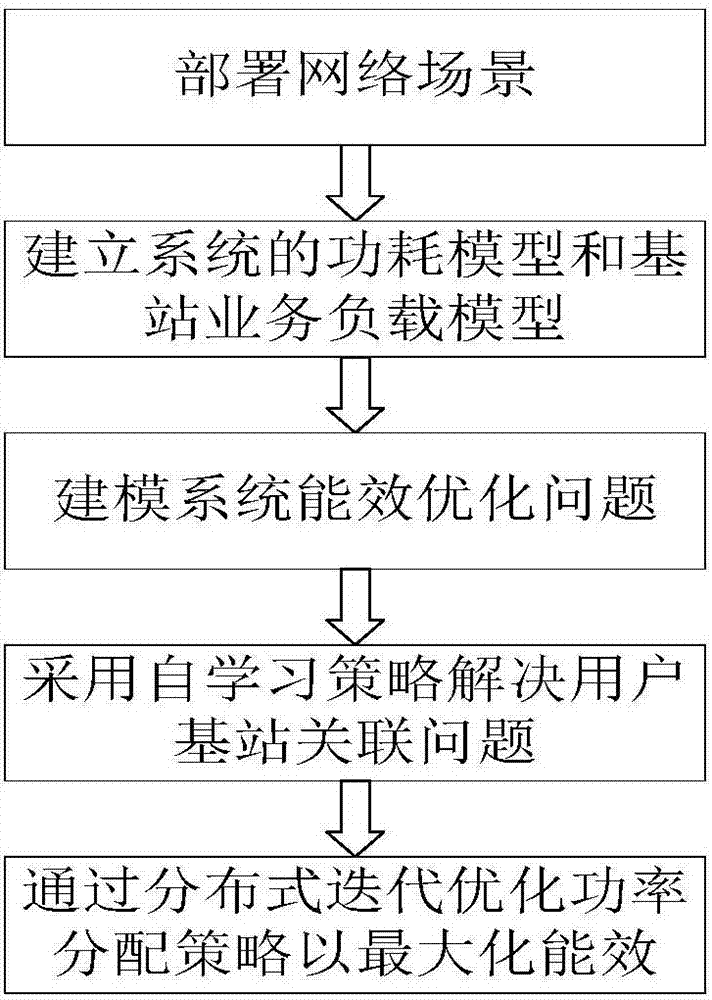

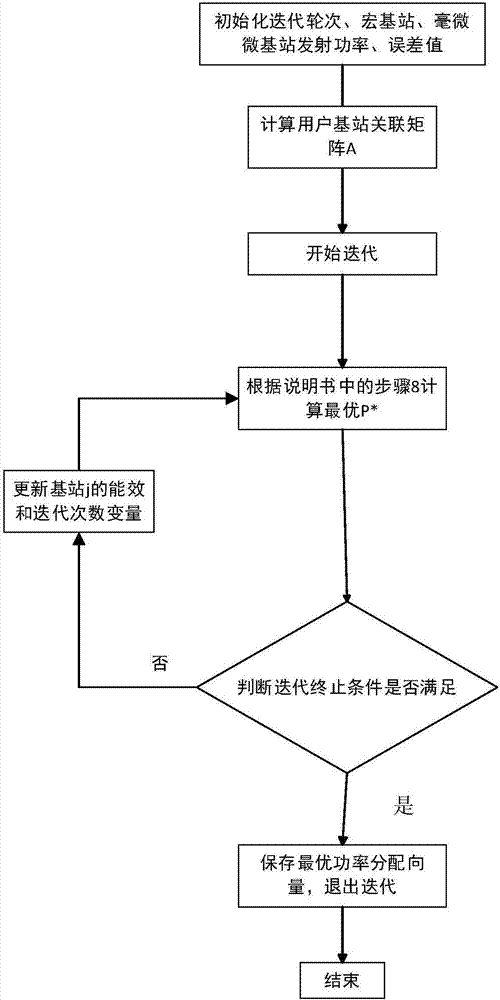

Energy efficiency-oriented distributed resource allocation method and device in wireless heterogeneous network

ActiveCN107426773ASelf-learningOptimize resource allocationPower managementNetwork traffic/resource managementOptimization problemAlgorithm complexity

The invention discloses an energy efficiency-oriented distributed resource allocation method and device in a wireless heterogeneous network. The method comprises the following steps: constructing a two-layer wireless heterogeneous network, wherein the network comprises a central macro base station and multiple uniformly distributed femto base stations, users in the network are randomly distributed, and all users share the network spectrum resource; analyzing the power consumption of each base station in the network, establishing a power consumption model and a base station business load model, and then constructing a network energy efficiency model; modeling the maximum network energy efficiency optimization problem; and resolving the maximum network energy efficiency optimization problem: firstly guaranteeing the network load balance and reducing the base station energy consumption by using the user and the base station based on the learning strategy; and then adopting a distributed iterative power distribution scheme based on the fraction planning method on the basis of the proposed associated strategy. The experimental results shows that the network energy efficiency can be effectively promoted while the algorithm complexity is lowered by using the technical scheme disclosed by the invention, and the technical scheme is easy to realize in the actual system.

Owner:SHANDONG NORMAL UNIV

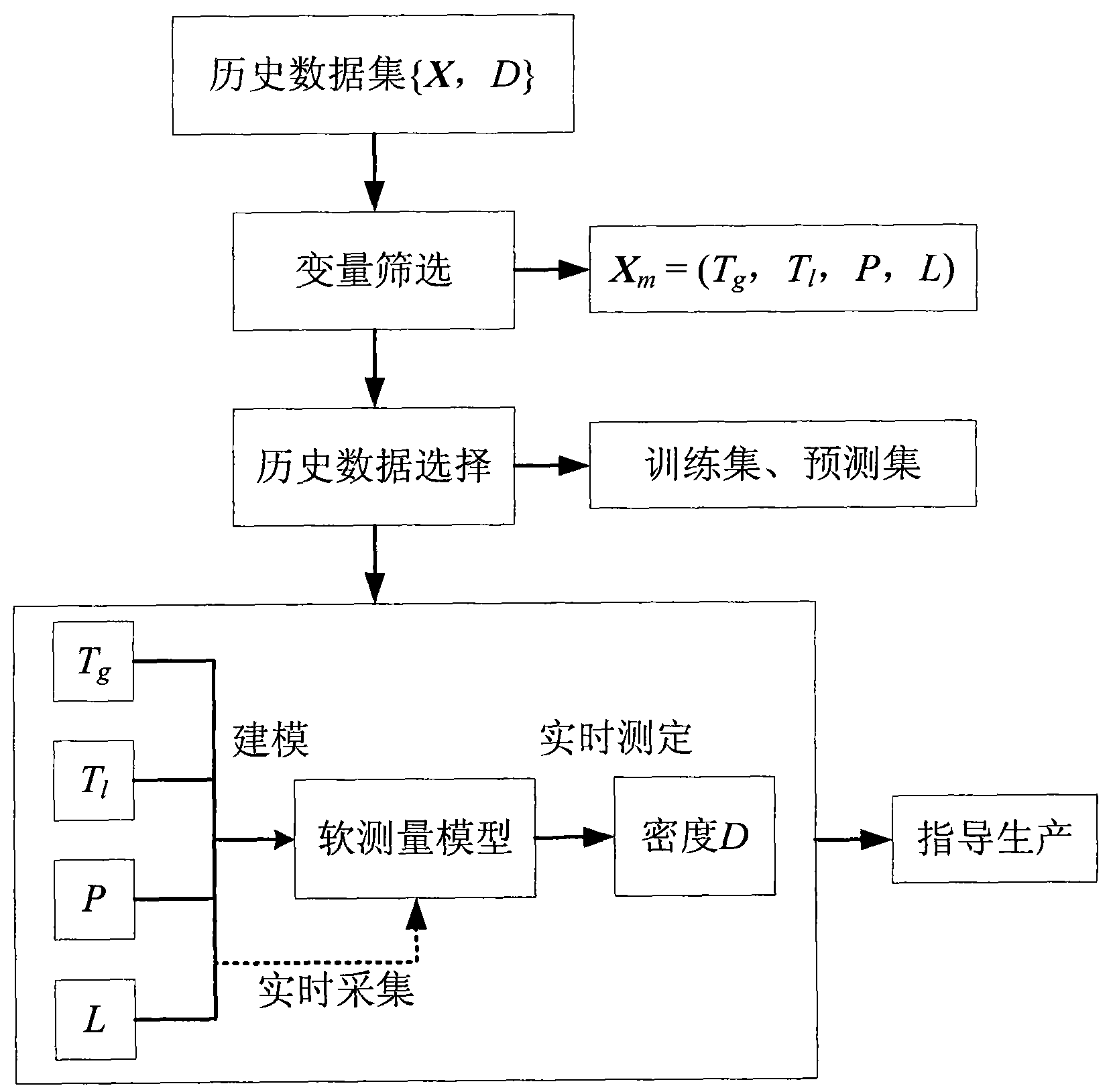

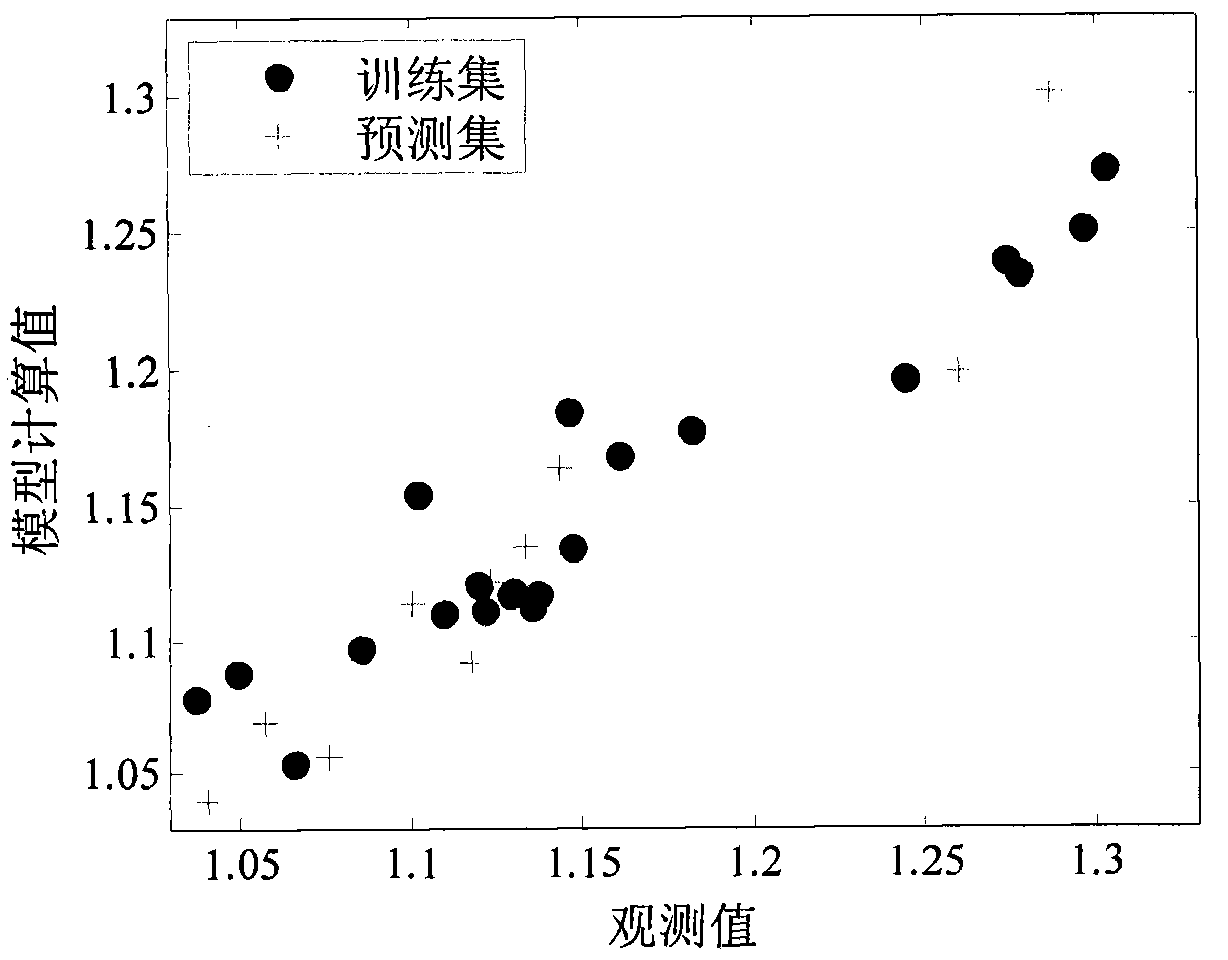

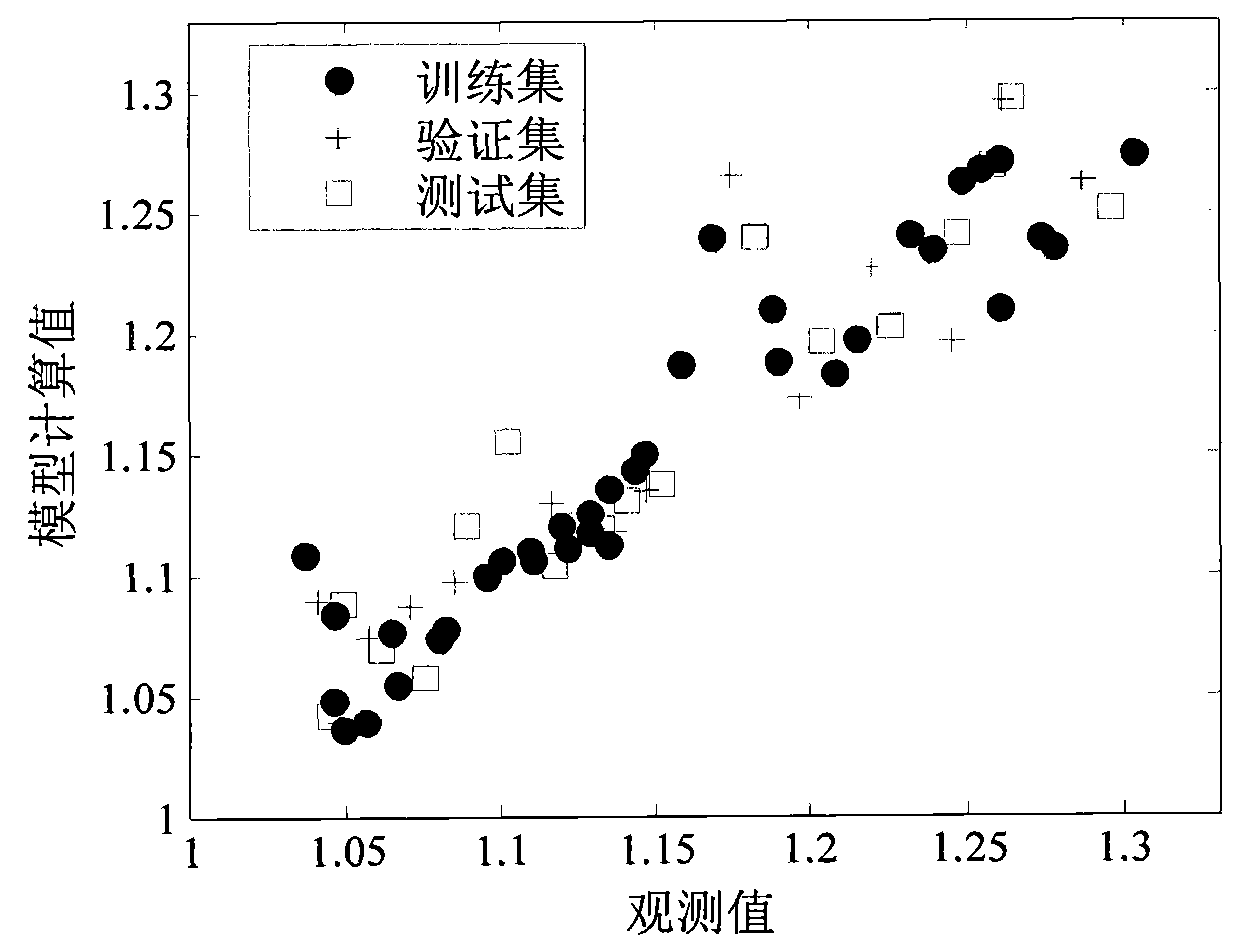

Soft-measuring method for density in concentration process of salvia miltiorrhiza injection production

InactiveCN101673096AStrong explanatory abilityInhibition effectProgramme controlComputer controlSalvia miltiorrhizaGas phase

The invention provides a soft-measuring method for density in concentrating process of salvia miltiorrhiza injection production, comprising the following steps: gathering the historical data of each sensor and densimeter in the concentration process of salvia miltiorrhiza, wherein the history data relate to concentrated solution density value and sensor data gathered on line in production process;selecting easily obtained procedure variables including gas phase temperature, liquid phase temperature, pressure and concentrated solution liquid level that have higher degree of correlation with density from each sensor data, and screening representative dataset; using a multivariate analysis method for building a soft-measuring model of density; and gathering the procedure variables on line, and using the soft-measuring model of density to carry out real-time estimation to control the concentration process. Aiming at the problem that the density in the concentration process of salvia miltiorrhiza injection production is difficultly monitored in real time, the invention provides a fast density soft-measuring method with high precision, which makes full use of the history data obtained by each sensor from the production process, and is beneficial to improvement of quality control on salvia miltiorrhiza injection production.

Owner:ZHEJIANG UNIV

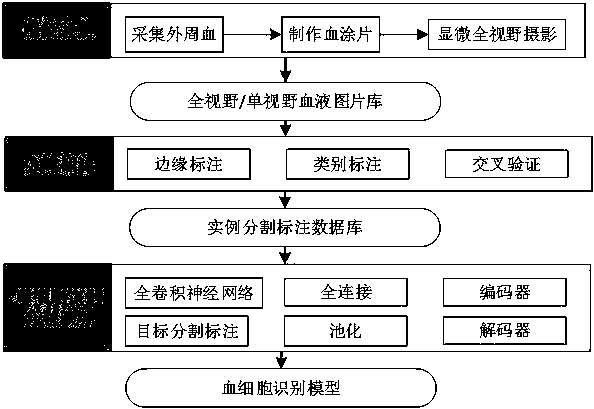

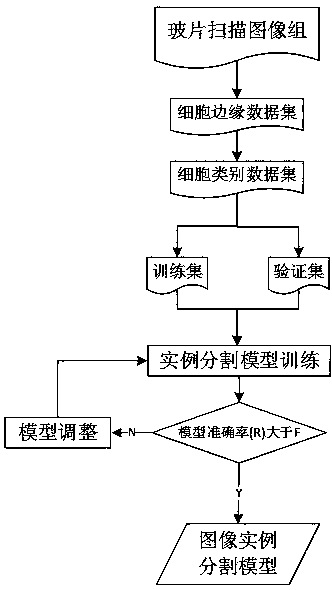

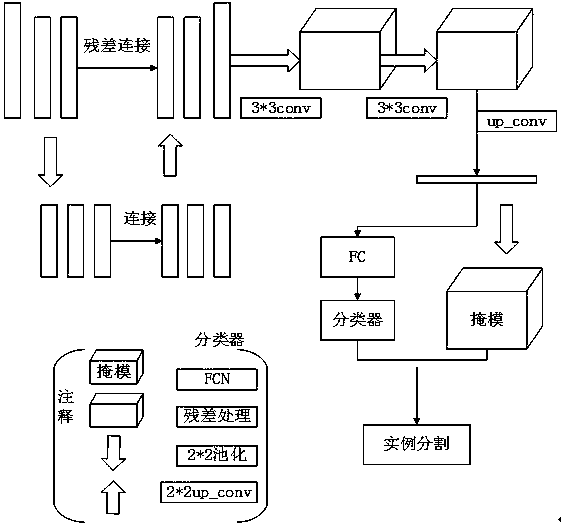

End-to-end blood cell recognition model construction method and application

ActiveCN110647874AIncrease opennessHigh selectivityRecognition of medical/anatomical patternsPattern recognitionBlood cell analysis

The invention relates to an end-to-end blood cell recognition model construction method and application. A data sample set is formed based on a full-view image. An artificial intelligence technology is used for training a blood cell recognition model, and a mature recognition model is finally formed through continuous parameter optimization and error analysis optimization of the model.The model input is a single-view blood smear image, and the output is all cell positions, edges and categories on the image. Full-view blood cell analysis is achieved through a computer, interference of human objective factors is greatly reduced, and objectivity and consistency of inspection results are improved. The blood cell recognition model is intelligent, the software algorithm has a self-learning attribute, the training efficiency of the recognition model is gradually improved along with the increase of high-quality labeled images, and the software recognition and classification accuracy can be continuously optimized.

Owner:BEIJING XIAOYING TECH CO LTD

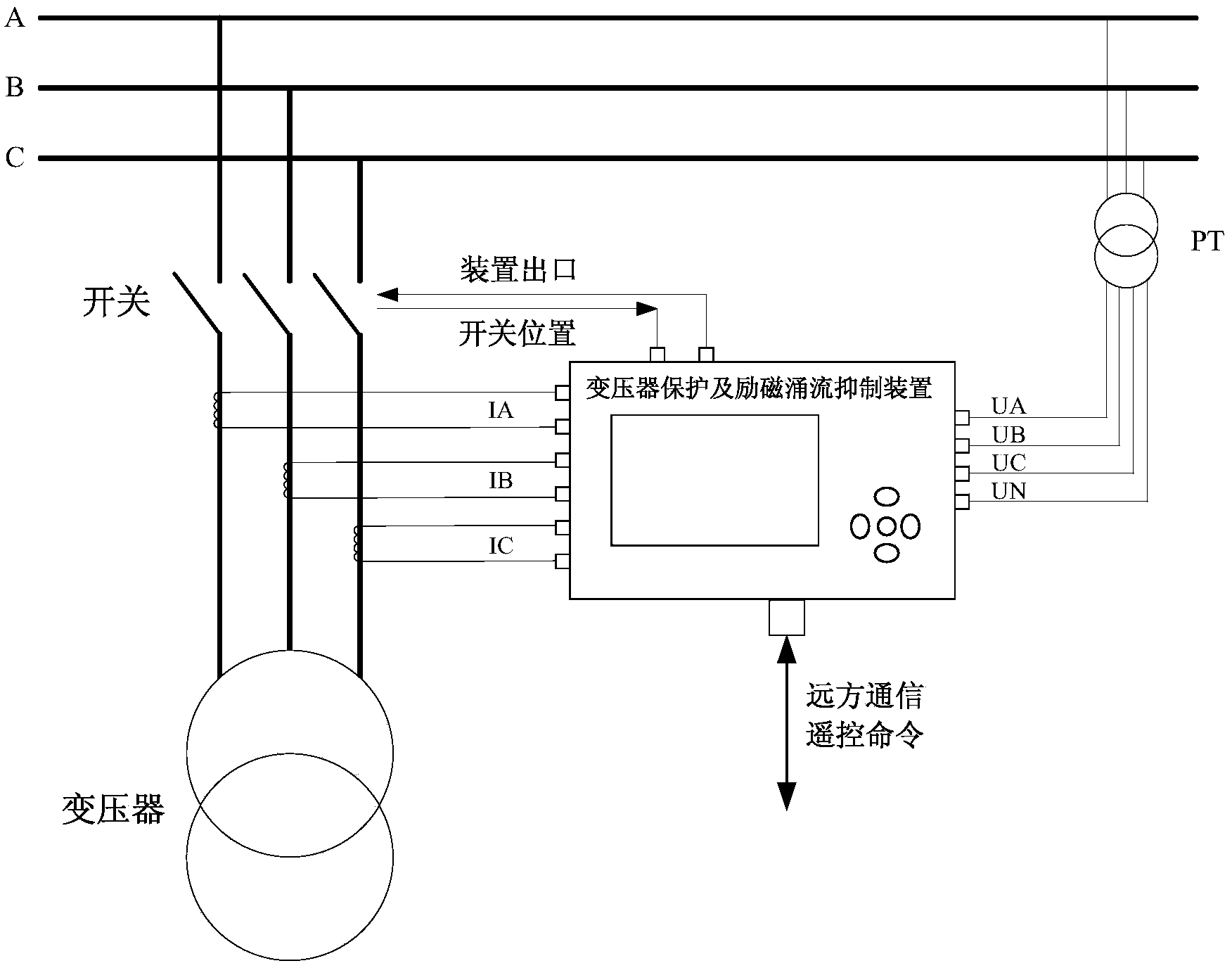

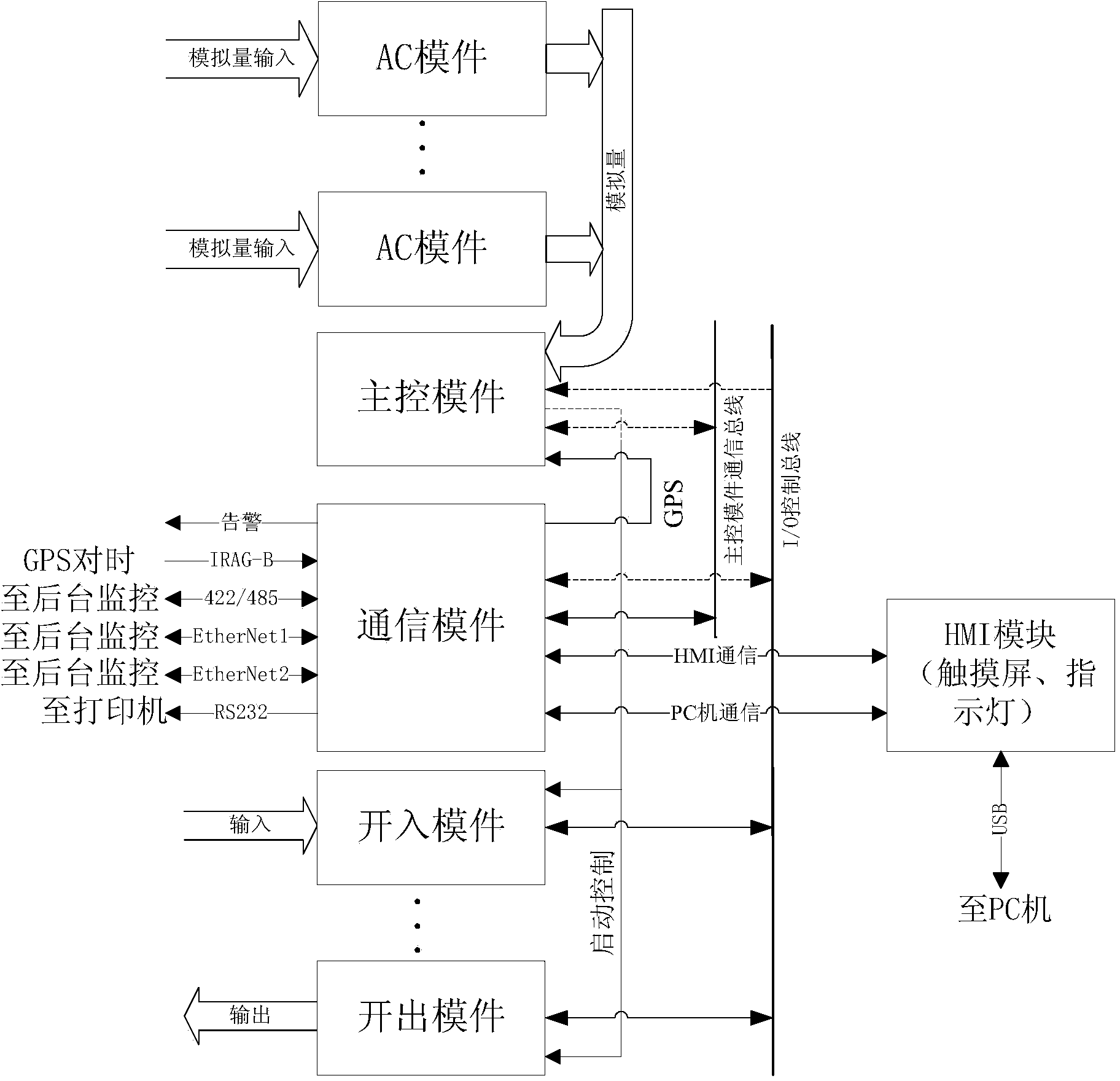

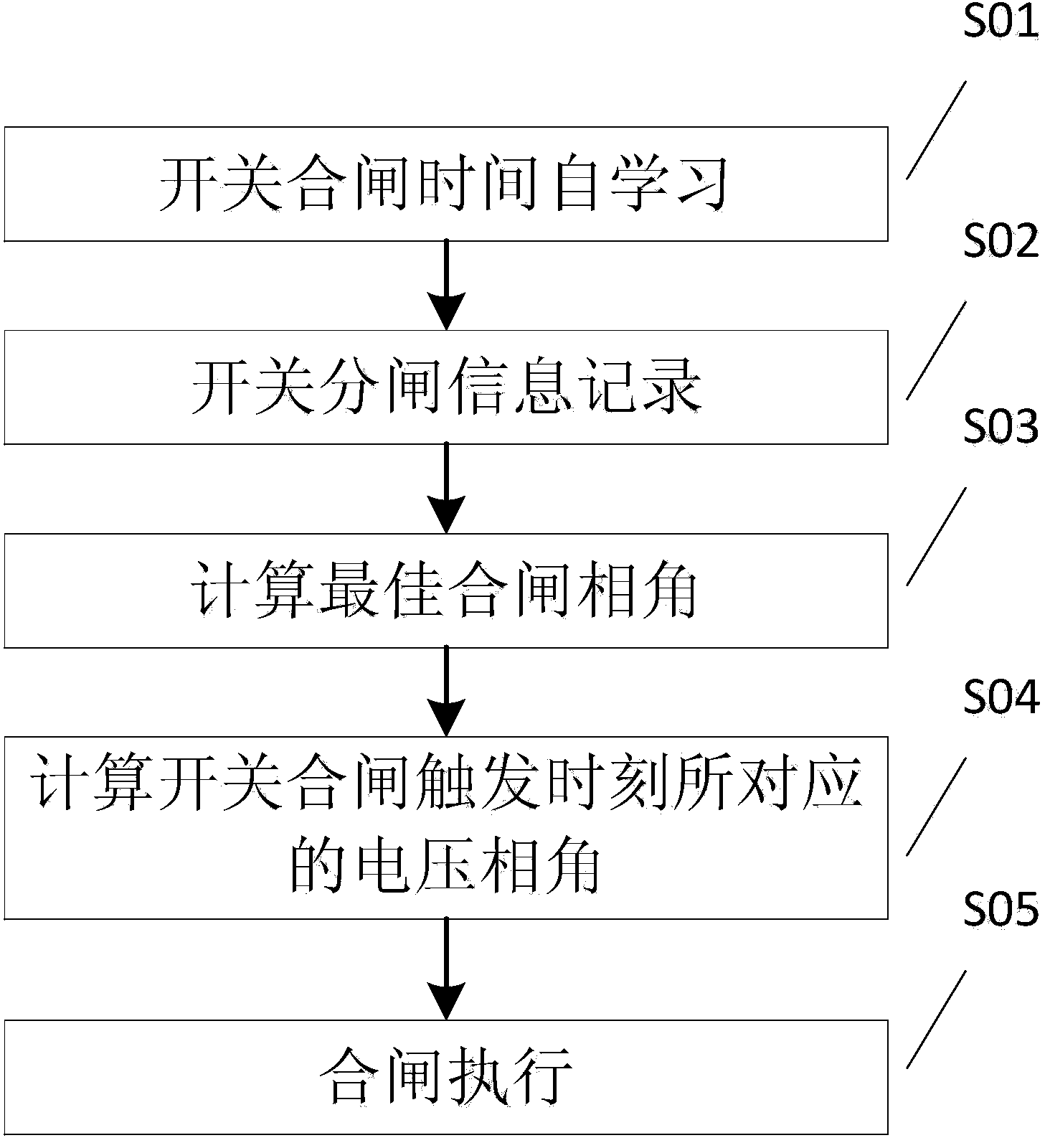

Self-adaptive magnetizing inrush current restraining device and method thereof

ActiveCN104362920ANo human intervention requiredAdaptableEmergency protective circuit arrangementsConversion without intermediate conversion to dcRemote controlThree-phase

The invention discloses a self-adaptive magnetizing inrush current restraining device and a method thereof. According to the method, the state of a transformer before no-load closing is considered comprehensively, and different control strategies are adopted according to different states; during local manual opening or distant remote-control opening, an angle identical to an opening phase angle is selected for closing; during tripping caused by short-circuit faults, magnetizing inrush currents at the moments of different closing phase angles in the range of 0-360 degrees are estimated according to three-phase voltage information at the moment of opening to acquire a closing phase angle corresponding to the minimum magnetizing inrush current; during man-made demagnetization after opening, the angle of any one of three phases is selected as 90 degrees. The magnetizing inrush current restraining device produced according to the method has the advantages of capability of automatically recognizing the state of the transformer before no-load closing and executing the corresponding control strategy, capability of automatically learning time needed by switch closing and automatically adjusting closing exit triggering moments and function of protecting the whole electric quantity of the transformer.

Owner:YANGZHOU POWER SUPPLY CO OF STATE GRID JIANGSU ELECTRIC POWER CO +3

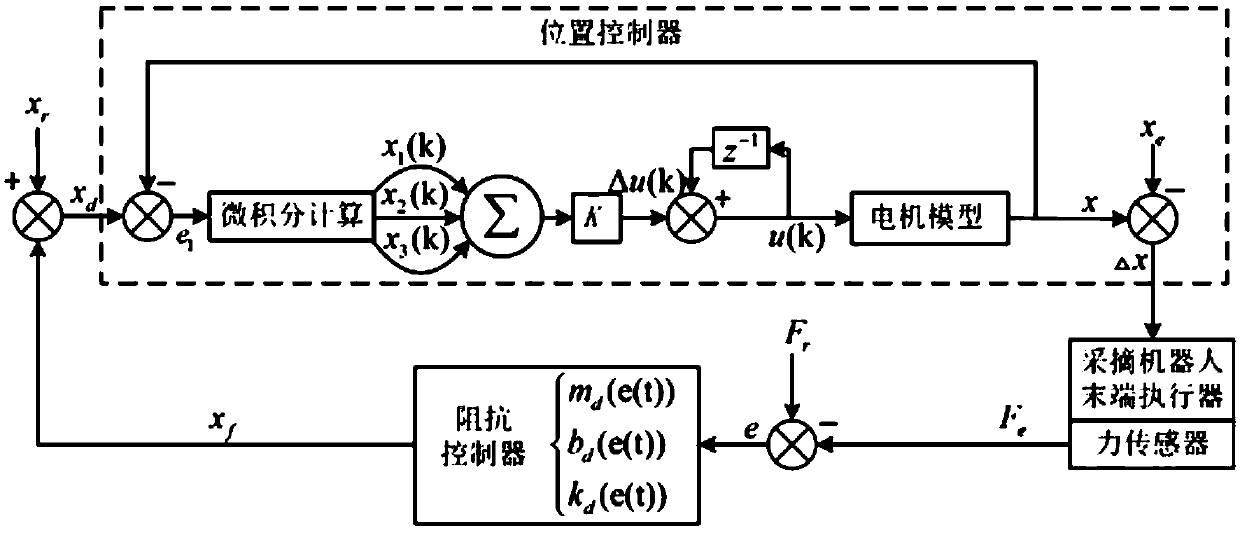

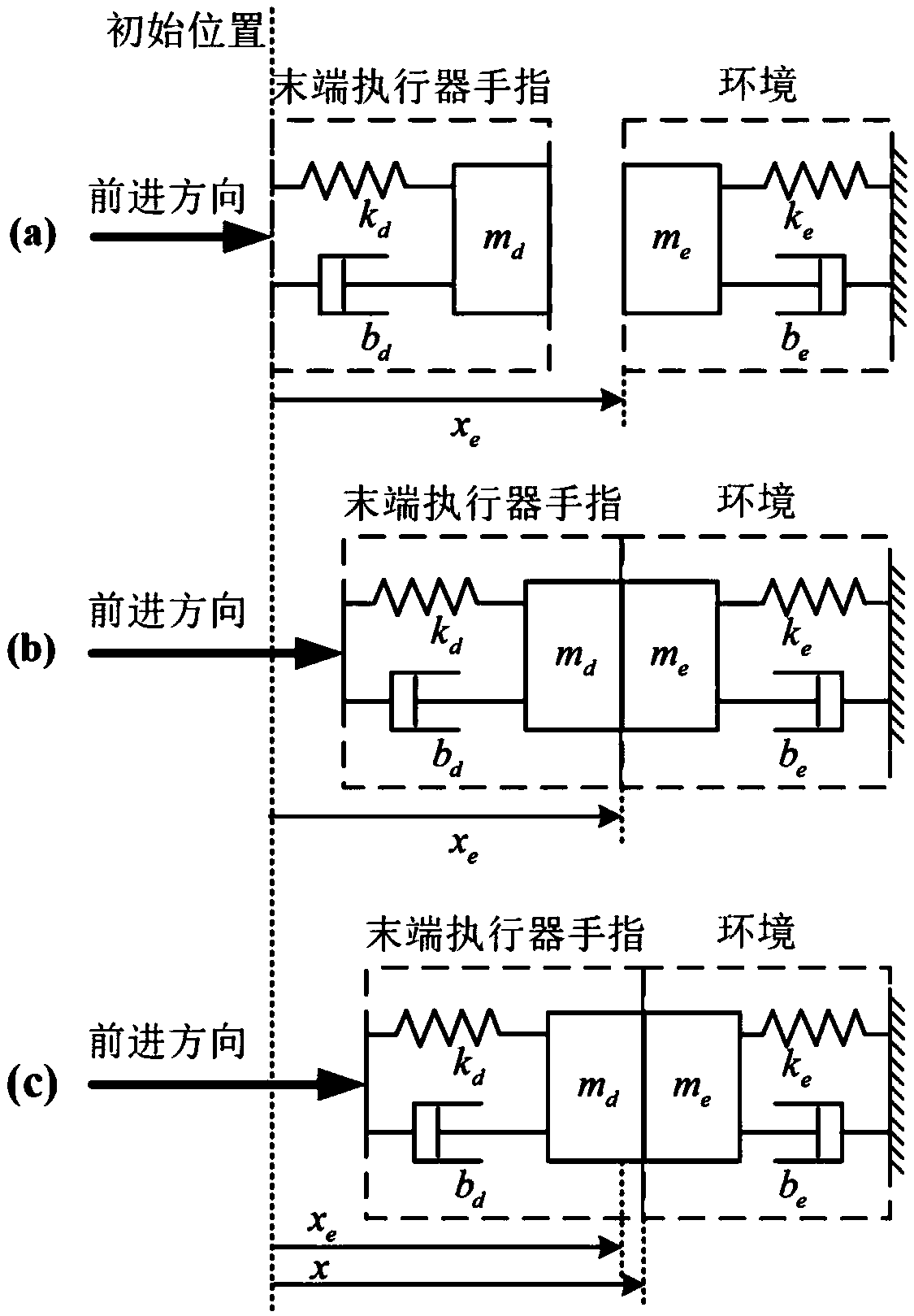

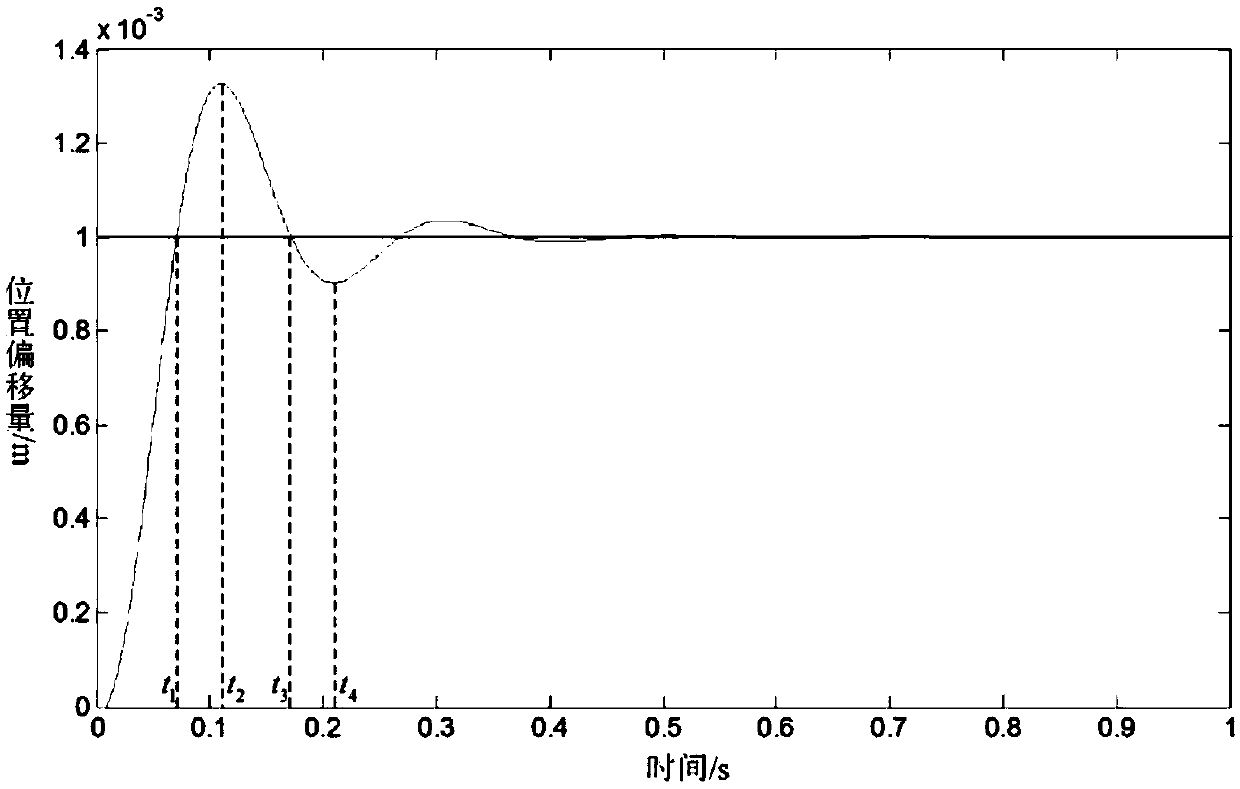

Parameter self-tuning impedance control system construction method for improving flexible grasping performance of picking robot

ActiveCN108983601AImprove adaptabilityImprove robustnessPicking devicesAdaptive controlDamping factorSelf-tuning

The invention discloses a parameter self-tuning impedance control system construction method for improving the flexible grasping performance of a picking robot. A parameter self-tuning impedance control system is constructed. An outer ring is a parameter self-tuning impedance controller and an inner ring is a position controller. The position controller is a single neuron adaptive PID controller.A displacement variation which is collected by an encoder and is output to an end actuator by a controller is used to analyze the influence of an outer ring impedance controller parameter change on system output. Based on that, the nonlinear functions of impedance controller inertia, rigidity and a damping coefficient with an input force error are designed and constructed, and an impedance controller parameter is automatically changed along with the change of the input force error. By using the parameter self-tuning impedance control method, a control parameter can be adjusted automatically inan on-line mode, and the control performance and the work efficiency of a robot can be effectively increased.

Owner:JIANGSU UNIV

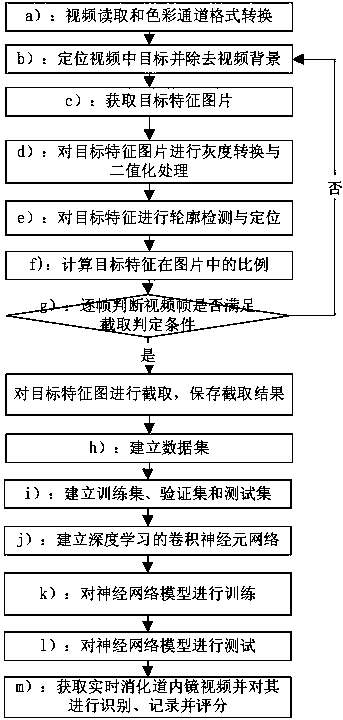

Method for automatically scoring intestinal preparation after enteroscopy

ActiveCN110335241ASelf-learningShorten observation timeImage enhancementImage analysisData setLearning data

The invention discloses a method for automatically scoring intestinal preparation after enteroscopy. Learning data sets in videos can be obtained in batches, the data sets are trained through a deep neural network model, intestinal foreign bodies are recognized, intestinal preparation conditions are recorded, the intestinal preparation conditions are scored through an ASTP scoring method and an EAREI scoring rule, and the quantitative scoring standard of intestinal preparation is defined.

Owner:河南萱闱堂医疗信息科技有限公司

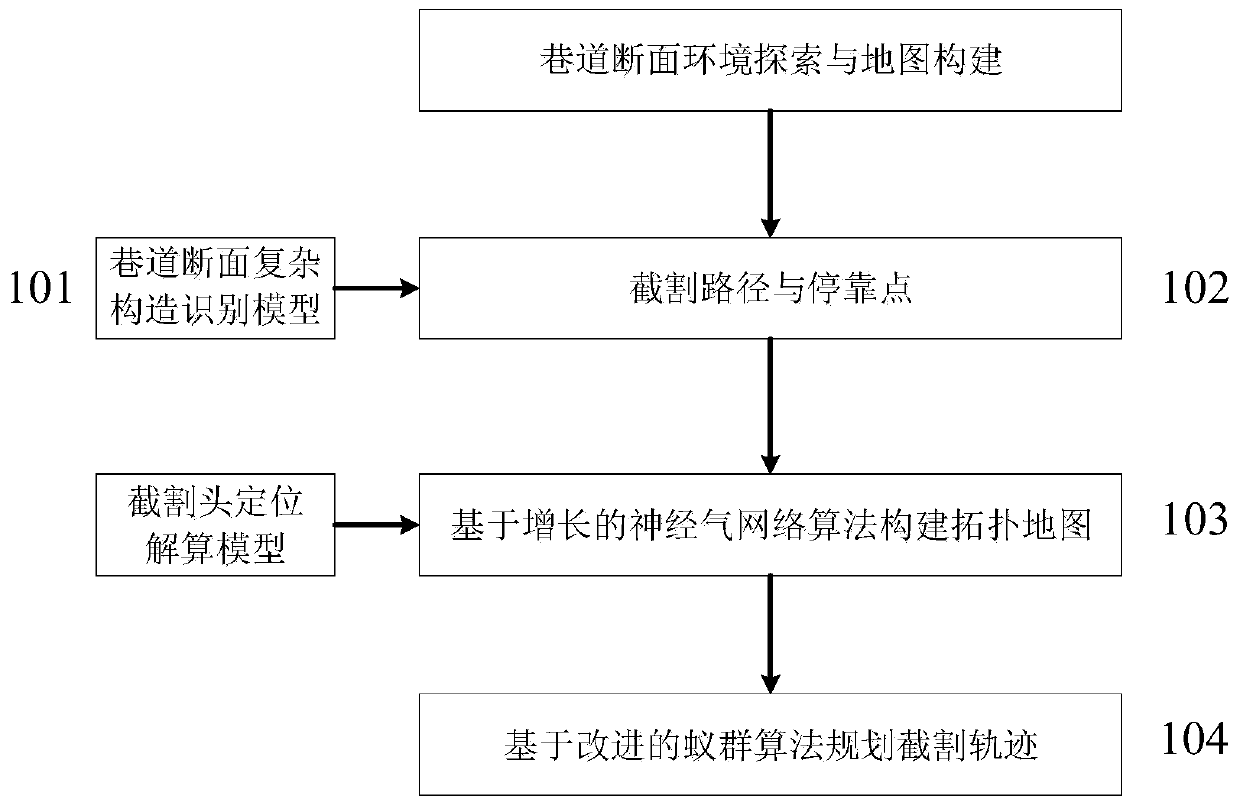

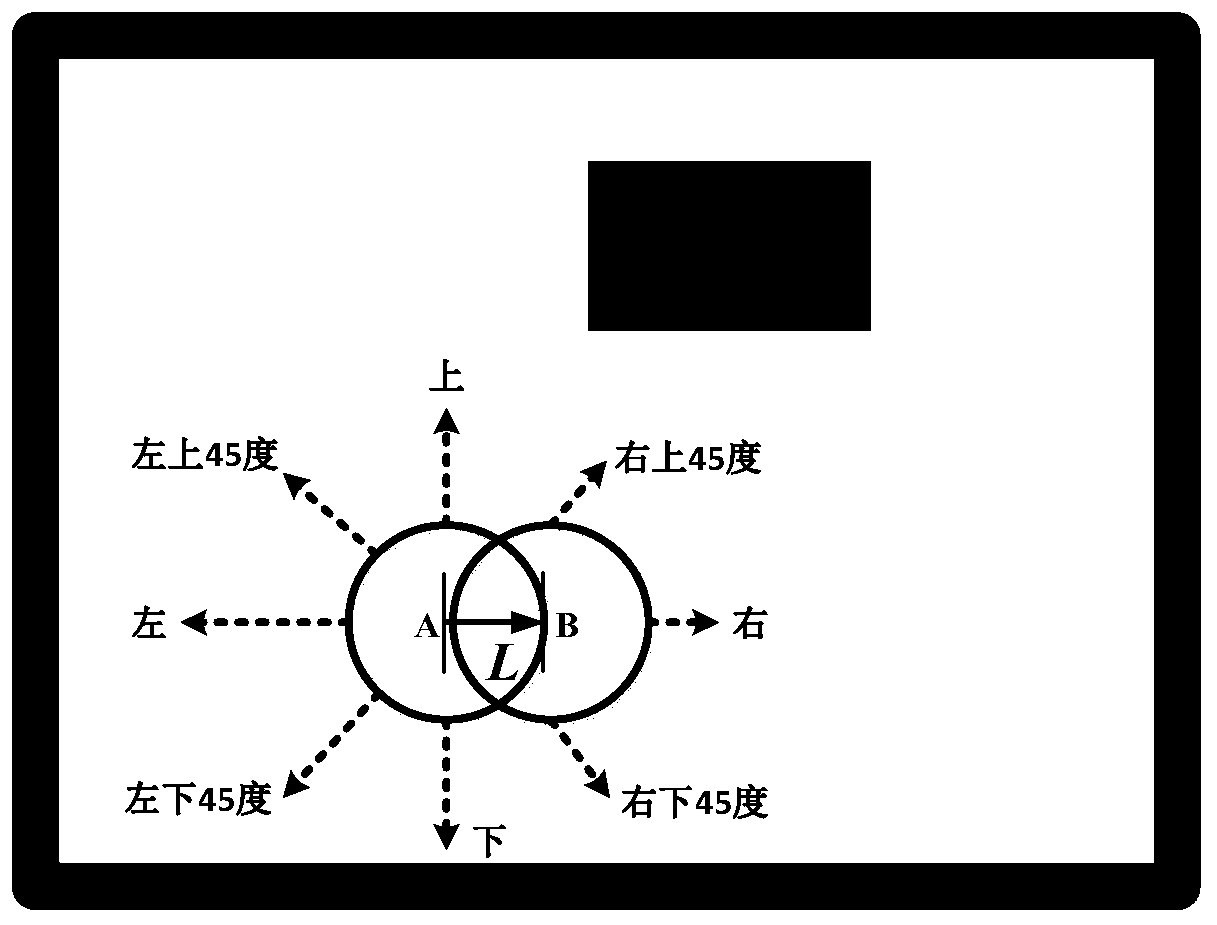

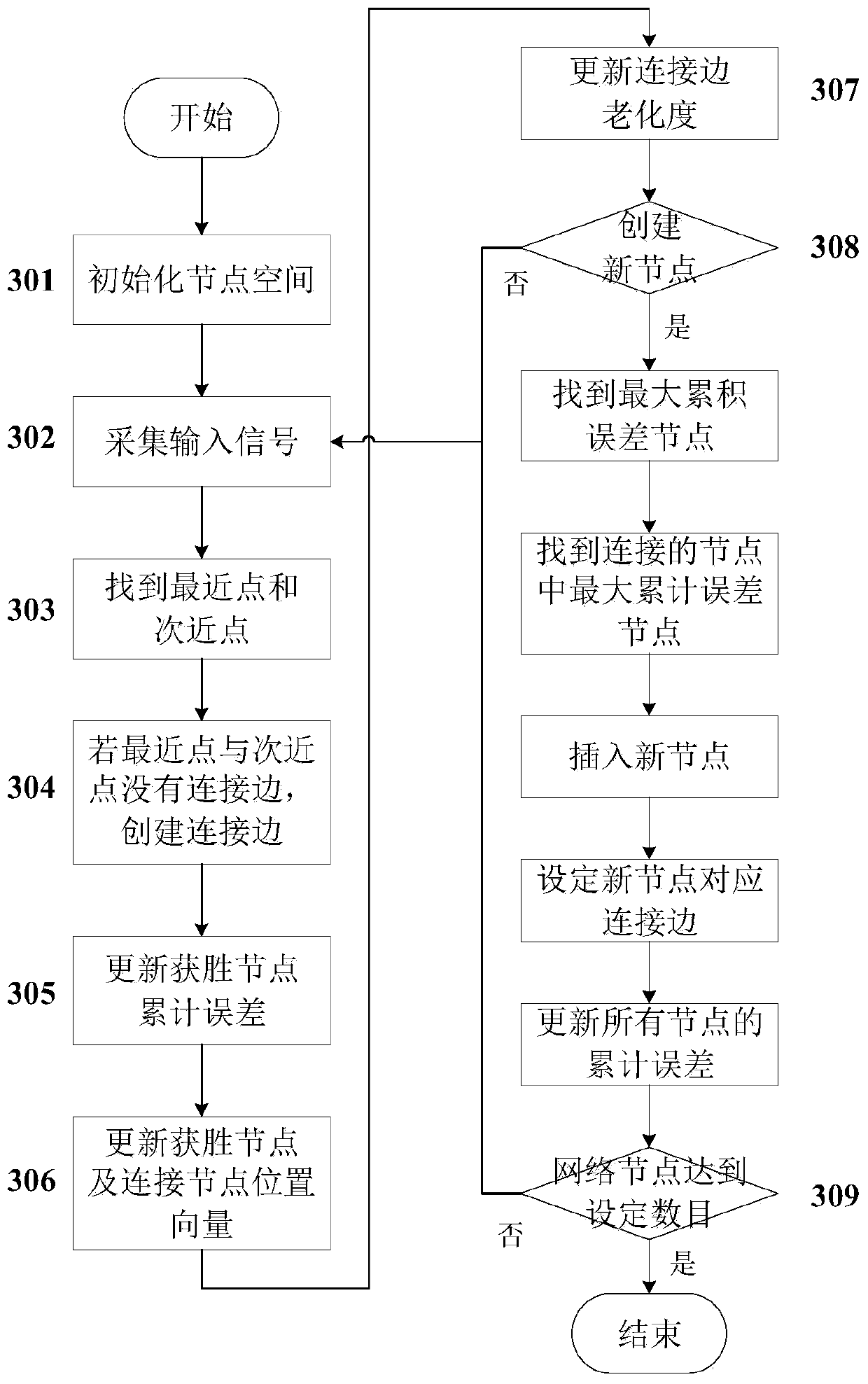

Topological map-based cutting track planning method for cantilever type heading machine

InactiveCN109754130AAccurate descriptionEasy to planForecastingBiological modelsEngineeringNeural gas network

The invention discloses a cutting track planning method for a cantilever type heading machine based on a topological map. The method comprises the following steps: judging a cutting environment according to a tunnel section complex structure identification model, and planning a cutting path and a stop point for exploring a cantilever environment of the heading machine; according to a cutting headpositioning resolving model, resolving the position of the cutting head in the roadway, and constructing a roadway section topological environment map by utilizing an increased neural gas network algorithm; according to the coal roadway cutting rule, an improved ant colony algorithm is utilized, and the shortest path avoiding waste rock inclusion is obtained through planning. In the subsequent section cutting process, if the section environment is obviously changed, the section of the roadway is explored again, meanwhile, a topological map is constructed, and a new optimal cutting track is obtained through planning. By the adoption of the method, the complex and changeable roadway environment can be coped, the optimal track suitable for tunneling is obtained, and therefore autonomous unmanned cutting is achieved step by step.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

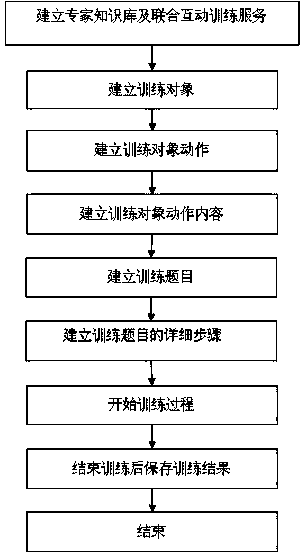

Multi-object interaction joint training method

ActiveCN103854527ARealize automatic judgmentRealize process managementElectrical appliancesElectric power systemObject definition

The invention relates to the technical field of educational training systems, and discloses a multi-object interaction joint training method to solve the technical problem that an existing method is low in training efficiency. According to the method, an expert knowledge base and joint interaction services are established according to the training content, students and teachers are divided into various objects according to different industries, object behaviors are defined according to the objects, each behavior is defined with different operations to achieve different training content, each operation of each object is defined into decomposable interaction procedures, standard answers are set and stored in the knowledge base, and the behavior operations of each object are compared with the knowledge base to achieve automatic judgment in the training process. The method is suitable for simulative training of an education system, an electric system and a railway system.

Owner:广东圣火网络科技有限公司

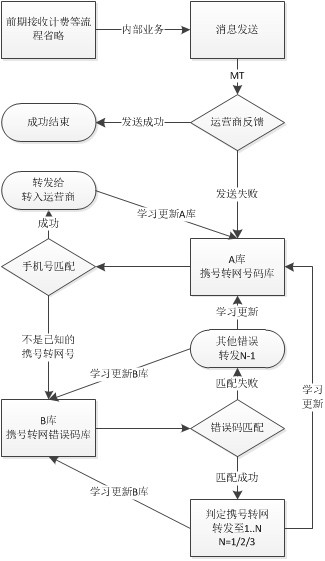

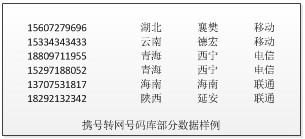

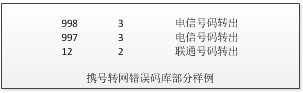

Method for improving message instruction delivery rate under condition of number portability

ActiveCN112423293AReduce overheadLow costNetwork data managementMobile Telephone NumberComputer engineering

Short messages and multimedia messages in number-carrying and network-transferring services and telecommunication value-added services are issued by a communication operator according to the number segment, and the operator of the number-carrying and network-transferring service is judged to be inconsistent with the operator to which the number belongs due to network transferring, so that a number-carrying and network-transferring user cannot acquire a verification code, a notification message and a subscription message in time. The invention aims to ensure that value-added service messages (including short messages and multimedia messages) can be accurately delivered to the number of a number portability user. The method comprises the steps: establishing a number portability number library, establishing a number portability error code library, managing an operation persistence library, using a cache library for program research and judgment, and synchronously updating the persistencelibrary and the cache library at regular time by a program; searching the mobile phone number corresponding to the sending failure message in a number library, and if the number exists, forwarding thenumber directly to an operator; if not, querying the error code library by using the failure message error code, and forwarding the error code library to a corresponding operator (possibly a plurality of error codes) according to a query result.

Owner:山东兆永信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com