Planetary gear train tray seedling transplanting inter-plant hole covering mechanism

A technology of planetary gear train and pits, which is applied in the field of pot seedling transplanting pot seedling pit covering operation mechanism, and can solve the problems of not being able to use pot seedling pit pit covering soil operations in dry fields and backward technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

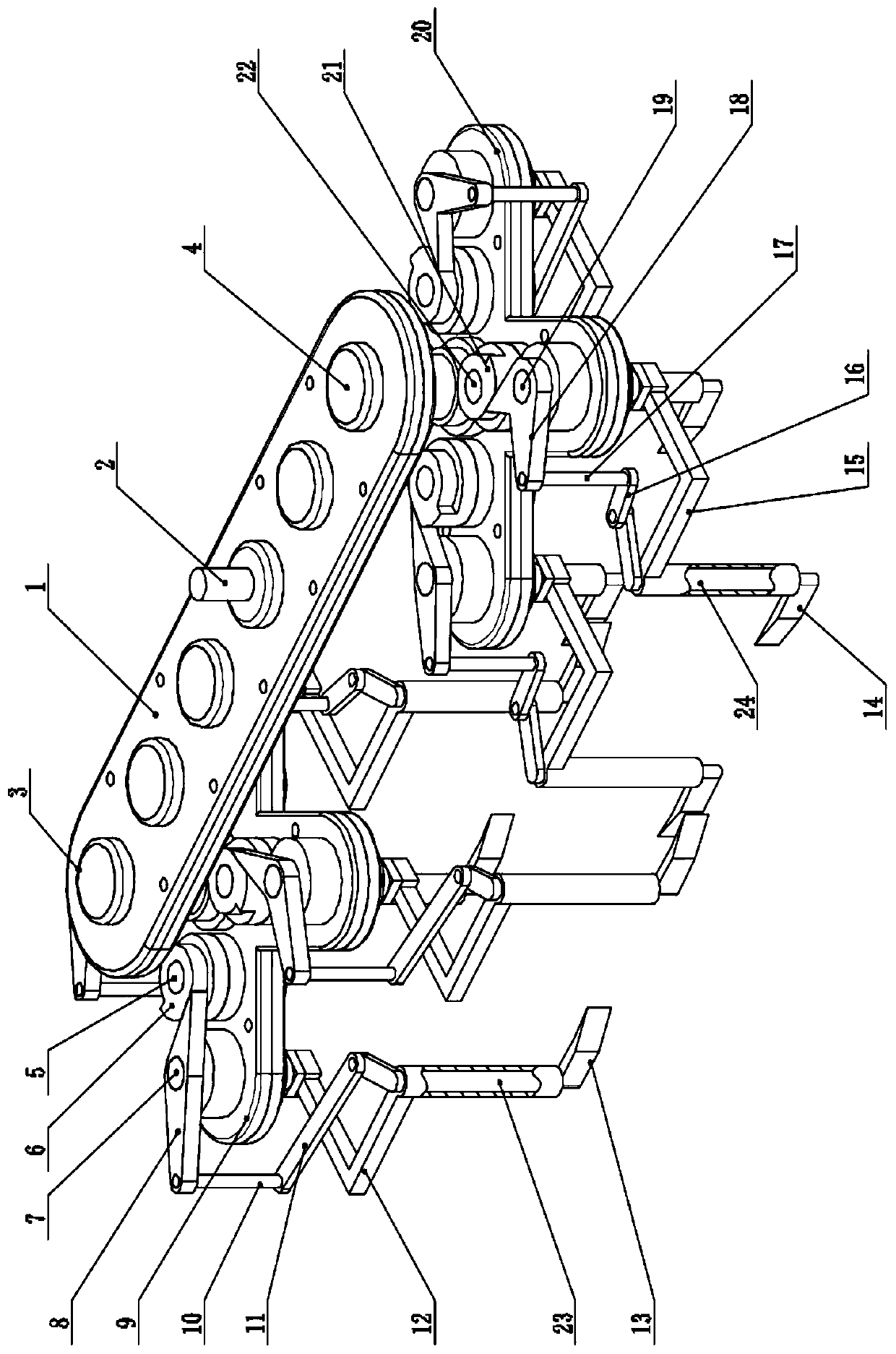

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A planetary gear train pot seedling transplanting hole pit soil covering mechanism, which is respectively fixed on the lower part of the power output left shaft 3 and the power output right shaft 4 of the driving power input gearbox 1 with a fixed configuration and a power input shaft 2. Install the left cross planetary gear box 9 and the right cross planetary gear box 20, the rotation direction of the power output left shaft 3 is opposite to the power output right shaft 4; in the left cross planetary gear box The left cams 6 are respectively fixed on the upper ends of the four left intermediate shafts 5 of 9, and the left dials are rotatable on the upper ends and lower ends of the four left drive shafts 7 of the left cross planetary gear box 9 respectively. Fork 8 and fixed bell crank shape left arm 12, on four bell crank shape left arms 12, the left ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com