Patents

Literature

53results about How to "Improve uprightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

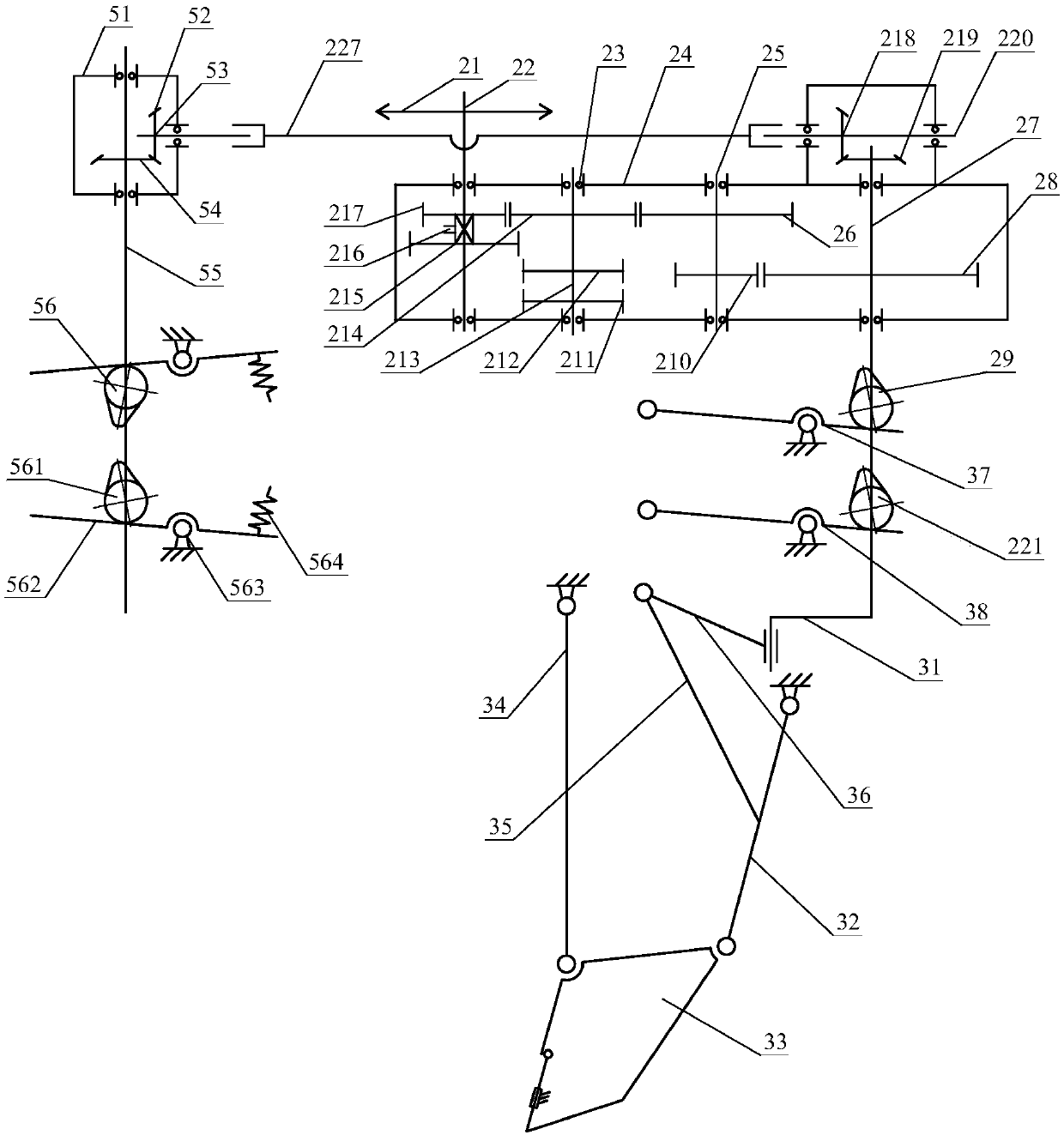

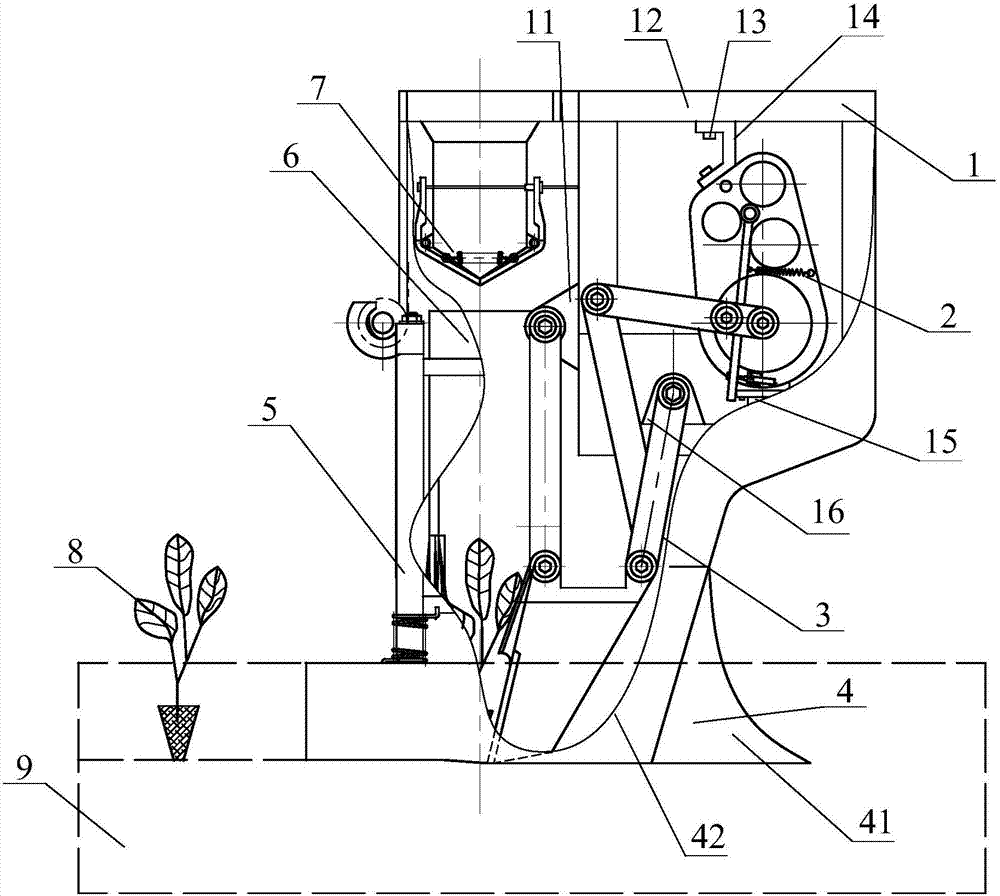

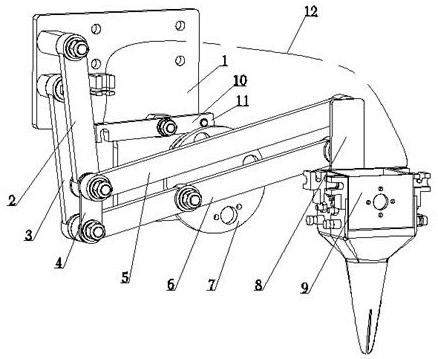

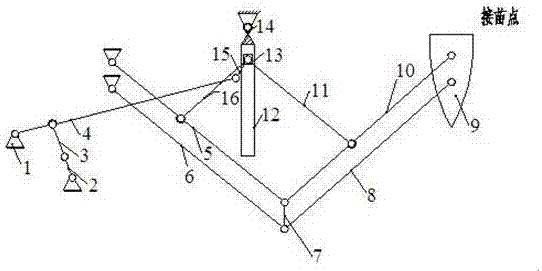

Transplanting mechanism capable of implementing continuous perpendicular planting

The invention discloses a transplanting mechanism capable of implementing continuous perpendicular planting. The translating mechanism comprises a transmission box, a planting arm assembly, a planter and a cam starting mechanism, wherein the transmission box is fixed on a stander; three output shafts, an input shaft and two hanging shafts are arranged on the transmission box; the first output shaft, the second output shaft and the two hanging shafts are arranged on one side of the transmission box and are used for hanging the planting arm assembly and driving the planting arm assembly; the third output shaft and the input shaft are arranged on the other side of the transmission box; the third output shaft is used for mounting and driving the cam starting mechanism; the input shaft is connected with an output shaft of a planter handpiece; the planting arm assembly consists of a four-rod mechanism, a five-rod mechanism and two parallel mechanisms; the planter is hung on the planting arm assembly through a square shaft. The transplanting mechanism disclosed by the invention is compact in structure, has the advantages of low seedling injury rate, low seedling leakage rate, low seedling burying rate, low seedling exposure rate and high seedling growth rate and can completely meet an agriculture requirement on oilseed rape transplanting.

Owner:HUNAN AGRICULTURAL UNIV

Multifunctional compound fertilizer additive and preparation method thereof

InactiveCN101774850AComprehensive nutritionLong-lasting and effectiveFertilizer mixturesSal ammoniacRare-earth element

The invention discloses a multifunctional compound fertilizer additive and a preparation method thereof. The preparation method comprises the following steps: uniformly spraying a compound amino acid complex solution of trace elements containing Fe, B, Mn, Cu, Zn and Mo, rare earth elements containing Ce and La and beneficial mineral elements containing Ni, Co and Ti on grass carbon, brown coal or weathered coal powder, airing or drying, and then crushing to obtain a material A; preparing dicyandiamide used as a nitrification inhibitor into an ammonia solution to be adsorbed on carboxymethyl cellulose used as a water retention agent, airing or drying, and then crushing to obtain a material B; mixing cobalt sulfide and molybdenum sulfide which are used as nitrogen fixation catalysts with bean cakes or corn starch to obtain a material C; and uniformly mixing the material A, the material B and the material C to obtain the additive. The multifunctional compound fertilizer added with the additive of the invention has the advantages of fixing nitrogen, dissolving phosphorus, enriching soil, reducing nutrient loss, improving nutrient utilization ratio, improving crop enzyme activity, promoting metabolism, improving crop quality, increasing crop yield, retaining water, saving water, resisting drought, regulating buffering acidity or saline-alkali soil, and improving soil structure.

Owner:GANSU AGRI MATERIALS

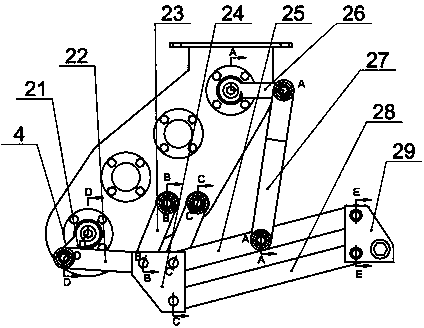

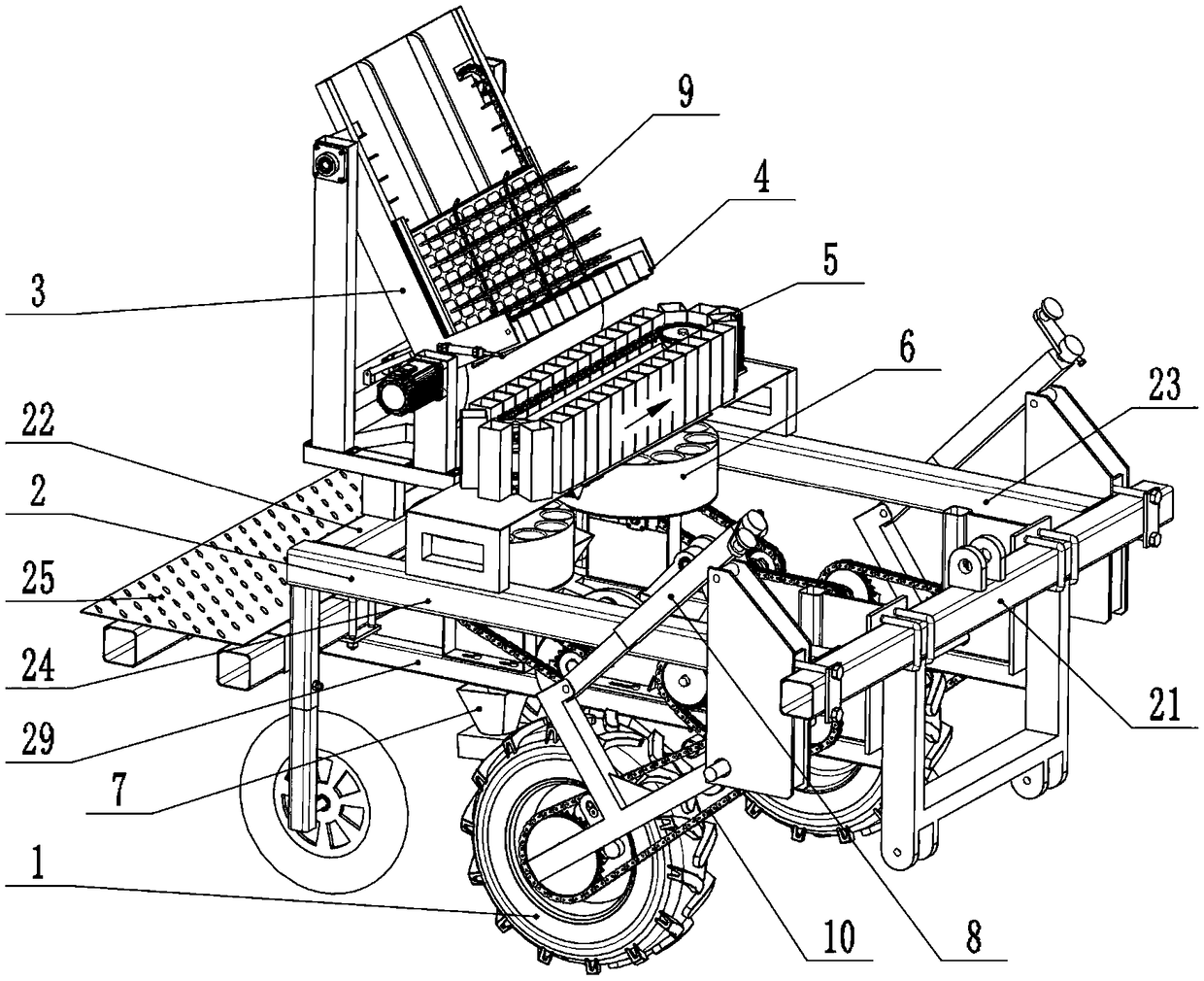

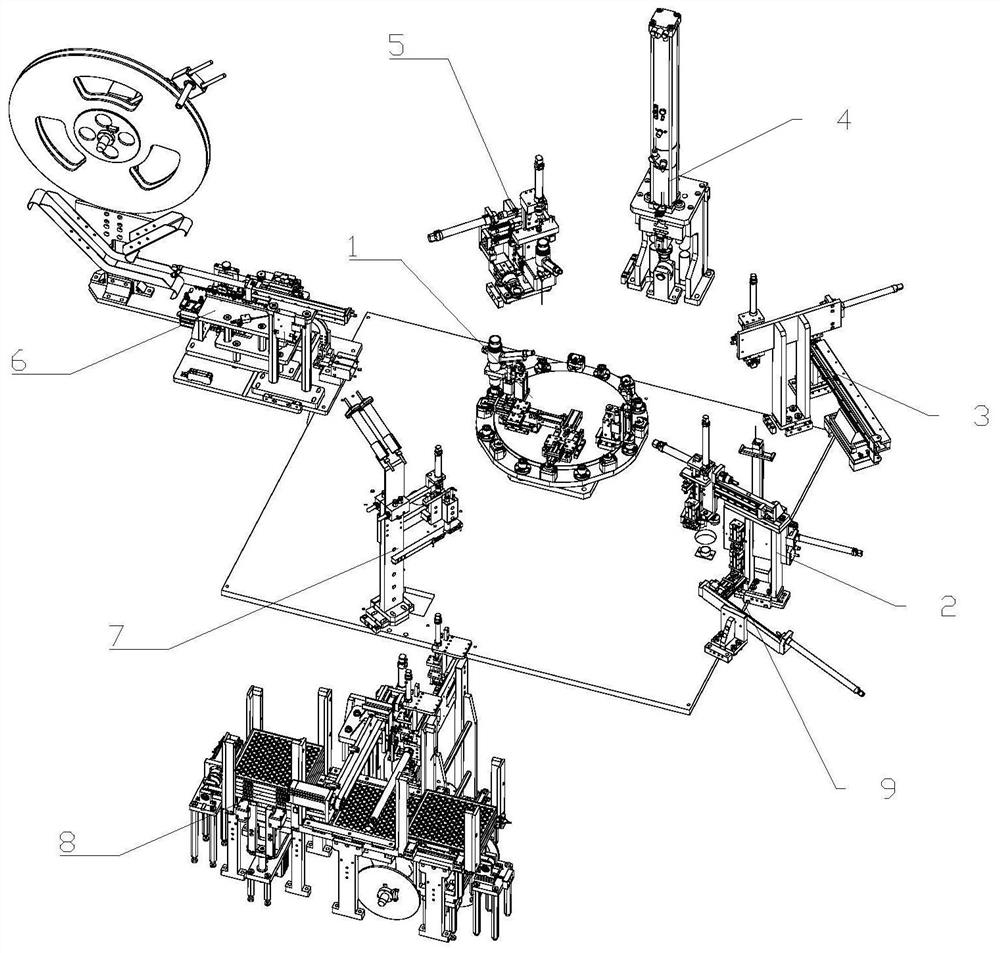

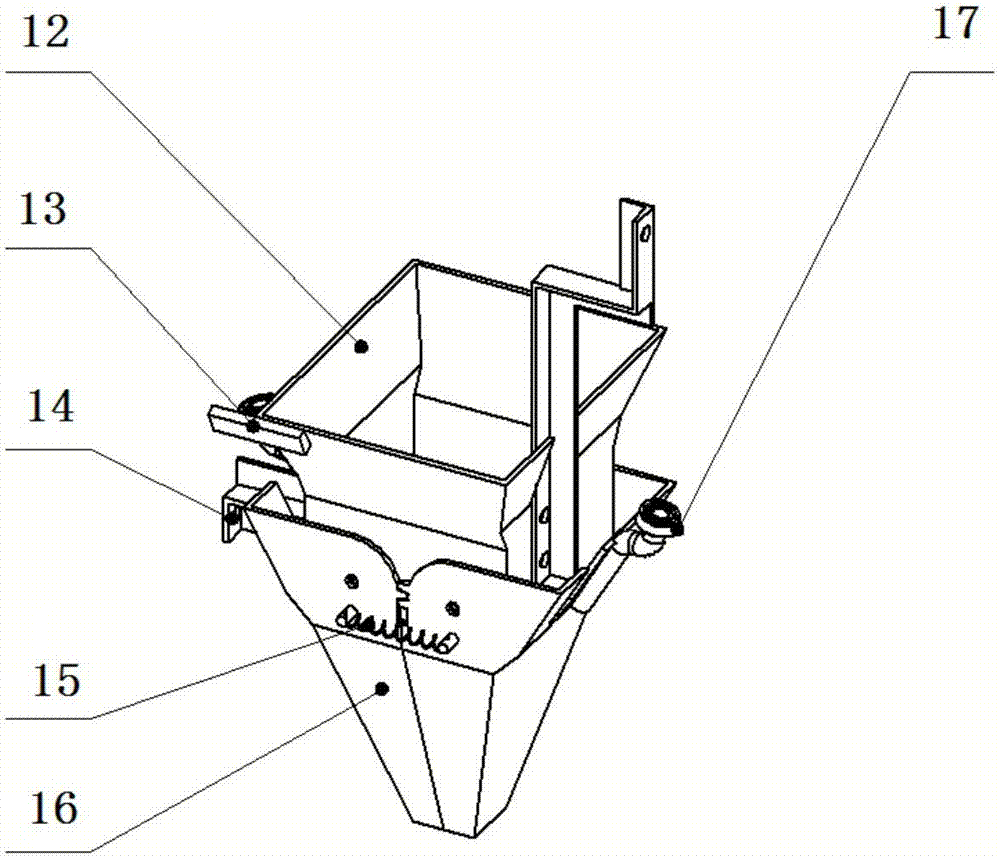

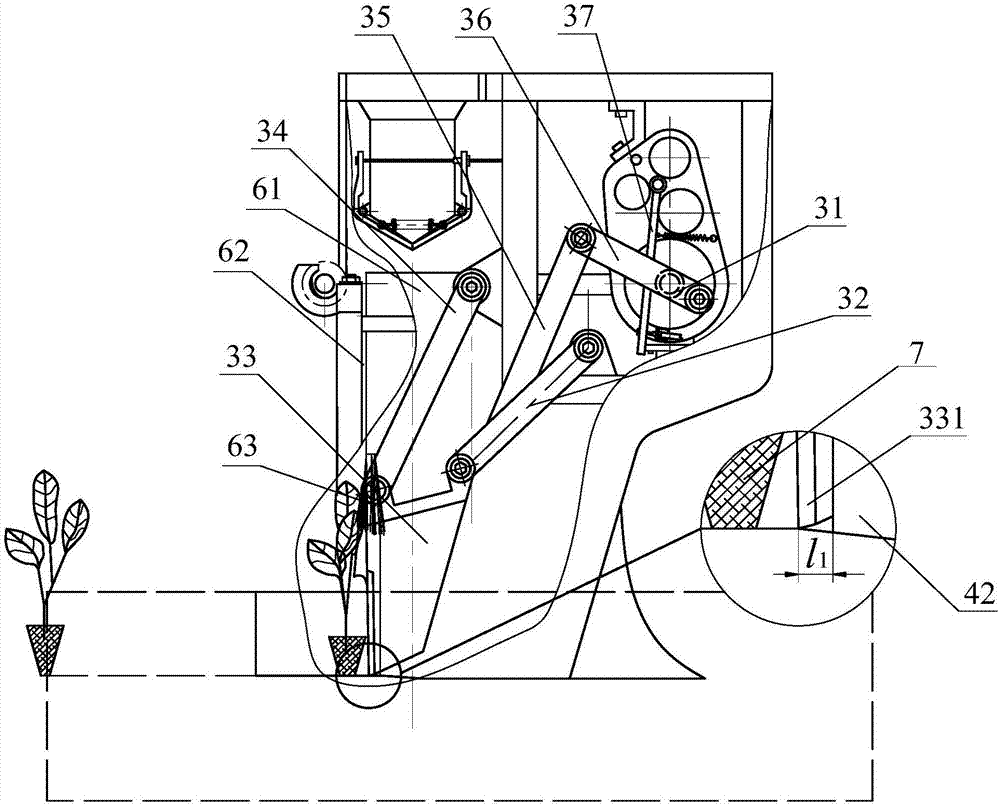

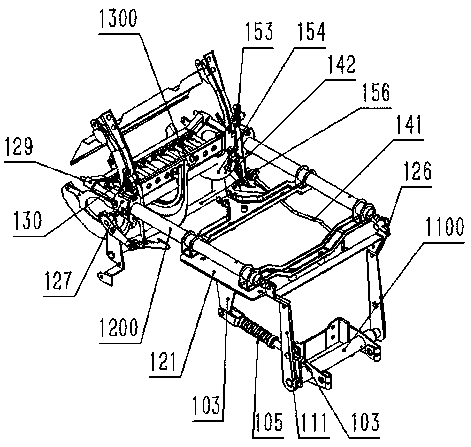

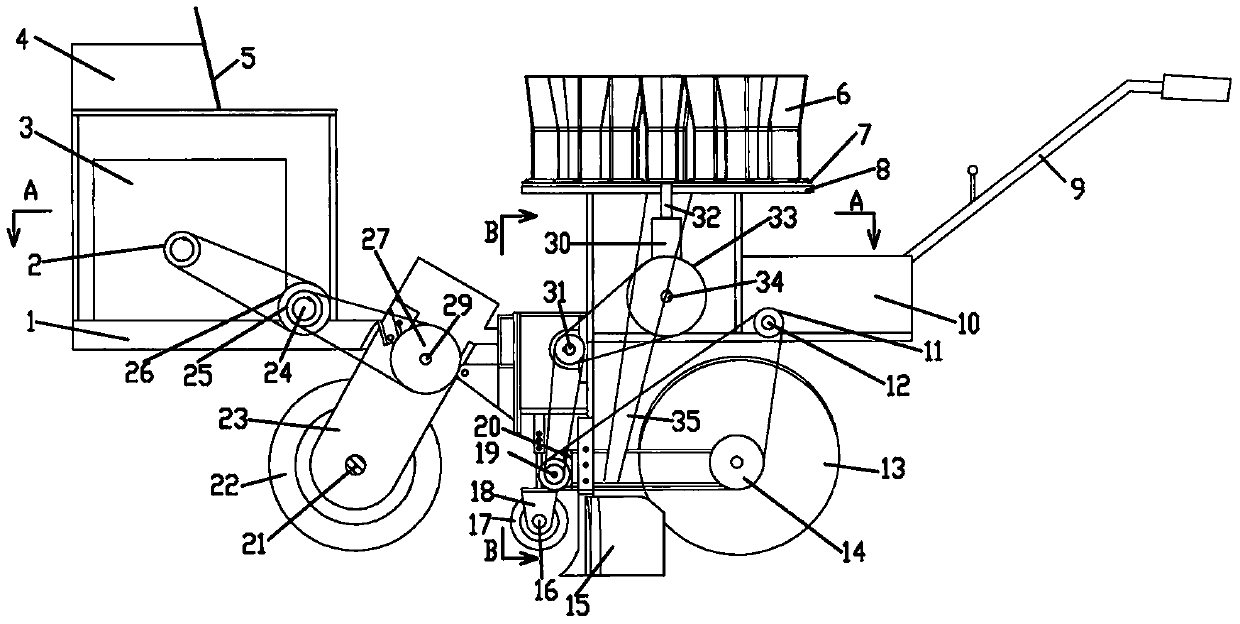

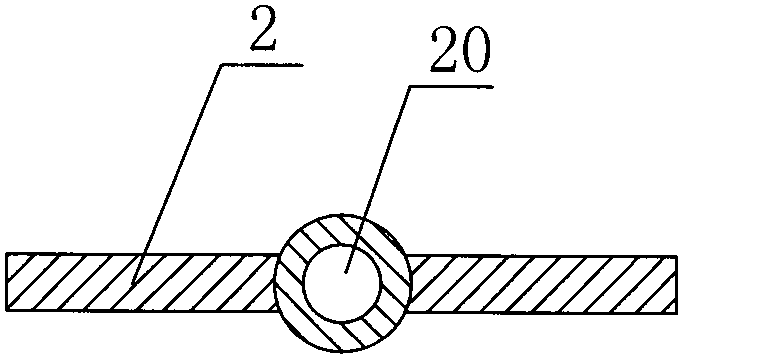

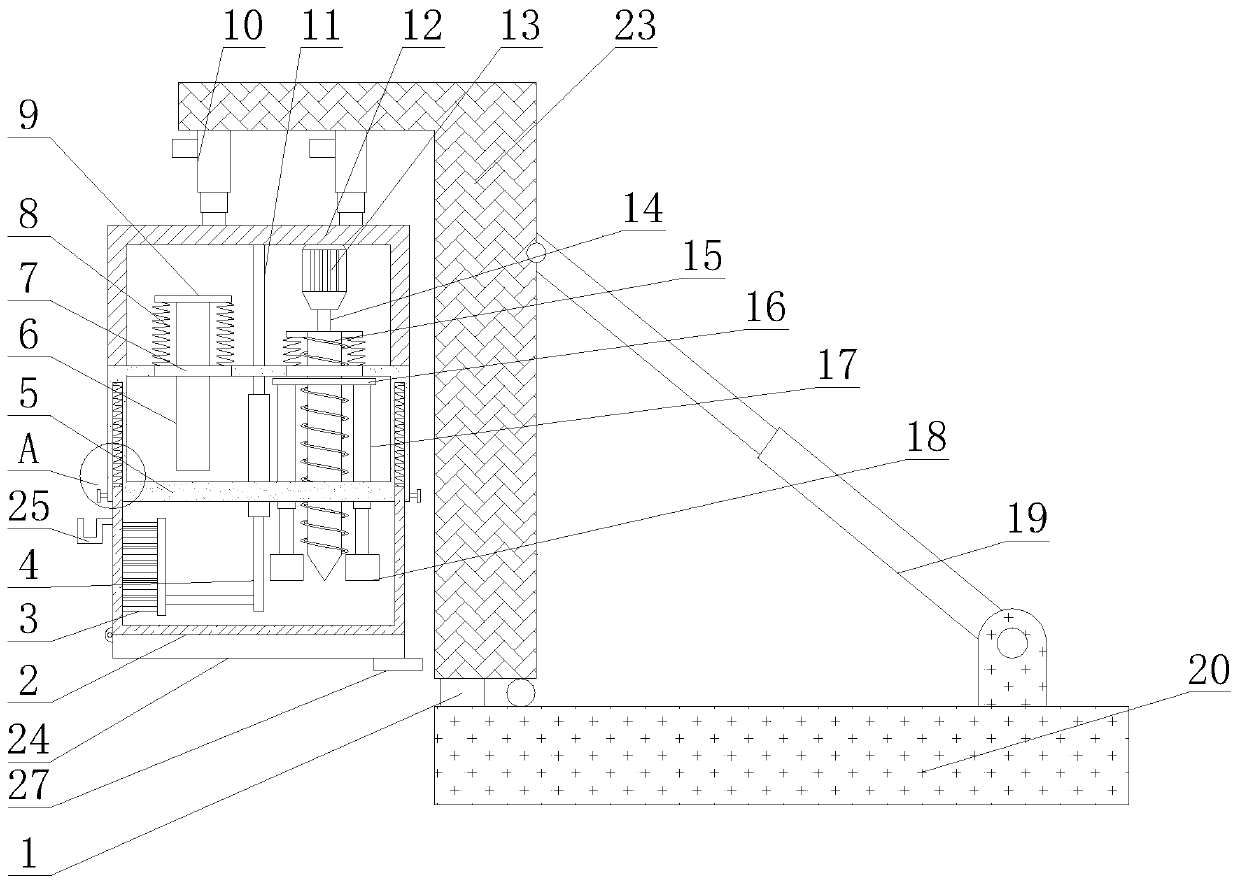

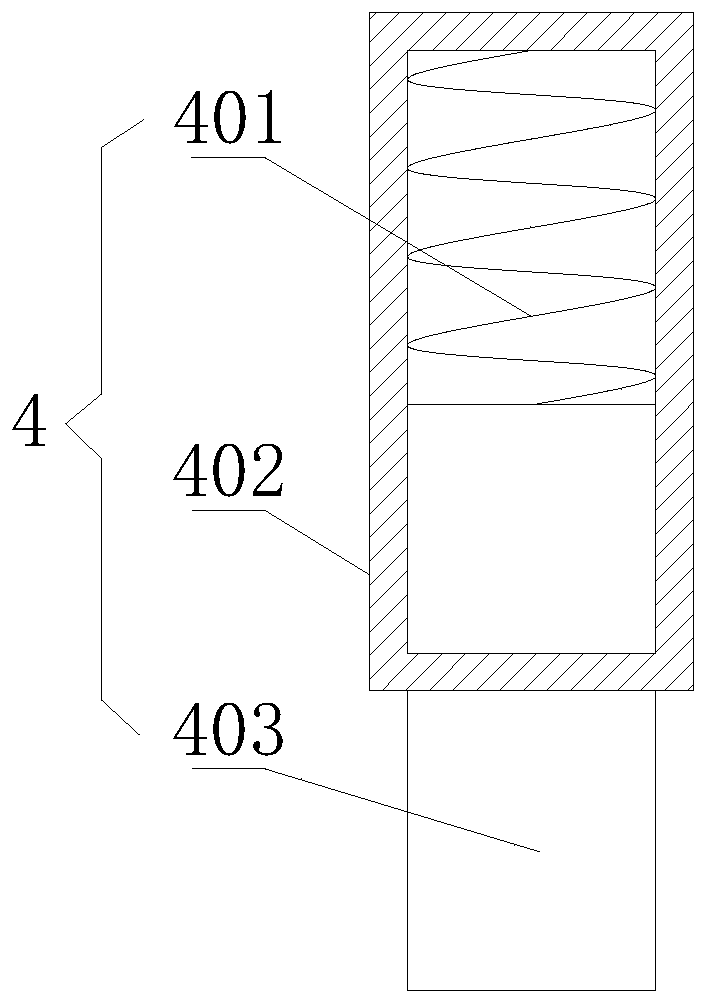

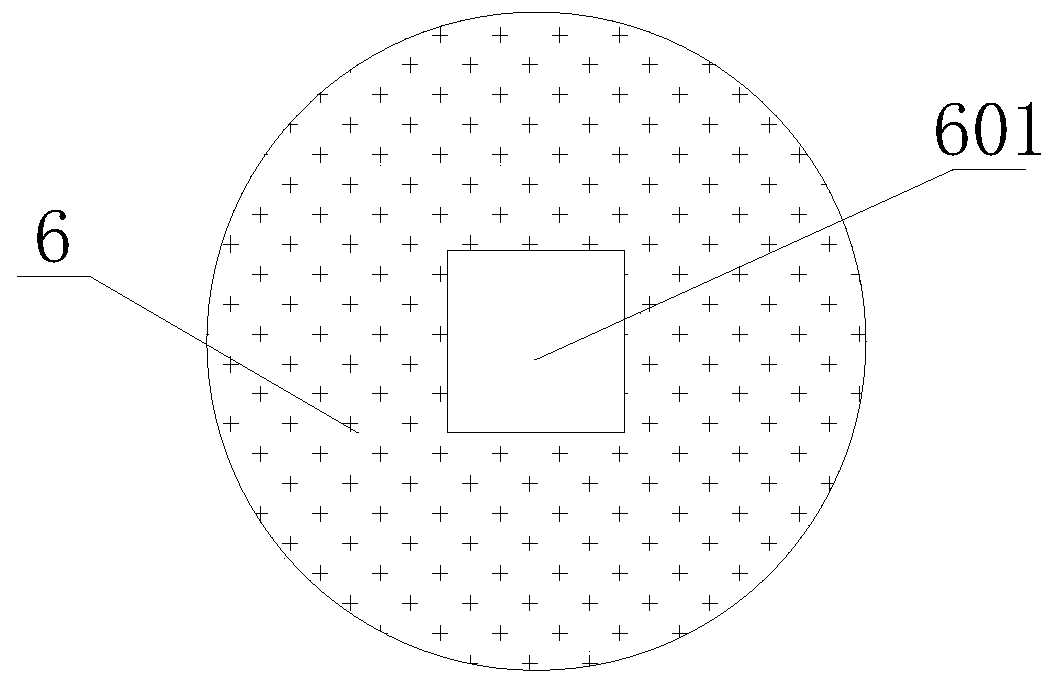

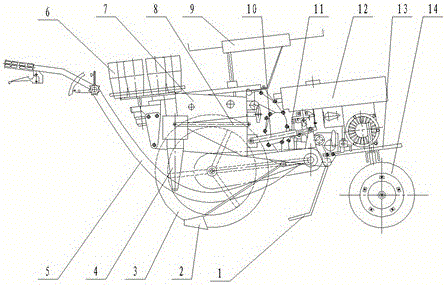

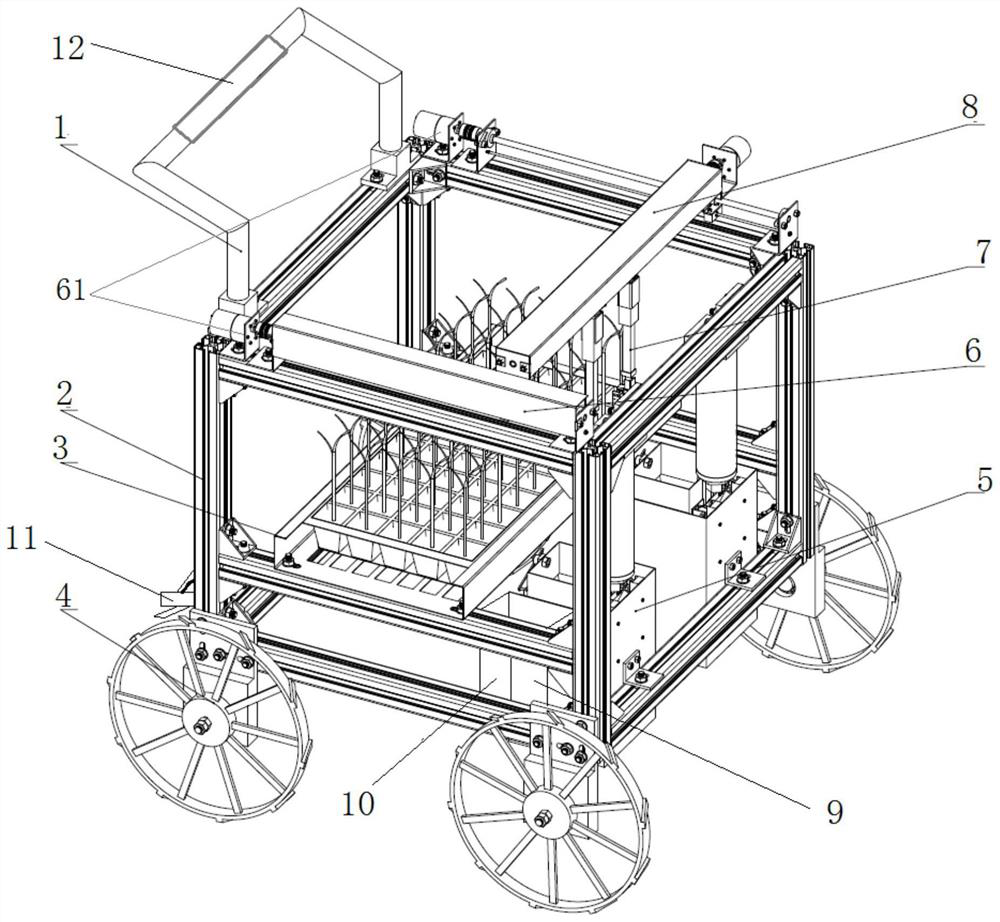

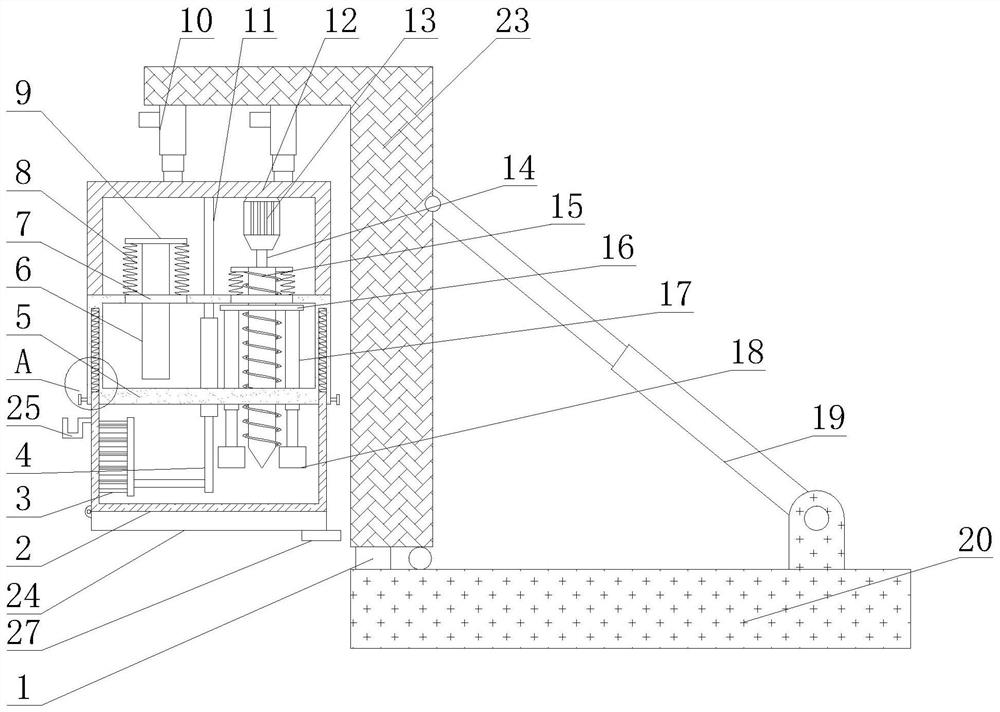

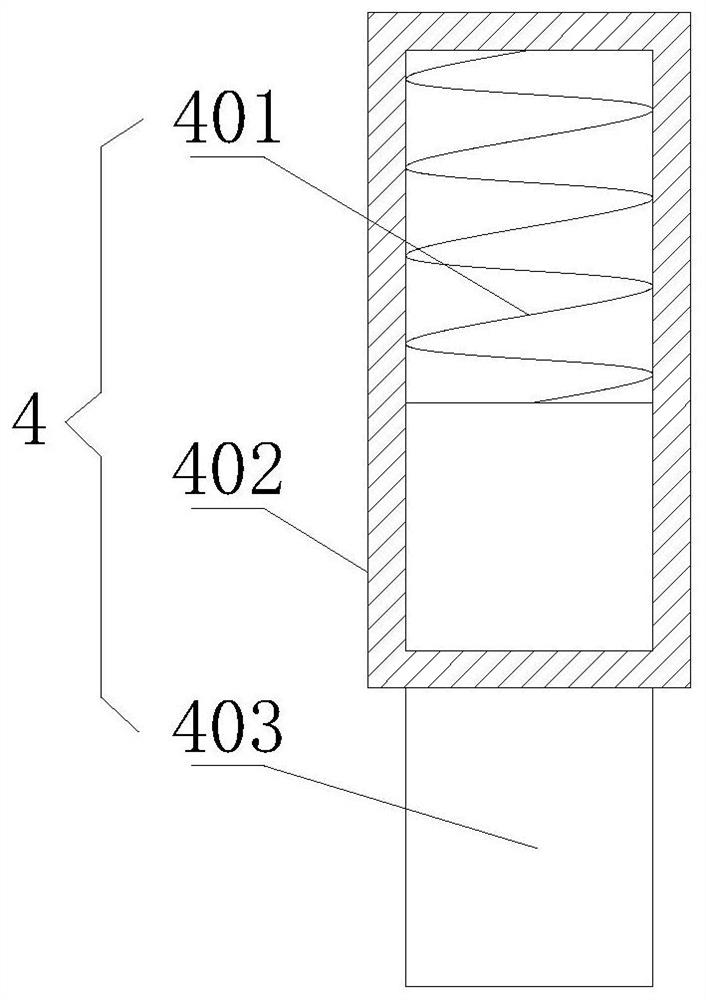

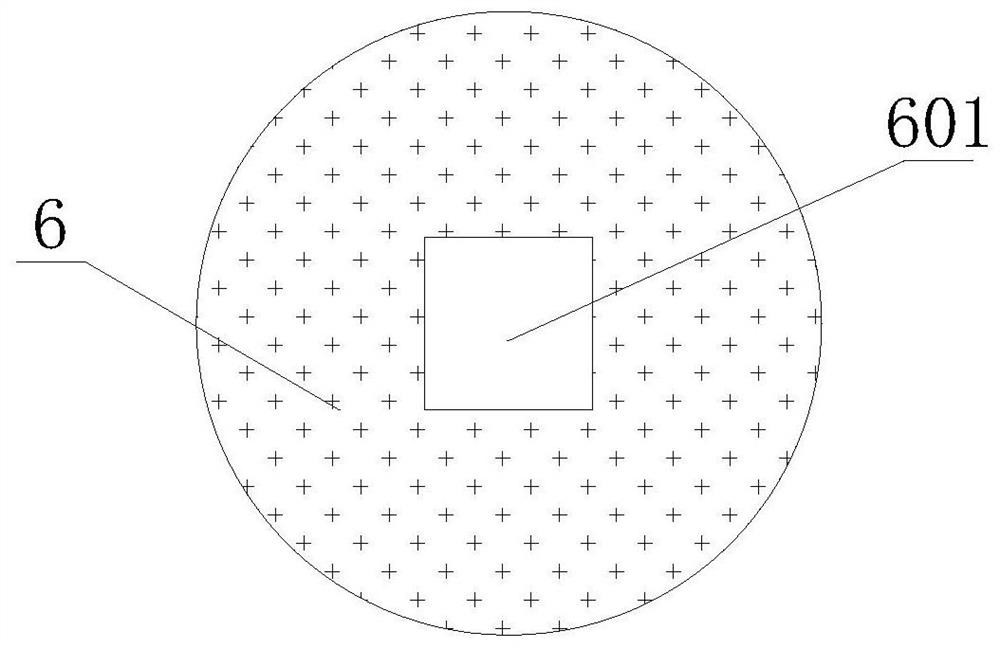

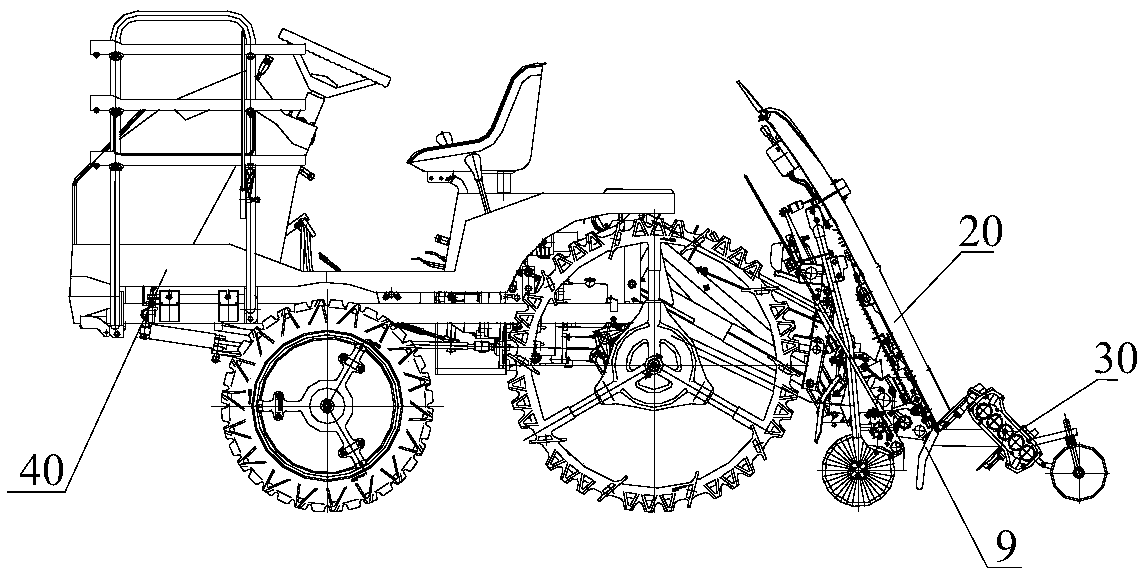

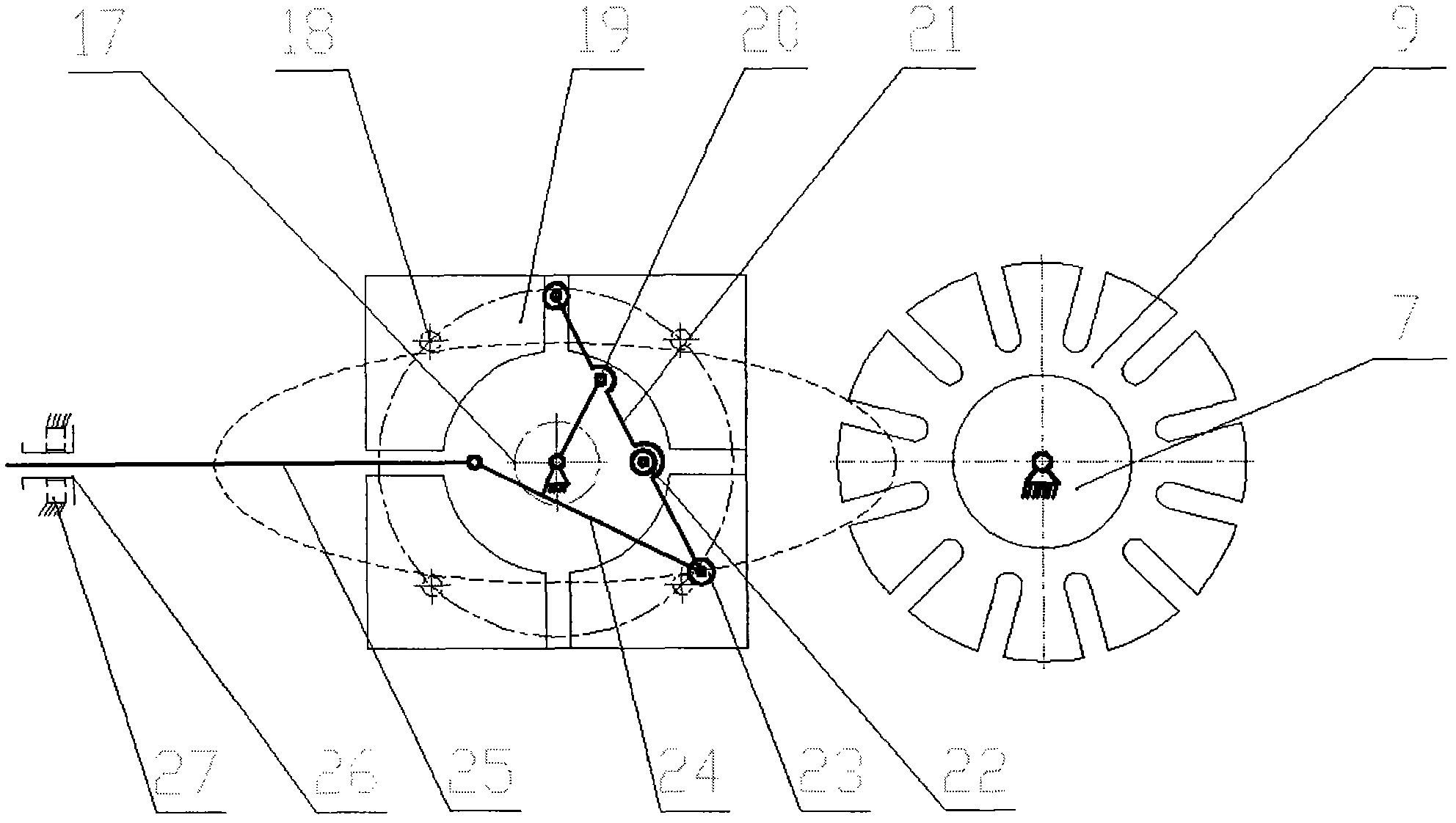

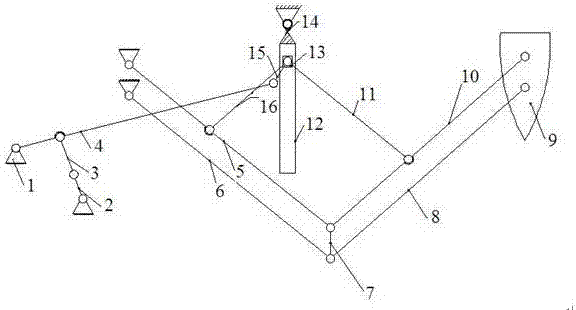

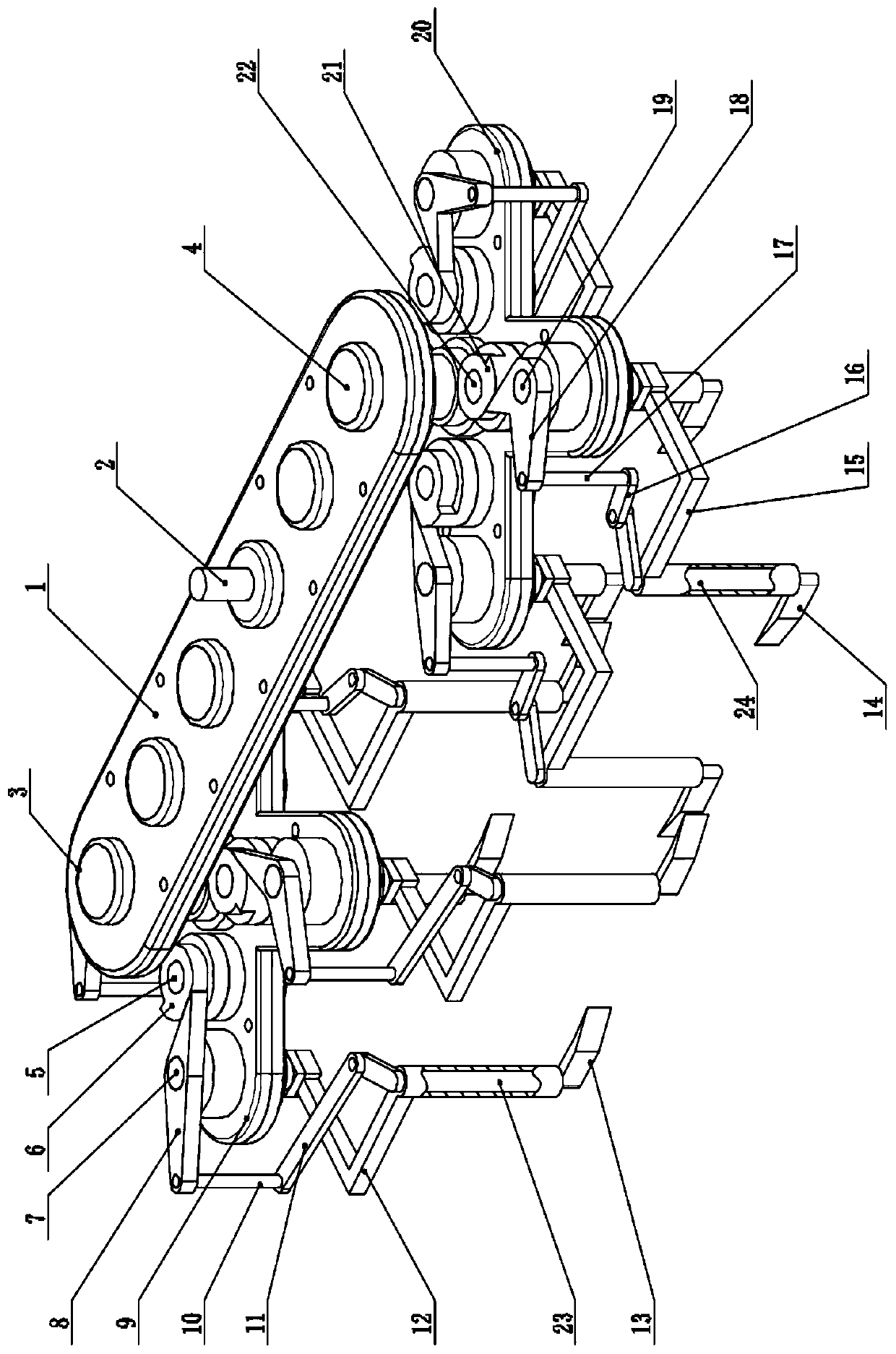

Fully automatic transplanting machine for plug seedlings

ActiveCN108738557AImprove seedling efficiencyReduce damage rateTransplantingAgricultural engineeringTransfer mechanism

The invention belongs to the field of agricultural machinery and particularly relates to a fully automatic transplanting machine for plug seedlings. The fully automatic transplanting machine comprisesground wheels (1), a frame (2), a seedling picking mechanism (3), a transfer mechanism (4), a transport mechanism (5), a seedling feeding mechanism (6), transplanting mechanisms (7) and a seedling feeding and planting transmission mechanism (10). The transplanting machine is suitable for transplanting a multi-row and multi-row matrix-type plug seedling tray (9). The fully automatic transplantingmachine has high seedling taking efficiency. Through one process, the whole row of plug seedlings is transferred to the transport mechanism. The fully automatic transplanting machine can reduce the damage rate of the plug seedlings during the transplanting process. The one seedling picking mechanism can simultaneously feed seedlings for two lines of the transplanting mechanisms. The fully automatic transplanting machine has the advantages of compact structure, high automation degree, high transplanting efficiency, low labor intensity and low manufacturing cost, can transplant plug seedlings ofdifferent crops and has wide applicability.

Owner:CHINA AGRI UNIV

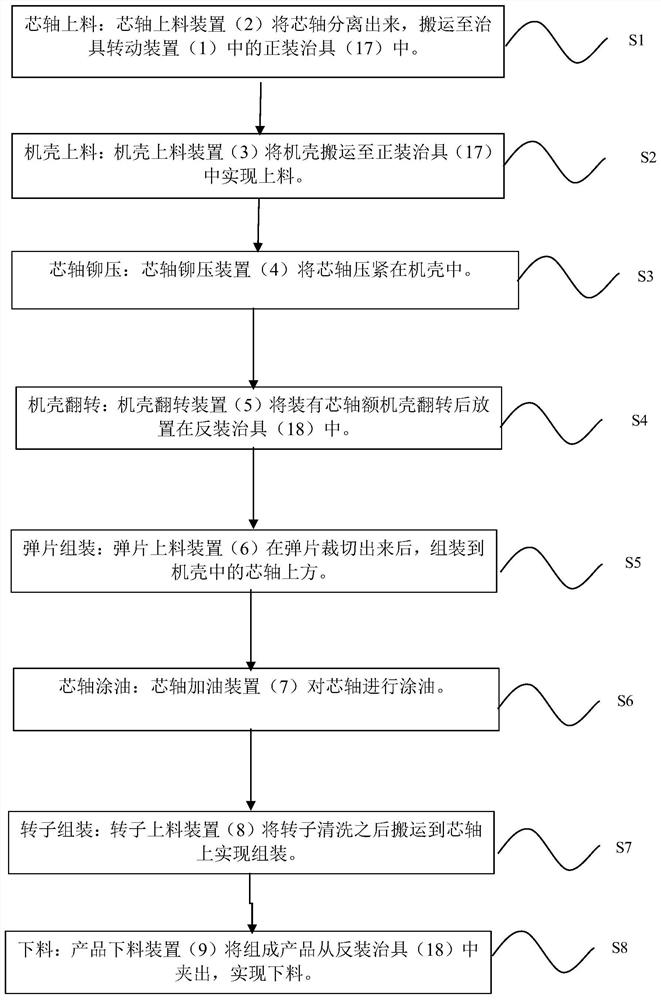

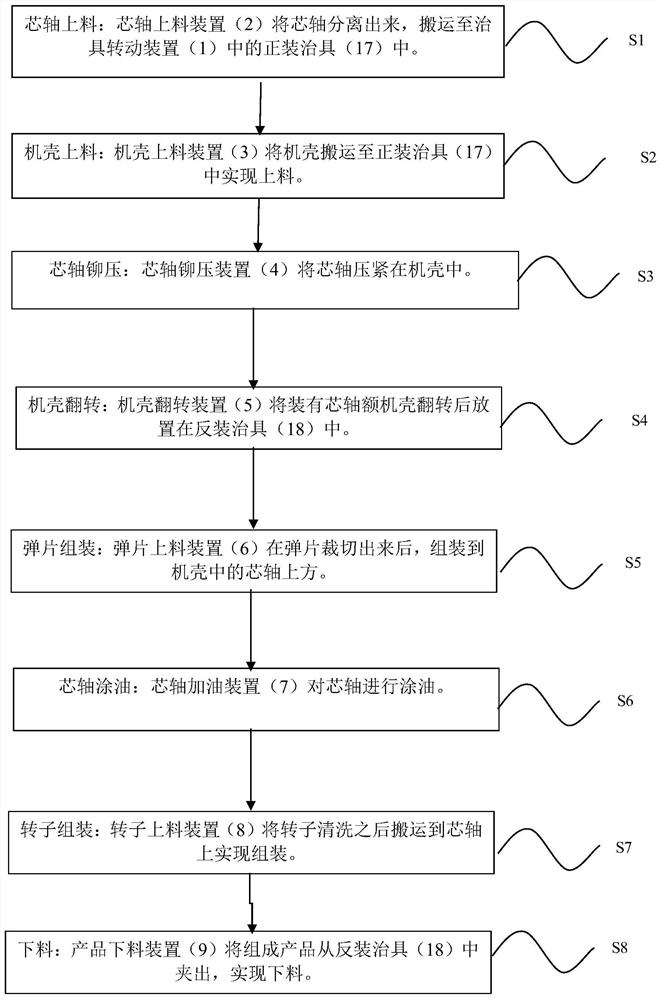

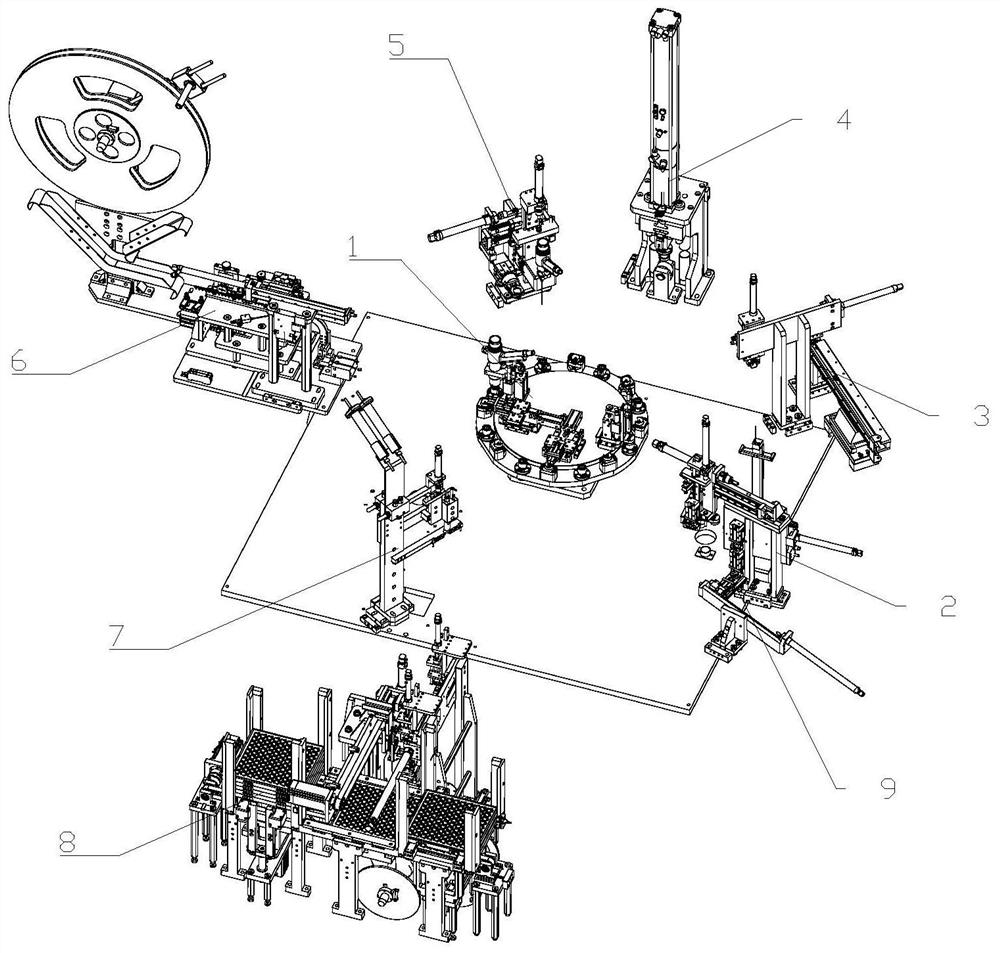

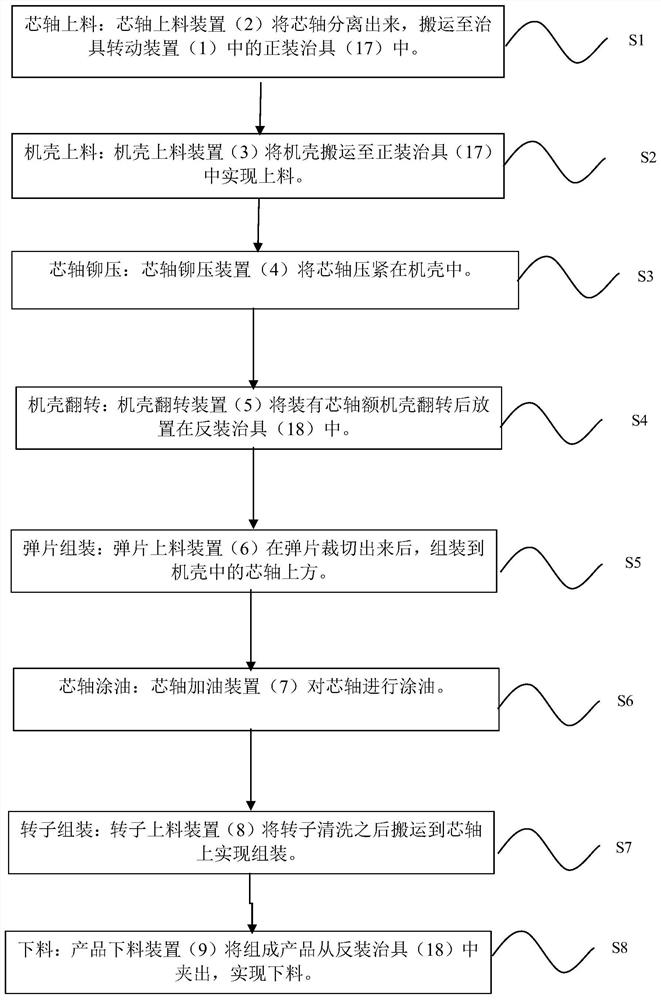

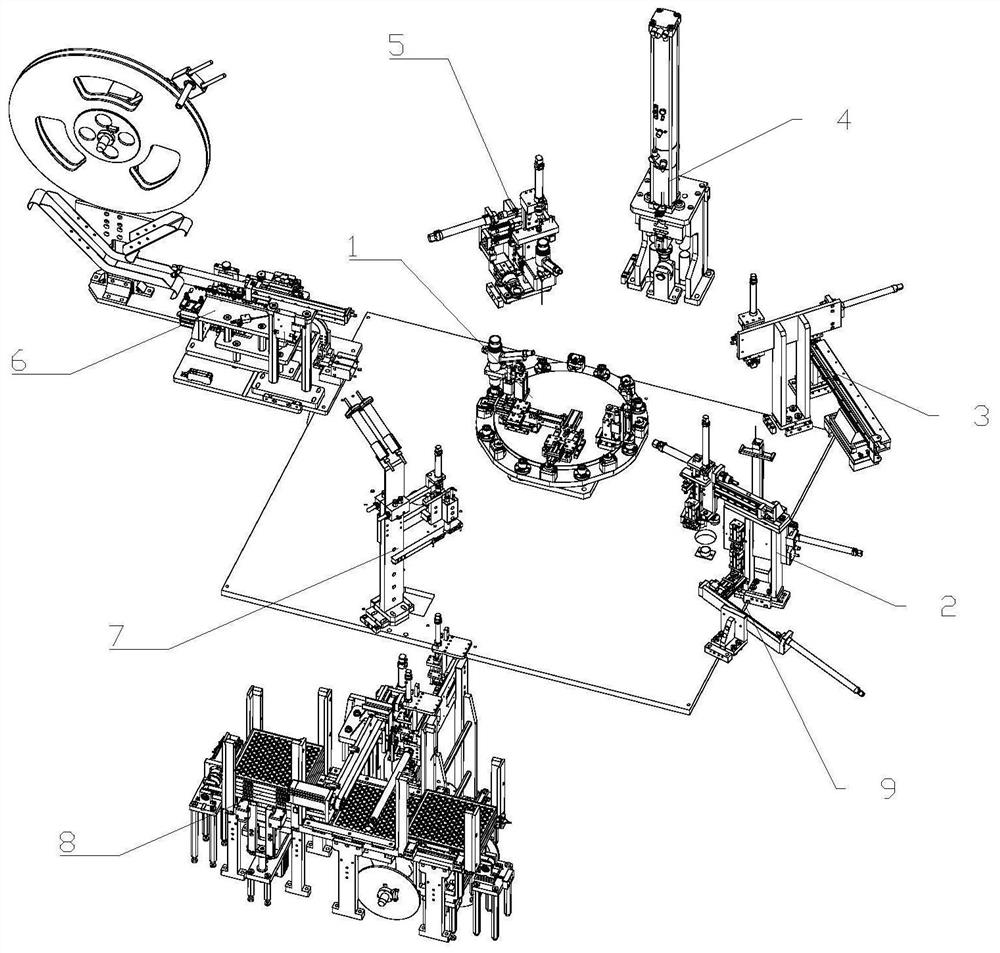

Automatic assembly production method of permanent magnet direct current motor

InactiveCN113241907AIncrease success rateImprove assembly efficiencyManufacturing stator/rotor bodiesCleaning processes and apparatusElectric machineryProcess engineering

The invention relates to the field of motor production, in particular to an automatic assembly production method of a permanent magnet direct current motor. The invention discloses an automatic assembly production method for a motor. Equipment adopted by the method comprises a rack, and a jig rotating device, a mandrel feeding device, a shell feeding device, a mandrel riveting device, a shell overturning device, an elastic piece feeding device, a mandrel oiling device, a rotor feeding device and a product discharging device which are mounted on the rack; a plurality of stations are arranged on the circumference of the jig rotating device and include a mandrel feeding station, a machine shell feeding station, a riveting station, an overturning station, an elastic piece feeding station, an oiling station, a rotor feeding station and a discharging station, and the mandrel feeding device, the machine shell feeding device, the mandrel riveting device, the machine shell overturning device, the elastic piece feeding device, the mandrel oiling device, the rotor feeding device and the product discharging device sequentially correspond to the jig rotating device by one circle in the machining direction. The equipment has the advantages that multi-station simultaneous machining is achieved, workpiece circulation is efficient, and machining efficiency is high.

Owner:陈荣乾

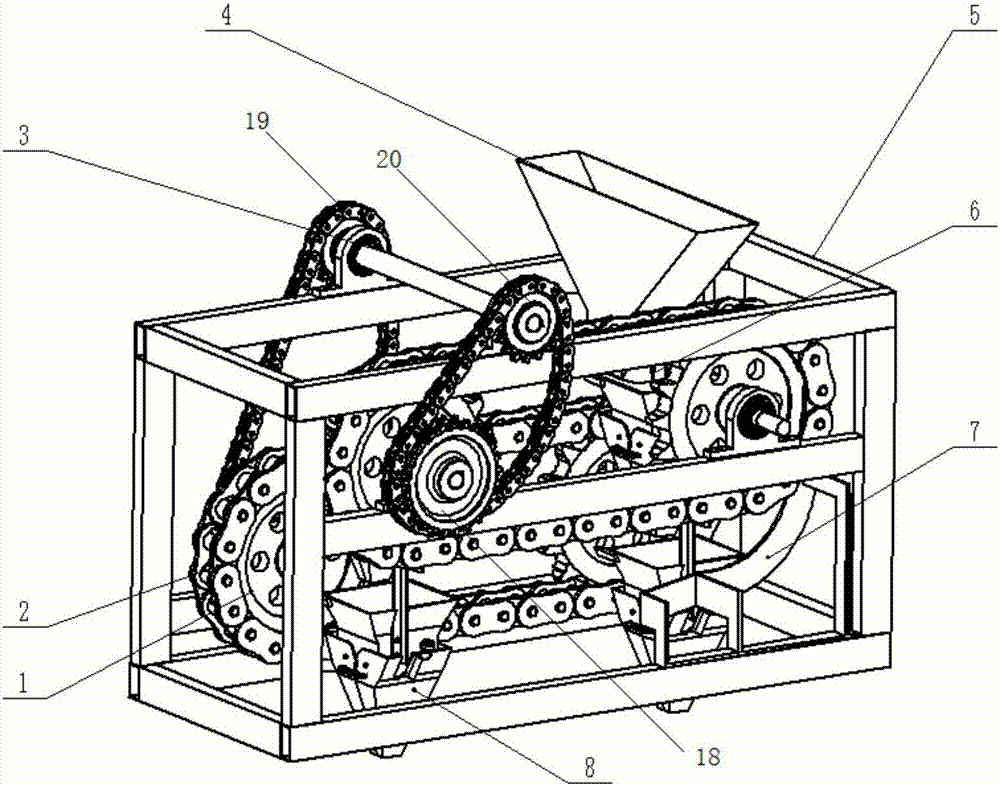

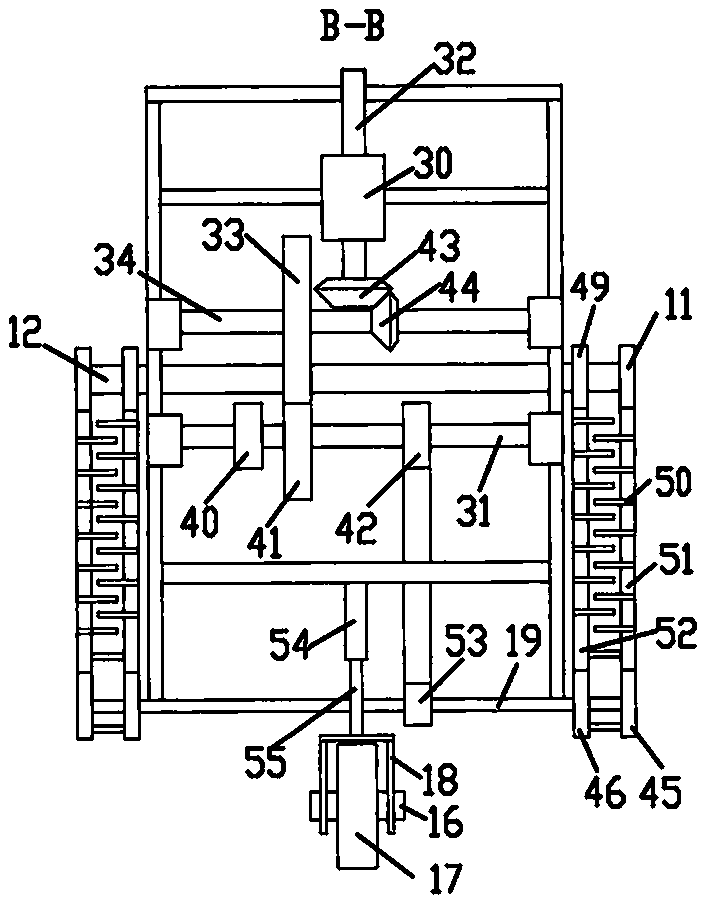

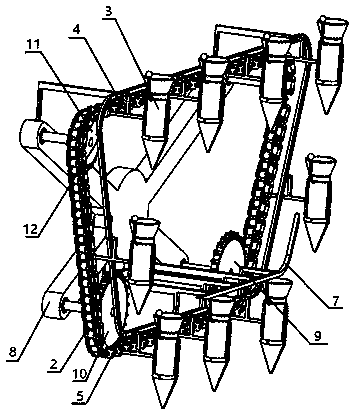

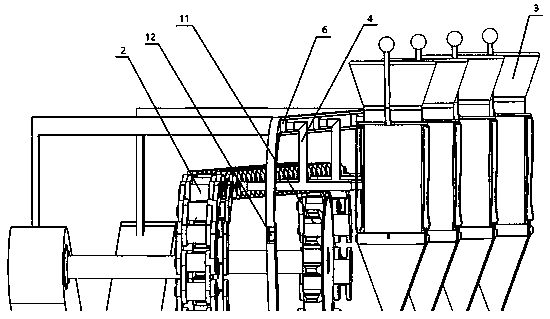

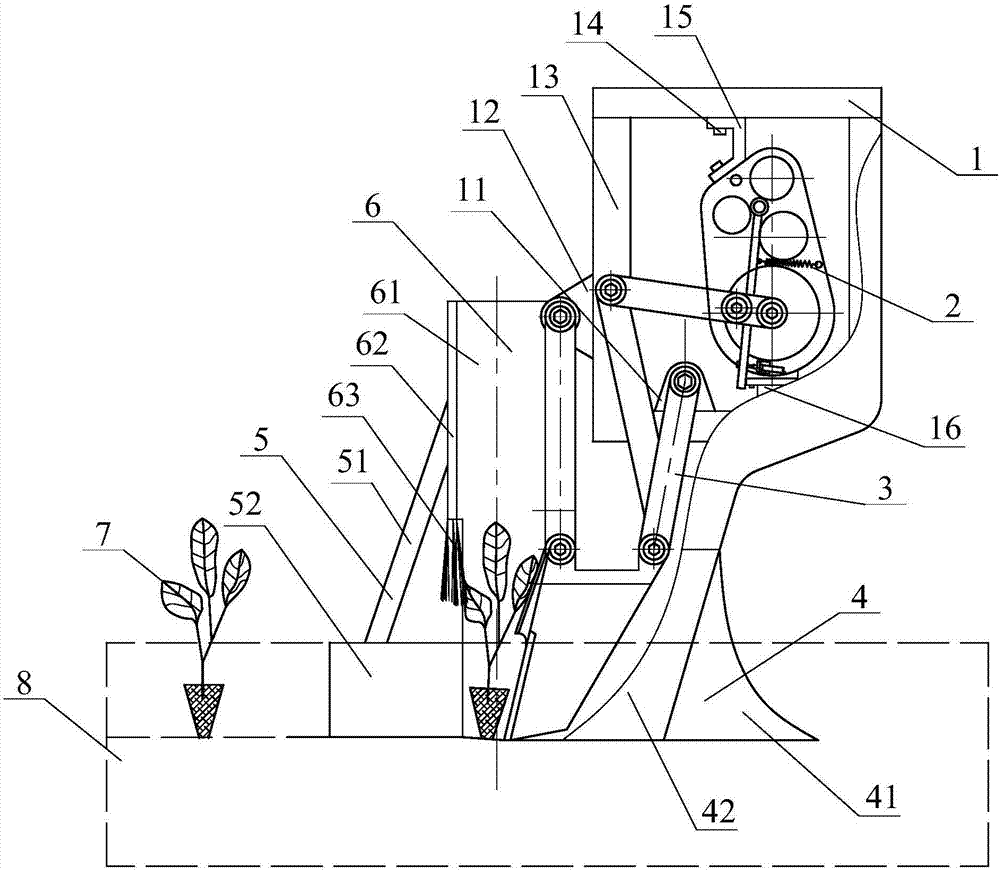

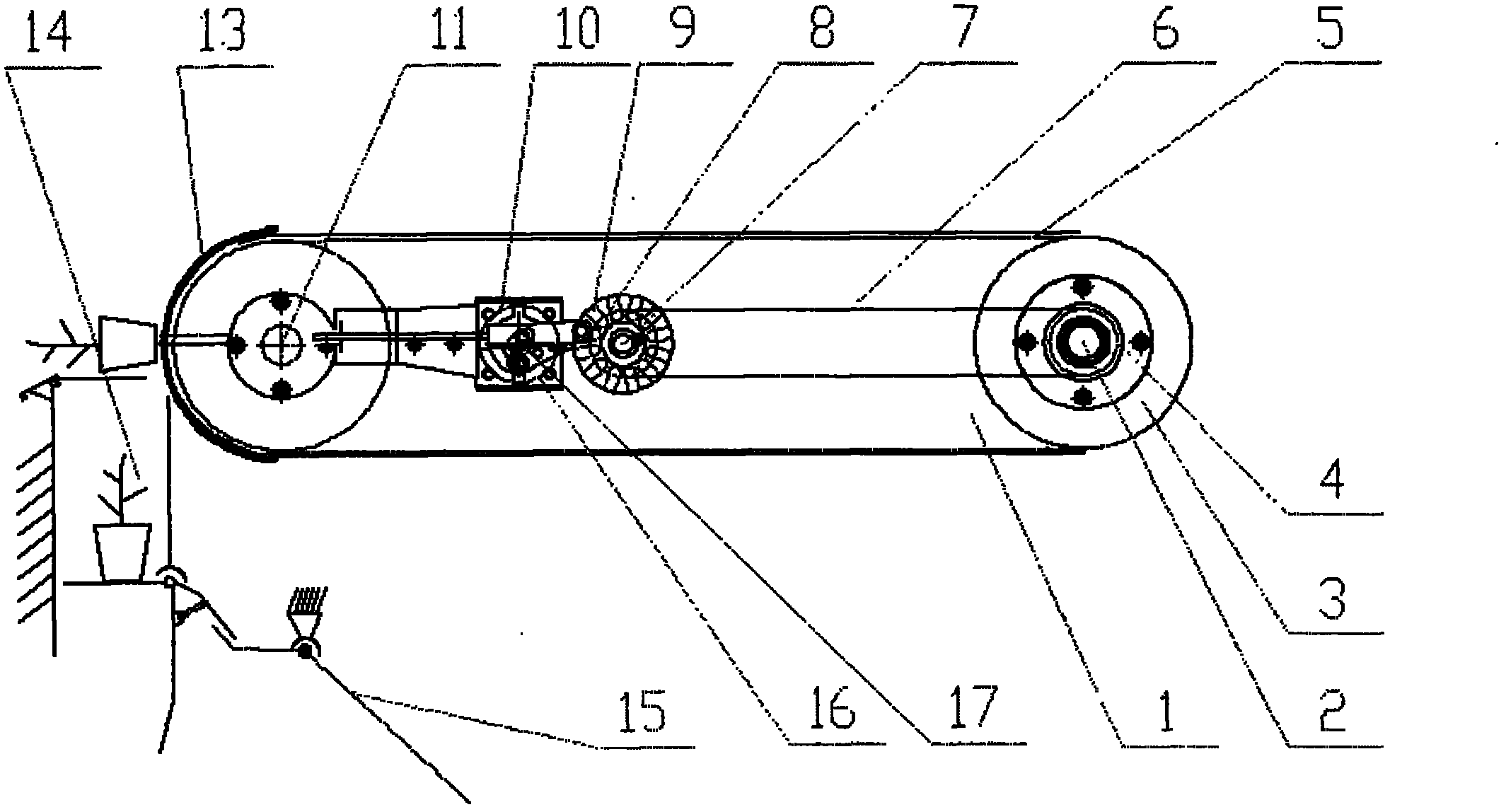

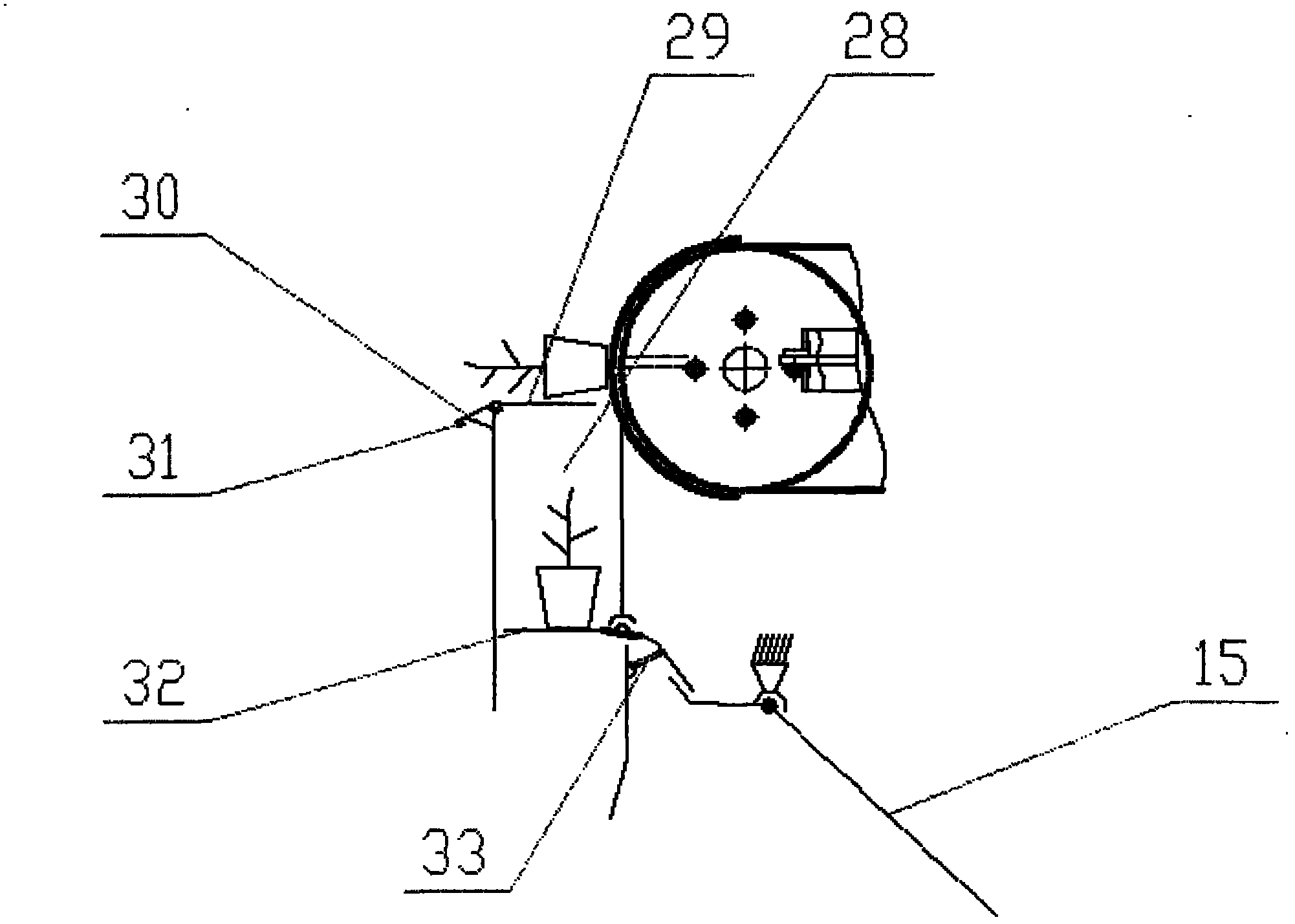

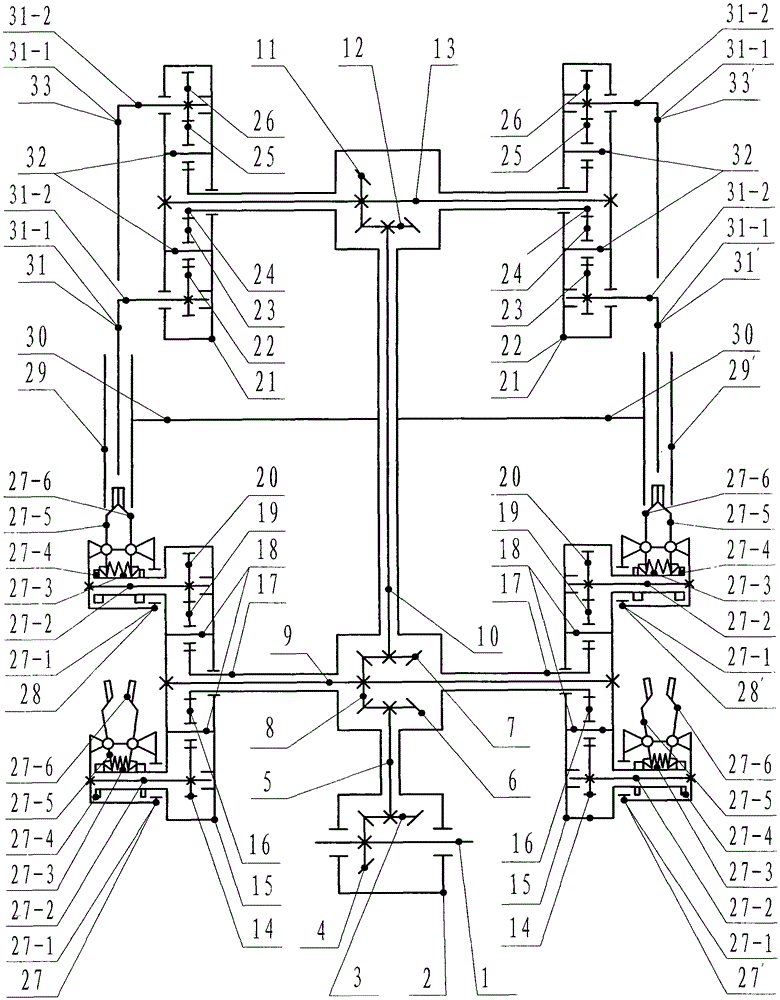

Runway-shaped hanging-cup-type zero-speed planting mechanism

InactiveCN107135722AExtension of timeReduce distractionsTransplantingFeed driveAgricultural engineering

The invention relates to a runway-shaped hanging-cup-type zero-speed planting mechanism. The planting mechanism comprises two groups of chain wheels, track chains, a plurality of hanging cups, an intermittent automatic seedling placement device, a seedling feeding driving track, a mounting rack and a transmission device, wherein the mounting rack is a cubic framework, and the seedling feeding driving track is mounted on the rear side of the mounting rack; two groups of the chain wheels are respectively mounted on the left and right sides in the mounting rack, the two track chains are respectively mounted on two group of the chain wheels, and the chain wheels are connected through the transmission device; the hanging cups are hinged to the two chain wheels at equal intervals; and a seedling receiving hopper is connected to a crossbeam on the top end of the rear side of the mounting rack, an intermittent seedling placement hole is formed in the bottom of the seedling receiving hopper, two rotating baffles below the seedling receiving hopper are respectively hinged with the seedling receiving hopper and are meshed with each other through tooth-shaped structures, a reset spring I is mounted between the two rotating baffles, and a handle is welded below one rotating baffle. By utilizing the runway-shaped hanging-cup-type zero-speed planting mechanism, the zero-speed planting is realized, and the increase of the perpendicularity of the seedlings is guaranteed.

Owner:CHINA AGRI UNIV

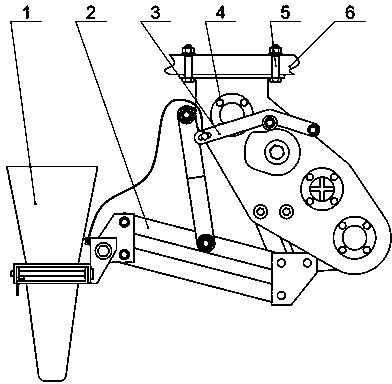

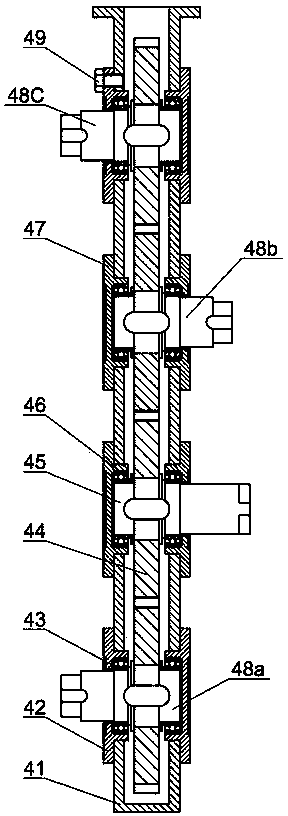

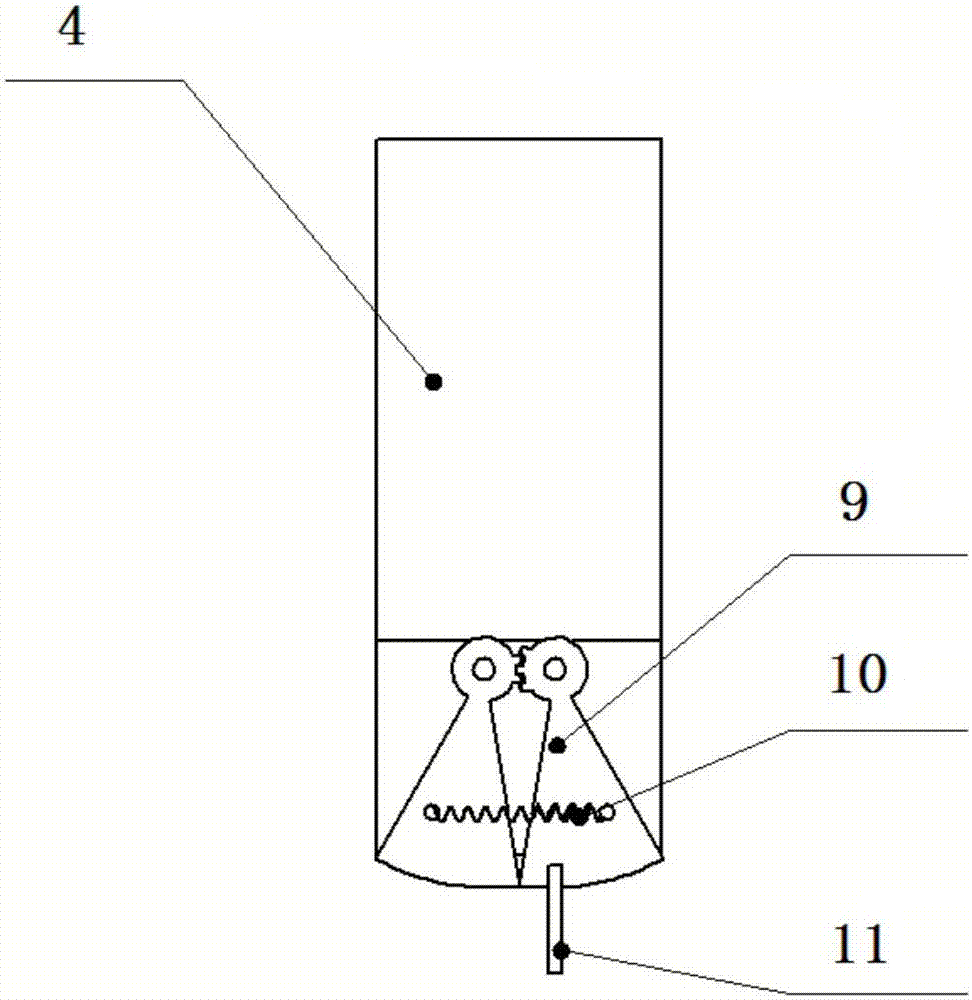

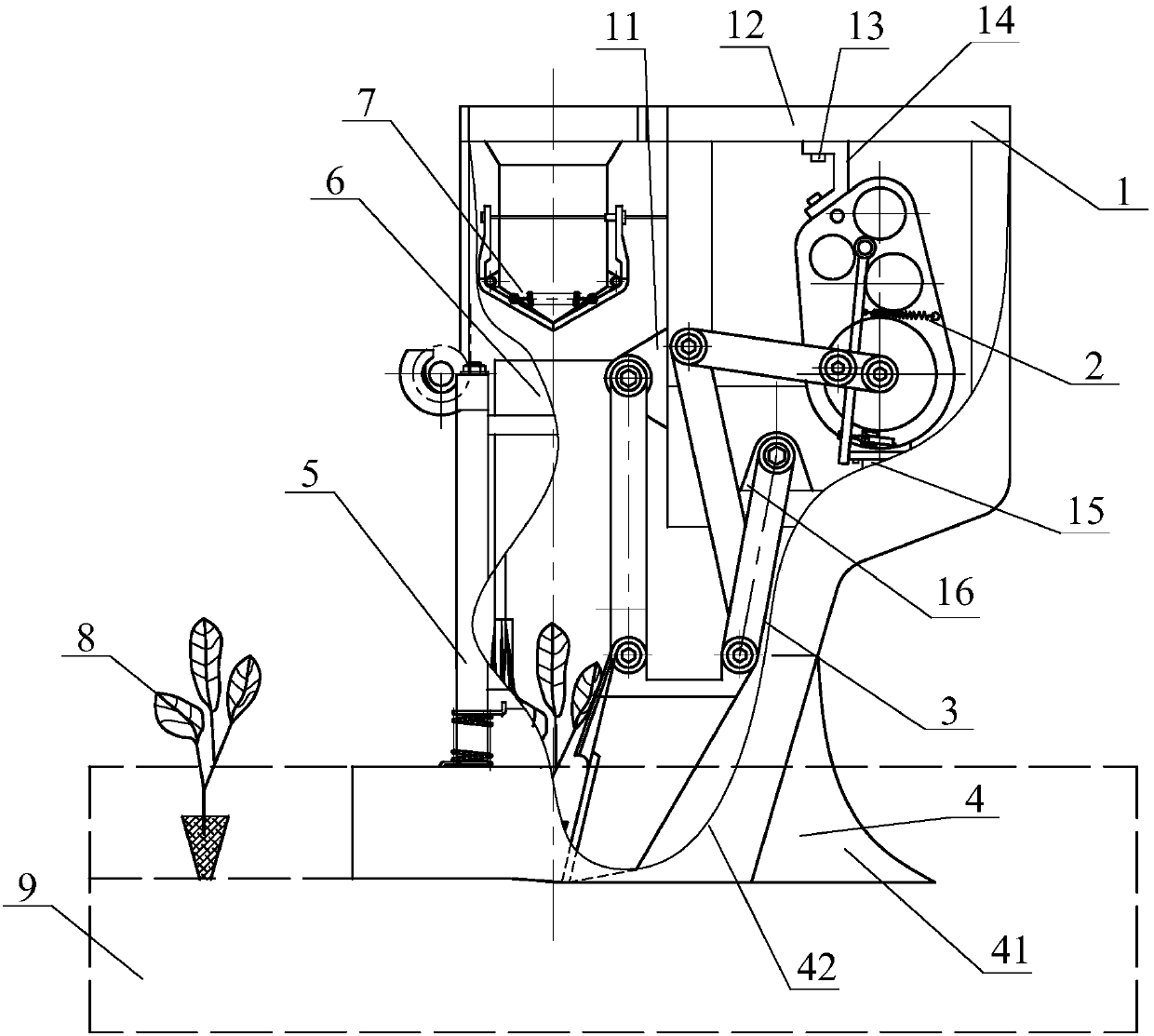

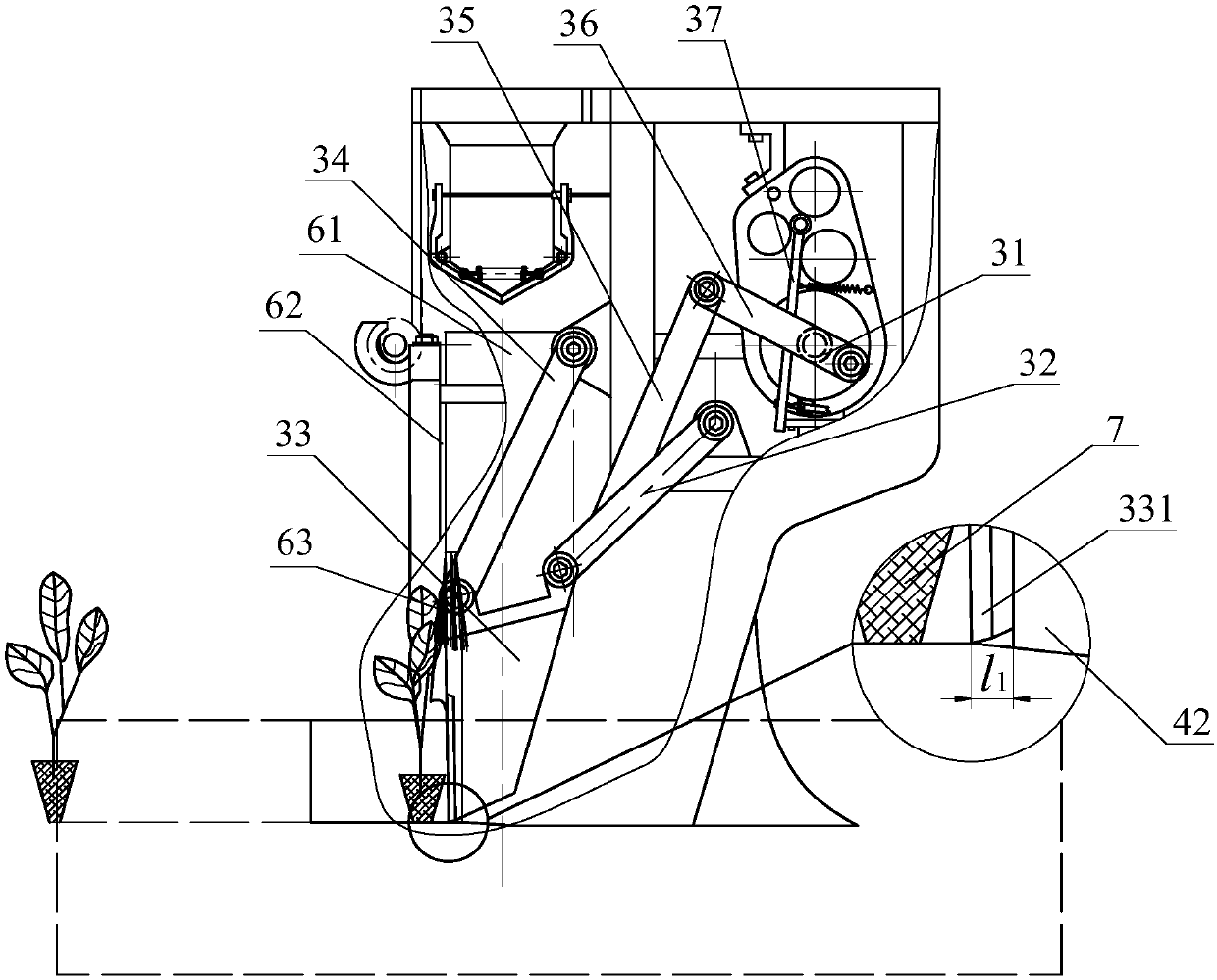

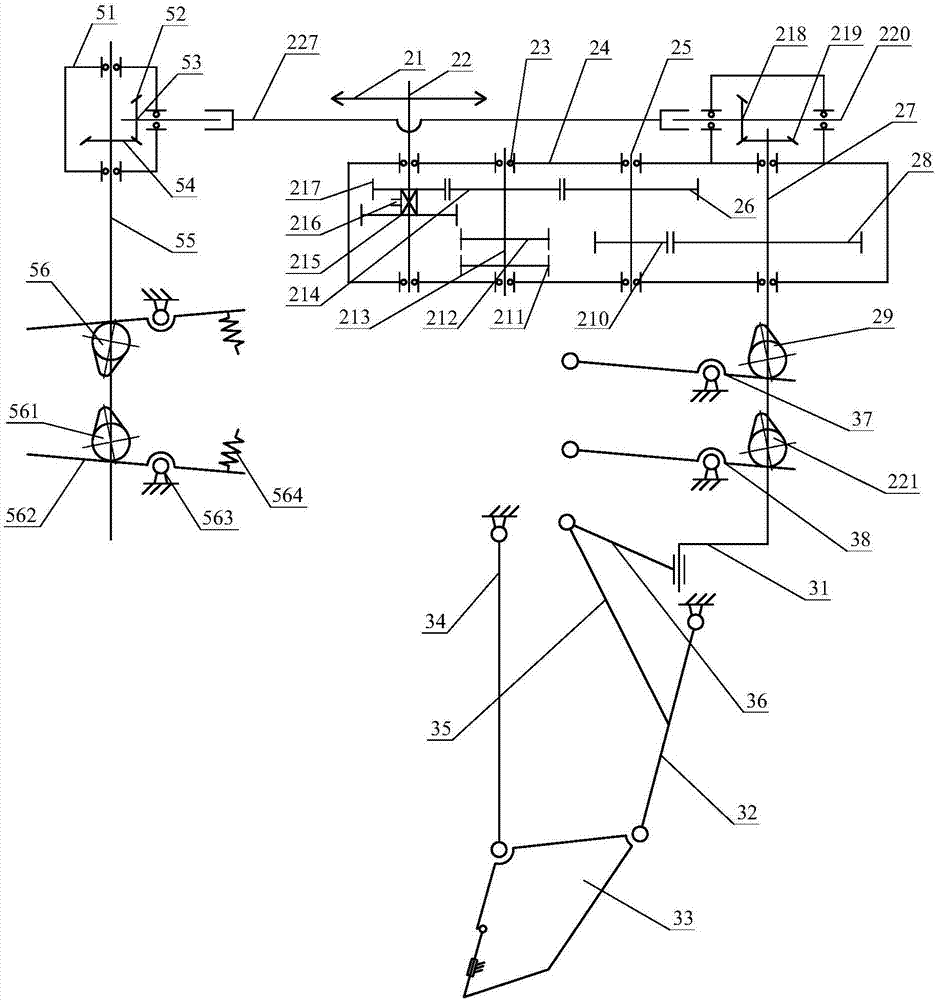

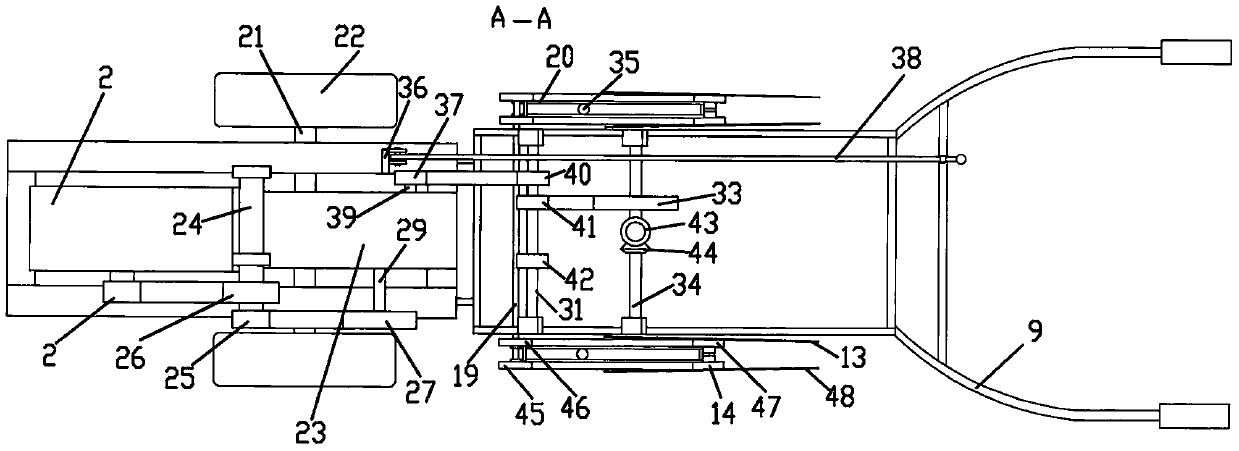

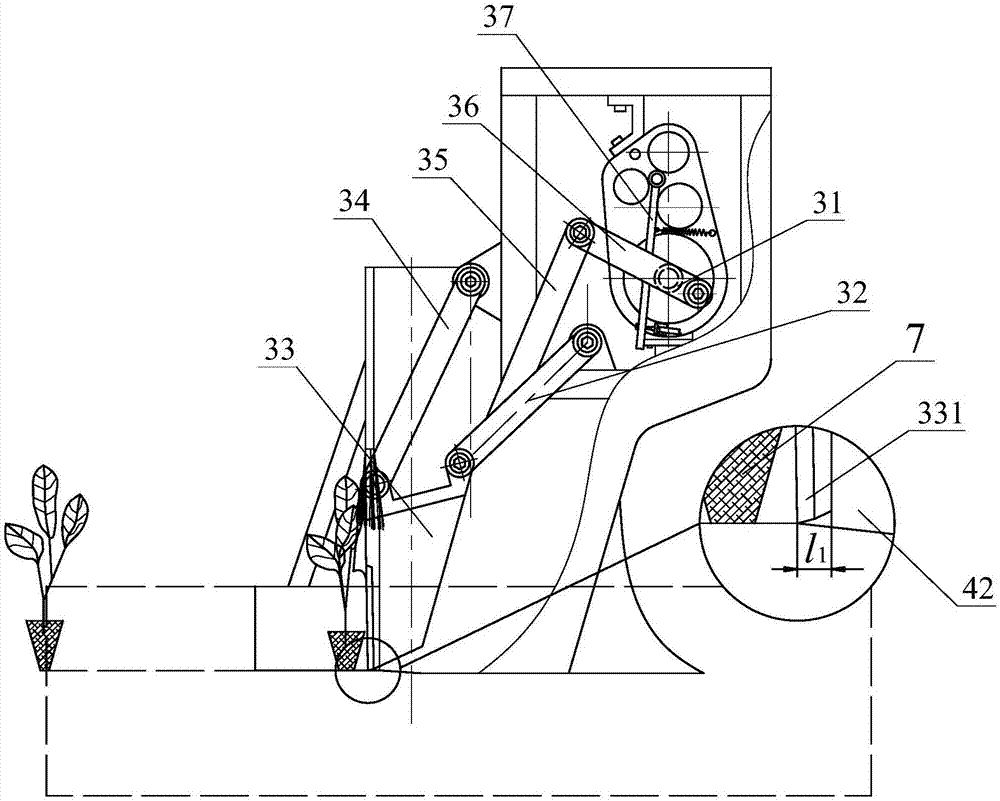

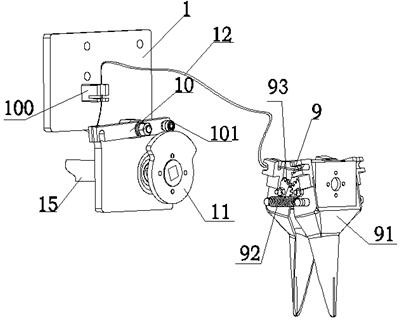

Device for longitudinal transplanting oilseed rape pot seedling in groove

ActiveCN107896590ARealize the effect of simulating manual soil transplantingImprove transplant qualityTransplantingCultivating equipmentsAgricultural engineeringMechanical engineering

The invention discloses a device for longitudinal transplanting an oilseed rape pot seedling in a groove. A rack is provided with a transmission; the transmission is connected with a planter and a soil holding device, wherein the planter and the soil holding device are installed on the rack; a furrower, a soil pushing device, a seedling guidance device and a seedling conveying cup assembly are installed on the rack; a side surface is provided with a plantation groove; the planter carries out longitudinal reciprocating type transplantation in the plantation groove; the oilseed rape pot seedlingis implanted in the backfill soil in the plantation groove, transplantation speed is effectively improved, and high efficient plantation is realized; a seedling pushing plate in the planter rotates around an own small angle while carrying out horizontal seedling pushing for preventing backward seedling and soil throwing during high-speed horizontal transplantation; horizontal and longitudinal transplantation is cooperated with the soil covering way of the soil holding plate to generate an effect on simulating manual transplantation and soil holding, and young seedling transplantation qualityis effectively improved; a cam is adopted to control a seedling conveying cup opening and closing mechanism so as to effectively improve seedling falling accuracy and row spacing consistency; a slippage shifting gear is adopted to form a three-gear regulation function of sparse row spacing, middle row spacing and close row spacing so as to adapt to the requirements of the oilseed rape plantation density of different parcels of rice field.

Owner:HUNAN AGRICULTURAL UNIV

Transplanting method for performing longitudinal control in rape pot seedling ditch

ActiveCN107980299AReduce the amount of dozingImproving the uprightness of transplantingCleaning using toolsTransplantingStart stopEngineering

The invention discloses a transplanting method for performing longitudinal control in a rape pot seedling ditch. A rape pot seedling transplanting operation is carried out by an inner-ditch longitudinal transplanting machine; a transmission gear is arranged on a frame of the inner-ditch longitudinal transplanting machine; the transmission gear is connected with a planting device and a soil holdingdevice mounted on the frame; a ditcher, a bulldozer, a seedling guiding device and a seedling conveying cup assembly are mounted on the frame; a planting ditch is formed on a ridge side; the plantingdevice is used for performing reciprocating transplanting along a horizontal-longitudinal direction in the planting ditch in order to plant the rape pot seedlings into reclaimed soil of the plantingditch, so that the transplanting speed is increased effectively; a seedling pushing plate of the planting device is used for pushing the seedlings and can rotate at a small angle to prevent backward throwing of seedlings and soil during high-speed horizontal transplanting; the horizontal longitudinal transplanting is performed together with earthing by a soil holding plate in order to simulate manual transplanting and soil holding, and effectively enhance the seedling transplantation quality; a starting-stopping mechanism of a seedling conveying cup is controlled through a cam, so that the seedling dropping accuracy and row spacing consistency are improved effectively; multi-gear adjustment is performed by adopting a slide shifting gear in order to meet the requirement on different planting densities.

Owner:SUZHOU SABO IND DESIGN

Flexible disc type green Chinese onion automatic transplanter

The invention relates to a flexible disc type green Chinese onion automatic transplanter which comprises a traction support and a power device. A seedling put-in device, a seedling collecting and placing device, a seedling dividing device and a seedling planting device which are driven by the power device are arranged on the traction support. The seedling put-in device comprises an automatic intermittent seedling dividing device and an automatic intermittent whole-row seedling put-in device. The automatic intermittent seedling dividing device comprises a plurality of seedling put-in rods connected with the power device through a transmission device and corresponding to all bottom holes of a seedling culture disc. The automatic intermittent whole-row seedling put-in device comprises at least two seedling put-in device supports fixedly connected with the traction support and a disc driving mechanism for driving the seedling culture disc to do stepping movements in stepping grooves in theseedling put-in device supports. The seedling collecting and placing device comprises a seedling collecting handle assembly located on the seedling output side of the seedling culture disc and a seedling collecting transmission mechanism for driving the seedling collecting hand assembly to reciprocate in the seedling collecting and placing direction. The seedling dividing device comprises a transverse green Chinese onion seedling conveying device located on the seedling discharge side of the seedling collecting and placing device and a vertical green Chinese onion seedling conveying device located on the seedling output end of the transverse green Chinese onion seedling conveying device.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

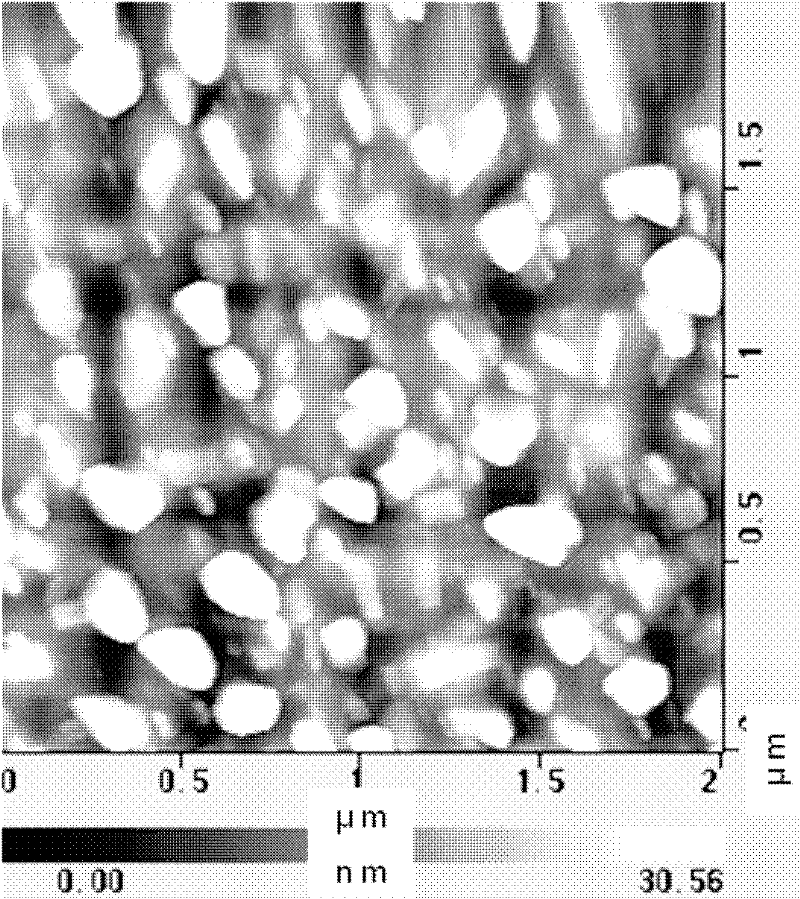

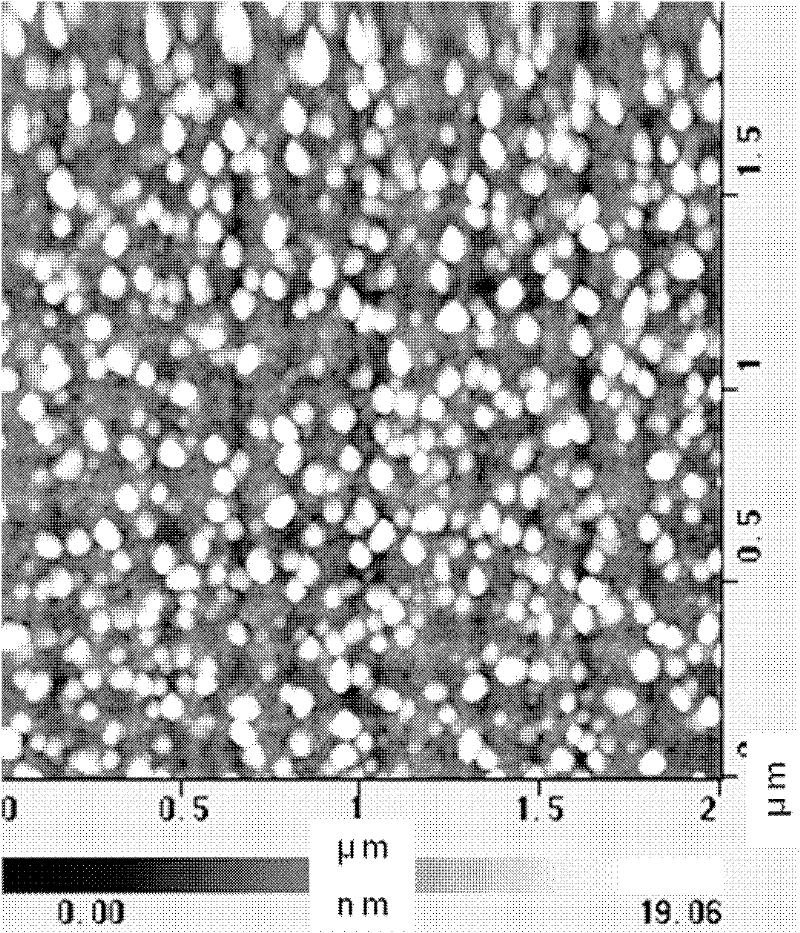

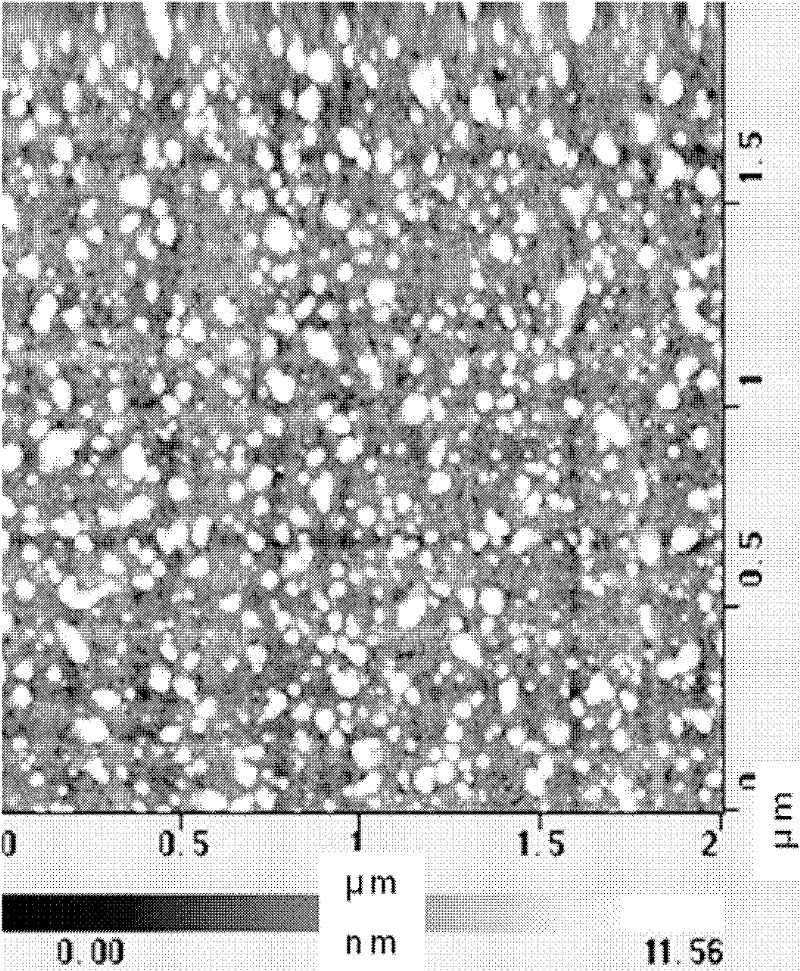

Method for affecting growth morphology of carbon nanotubes by controlling hydrolysis degree

InactiveCN102249216AImprove uprightnessImproved growth processNanotechnologyTube furnaceCarbon nanotube

The invention relates to a method for affecting growth morphology of carbon nanotubes by controlling hydrolysis degree, and the method comprises the following steps: (1) preparing a precursor liquid film containing iron ions; (2) baking a substrate to which the precursor liquid film is attached in a constant-temperature oven for a certain time until the substrate is dried; (3) placing the dried substrate in the constant-temperature region of a tubular furnace for annealing treatment; (4) preparing an iron catalyst film with controllable particle size and density; and (5) preparing carbon nanotube arrays with different lengths and morphologies: heating the substrate to a certain temperature in the tubular furnace, introducing acetylene and argon, and decomposing acetylene gas on the surface of the film containing the iron catalyst particles to precipitate vertical carbon nanotube arrays. The method provided by the invention has the beneficial effects that: the purpose that the growth morphology of the carbon nanotubes is affected by controlling the hydrolysis degree is realized, an unexpected effect is acquired, the carbon nanotube growth process is effectively optimized, and the industrial production cost is lowered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Double-row little pepper transplanter

The invention discloses a double-row little pepper transplanter which comprises a rack, wherein an engine and a reduction gearbox are fixedly connected to the rack; the lower end of the reduction gearbox is rotationally connected with a front wheel; a power output chain wheel is arranged at the upper end of the reduction gearbox; a one-axle one-chain wheel is in transmission connection with the power output chain wheel, and a one-axle two-chain wheel is in transmission connection with a three-axle chain wheel; a vertical shaft bevel gear is meshed with a three-axis bevel gear; the upper end ofa vertical shaft penetrates through the center of a seedling cup tray and is fixedly connected with the seedling cup tray; a seedling cup is fixedly connected onto the seedling cup tray; a seedling supporting rack is arranged on two sides of the rack; a first supporting belt pulley, a first seedling supporting belt pulley and a first earthing belt pulley are in transmission connection with one another by virtue of a first seedling supporting belt; a second supporting belt pulley, a second seedling supporting belt pulley and a second earthing belt pulley are in transmission connection with oneanother by virtue of a second seedling supporting belt; seedling supporting strips are uniformly arranged between the first seedling supporting belt and the second seedling supporting belt in a crossmanner; one ends of the seedling supporting strips are fixedly connected with the surface of the seedling supporting belts, and the other ends of the seedling supporting strips are suspended; and a seedling dropping pipe and a furrow opener are arranged on two sides of the rack. The operating speed is high, and excellent little pepper seedling upright degree, row spacing uniformity and depth stability can be ensured.

Owner:潘颍芳

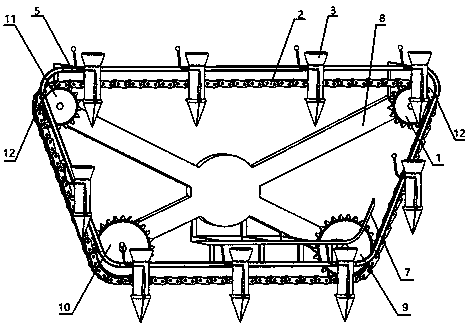

Chain-rail combined type planting device

The invention discloses a chain-rail combined type planting device. The chain-rail combined type planting device comprises a star frame, a chain, four sprockets, a parallel rail, connecting rod racksand planting tubes and is characterized in that the chain is supported by the four sprockets and annularly distributed; the included angle between the ground horizontal chain section of the chain andeach of the adjacent left and right chain sections is an obtuse angle; one end of each connecting rod rack is hinged to one chain link plate, a slide wheel which can roll in the parallel rail is hinged to the other end of each connecting rod rack, and the extension end of the connecting rod rack is fixedly connected with one planting tube; the shape of the parallel rail is completely identical with that of the chain, the parallel rail has certain offset relative to the chain transmission system, and the parallel rail is provided with two notches and one drive guide rail; the drive guide rail on the parallel rail is used to control the opening and closing of the duckbill of each planting tube to complete seedling planting. The chain-rail combined type planting device has the advantages thatthe planting tubes can be kept in a translational motion state in the whole operation process, zero-speed vertical planting and transplanting can be achieved, and high-speed transplanting can be achieved.

Owner:SHIHEZI UNIVERSITY

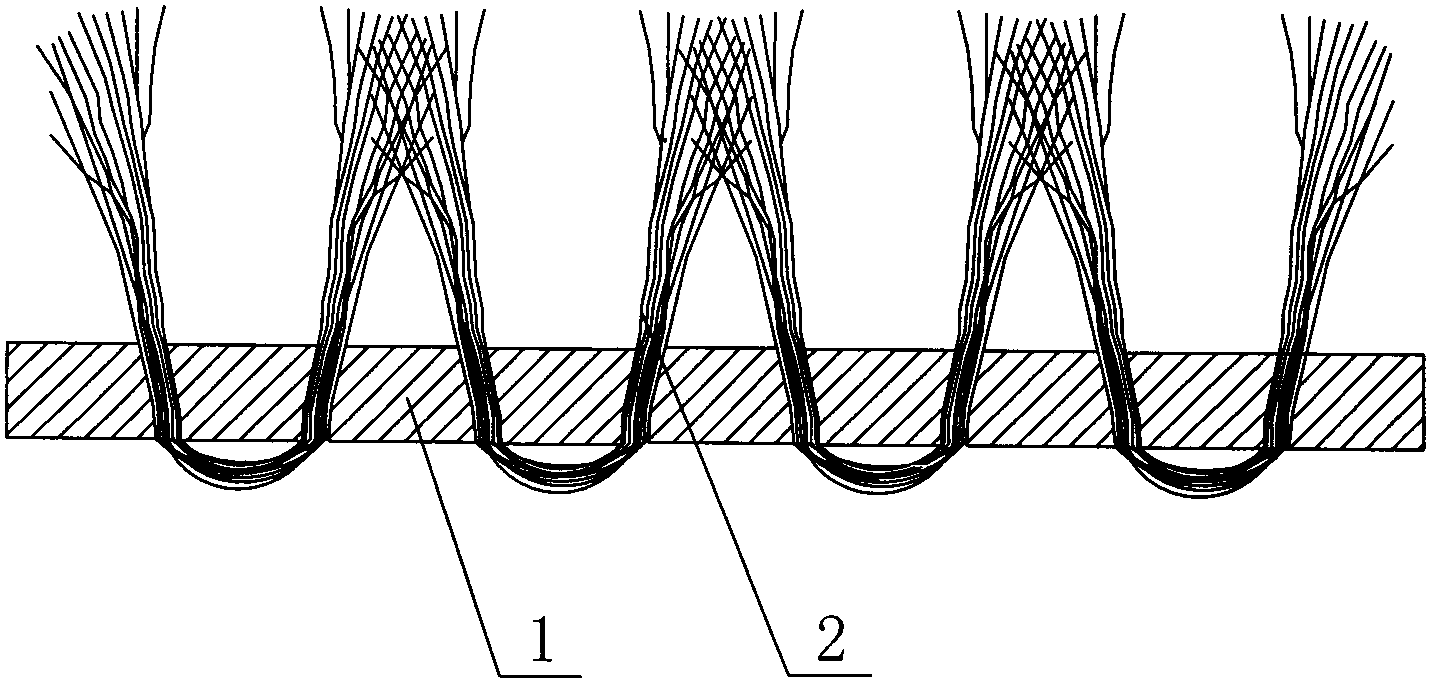

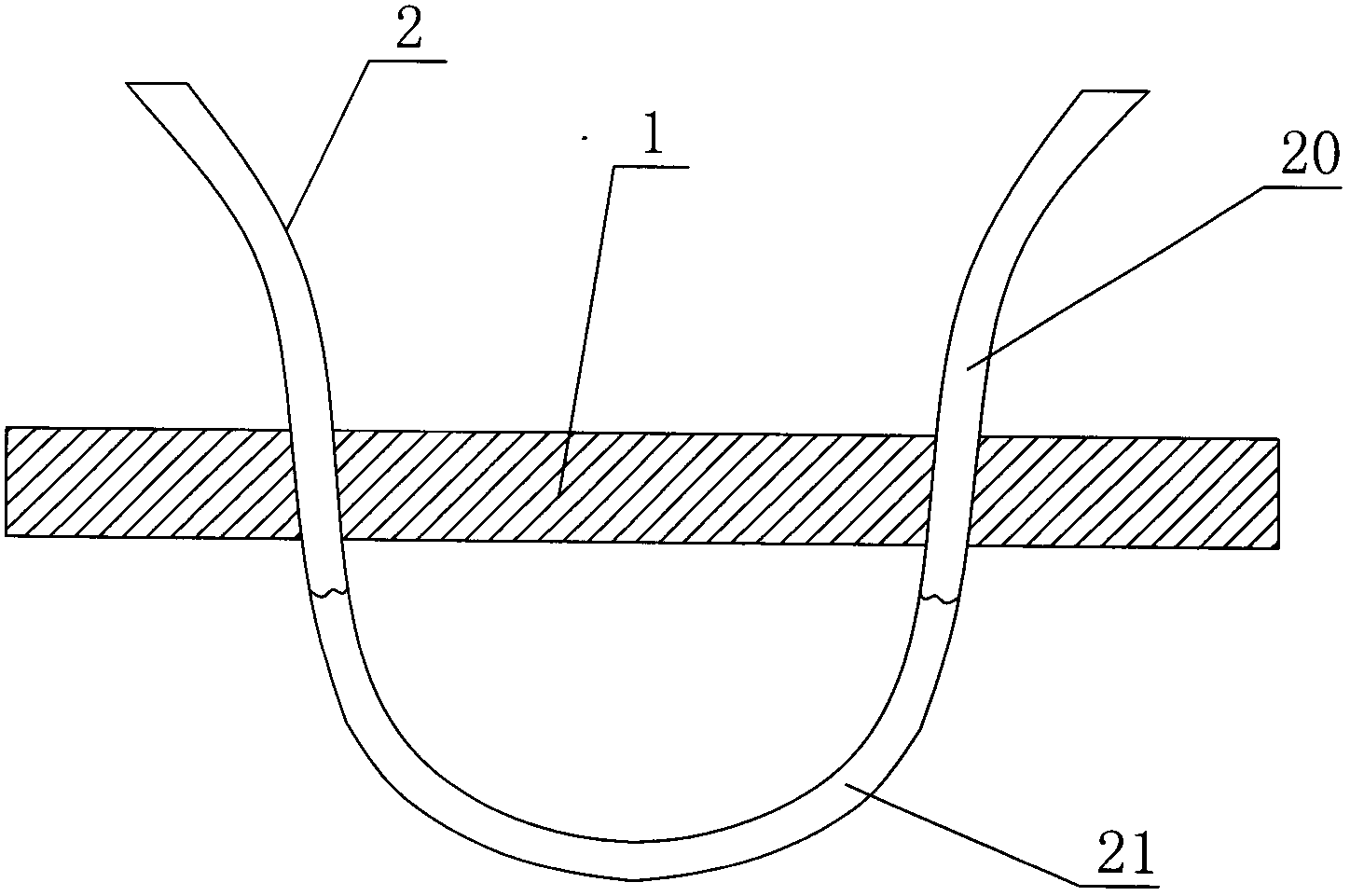

High-simulation artificial grass

The invention discloses high-simulation artificial grass, which comprises simulation grass blades made of plastic and a base, wherein the simulation grass blades are arranged on the base, and at least one water storage channel is formed on each simulation grass blade. The water storage channel of the high-simulation artificial grass can store a certain amount of water, and the temperature of a lawn can be lowered through the evaporation of moisture in a high-temperature environment, thereby prolonging the service life of the lawn; at the same time, the temperature of the surrounding environment can be reduced through moisture evaporation, thereby enhancing the comfort degree of the environment; the water in the water storage channel can effectively lock dust in the surrounding environment, thereby preventing the dust flying around, and purifying the surrounding environment; and in addition, the erectness of the grass blades can be enhanced through the water storage channel, thereby enhancing the simulation effect.

Owner:无锡润翔新材料科技有限公司

Pile driver for engineering

ActiveCN109736306ASimple structureEasy to operateEarth drilling toolsBulkheads/pilesArchitectural engineeringPile driver

The invention belongs to the technical field of pile drivers, and specifically relates to a pile driver for engineering, including a support block, a mud guard, a brush, a first telescopic rod, a sleeve, a third telescopic spring, a sliding rod, a sleeve frame, an impact hammer, a clamping groove, a rotating plate, a first telescopic spring, a round plate, a first jack, a shaft rod, a mounting box, a motor, a square column, a threaded drill bit, a rotating disc, a second telescopic rod, a mud scraping plate, a second jack, a base, a second supporting spring, a mounting groove, a supporting frame, a cover plate, a hook, a fixing bolt and a bail. According to the pile driver for engineering, pile driving can be better carried out, a wood pile can be better prevented from being obliquely driven into soil, and therefore the pile driving uprightness is greatly improved, and meanwhile the pile driving efficiency is improved. According to pile driver, dust and soil can be better protected, environmental pollution caused by the dust is avoided, the dust is prevented from entering the lung of a worker to cause infection, and meanwhile soil drilled by a threaded drill rod is prevented from falling into a drilled hole.

Owner:涡阳县禾淼建筑工程有限公司

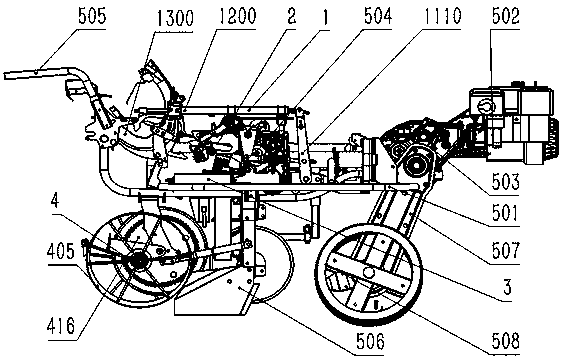

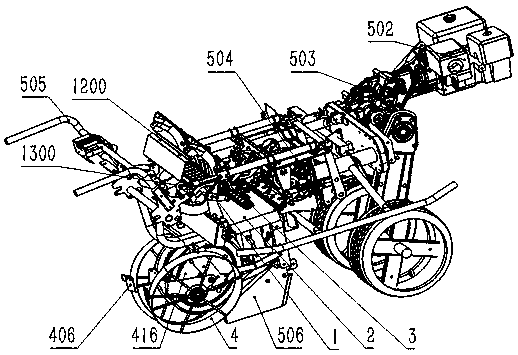

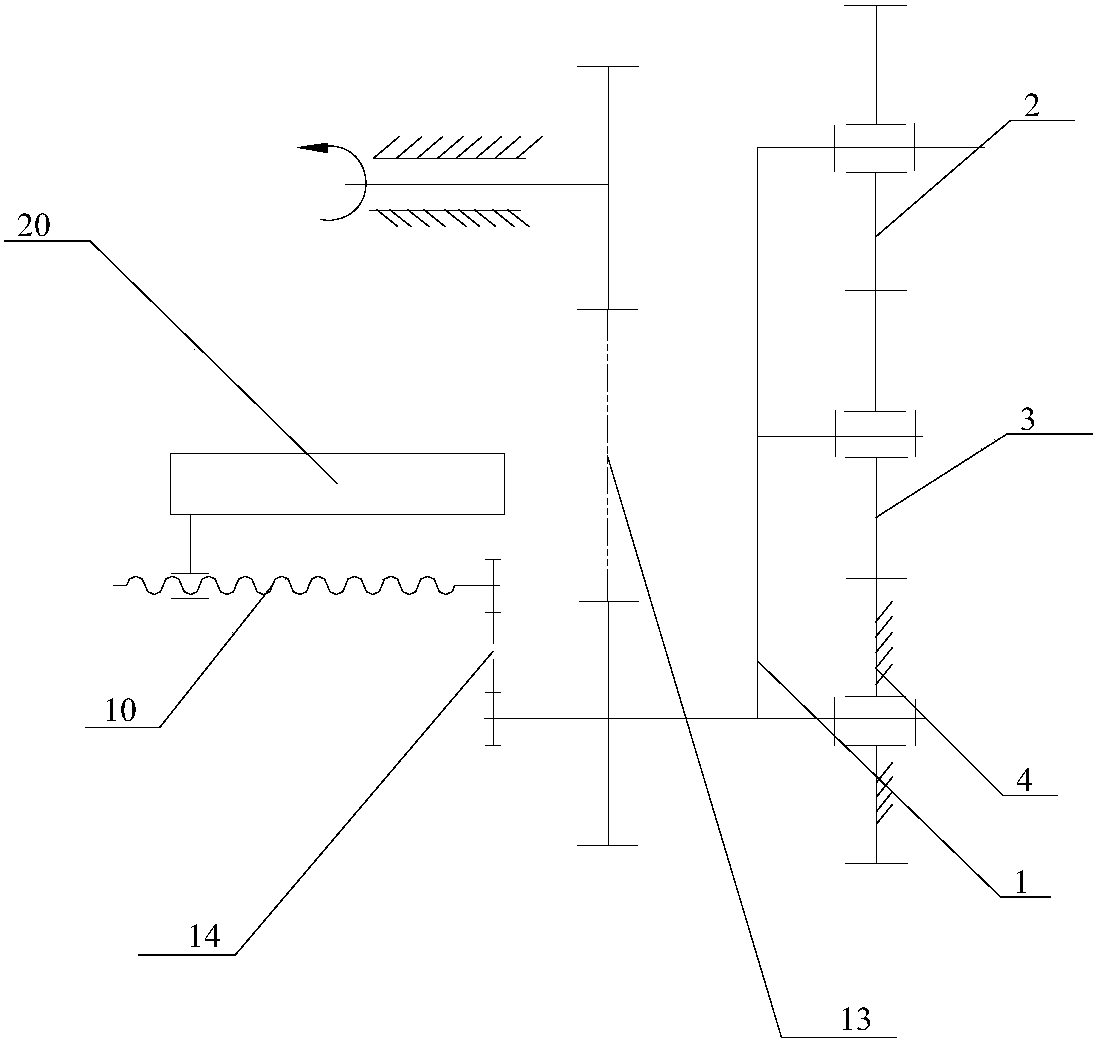

Ridge height self-adaption seedling digging planting machine

PendingCN106538124AImprove uprightnessDeep stabilityTransplantingFurrow making/coveringControl switchSeedling

The invention discloses a ridge height self-adaption seedling digging planting machine. The ridge height self-adaption seedling digging planting machine comprises a ridge height sensor, a digging plough, a rear wheel, a planting part, an operation handrail, a seedling releasing device, a seedling planting gearbox, a connecting rod mechanism, a seedling storage rack, a hydraulic system, a walking gearbox, an engine, a rack and a front wheel, wherein the ridge height sensor is arranged below the rack; the seedling planting gearbox, the walking gearbox and the engine are arranged on the rack; the front wheel is arranged at the front end of the rack; an output shaft of the engine is connected to an input shaft of the walking gearbox; the walking gearbox is provided with three output shafts; the seedling storage rack is arranged at the top of the machine; the seedling planting gearbox is provided with three output shafts; the operation handrail is fixed on the rack; and various control switches are arranged on the operation handrail. The ridge height self-adaption seedling digging planting machine has the advantages of simultaneous completion digging and planting, high degree of automation, stable seedling planting depth and good row spacing consistency.

Owner:SICHUAN RES & DESIGN INST OF AGRI MACHINERY

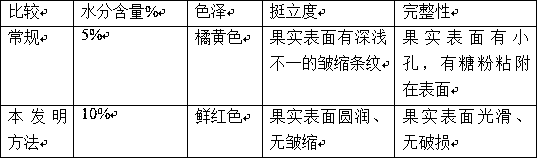

Processing method and application of slightly lyophilized Chinese wolfberries

ActiveCN108041153AReduce microbial contentReduce pesticide residuesFruit and vegetables preservationFreeze-dryingNatural state

The invention discloses a processing method of slightly lyophilized Chinese wolfberries. The method comprises the following steps of soaking, cleaning, freeze-drying protection and freeze-drying. Themethod mainly relates to the following steps in detail: adding a freeze-drying protective agent containing 1-10% w / w of trehalose and 0.5-1% w / w of calcium chloride to washed Chinese wolfberries; uniformly spraying the protective agent on the surface of the Chinese wolfberries by adopting atomization spray heads; putting the Chinese wolfberries into a freeze-drying machine, and starting vacuumizing under the condition of no heating and no freezing; keeping a negative pressure for 10 to 30 minutes as the pressure drops to 60 Pa; and maintaining a vacuum degree for 2-5h. according to the lyophilized fresh Chinese wolfberry fruits produced by adopting a vacuum freeze-drying technology, the method maintains the original natural state of fresh Chinese wolfberry fruits, and the color, the appearance shape and the appearance and mouth feel after rehydration of the lyophilized Chinese wolfberry fruits are basically the same as that of the picked fresh Chinese wolfberry fruits. The method maintains the integrity and stiffness of dried Chinese wolfberry cells, and reduces the production cost of products, and the products are easier to preserve in marketing sale process.

Owner:早康枸杞股份有限公司

Alpine- semiarid-area alfalfa seeding method

InactiveCN107360834APromote growthDoes not cause deathFertilising methodsPlant cultivationHuman fertilizationDouble fertilization

The invention discloses an alpine-semiarid-area alfalfa seeding method. The method includes steps: variety selection, fine soil preparation, formula fertilization and mulching precise hole sowing, wherein the step of formula fertilization specifically includes: analyzing and testing soil nutrient of a planting land plot, preparing organic compound fertilizer according to nutritional needs of alfalfa and condition of soil nutrient, and applying the prepared compound fertilizer onto the planting land plot; the step of mulching precise hole sowing includes full mulch covering, earthing and compacting and holing and hole sowing, full mulch covering refers to fully covering the planting land plot after going through the step of formula fertilization with mulch, earthing and compacting refers to covering the mulch with a layer of soil, and holing and hole sowing refers to holing the mulch after going through earthing and compacting and sowing alfalfa seeds in holes and then earthing. By the method, wintering rate of alfalfa can be ensured effectively, seedling emergence rate of alfalfa can be increased, unit area yield of alfalfa can be increased, mechanical action is facilitated, and convenience is brought to harvesting.

Owner:QINGHAI ACAD OF ANIMAL SCI & VETERINARY MEDICINE

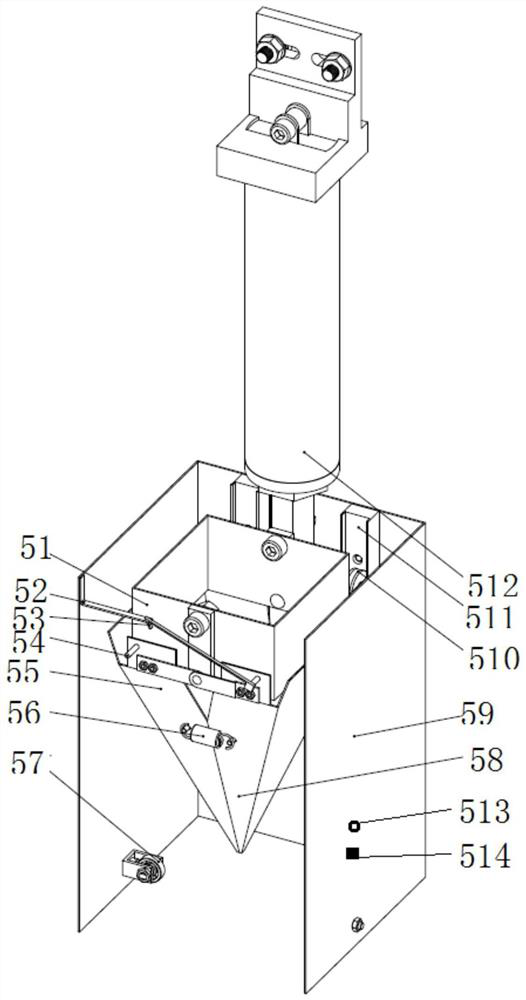

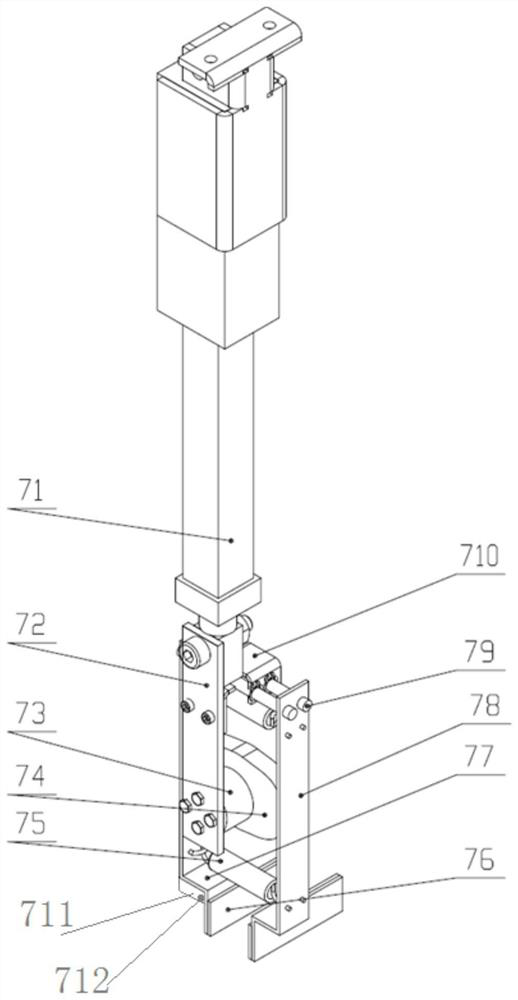

Seedling transplanting and planting integrated machine suitable for greenhouse

PendingCN113330876AImprove uprightnessImprove planting qualityTransplantingFurrow making/coveringAgricultural scienceAgricultural engineering

The invention discloses a seedling transplanting and planting integrated machine suitable for a greenhouse. The seedling transplanting and planting integrated machine comprises a rack, a storage battery and a controller, wherein the storage battery and the controller are arranged on the rack, a moving assembly is arranged at the bottom of the rack, the rack is provided with a parking device corresponding to the moving assembly, a seedling tray fixing mechanism is arranged in the rack, two cam seedling clamping mechanisms and two planting mechanisms corresponding to the seedling tray fixing mechanism are also arranged in the rack, and two screw rod mechanisms corresponding to the cam seedling clamping mechanisms are arranged at the top of the rack; and under the condition that to-be-transplanted seedlings are placed in the seedling tray fixing mechanism, the controller is used for controlling the two cam seedling clamping mechanisms to clamp the to-be-transplanted seedlings to the corresponding planting mechanisms and controlling the planting mechanisms to plant the to-be-transplanted seedlings. According to the seedling transplanting and planting integrated machine, in-situ shutdown planting is adopted, the upright degree is high after pot seedlings are planted, the planting quality is high, the integrated operation of punching, seedling taking and seedling planting is achieved on the basis, the integration degree is higher, meanwhile, unnecessary labor force is reduced, and the operation efficiency is improved.

Owner:XIAN UNIV OF TECH

Transplanting method for horizontal-reciprocating control of rape pot seedlings

A transplanting method for horizontal reciprocating control of rape pot seedlings includes: adopting a rape pot seedling horizontal-reciprocating transplanting machine to implement horizontal-reciprocating transplanting; and utilizing a slidable dual gear composed of second-gear and third-gear driving gears, a shifting fork and a first-gear driving gear, wherein the slidable dual gear can be meshed with a third-gear driven gear and a second-gear driven gear to realize a row spacing three-gear adjusting function to meet different planting density requirements; allowing an output shaft of a speed changer to drive a crank to rotate, wherein the crank drives a first crank rocker component and a second crank rocker component to be in horizontal reciprocating motion to reciprocatingly plant therape pot seedlings onto backfilled soil of planting trenches from the horizontal direction to realize horizontal-reciprocating transplanting. A seedling pushing plate in the transplanting machine rotates by a small angle around itself during horizontal seedling pushing to prevent backward seedling throwing and soil throwing during high-speed horizontal transplanting, so that speed and quality of the rape pot seedlings are improved.

Owner:SUZHOU SABO IND DESIGN

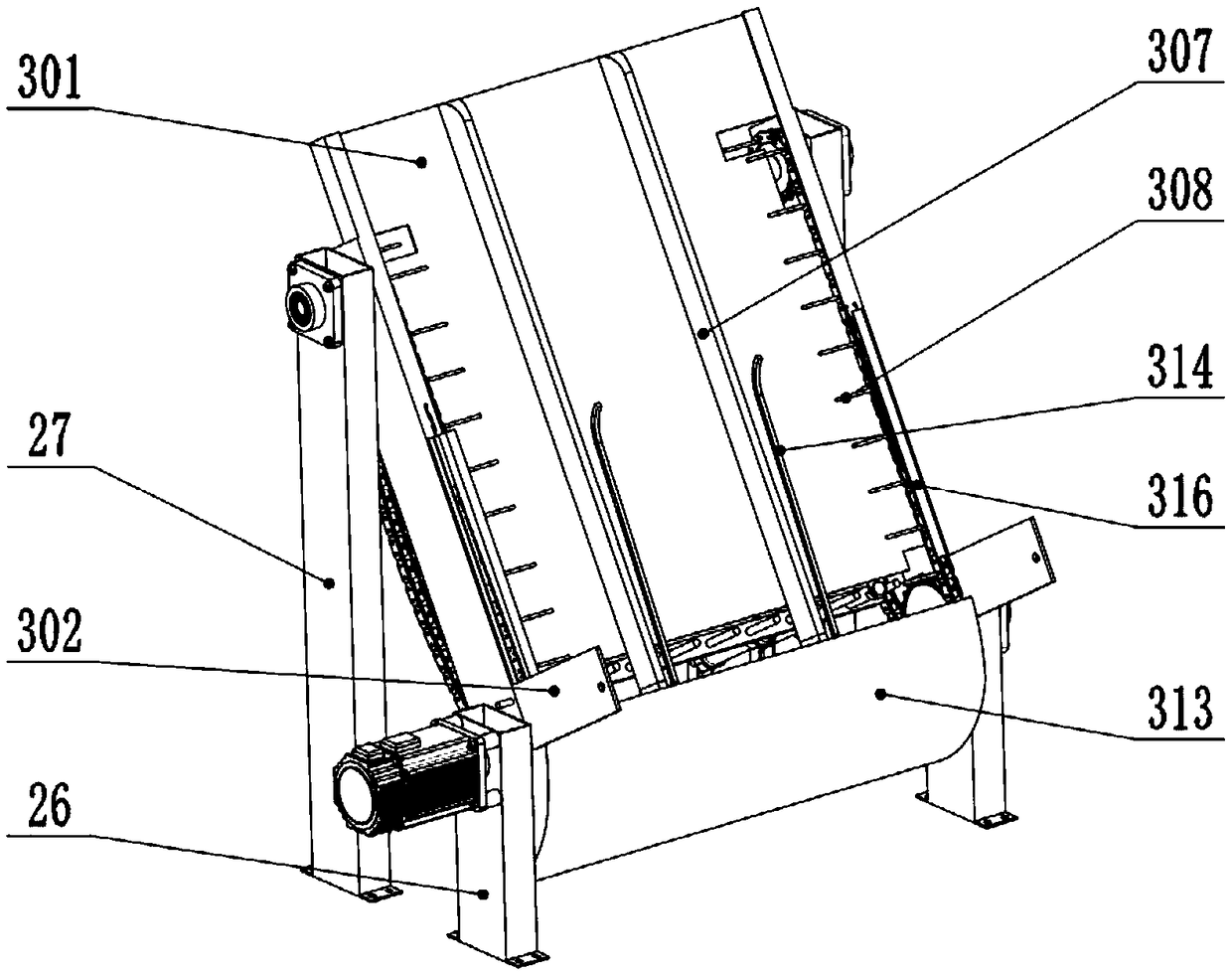

Permanent magnet direct current motor elastic piece feeding device, feeding method and motor assembling equipment

InactiveCN113231821AImprove uprightnessIncrease stiffnessMetal-working feeding devicesAssembly machinesElectric machineWaste material

The invention relates to the field of motor production, in particular to a permanent magnet direct current motor elastic piece feeding device, a feeding method and motor assembling equipment. The motor elastic piece feeding device comprises a base plate, a material belt feeding mechanism, an elastic piece cutting mechanism, an elastic piece carrying mechanism and a material belt collecting mechanism. The material belt feeding mechanism is installed on the base plate, the elastic piece cutting mechanism is located below the material belt feeding mechanism, the elastic piece carrying mechanism corresponds to the discharging end of the material belt feeding mechanism, and the material belt collecting mechanism is connected with the lower end of the material belt feeding mechanism. The material belt feeding mechanism is used for driving a material belt of an elastic piece to achieve feeding, the elastic piece cutting mechanism is used for separating the elastic piece from the material belt, the elastic piece carrying mechanism is used for carrying and feeding the elastic piece, and the material belt collecting mechanism is used for cutting and collecting waste materials of the material belt. The elastic piece carrying mechanism comprises a vertical base, a horizontal air cylinder, a vertical air cylinder, a suction block, a centering column and a limiting sensor. The permanent magnet direct current motor elastic piece feeding device, the feeding method and the motor assembling equipment have the advantages of accurate connection, high carrying efficiency and high accuracy.

Owner:陈荣乾

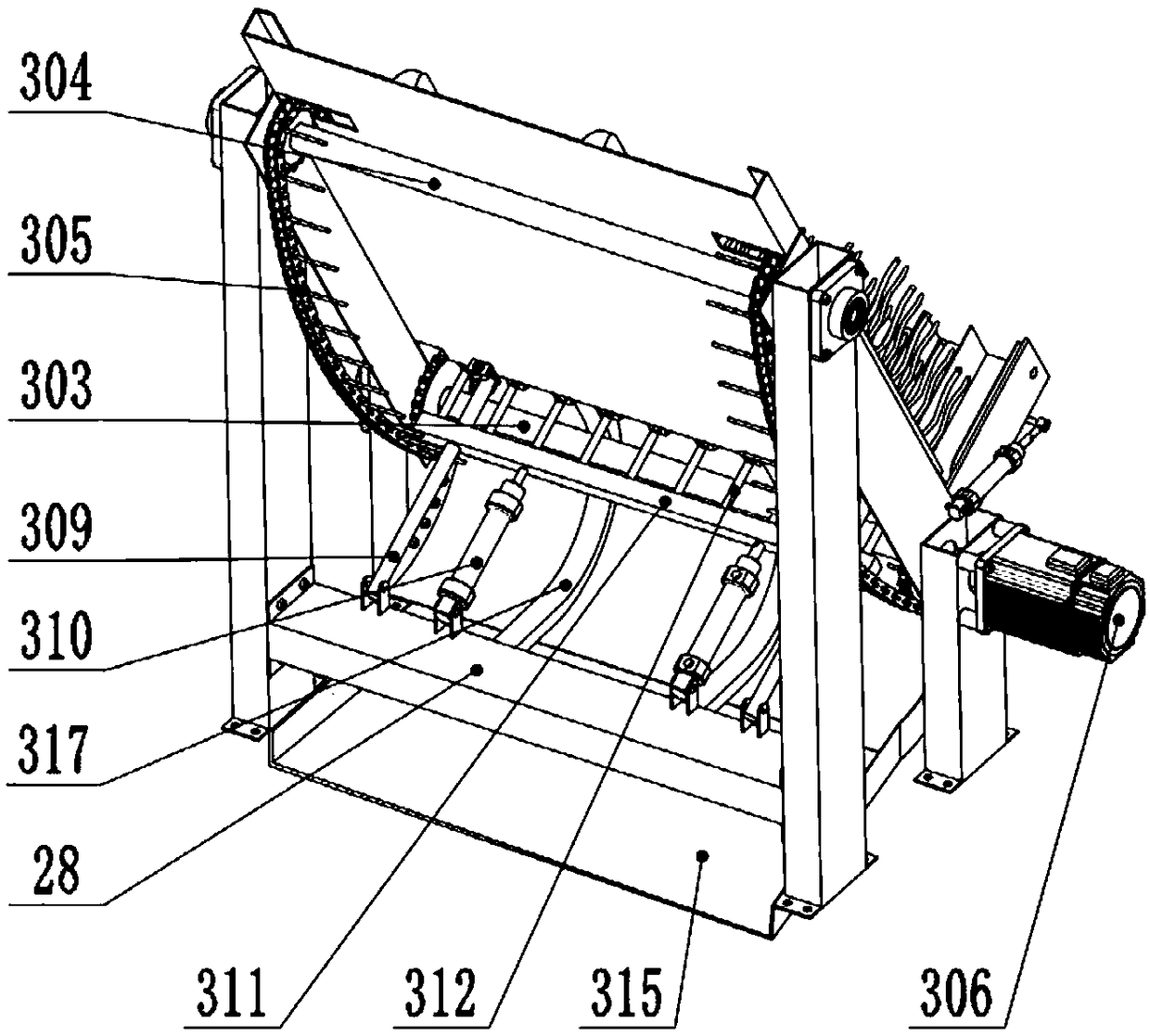

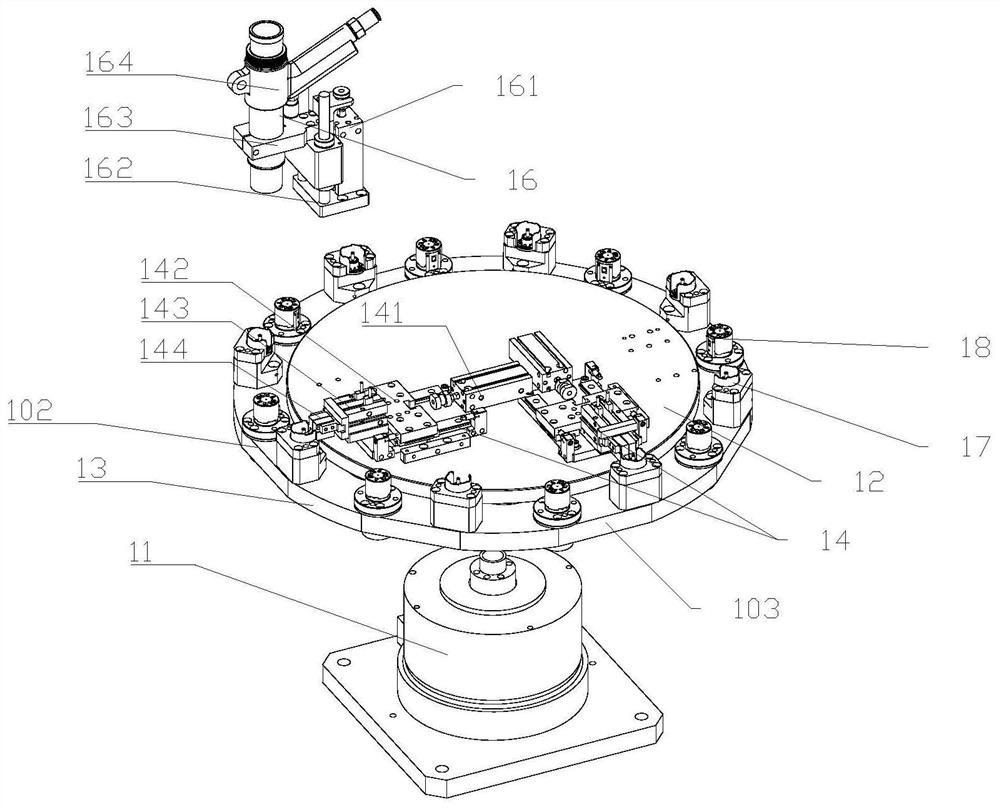

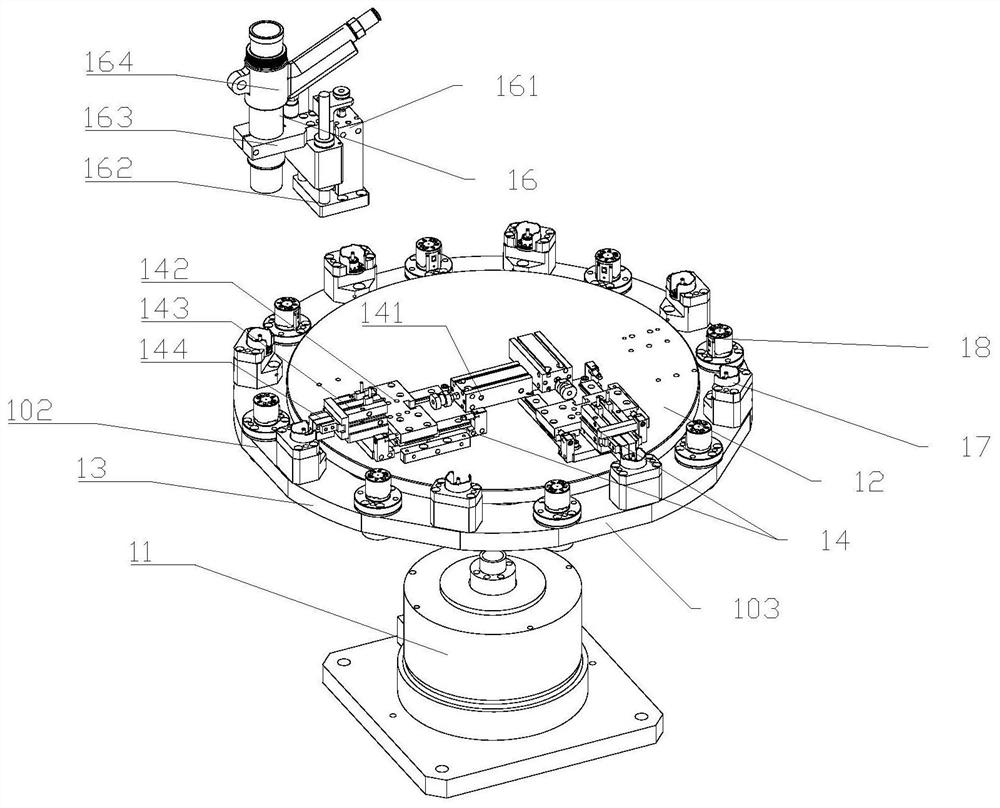

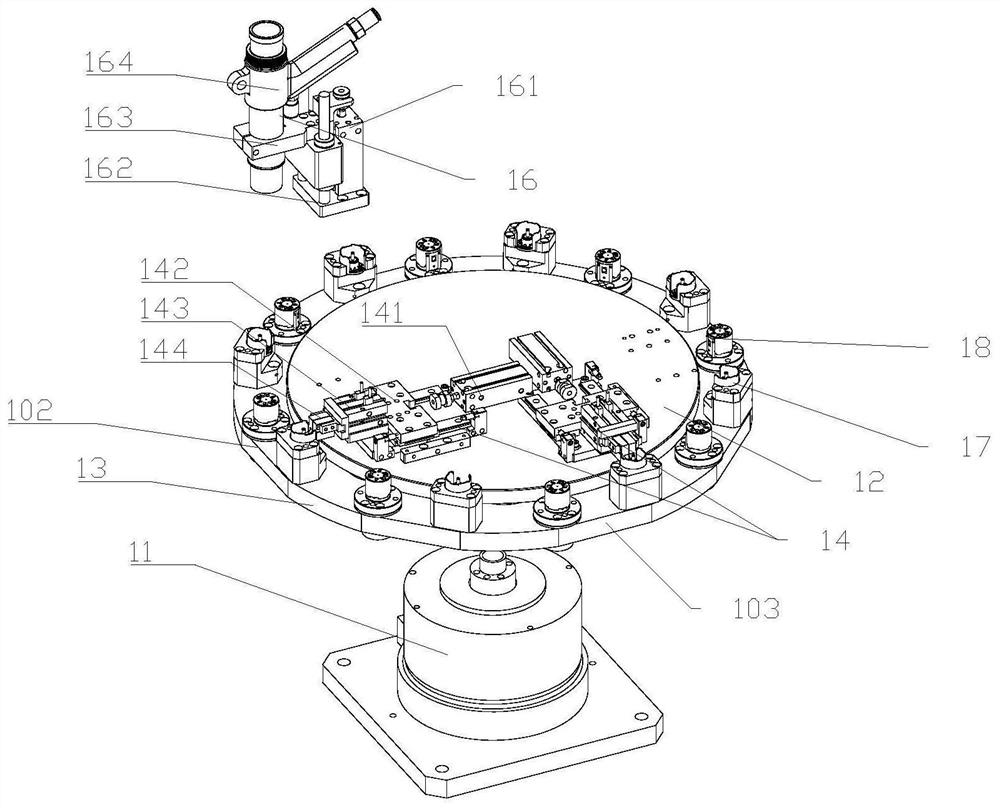

Jig rotating device and circulating method for permanent magnet direct-current motor and motor assembling equipment

InactiveCN113385932AImprove uprightnessIncrease stiffnessAssembly machinesWork holdersCircular discElectric machinery

The invention relates to the field of motor production, in particular to a Jig rotating device and circulating method for a permanent magnet direct-current motor and motor assembling equipment. The jig rotating device for motor assembly production comprises a turntable, a fixed disc, a rotating disc, a clamping assembly, an air blowing assembly, a forward mounting jig and a reverse mounting jig, wherein the turntable is arranged on the rack; a fixed shaft and a rotating shaft are arranged at the upper end of the turntable; the center of the fixed disc is fixed on the fixed shaft;the rotating disc is mounted on the rotating shaft; and the fixed disc is positioned above the rotating disc; the forward mounting jig and the reverse mounting jig are mounted on the periphery of the clamping assembly mounted on the rotating disc; the clamping assembly is fixed on the disc; and the air blowing assembly is arranged on the fixed disc and corresponds to the reverse mounting jig at an elastic sheet feeding station. Two jigs are adopted, so that the jig rotating device has the advantages of being suitable for mandrel loading and high in loading precision.

Owner:陈荣乾

A pile driver for engineering

ActiveCN109736306BSimple structureEasy to operateEarth drilling toolsBulkheads/pilesArchitectural engineeringElectric machinery

Owner:涡阳县禾淼建筑工程有限公司

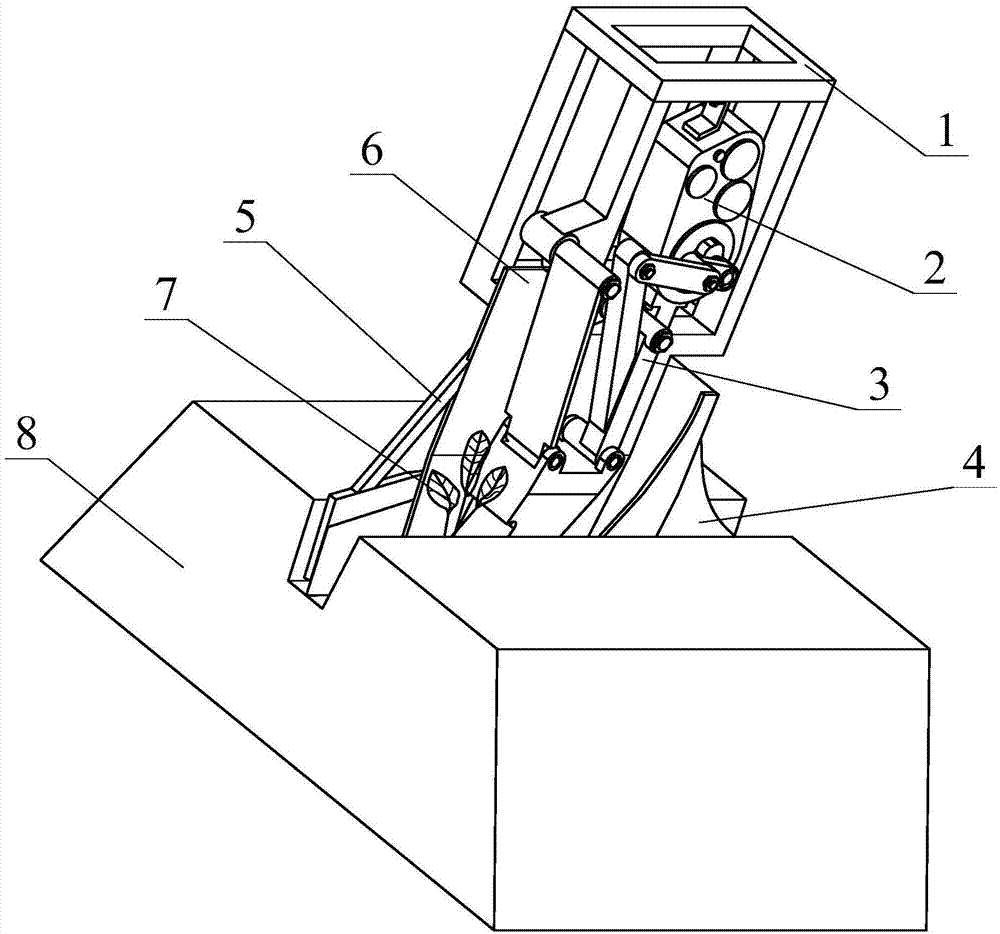

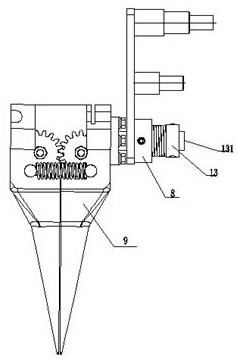

High-speed cutting, fetching and planting device for blanket rape seedlings

The invention relates to a high-speed cutting, fetching and planting device for blanket rape seedlings. The high-speed cutting, fetching and planting device comprises a seedling box mover and a cutting and fetching mechanism, wherein the seedling box mover is provided with a seedling box, a seedling door is arranged at the lower part of the seedling box, the cutting and fetching mechanism comprises a box body, a seedling claw and a seedling pushing rod capable of moving along the seedling claw in a reciprocating manner, and the seedling claw comprises a pair of clamping sheets and a pair of elastic sheets; the seedling claw does cyclic motions at the variable speed along a seedling fetching and planting track of the corresponding seedling door, the seedling fetching and planting track comprises a seedling fetching section, a seedling pushing section and a return section; the elastic sheets protruding oppositely are respectively arranged on the opposite two sides of the two clamping sheets; the seedling box mover and the cutting and fetching mechanism are synchronously driven by a special shape gear set at the variable speed, so that the revolving speed of the box body of the cutting and fetching mechanism is relatively low when the seedling claw is on the seedling fetching section and the seedling pushing section, and the revolving speed of the box body of the cutting and fetching mechanism is relatively high when the seedling claw is on the return section. By using the device, a blanket rape seedling block is not easy to fall off, the seedling is less damaged when being cut and fetched, the planting quality is high, and the device is adaptive to a larger range of row spacing.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Dry land pot seedling ejection dropping mechanism

InactiveCN102696320ASimple structureStructure, reduce the weight of the whole machine, and the pot seedling ejection operation is accurate and reliableTransplantingFixed frameEngineering

The invention discloses a dry land pot seedling ejection dropping mechanism and belongs to an agricultural machine. A cross-shaped roller slideway is fixedly installed on a pot disk side wall support plate through a fixing bolt, a fixing frame and the cross-shaped roller slideway are welded into a whole, one end of a driving arm is fixedly connected with a small ejection shaft, the other end of the driving arm is installed on a rotating arm in a hinged mode, rollers which are installed on the rotating arm are installed on portions of two sides of a hinge joint point of the driving arm and the rotating arm respectively, rollers on portions of two sides of the hinge joint point are located in the cross-shaped roller slideway respectively, two ends of a connecting rod are hinged with the rotating arm and an ejection rod respectively, an intermittent roller is installed at a position of a hinge joint point of the connecting rod and the rotating arm, a guide sleeve is installed on the fixing frame, and a seedling dropping mechanism is installed on the lower portion of the outer end of the front side of the ejection rod. The mechanism is simple and compact in structure, low in manufacturing cost, good in operation quality, high in efficiency and few in operation fault.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Combined crank rocker type transplanting mechanism

PendingCN111972083AGuaranteed to be always verticalImprove uprightnessTransplantingFurrow making/coveringDrive shaftCrank

The invention discloses a combined crank rocker type transplanting mechanism. A driving shaft is rotatably connected to a mounting plate, both a crank and a cam are fixedly connected with the drivingshaft, a cam swing link is hinged to the mounting plate, one end of a drawn wire is fixedly connected with the cam swing link, and the other end of the drawn wire is connected with a suspending cup; afirst link is hinged to the crank, both a first rocker and an intermediate connecting plate are hinged to one end of the first link, and a tail end connecting plate is hinged to the other end of thefirst link; one end of a second link is hinged to the intermediate connecting plate, the other end of the second link is hinged to the tail end connecting plate, and a second rocker is hinged to the intermediate connecting plate; and the suspending cup is connected to the tail end connecting plate through an elastic connector in a floating manner. The combined crank rocker type transplanting mechanism is simple in structure, the condition that the suspending cup is always vertical and meets the requirements on zero seedling throwing is guaranteed, and balanced inertial forces can be arranged in bilateral symmetry during operation. According to the combined crank rocker type transplanting mechanism, after the suspending cup pierces soil, the moving in a horizontal direction is little due toaction of a following device, a hole formed in a film is small, filming tearing is reduced, and the uprightness of pot seedlings is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

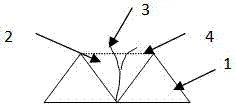

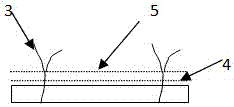

Production method of high-upright-degree flat velvet cloth

ActiveCN113930878ANot easy to lodgingNot easy to get togetherHeating/cooling textile fabricsGrip property fibresCold airPolymer science

The invention provides a production method of high-upright-degree flat velvet cloth. According to the invention, 200D / 48F flat polyester filament yarn is used as a fluff raw material, raising spinning in which W-shaped consolidation and V-shaped consolidation are alternated is adopted, and a plain weave weaving method is adopted for ground warp weave. In combination with specific grey cloth brushing conditions (including adoption of a grey cloth driving roller), A-shaped frame arrangement, specific grey cloth setting conditions, specific softening treatment and dehydration cloth stacking conditions, rapid cooling by opening cold air after setting and specific gluing and setting conditions, all the steps act together as a whole, so that fluff of the velvet cloth obtained by the method has high upright degree, and the problems of poor velvet cloth softness, disordered fluff, easy generation of wrinkle marks, fluffing and looping at the bottom of the velvet cloth and the like are solved.

Owner:沂水恒泰纺园有限公司

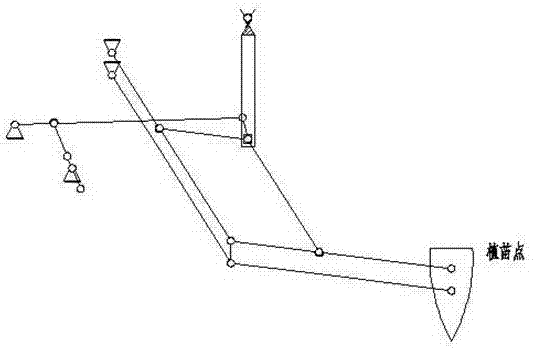

Plug seedling plantation driving mechanism

ActiveCN107980285AGuaranteed uprightnessImprove uprightnessTransplantingAgriculture gas emission reductionEngineeringElbow

The invention discloses a plug seedling plantation driving mechanism, which comprises a frame and a crank. The crank is connected to one end of a first connecting rod to form a rotation pair. The first connecting rod is connected to a rocking bar to form a rotation pair. The tail end of the rocking bar is connected to a slide block through a second connecting rod. The slide block is arranged in aslide rail, which is hinged to the frame. At the same time, the slide block, a third connecting rod, and a fourth connecting rod are connected to each other to form a rotation pair. The third connecting rod and the fourth connecting rod are respectively connected to a first arm rod and a first elbow rod to form a rotation pair. One end of the first arm rod, one end of the first elbow rod, and oneend of a fifth connecting rod are connected to each other. The other end of the fifth connecting rod, a second arm rod, and a second elbow rod are connected to each other. The tail ends of the first arm rod and the second arm rod are connected to a suspended cup. Through the arm rods parallel to each other, elbow rods parallel to each other, and swinging slide rail, the suspended cup is erected, and the size of punched holes is reduced. Based on the quick-return characteristics of the crank-rocking bar structure, the plantation and cup-pulling speed is reasonably set, and high speed plantationis realized.

Owner:NANJING AGRICULTURAL UNIVERSITY

Planetary gear train tray seedling transplanting inter-plant hole covering mechanism

InactiveCN110100531AReduce harmHigh quality transplanting workPlantingFurrow making/coveringDrive shaftEngineering

The invention provides a planetary gear train tray seedling transplanting inter-plant hole covering mechanism, and belongs to the field of agricultural machinery. A power output left shaft and power output right shaft of a driving power input gear box are fixedly provided with a left cross-shaped planetary gear train gearbox and a right cross-shaped planetary gear train gearbox respectively, the rotation direction of the power output left shaft is opposite to the rotation direction of the power output right shaft, left driving shafts of the left cross-shaped planetary gear train gearbox are provided with crank-shaped left arms and left stirring forks, left vertical shafts with left hole covering shovels are inserted in the crank-shaped left arms, right driving shafts of the right cross-shaped planetary gear train gearbox are provided with crank-shaped right arms and right stirring forks, right vertical shafts with right hole covering shovels are inserted in the crank-shaped right arms,and left middle shafts of the left cross-shaped planetary gear train gearbox and right middle shafts of the right cross-shaped planetary gear train gearbox are fixedly provided with left cams and right cams respectively. The planetary gear train tray seedling transplanting inter-plant hole covering mechanism has the advantages that the structure is novel and reasonable, the tray seedling transplanting inter-plant hole covering effect is good, the damage to tray seedlings during hole backfill operation can be effectively reduced and avoided, the upright degree of the transplanted tray seedlings is good, and the survival rate is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

A kind of formula and production process of edible fungus granules

The invention discloses a formula of edible mushroom granules and a production process. The formula of the culture medium of the fungus consists of the following components: 97.5% of sorghum grains, 1.5% of light calcium carbonate and 1% of glucose. Its main production process includes: material selection→rinsing→soaking→cooking→removal of free water→stirring→bottling→stopping→wrapping and tying→autoclaving→out of the pot, inoculation→mycelium cultivation→one shake flask → Secondary shake flask → Finished strain. In the production process of the present invention, a small bottle-mouth container bottle is used as the packaging material of the bacterial strain, and the film package of the sealed tampon can not only meet the oxygen demand for the growth of mycelia in the container bottle, but also reduce the contamination of the bacteria by bacteria; The shaking bottle process makes the mycelium filling speed more than double, and the upper and lower bacterial ages are the same when the mycelium is full. The strains produced by this production process have high purity, fast inoculation speed, fast germination, and good food, and are welcomed by the majority of mushroom farmers.

Owner:HEZE UNIV

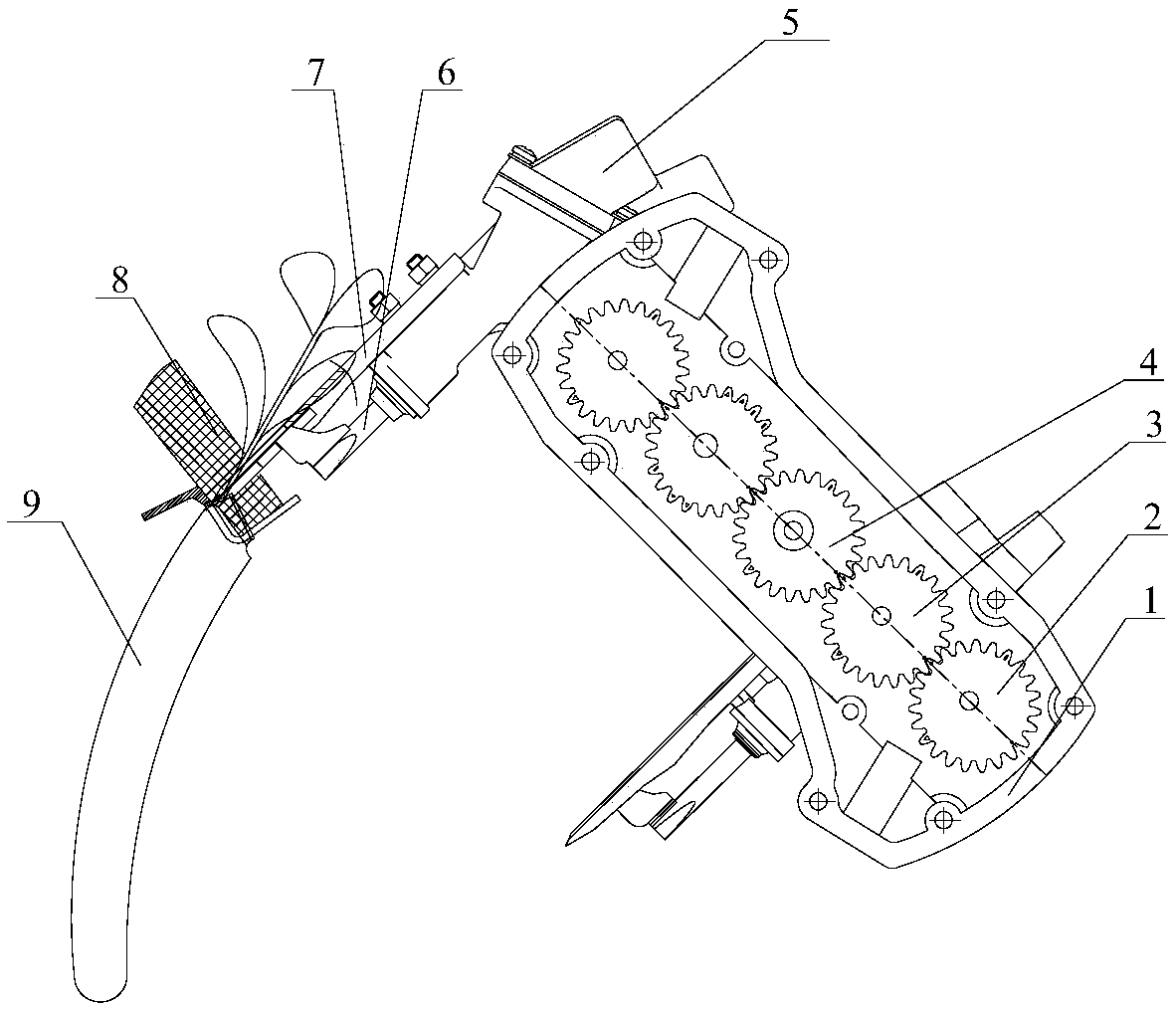

Pot seedling double row seedling pulling and swinging mechanism

ActiveCN104429243BImprove uprightnessImprove efficiencyTransplantingGear wheelAgricultural engineering

Owner:李精华

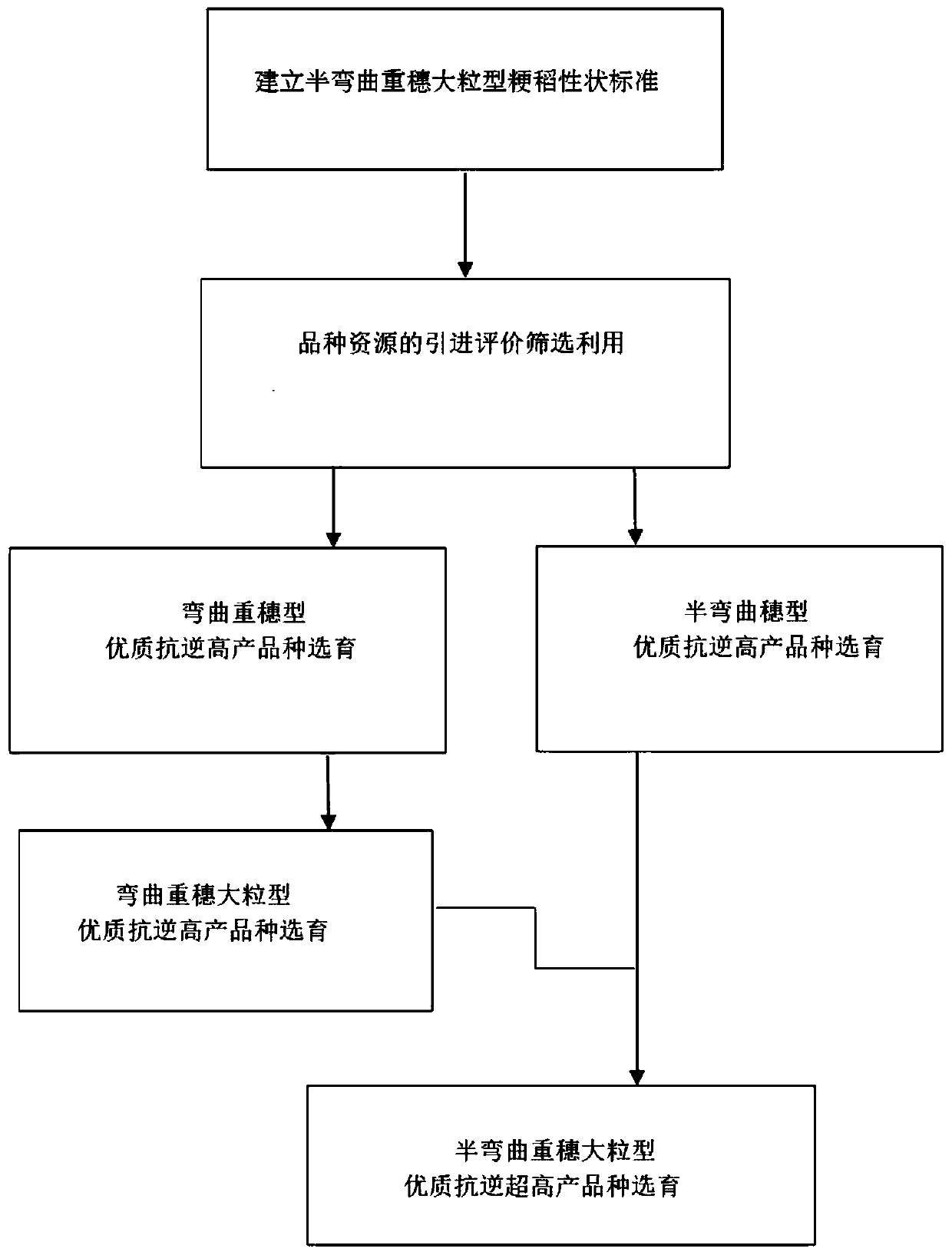

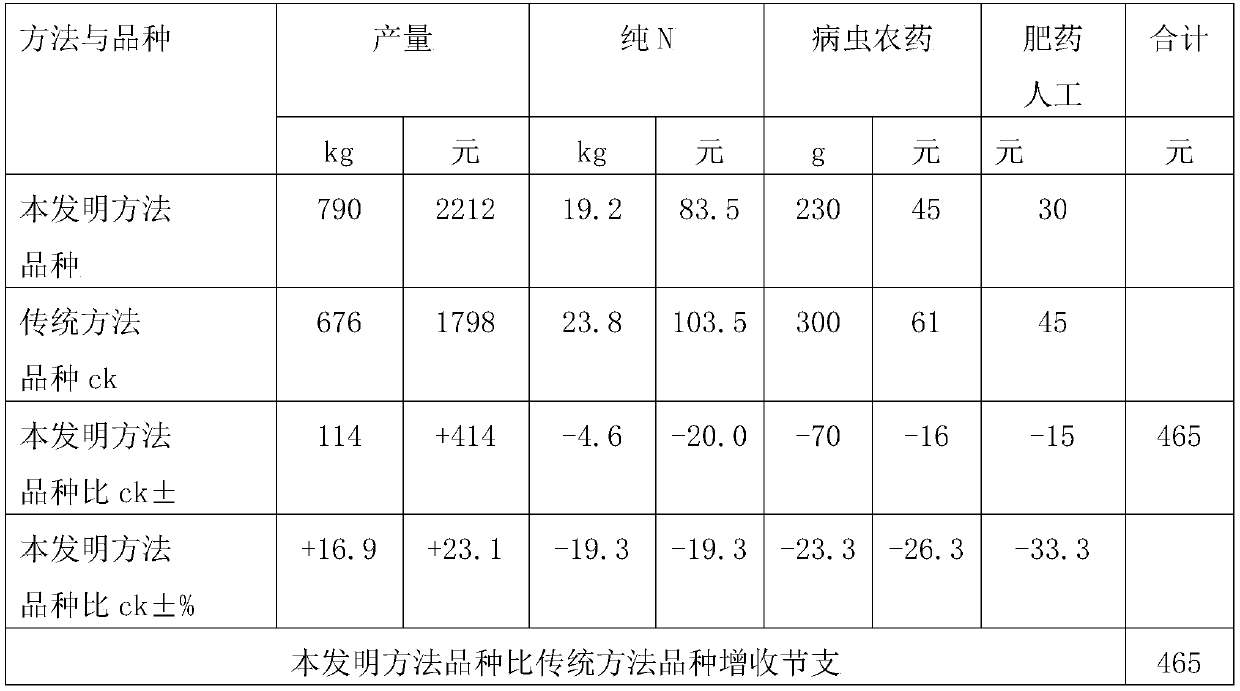

Method for breeding half-bending heavy-panicle large-grain type japonica rice

PendingCN111011209AGood ventilation and light transmissionImprove uprightnessPlant genotype modificationBiotechnologyAnimal science

The invention relates to a method for breeding half-bending heavy-panicle large-grain type japonica rice. The method comprises implementation steps of (I) establishing the property standard of the half-bending heavy-panicle large-grain type japonica rice; (II) performing introduction, evaluation, screening and utilization of variety resources; (III) performing breeding of bending heavy-panicle type superior-stress-tolerance high-yield varieties and half-bending panicle type superior-stress-tolerance high-yield varieties; (IV) performing breeding of bending heavy-panicle large-grain type superior-stress-tolerance high-yield varieties; and (V) performing breeding of half-bending heavy-panicle large-grain type superior-stress-tolerance extra-high-yield varieties. Through the adoption of the method disclosed by the invention, the bred varieties concurrently have double advantages of erect-panicle type varieties and bending-panicle type varieties, comprehensive stress tolerance polymerization is realized, breeding objectives of being superior, tolerant to stress and extra-high in yield are achieved, the selection efficiency and the probability of directionally breeding objective traitsare greatly improved, and the application effects are quite significant.

Owner:天津市优质农产品开发示范中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com