Intelligent unmanned inspection system of coal conveying system

A technology of coal conveying system and patrol inspection system, which is applied to conveyors, conveyor objects, transportation and packaging, etc., to achieve the effects of improving equipment life, reducing plant power consumption, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

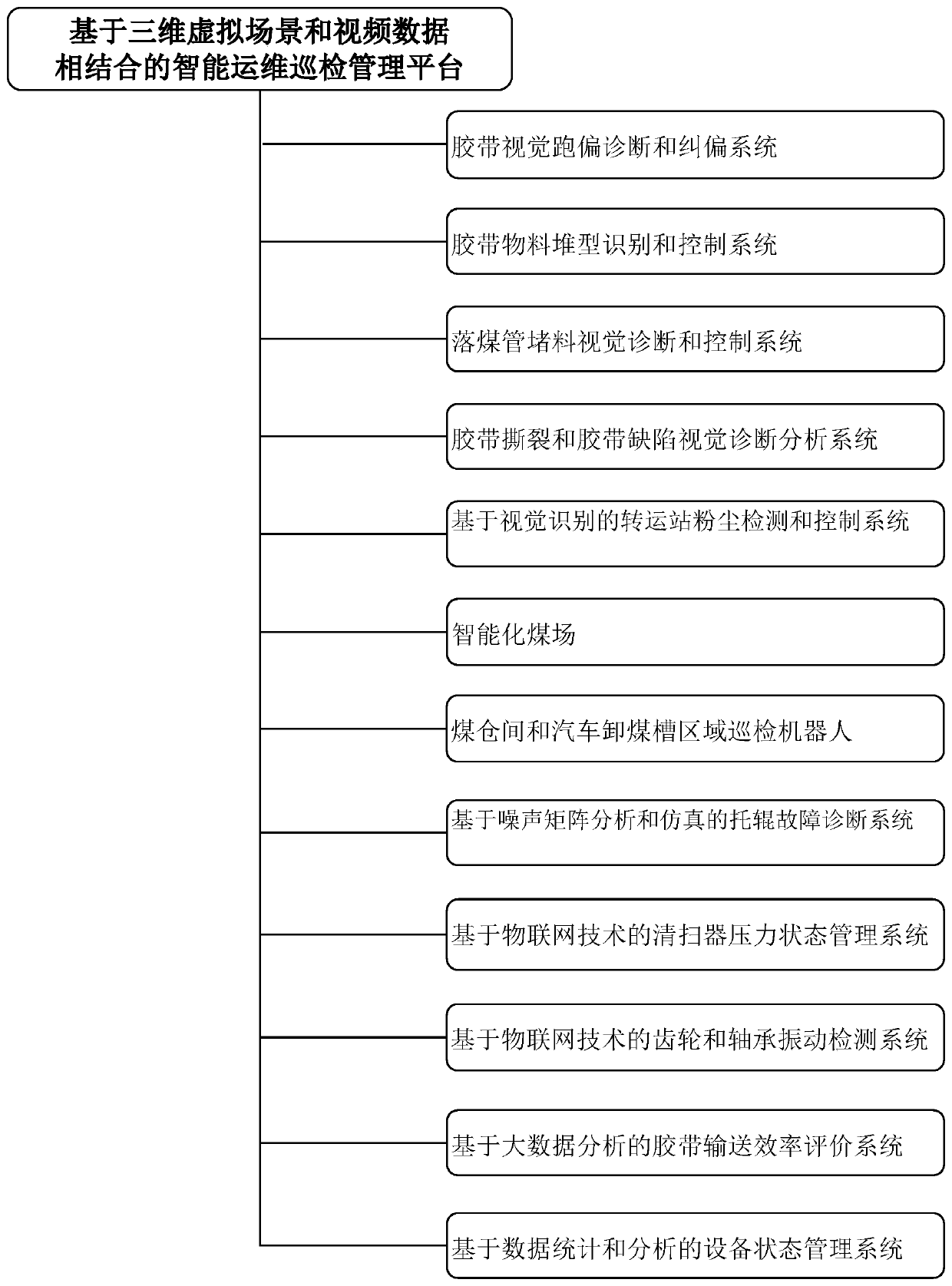

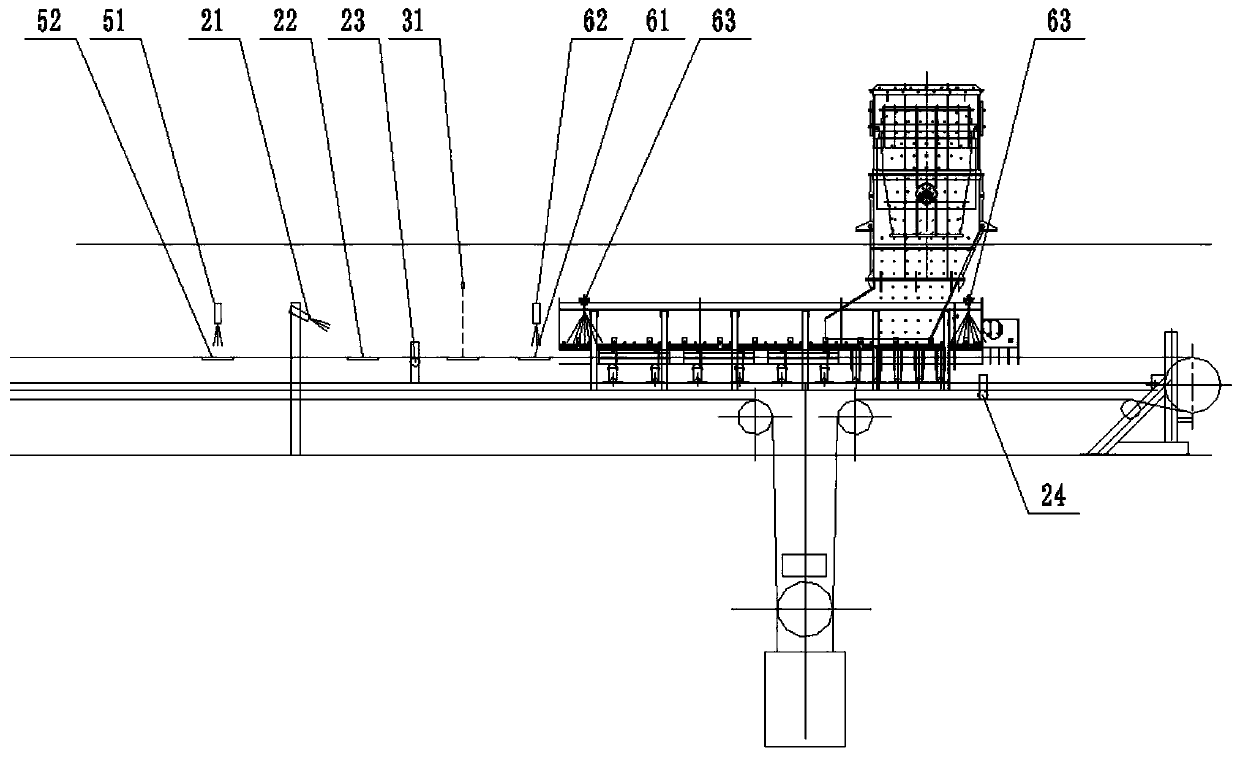

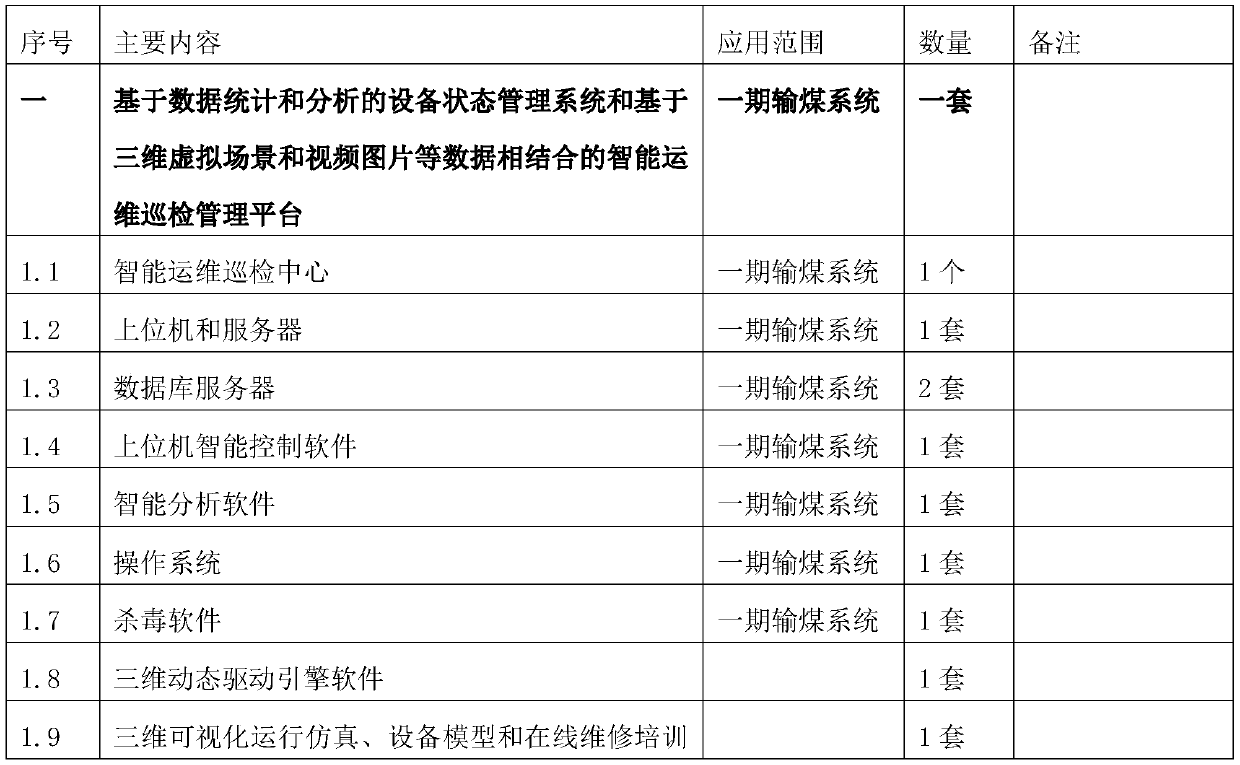

[0045] Such as figure 1 As shown, the intelligent unmanned inspection system of the coal handling system of the present invention includes an intelligent operation and maintenance inspection management platform based on the combination of data such as three-dimensional virtual scenes and video pictures, and is connected to a system based on the combination of data such as three-dimensional virtual scenes and video pictures. The tape visual deviation diagnosis and deviation correction system of the intelligent operation and maintenance inspection management platform, the tape material pile type identification and control system, the visual diagnosis and control system of coal falling pipe blockage, the visual diagnosis and analysis system of tape tea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com