Ridge height self-adaption seedling digging planting machine

A self-adaptive, planting machine technology, applied in transplanting machinery, application, planting methods, etc., can solve the problems of inaccurate control of nesting and planting depth, no ridge height control device, and poor erection of seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

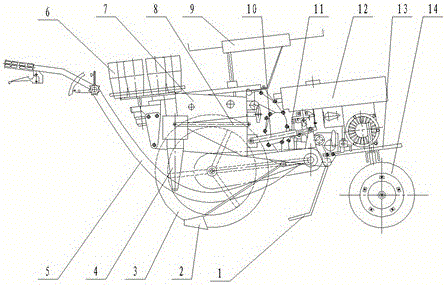

[0015] In the embodiment shown in the accompanying drawings, the present invention consists of a ridge height sensor 1, a nesting plow 2, a rear wheel 3, a planting part 4, an operating handrail 5, a seedling release device 6, a seedling gearbox 7, and a connecting rod mechanism. 8. Seedling storage rack 9, hydraulic system 10, travel gearbox 11, engine 12, frame 13, front wheels 14, ridge height sensor 1 is installed under the frame 13, seedling planting gearbox 7, travel gearbox 11 and engine 12 are installed on the frame 13, and front wheel 14 is installed on the front end of frame 13, and the output shaft of engine 12 links to each other with the input shaft of travel gearbox 11, and travel gearbox 11 has three output shafts, wherein one output shaft Drive the oil pump of the hydraulic system 10, an output shaft drives the rear wheel 3, and the other output shaft is connected to the input shaft of the seedling planting gearbox 7, the seedling storage frame 9 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com