Method for affecting growth morphology of carbon nanotubes by controlling hydrolysis degree

A technology of carbon nanotubes and hydrolysis degree, which is applied in the direction of nanotechnology, can solve the problems of affecting the growth shape of carbon nanotubes, difficult process, high cost, etc., and achieve the effect of improving the verticality, optimizing the process and increasing the degree of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described: a kind of method that influences carbon nanotube growth appearance by controlling hydrolysis degree, comprises the steps:

[0021] Step 1: Prepare the precursor solution film containing iron ions: place the precursor solution containing iron ions at room temperature, after hydrolysis for a certain period of time, absorb a certain amount of precursor solution and drop it on the substrate required for growing carbon nanotubes. , to obtain a precursor film evenly distributed on the surface of the substrate;

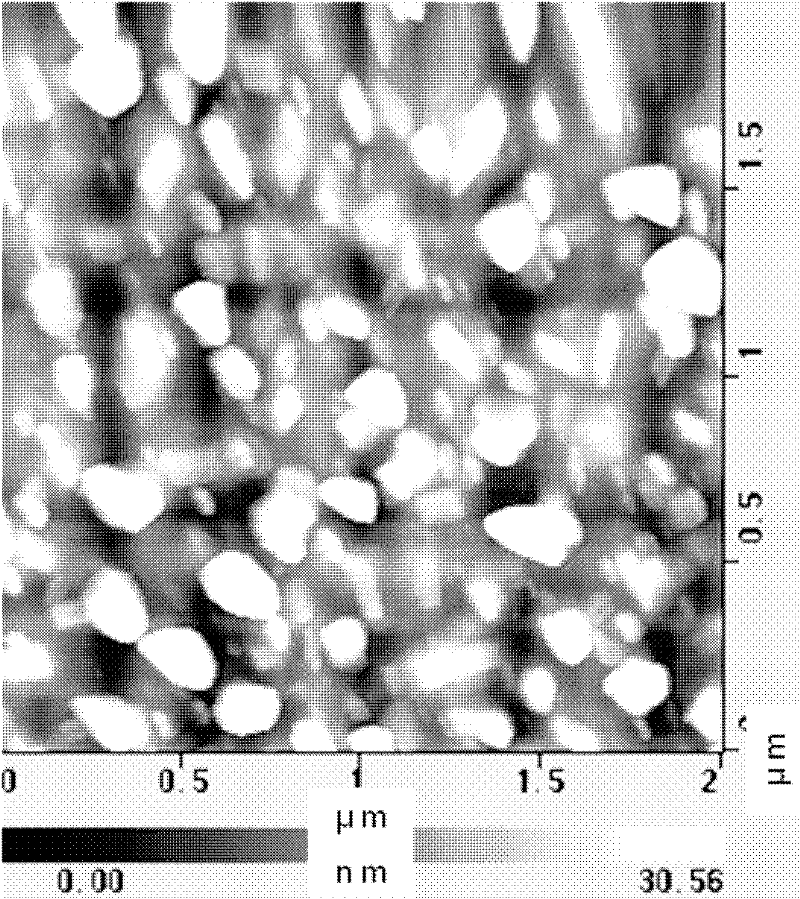

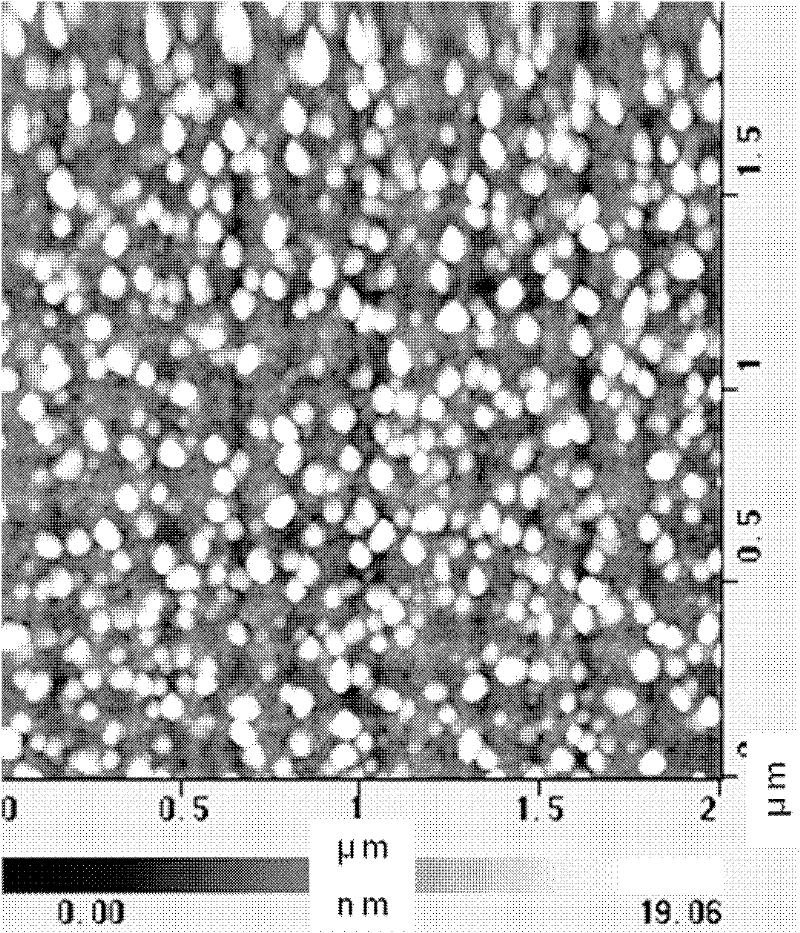

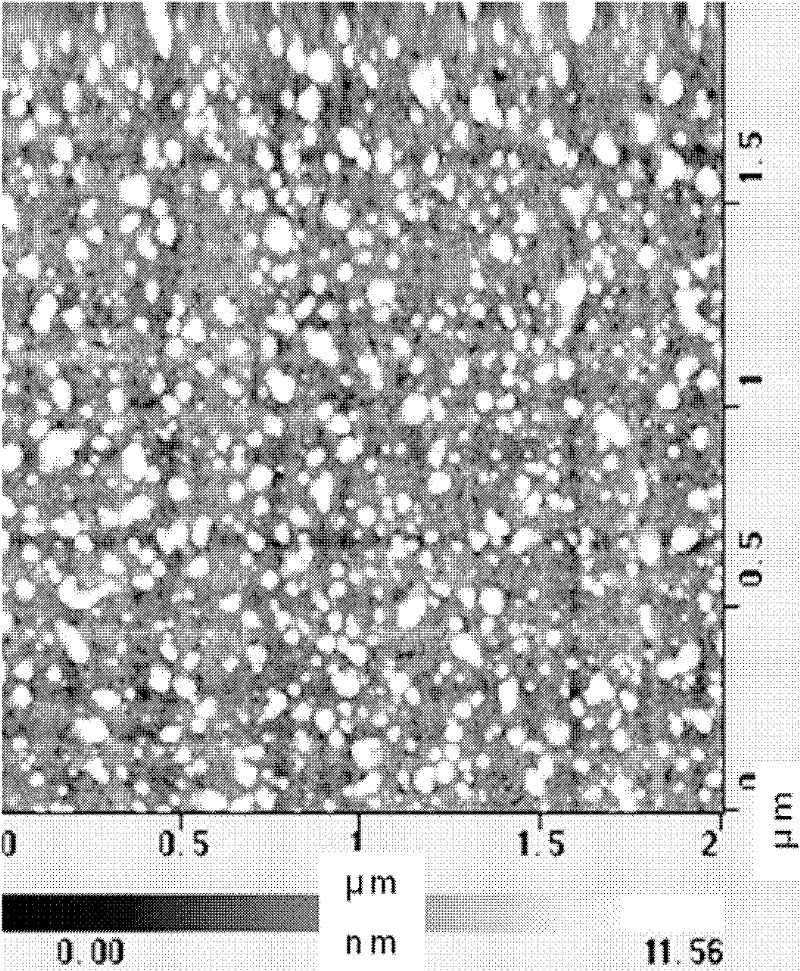

[0022] The specific implementation process and parameters of this step are as follows: the precursor solution containing iron ions prepared by the sol-gel method is placed at room temperature, and the gel is shaken for the first time after 24 hours, and the base after the gel is shaken The film is used as sample 1. After that, a substrate is selecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com