Patents

Literature

30results about How to "Meet the agronomic requirements for transplanting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

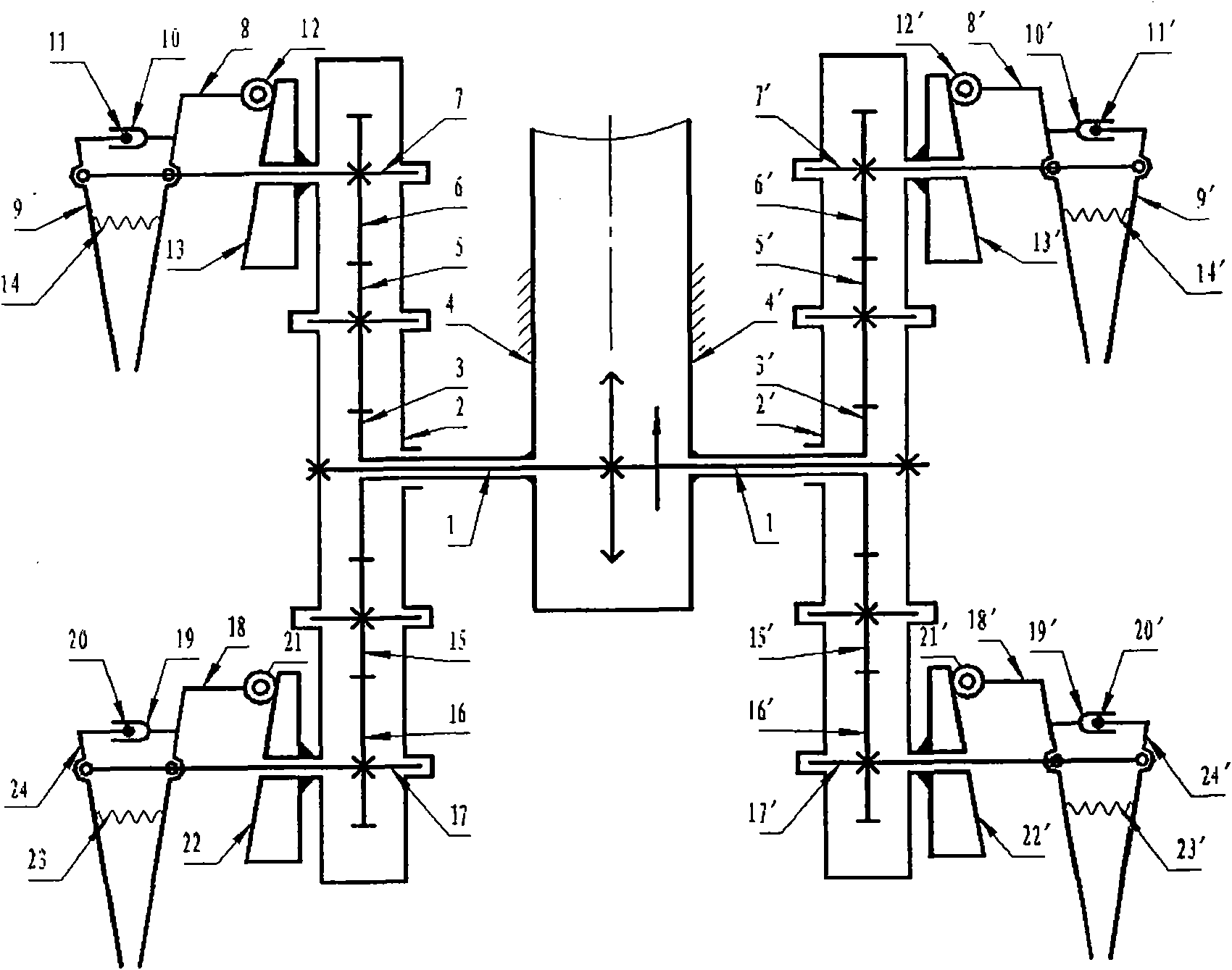

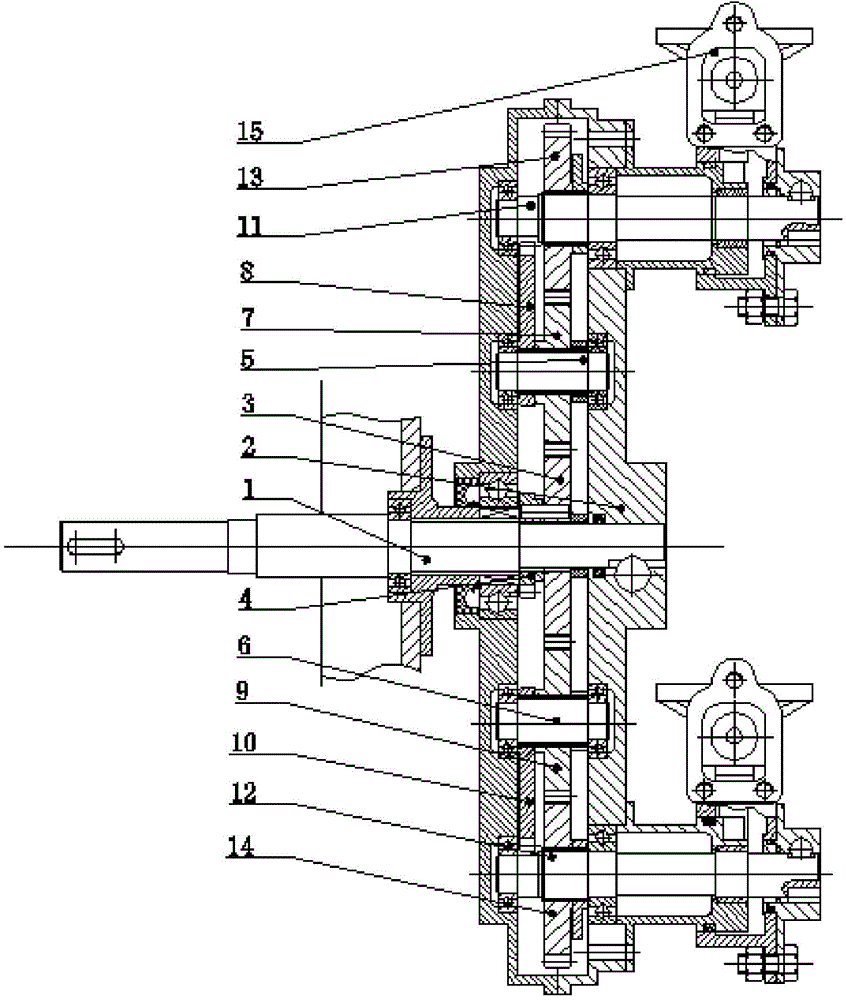

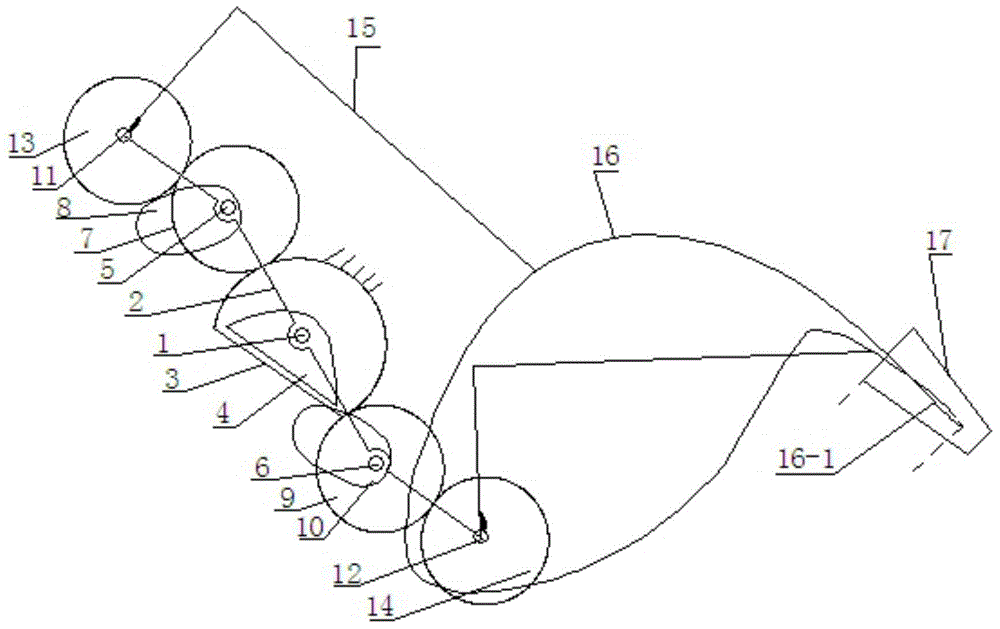

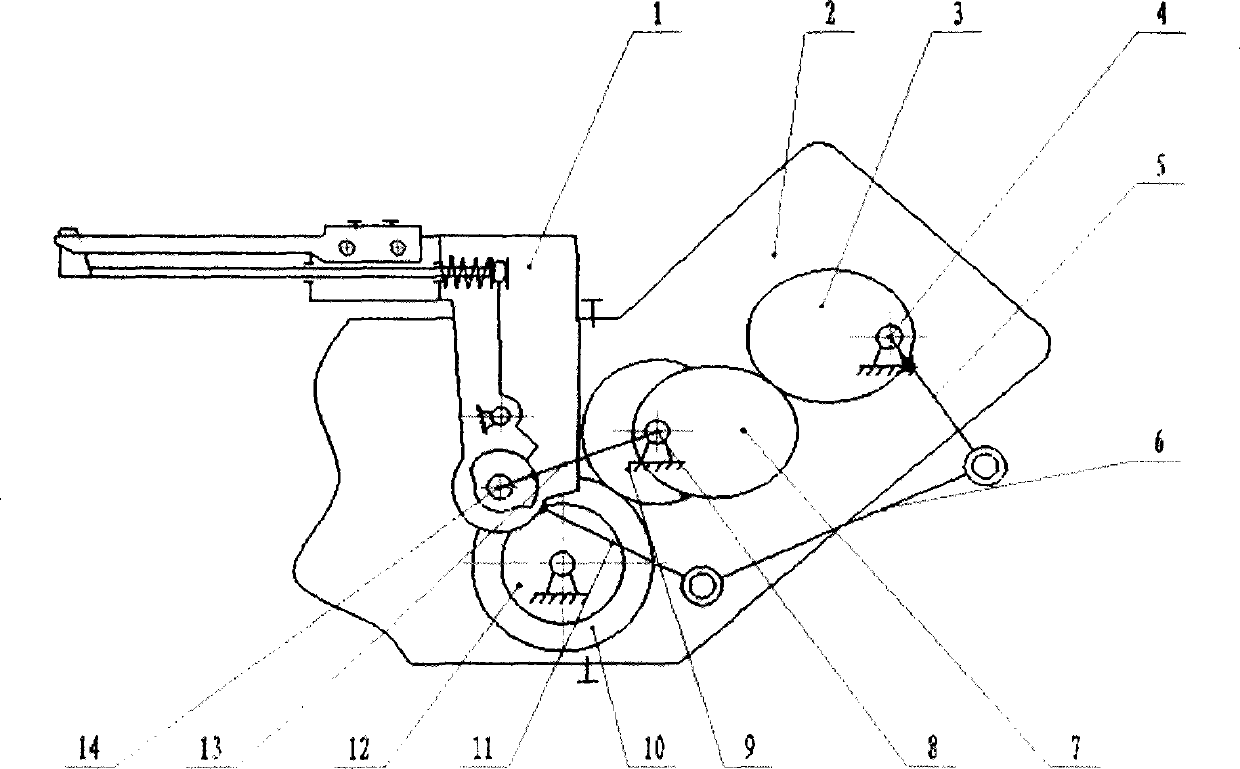

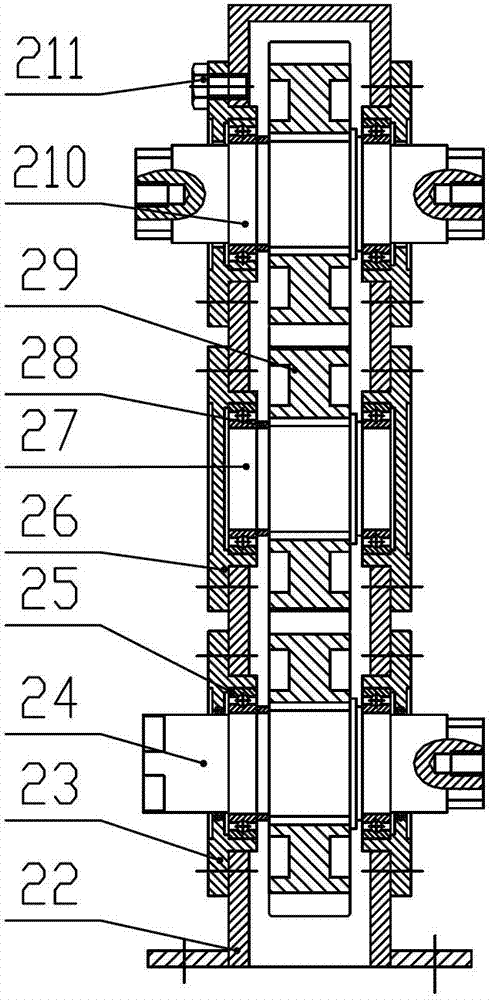

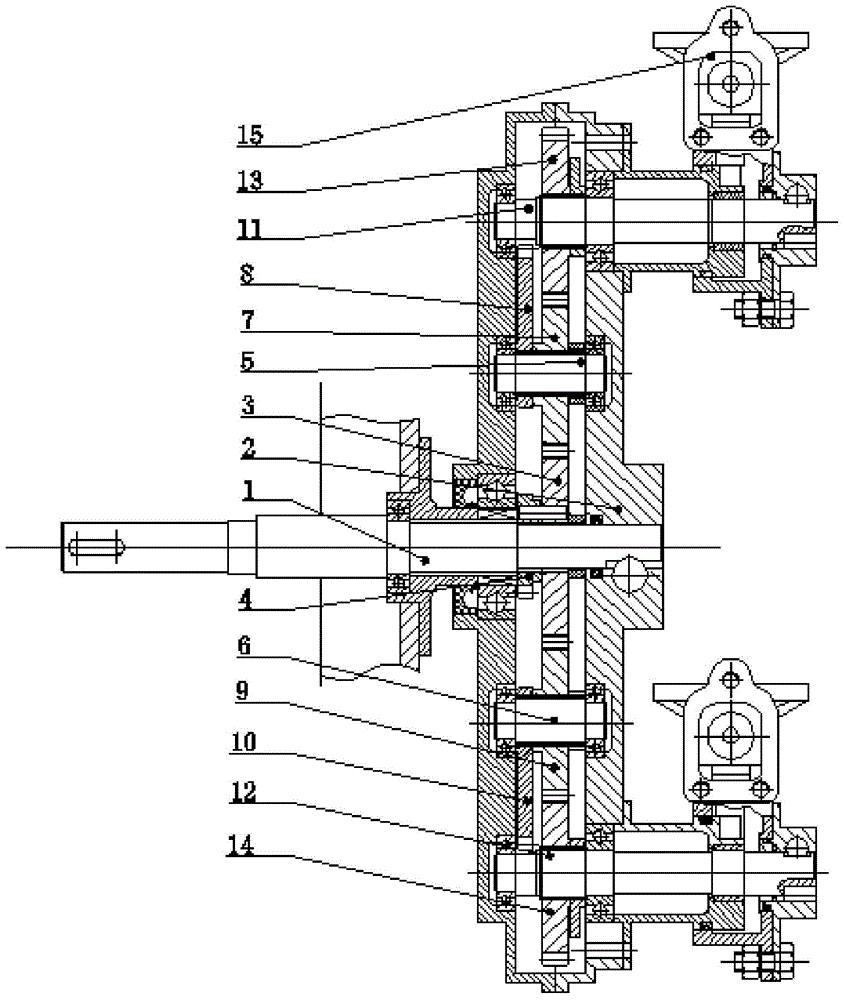

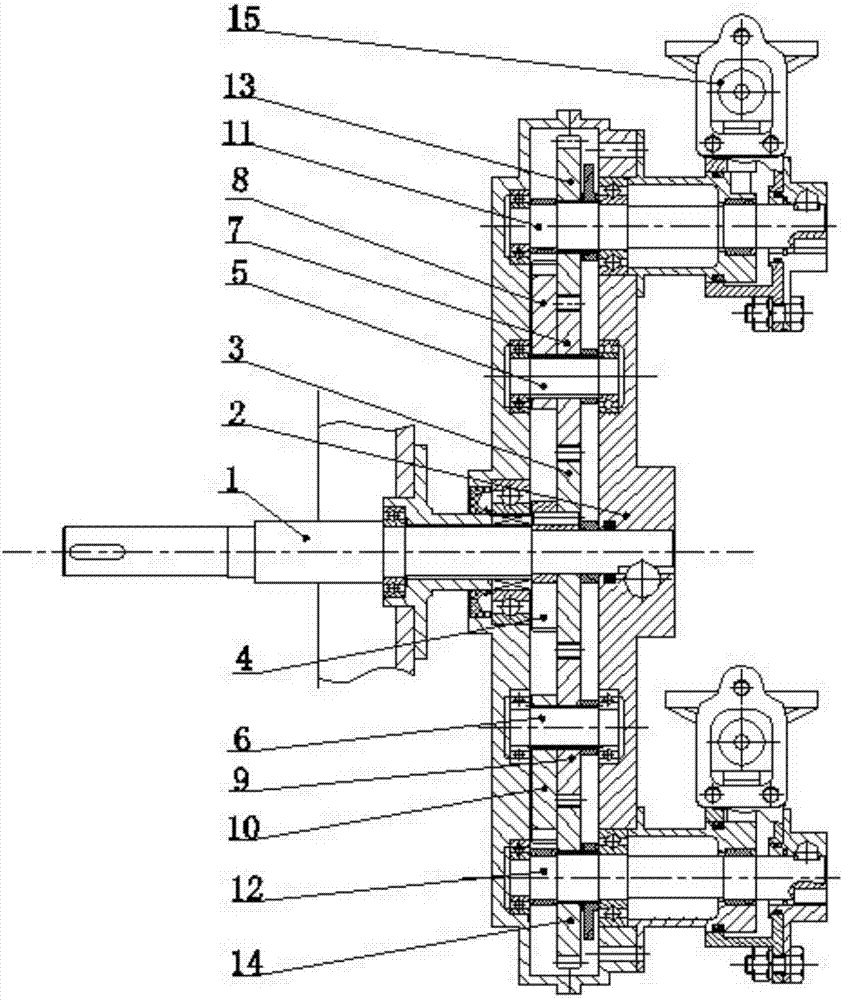

Transplanting mechanism capable of implementing continuous perpendicular planting

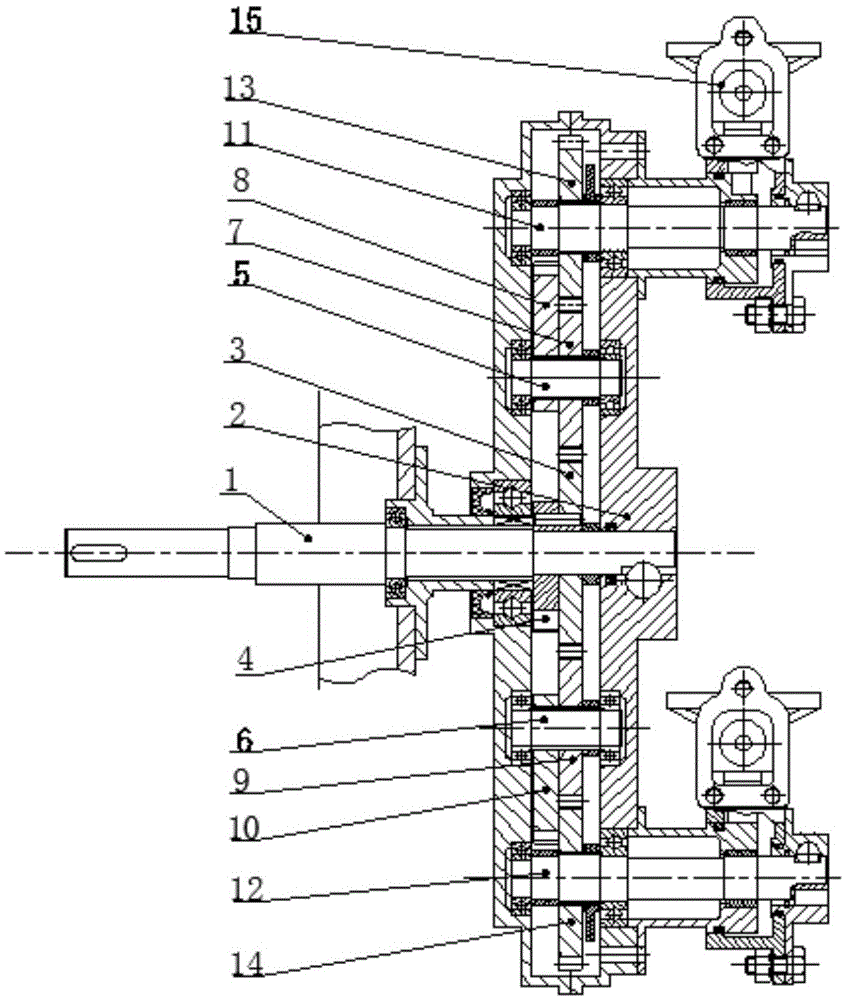

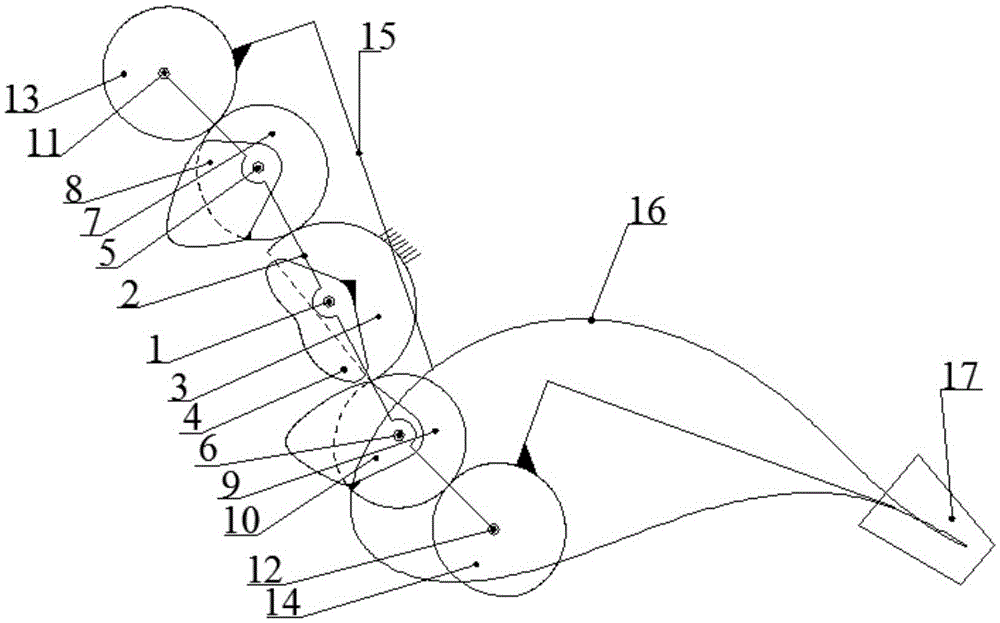

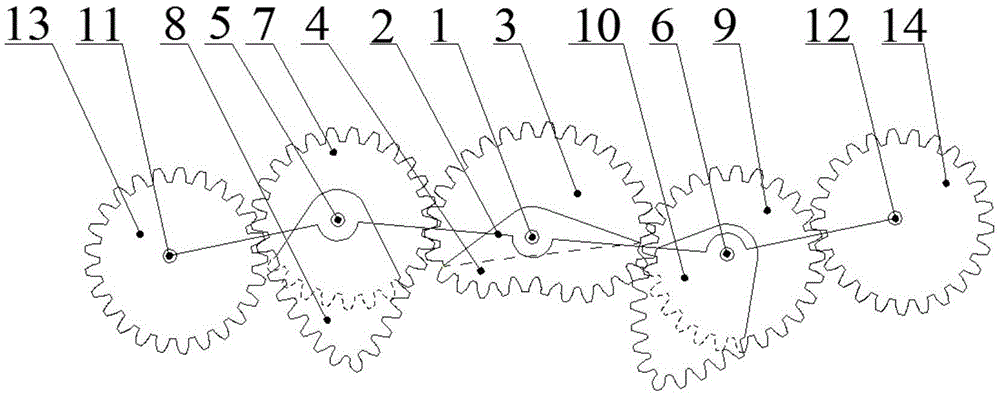

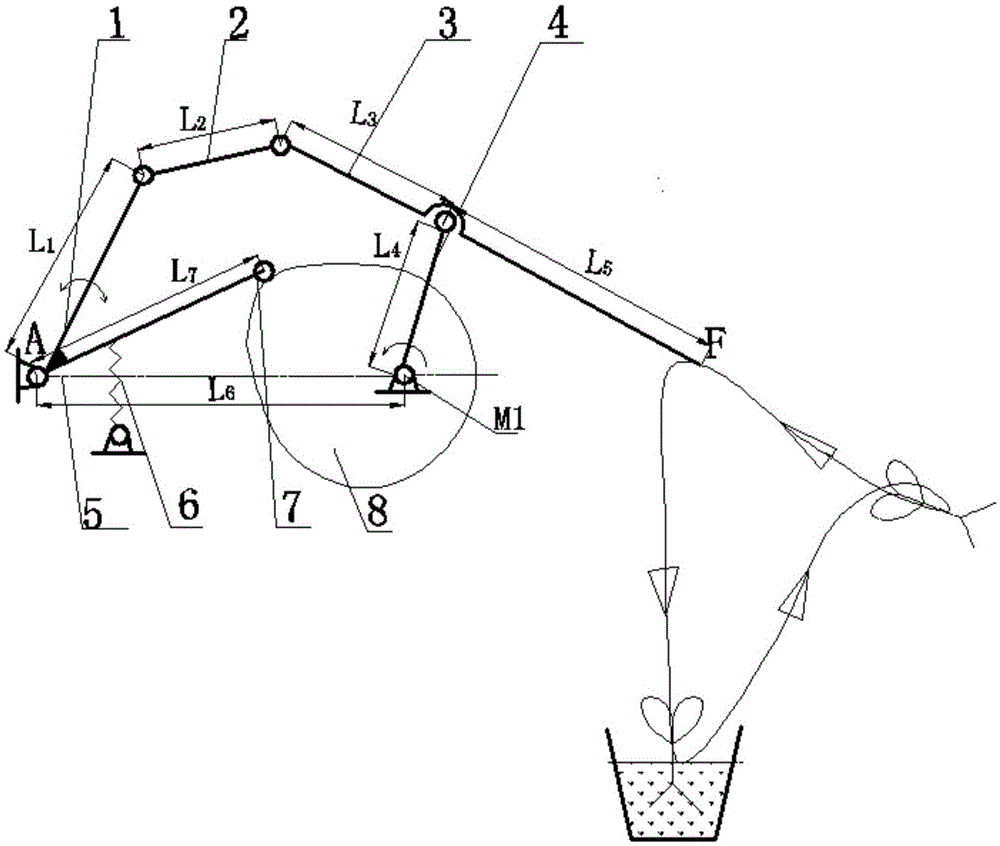

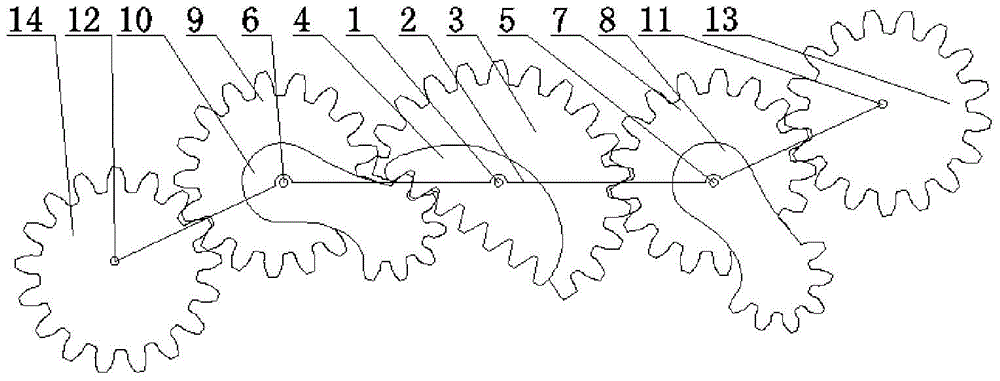

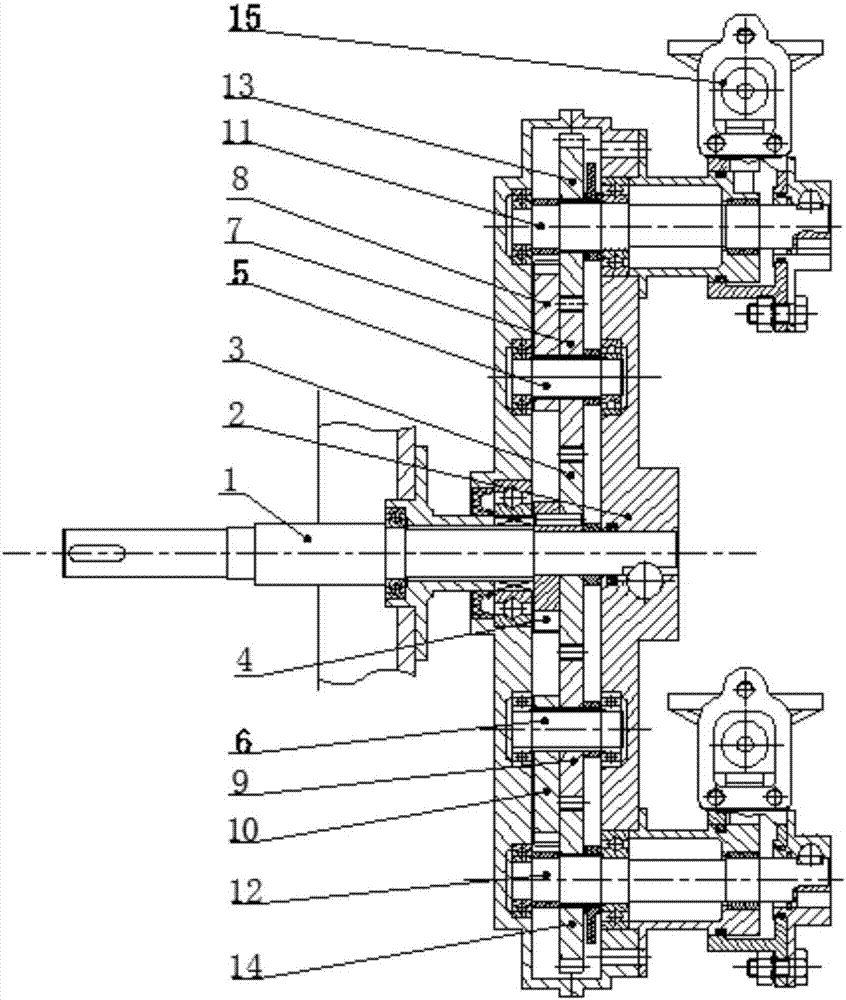

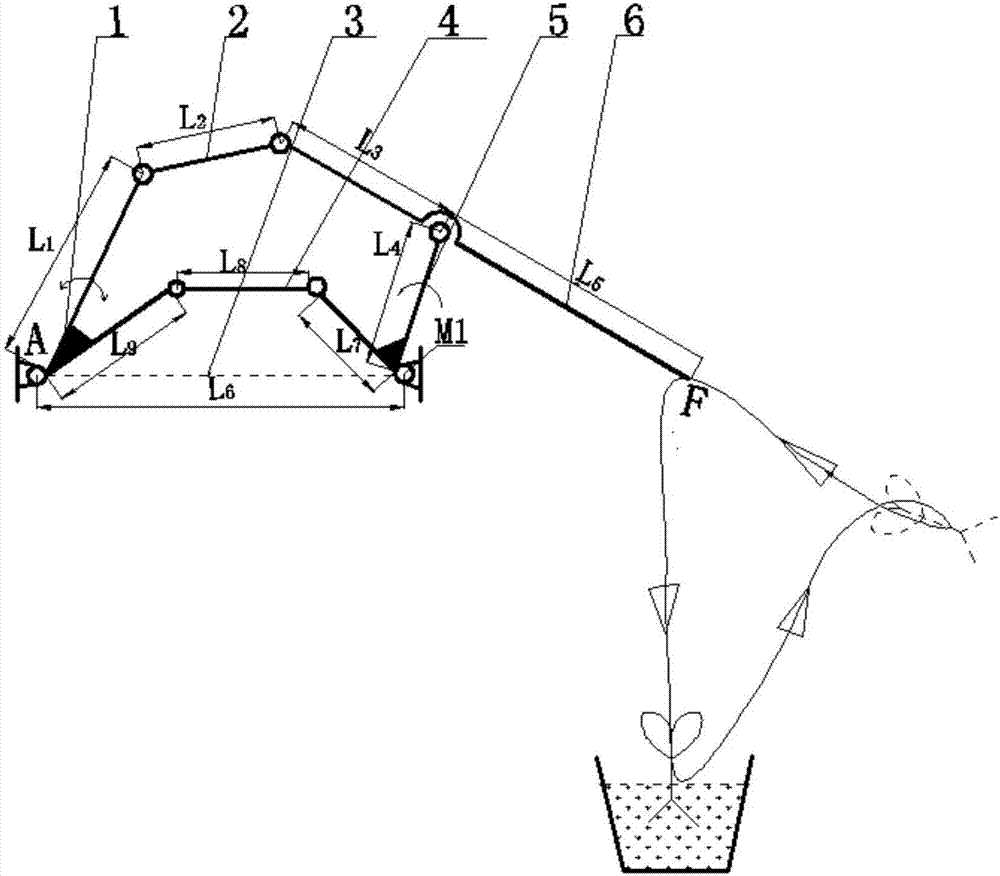

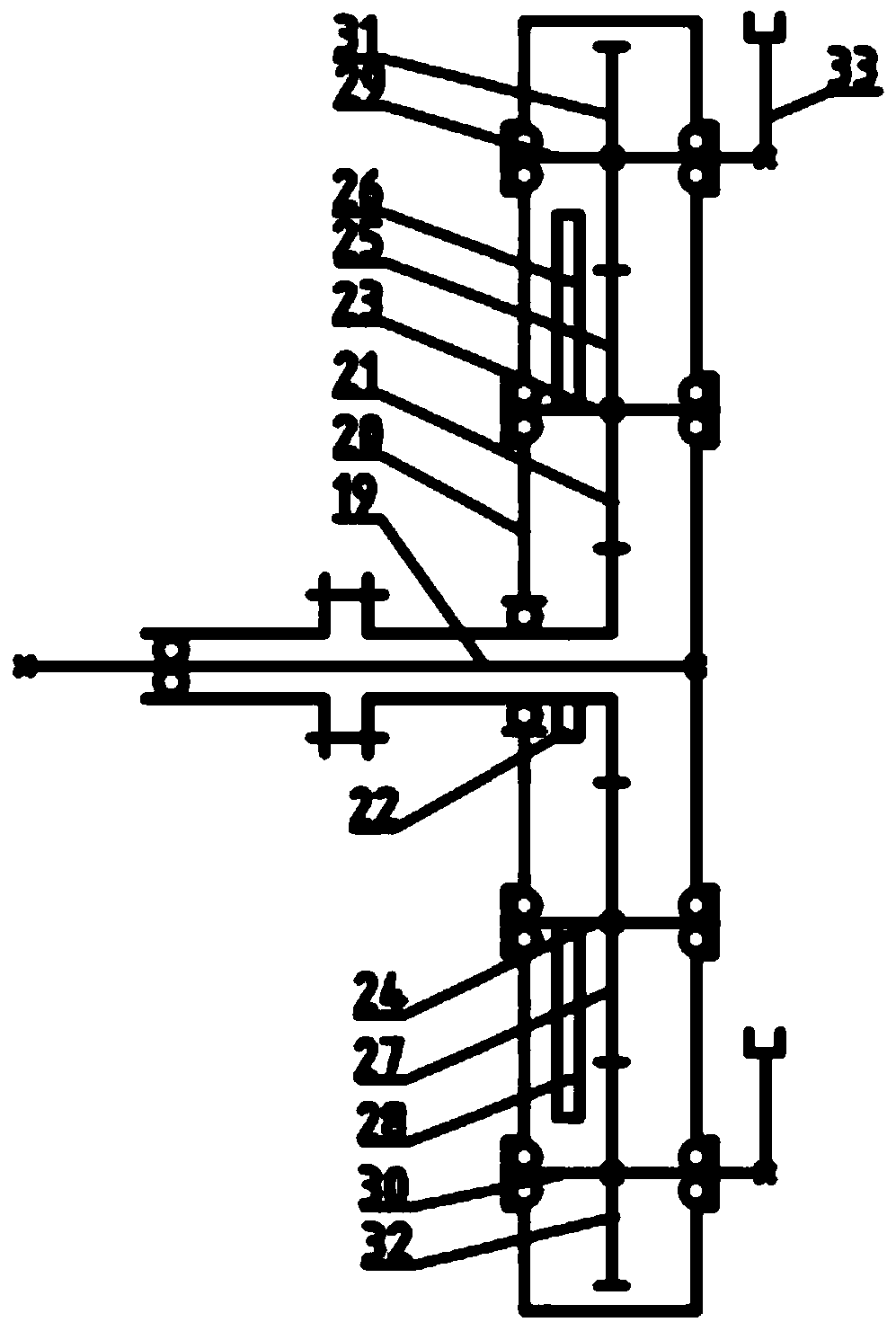

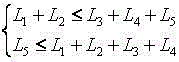

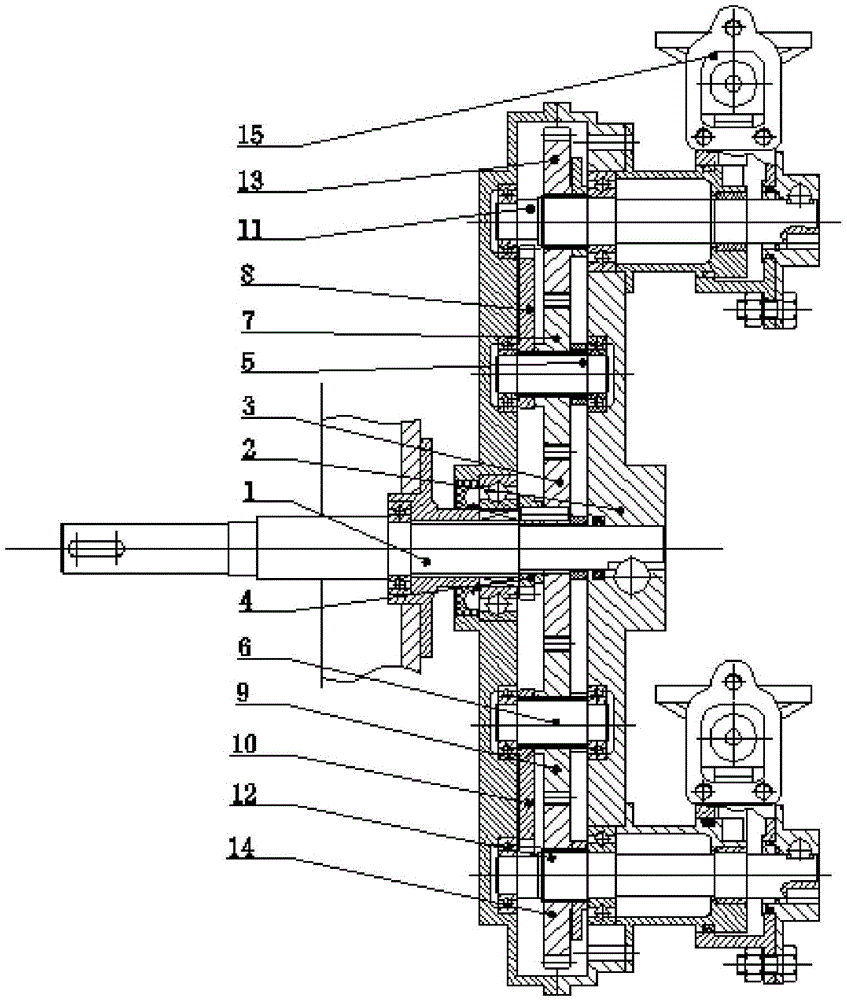

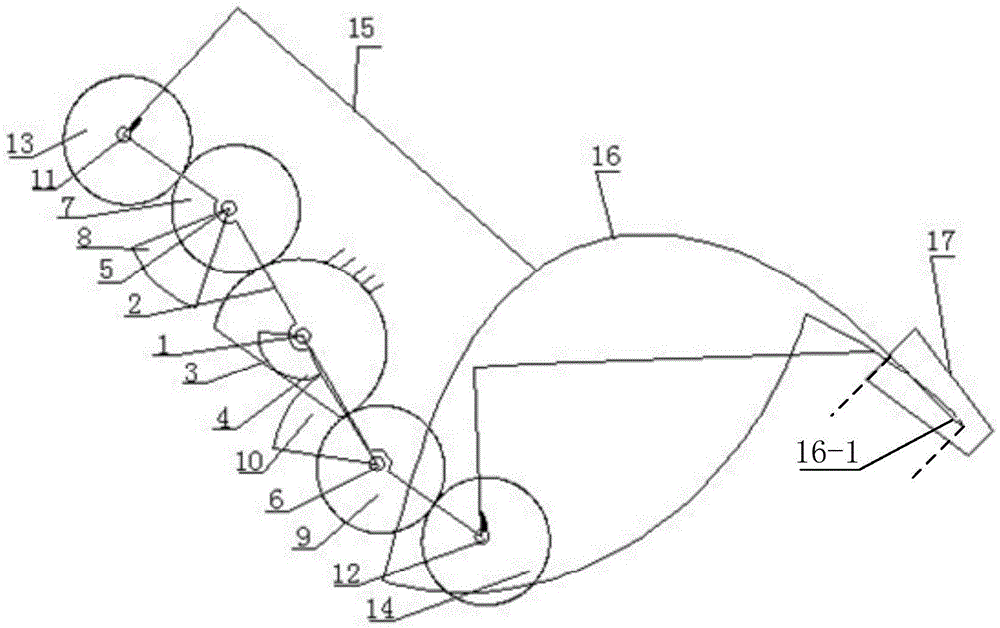

The invention discloses a transplanting mechanism capable of implementing continuous perpendicular planting. The translating mechanism comprises a transmission box, a planting arm assembly, a planter and a cam starting mechanism, wherein the transmission box is fixed on a stander; three output shafts, an input shaft and two hanging shafts are arranged on the transmission box; the first output shaft, the second output shaft and the two hanging shafts are arranged on one side of the transmission box and are used for hanging the planting arm assembly and driving the planting arm assembly; the third output shaft and the input shaft are arranged on the other side of the transmission box; the third output shaft is used for mounting and driving the cam starting mechanism; the input shaft is connected with an output shaft of a planter handpiece; the planting arm assembly consists of a four-rod mechanism, a five-rod mechanism and two parallel mechanisms; the planter is hung on the planting arm assembly through a square shaft. The transplanting mechanism disclosed by the invention is compact in structure, has the advantages of low seedling injury rate, low seedling leakage rate, low seedling burying rate, low seedling exposure rate and high seedling growth rate and can completely meet an agriculture requirement on oilseed rape transplanting.

Owner:HUNAN AGRICULTURAL UNIV

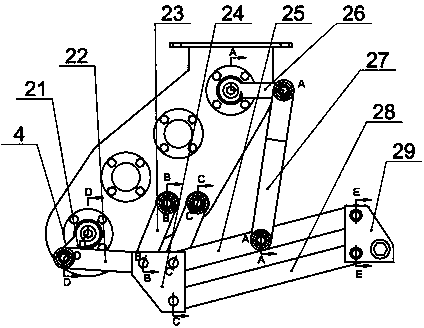

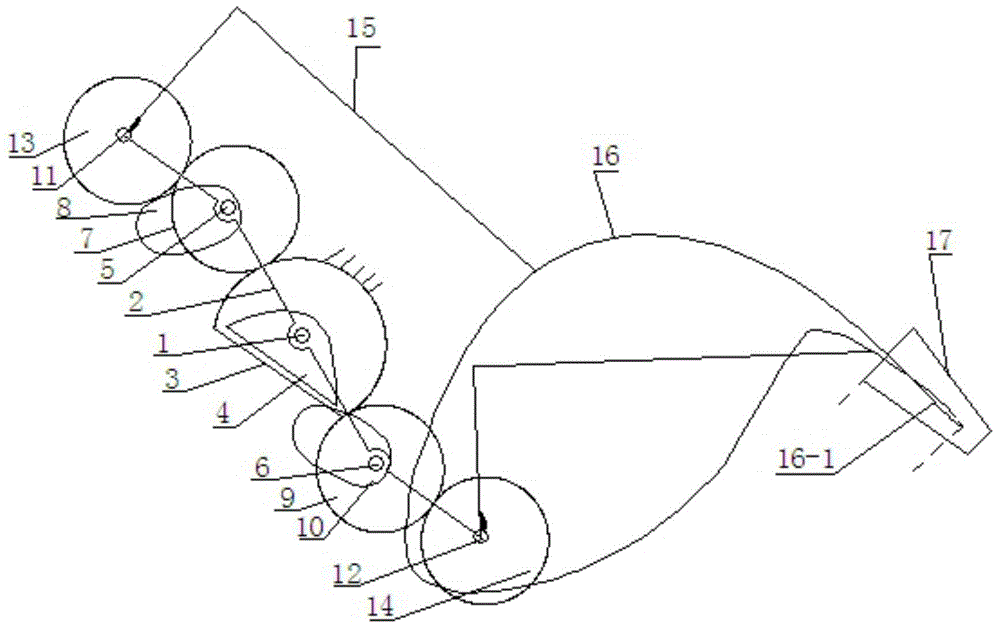

Rotary transplanting device of pot seedling transplanting machine

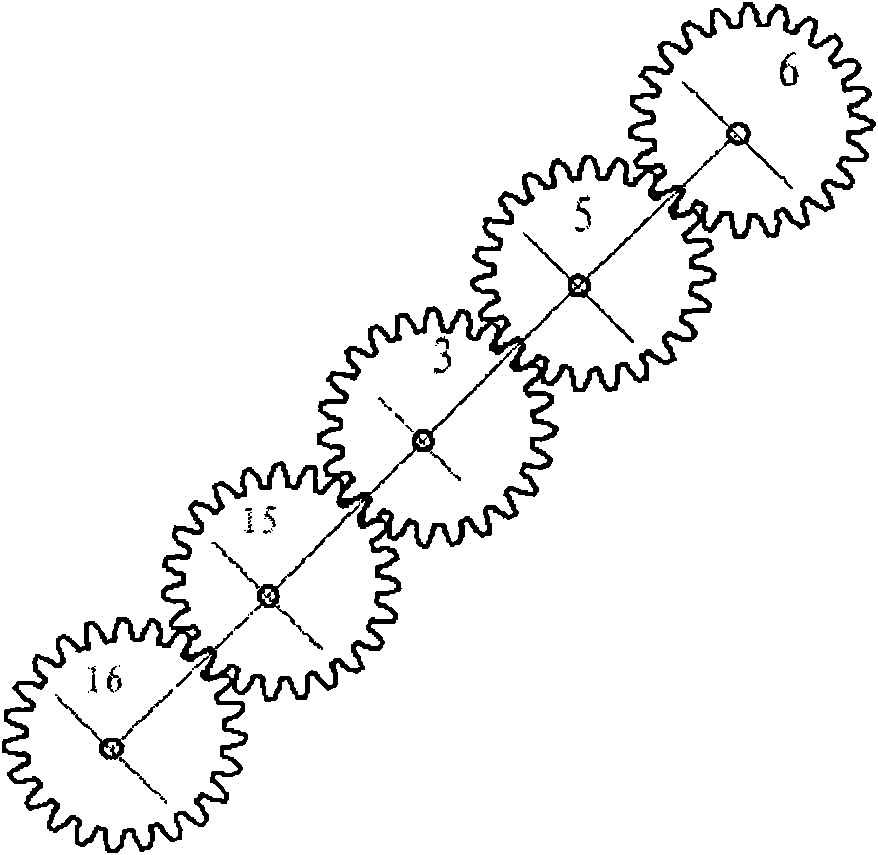

InactiveCN101878692ASmall inertia forceMeet the agronomic requirements for transplantingTransplantingGear wheelEngineering

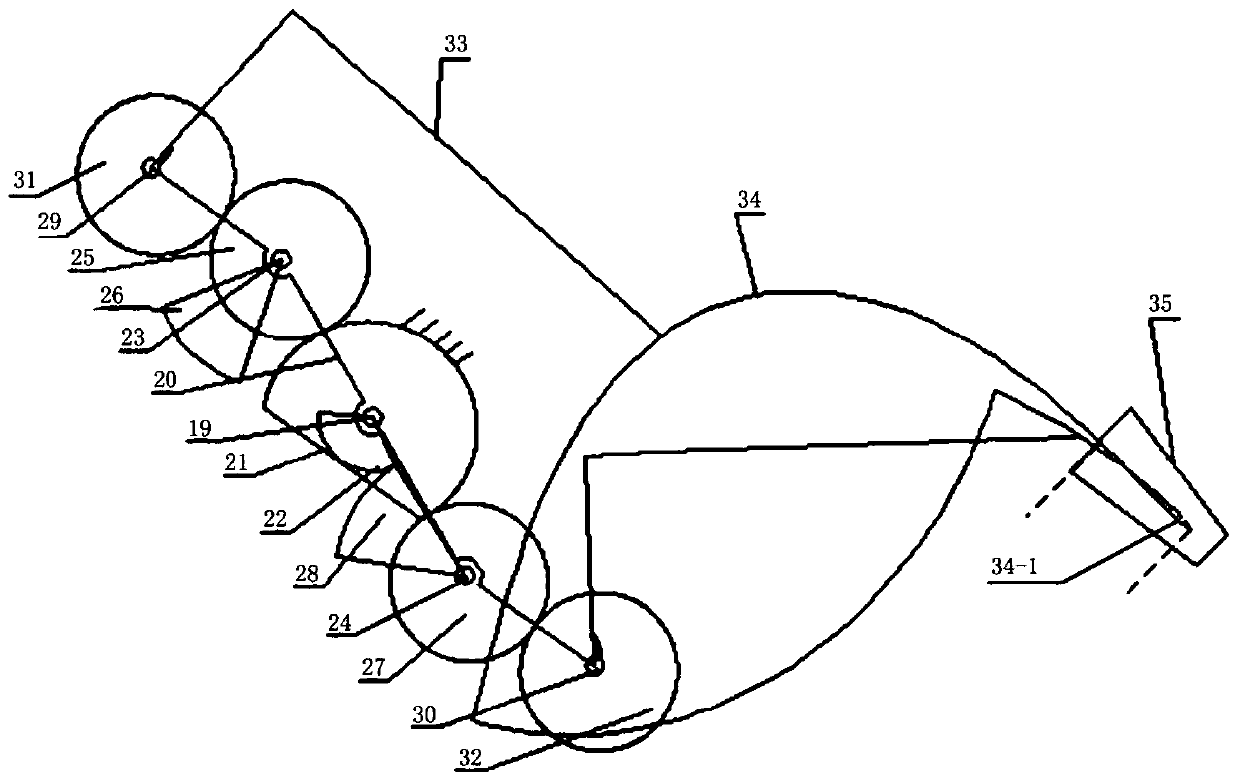

The invention discloses a rotary transplanting device of a pot seedling transplanting machine. Power is output by a sprocket shaft and transferred to a left planetary carrier system transplanting device and a right planetary carrier system transplanting device. A planetary carrier is driven by the sprocket shaft, a non-circular sun gear is fixedly connected with a sprocket box and is stationary in work, and a middle non-circular gear and a planetary non-circular gear are symmetrically arranged at both sides of the non-circular sun gear. The extending end of a planetary axle is upwards articulated with an inner half transplanting nozzle and an outer half transplanting nozzle which are respectively provided with a groove and a pin for realizing the centering opening of the transplanting nozzles. The transplanting nozzles are opened by the relative rotation of a roller on the inner half transplanting nozzle and an end surface cam fixed on the planetary carrier and closed by springs mounted on the inner half transplanting nozzle and the outer half transplanting nozzle. By a non-circular gear planetary system, the uniform rotation of the sprocket shaft is turned into the swinging absolute motion of the planetary axle to form an orbit and a stance which are needed by the transplanting nozzles on the planetary axle and satisfy the agricultural requirement of pot seedling transplantation.

Owner:ZHEJIANG SCI-TECH UNIV

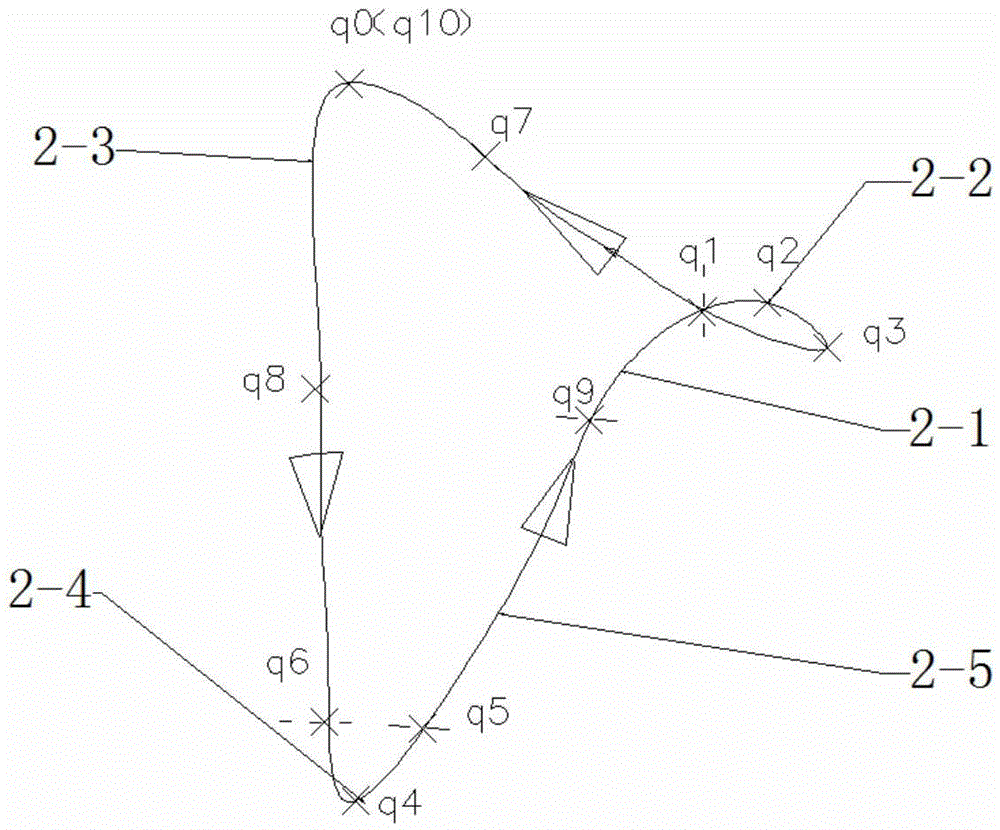

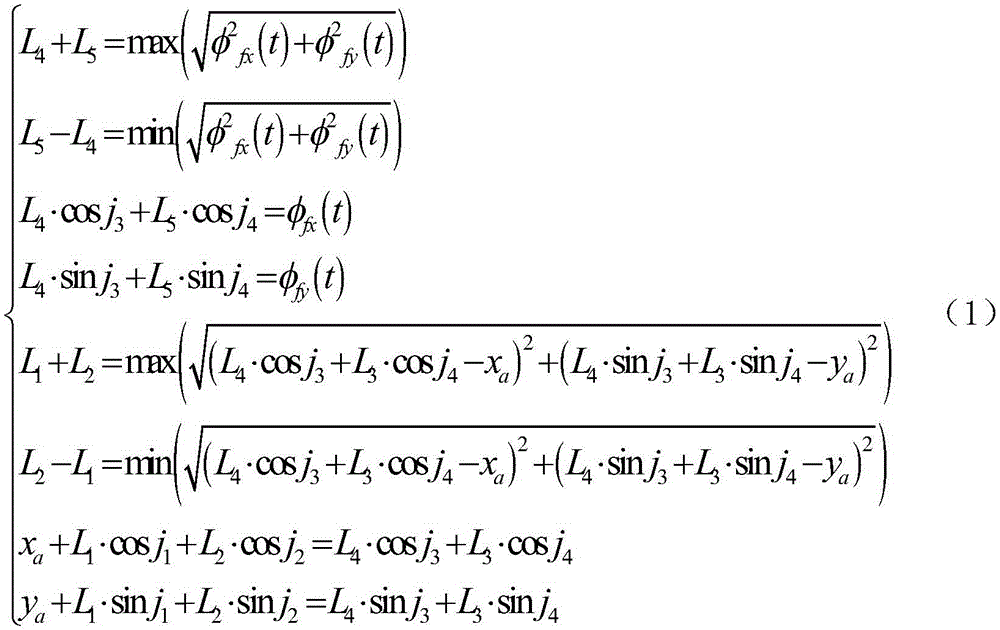

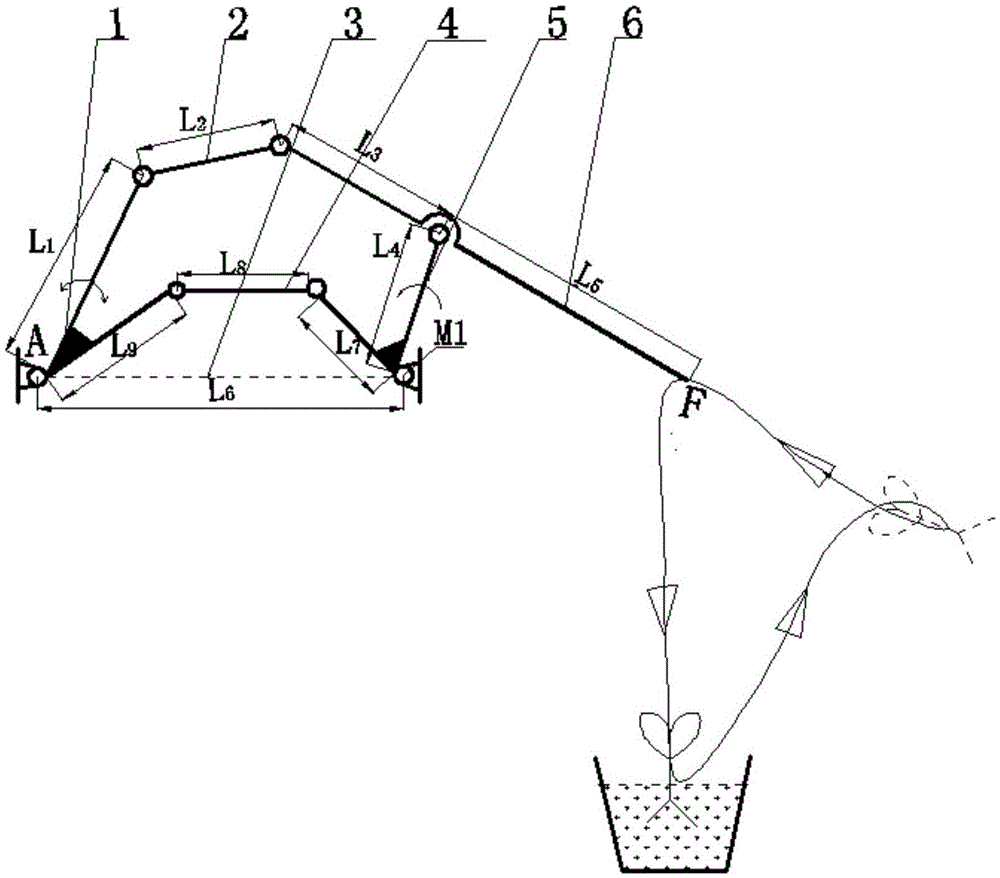

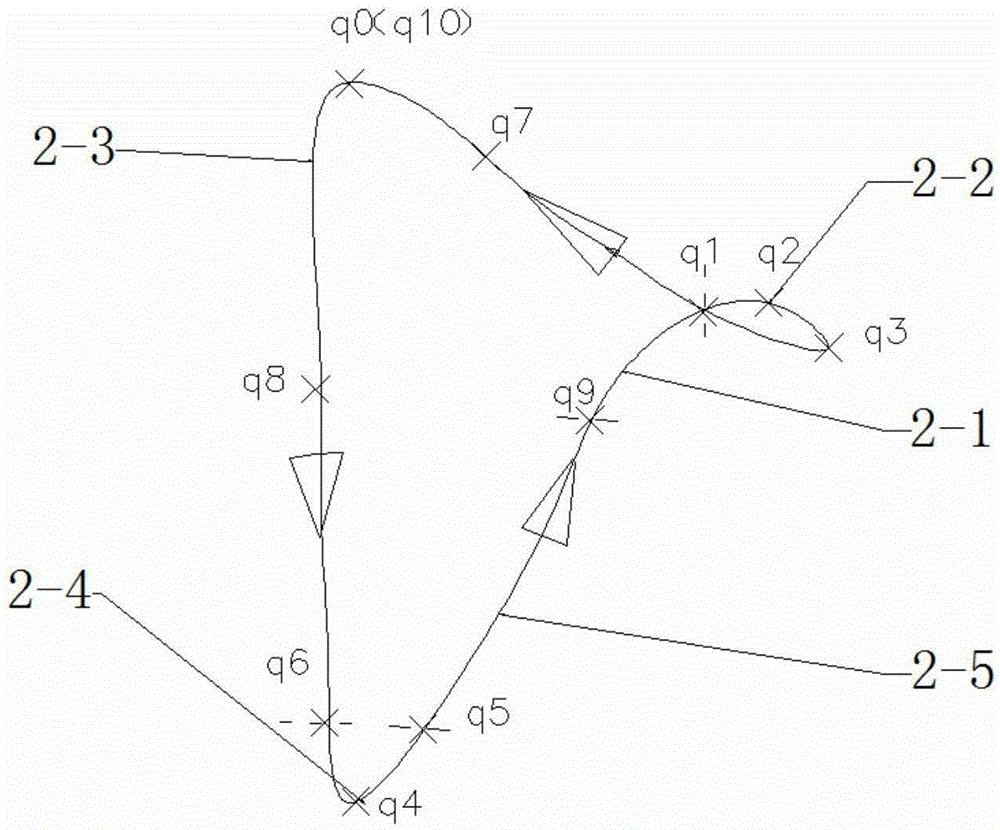

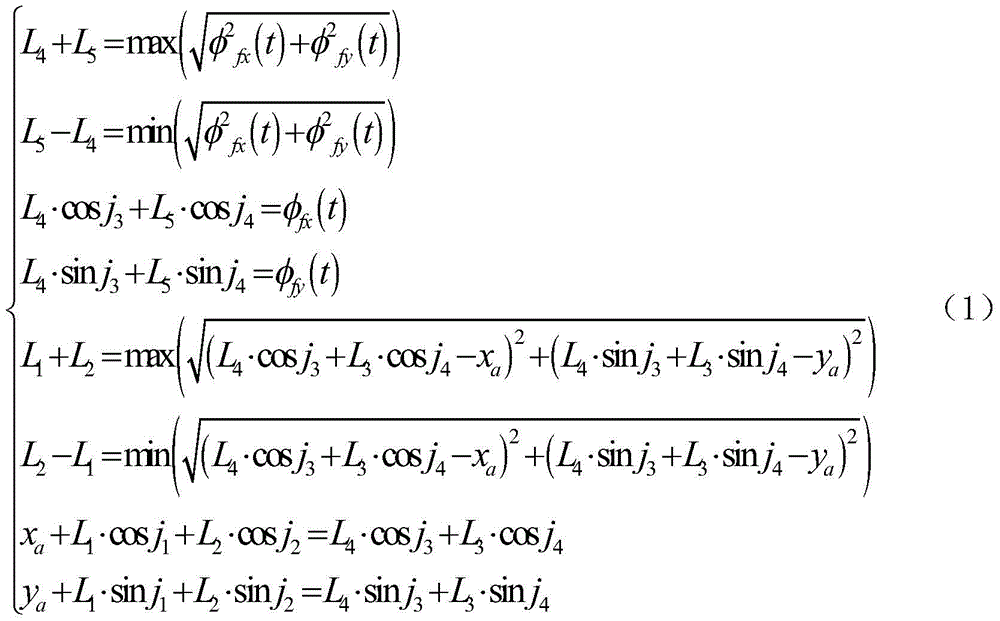

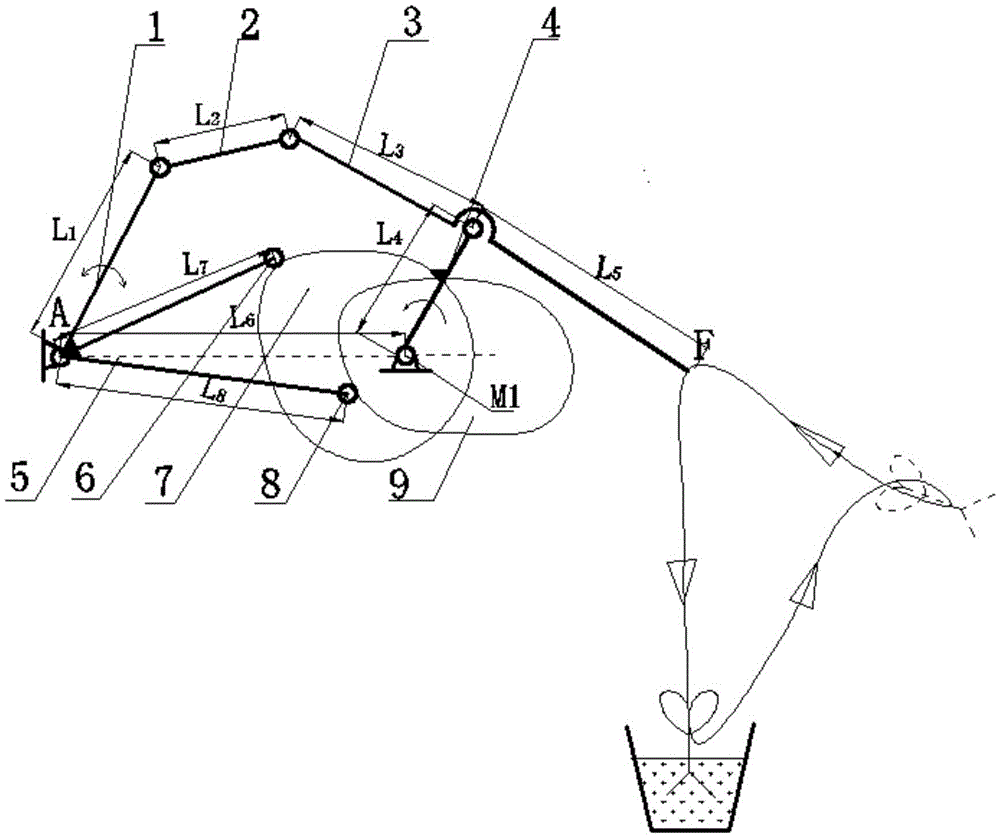

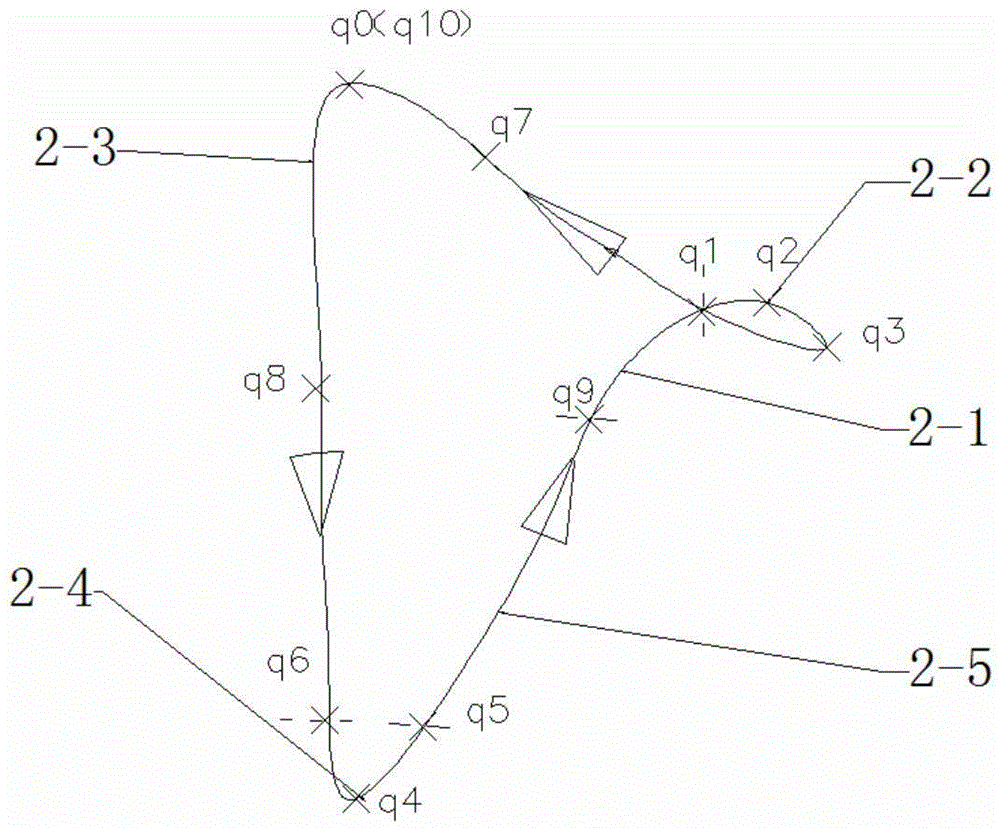

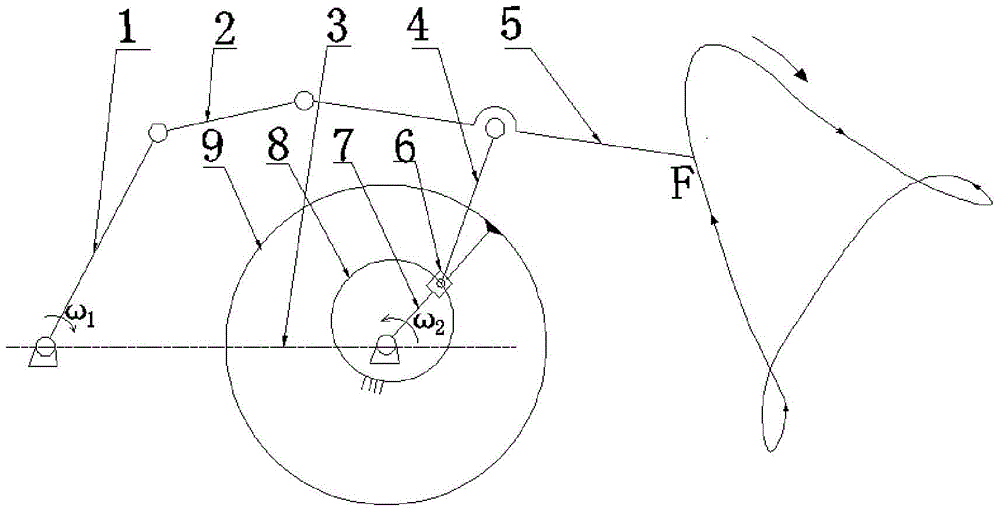

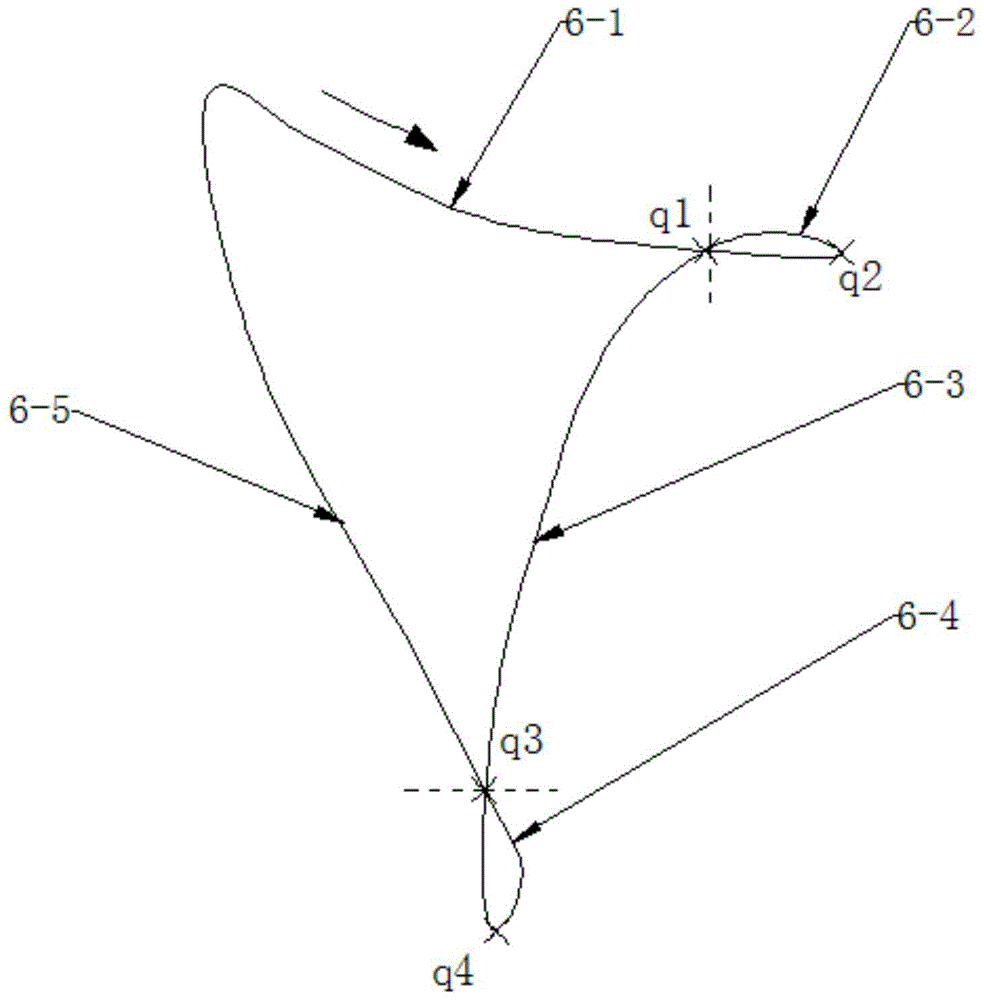

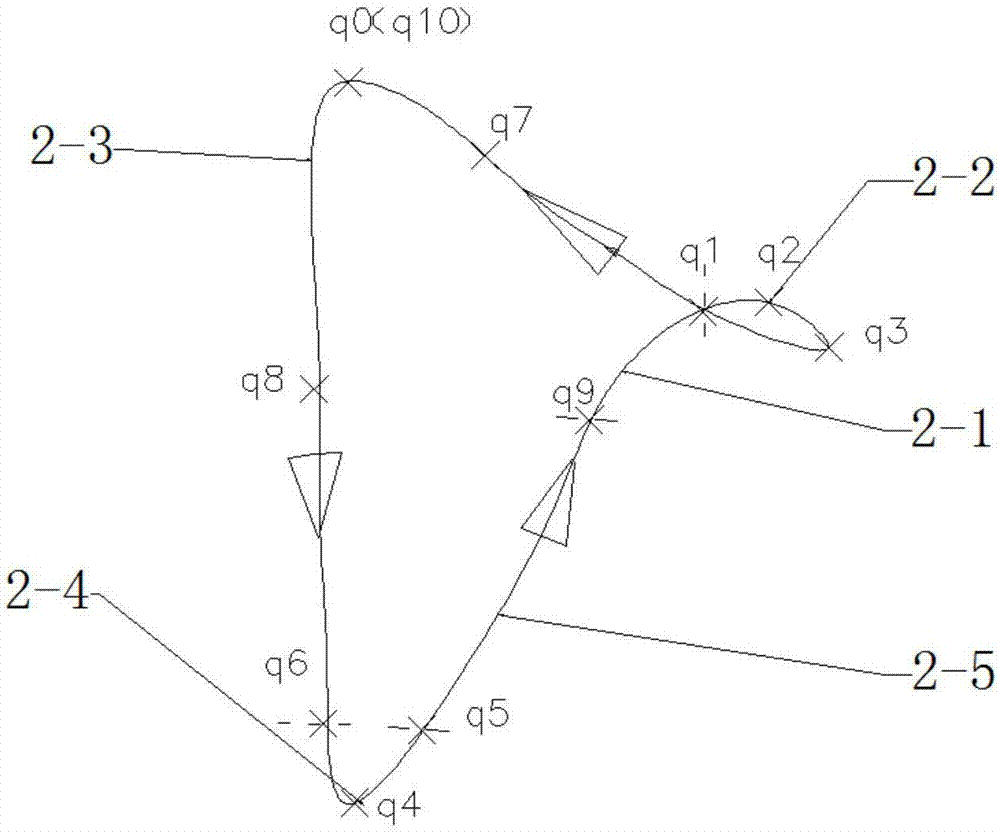

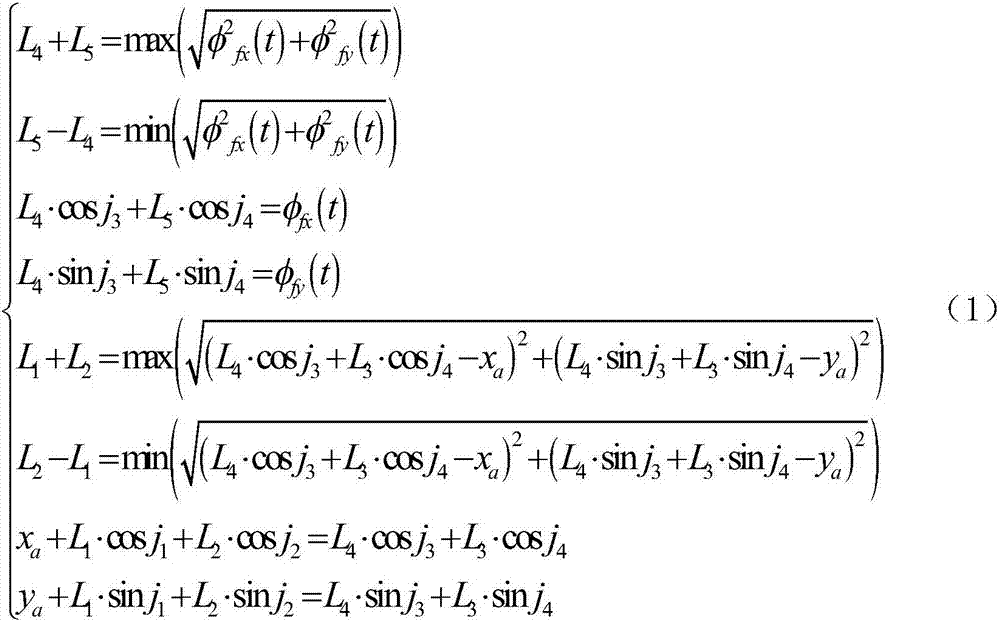

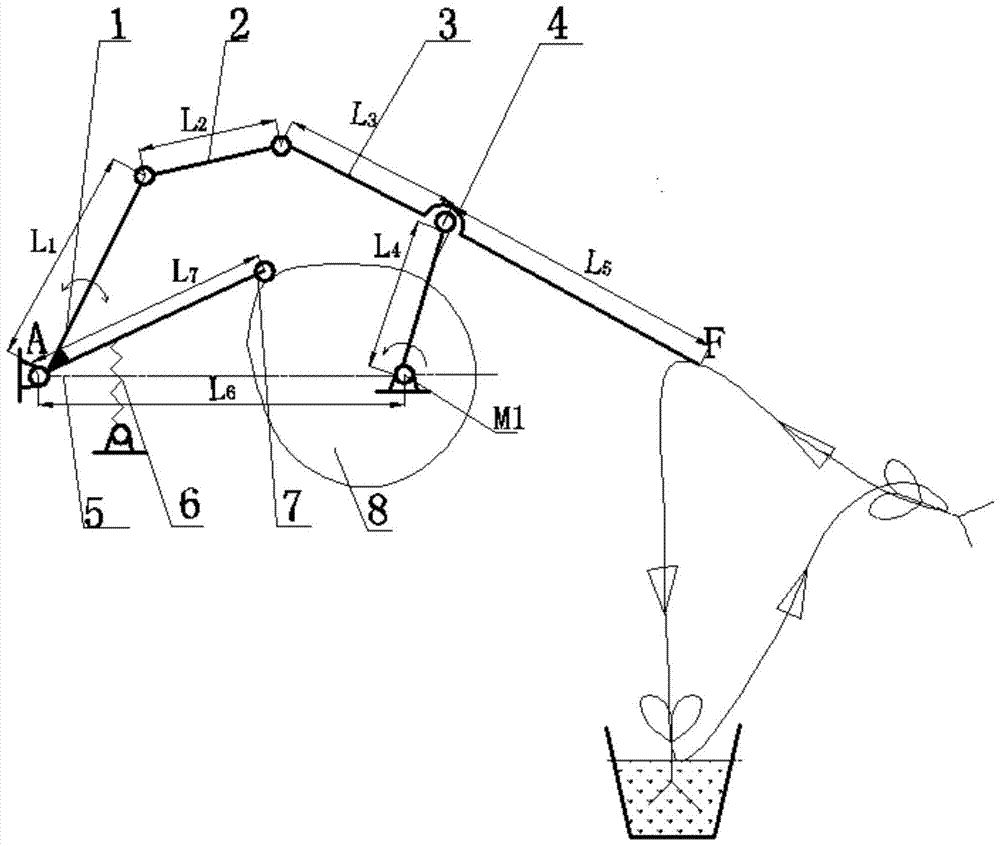

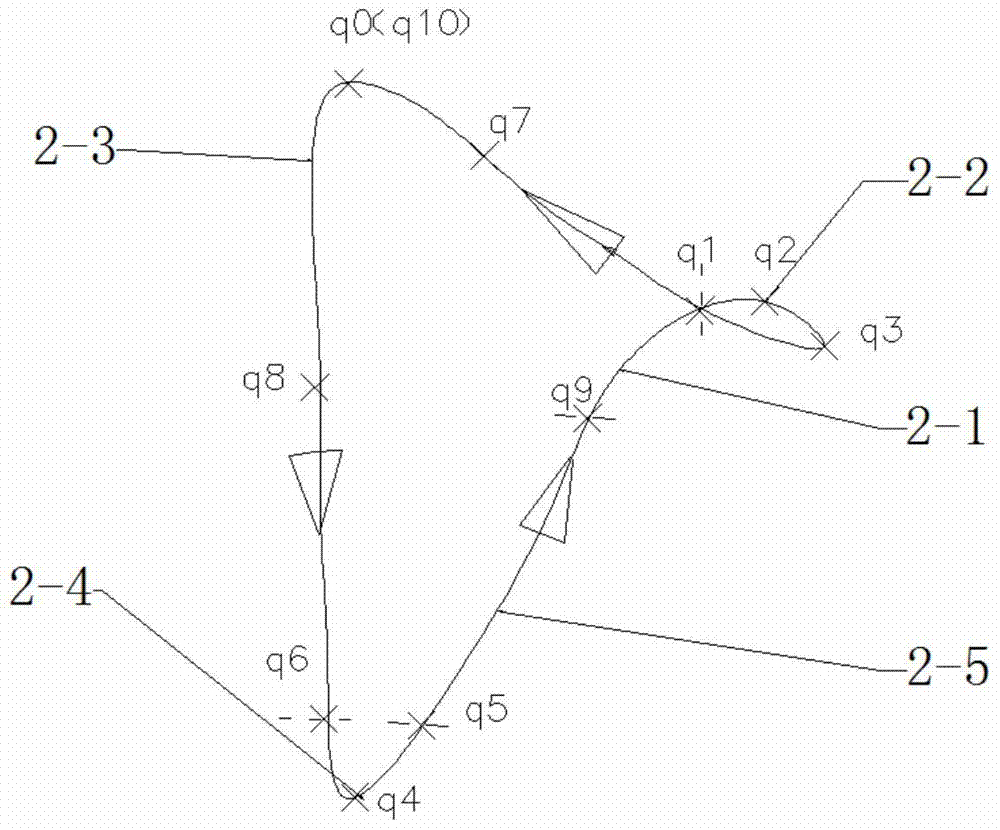

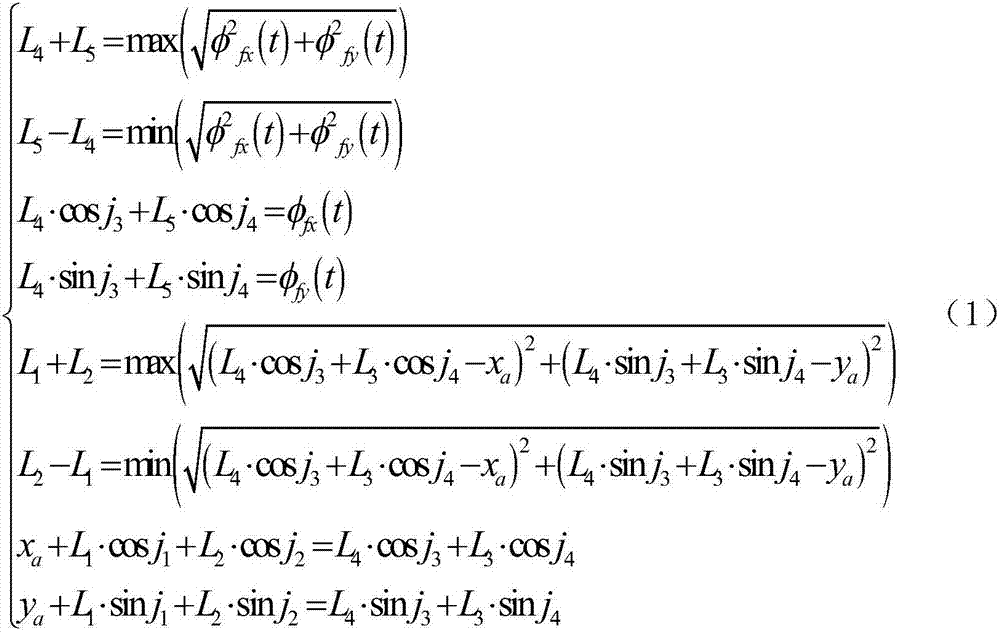

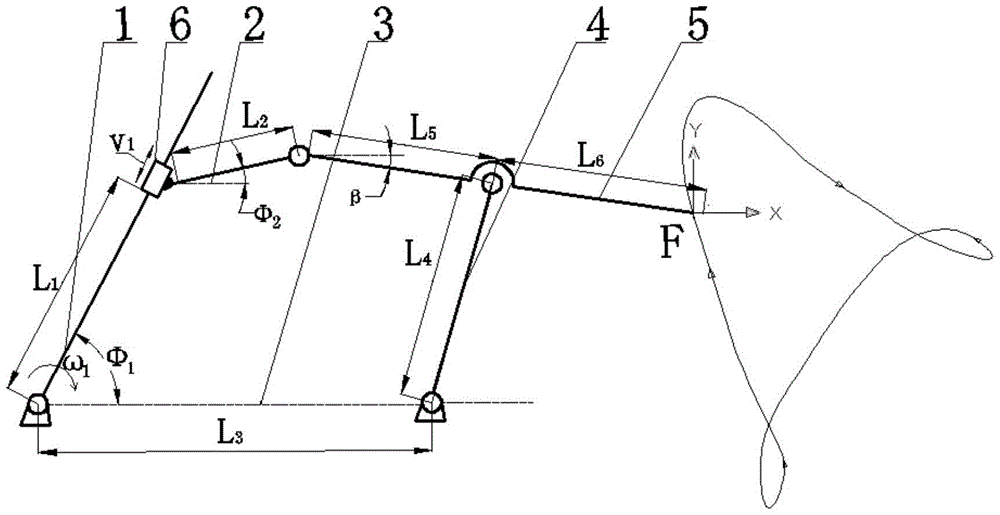

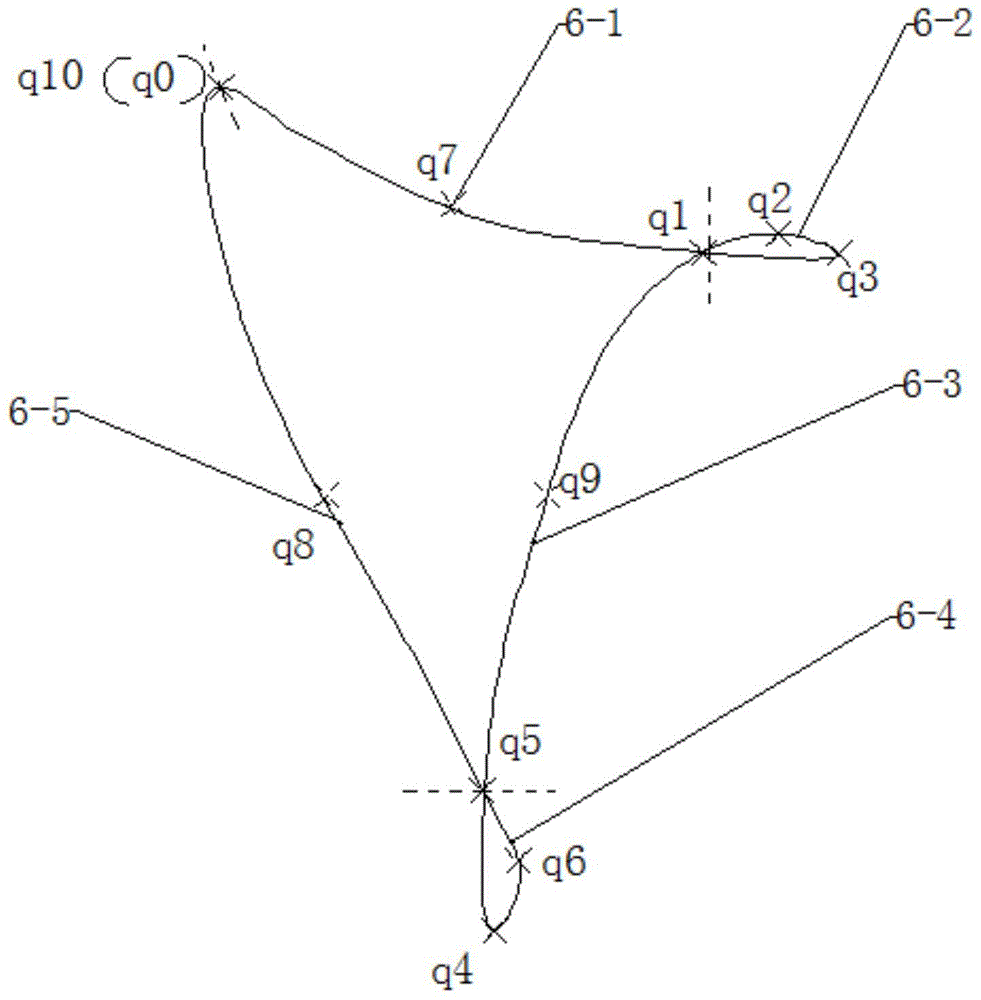

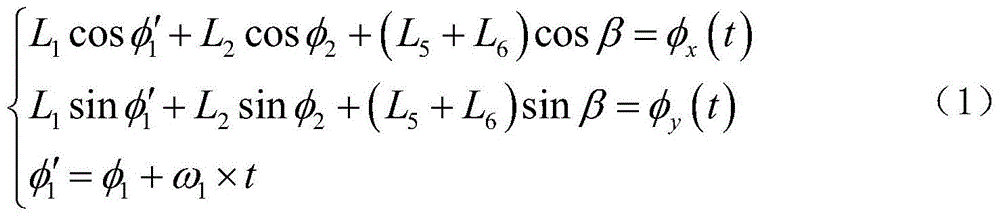

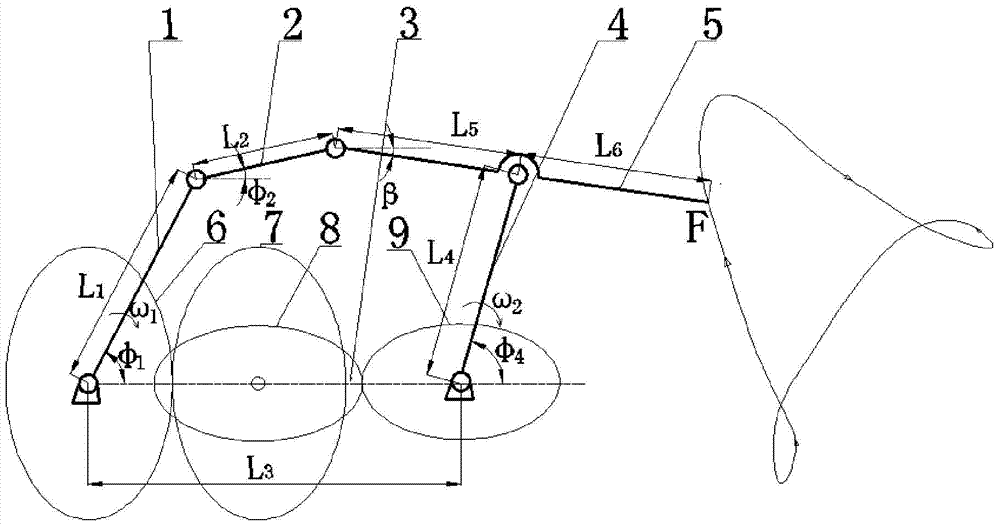

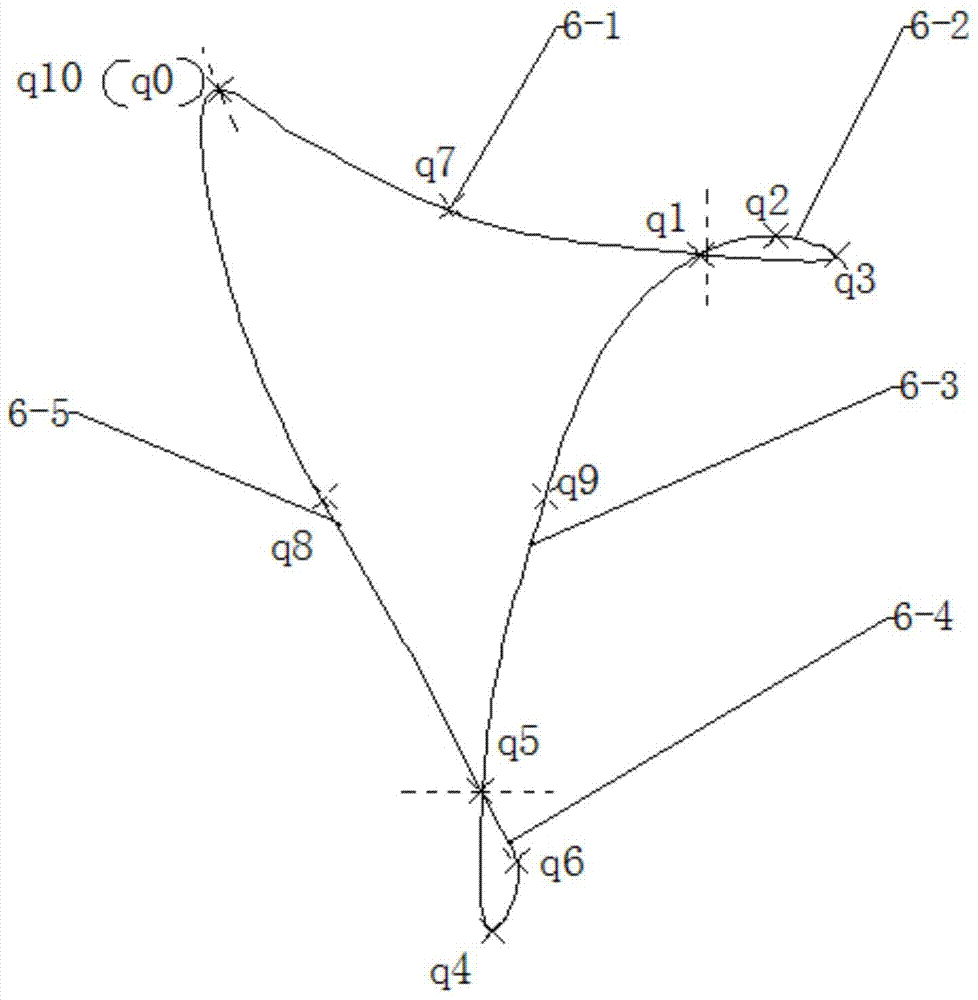

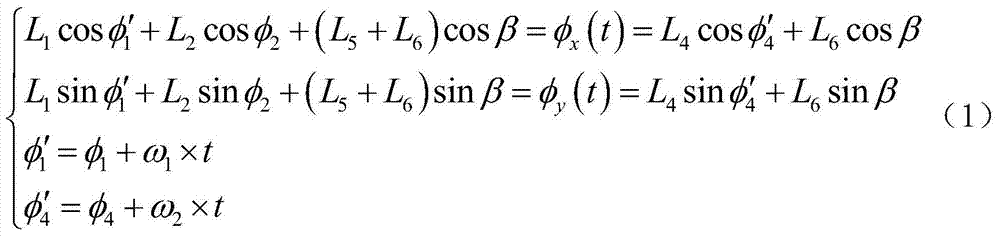

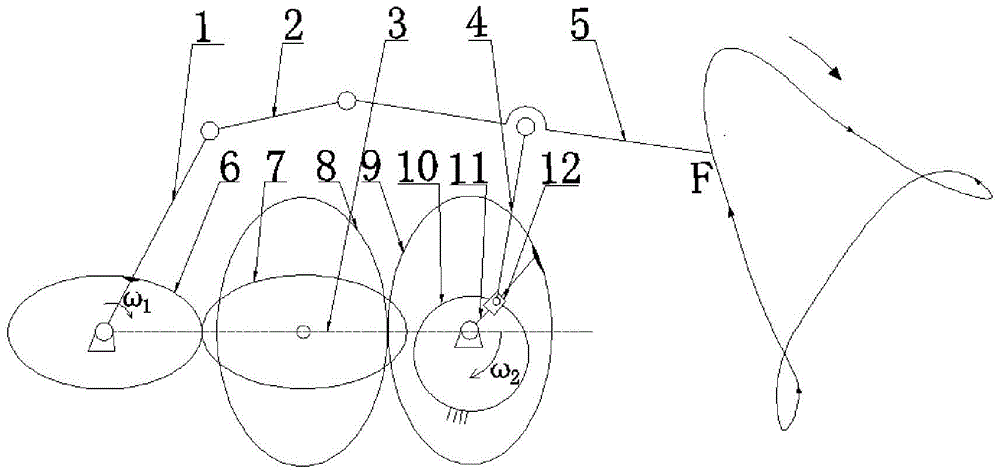

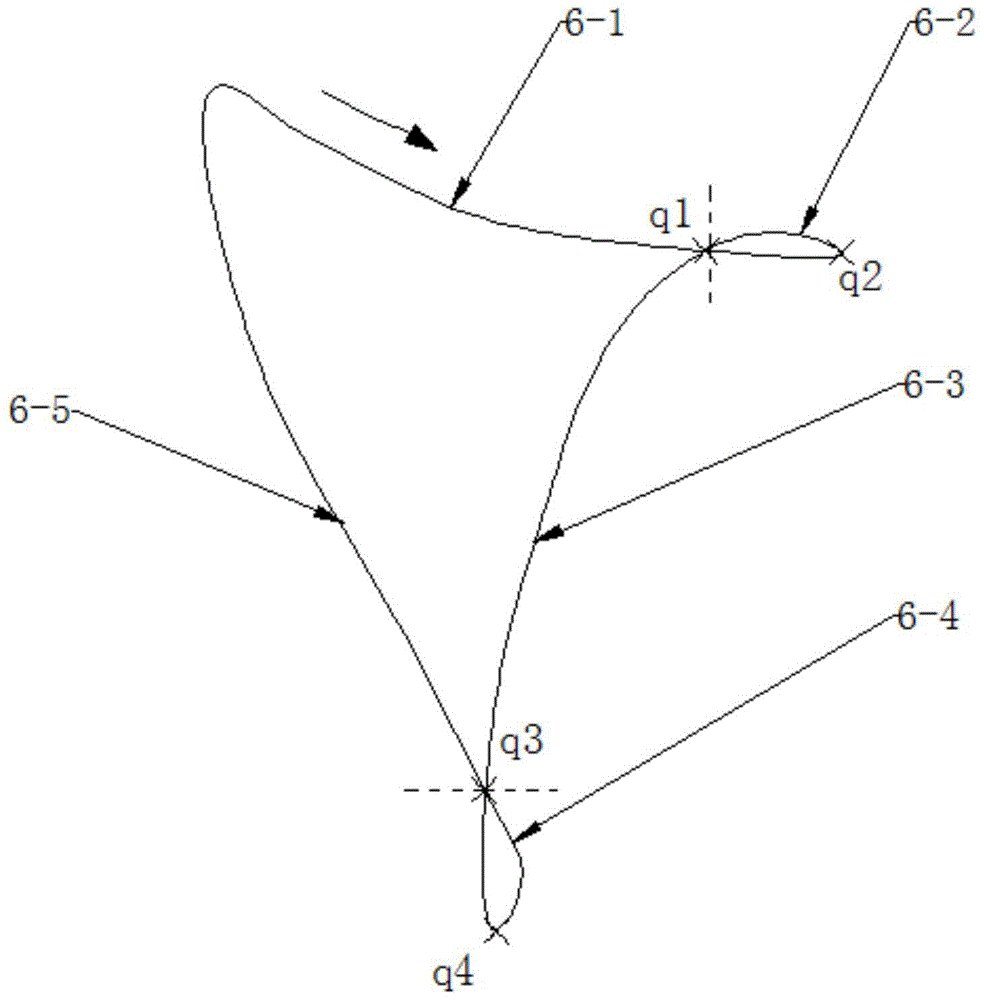

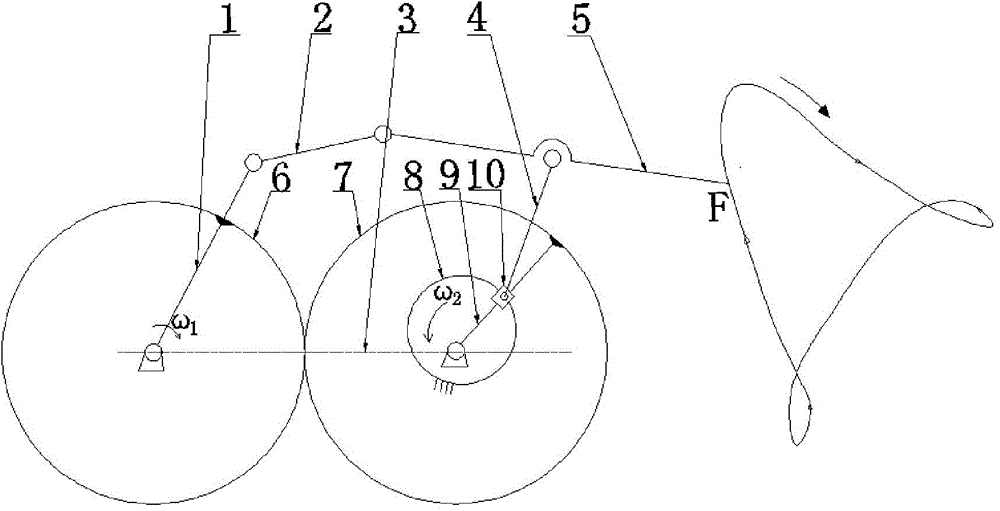

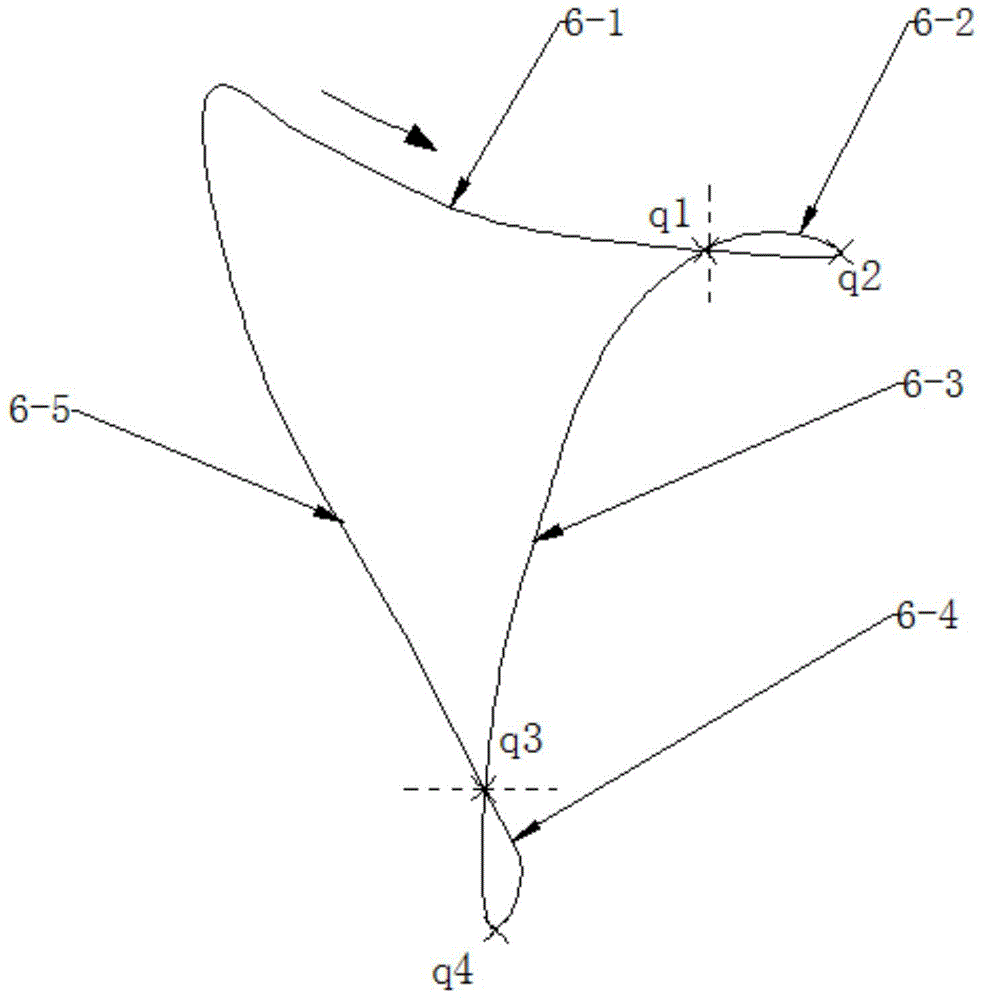

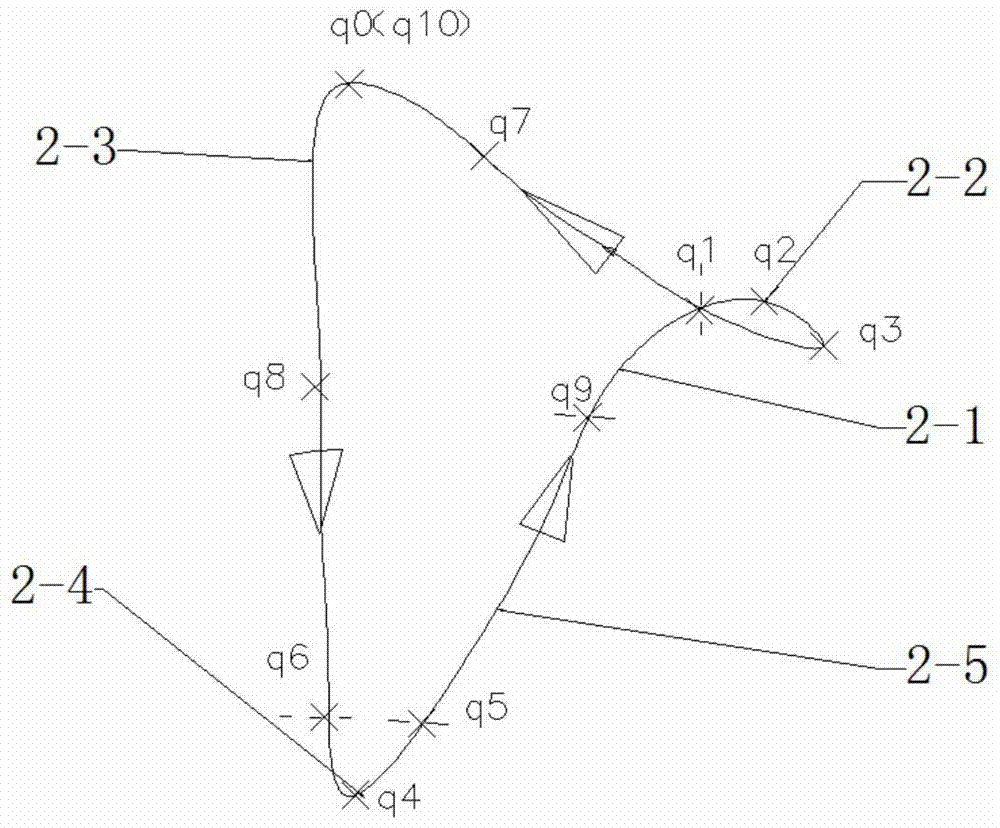

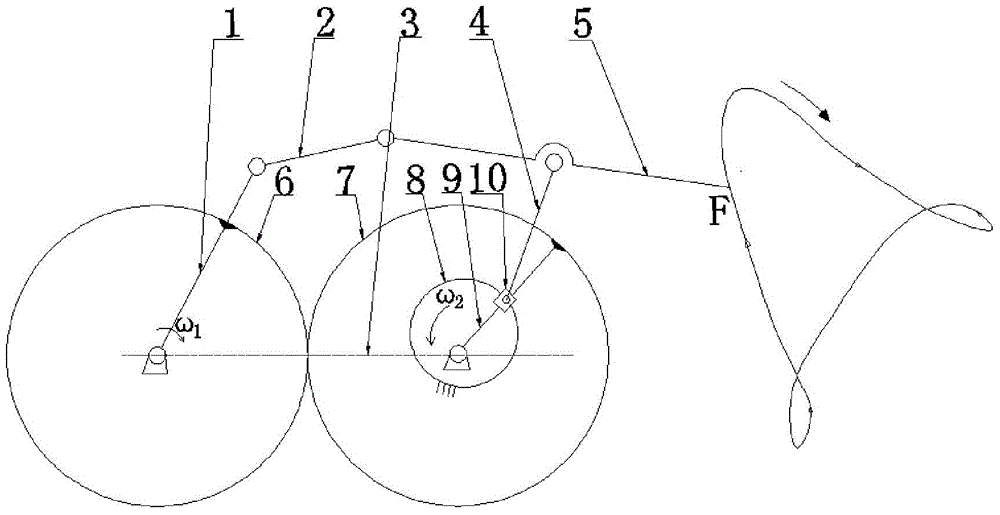

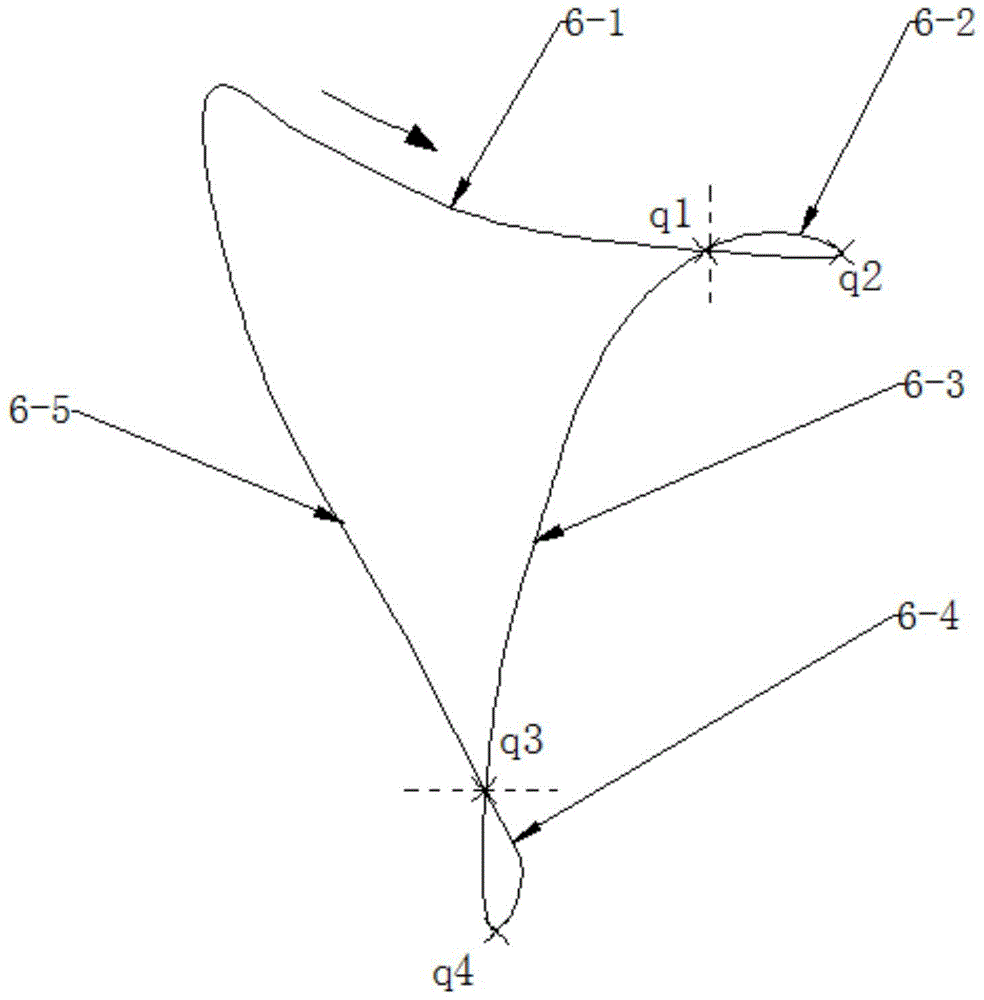

Design method for forming transplanting track by using five-rod driving mechanism with two degrees of freedom

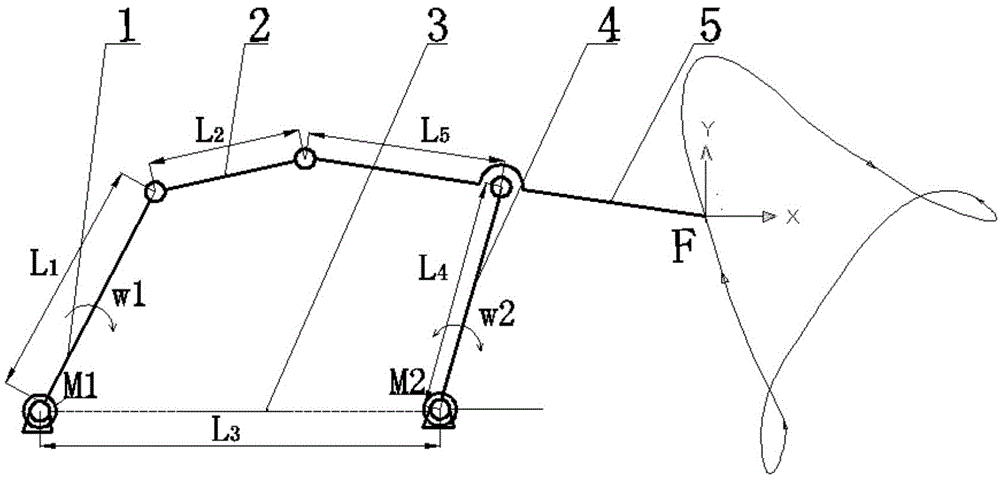

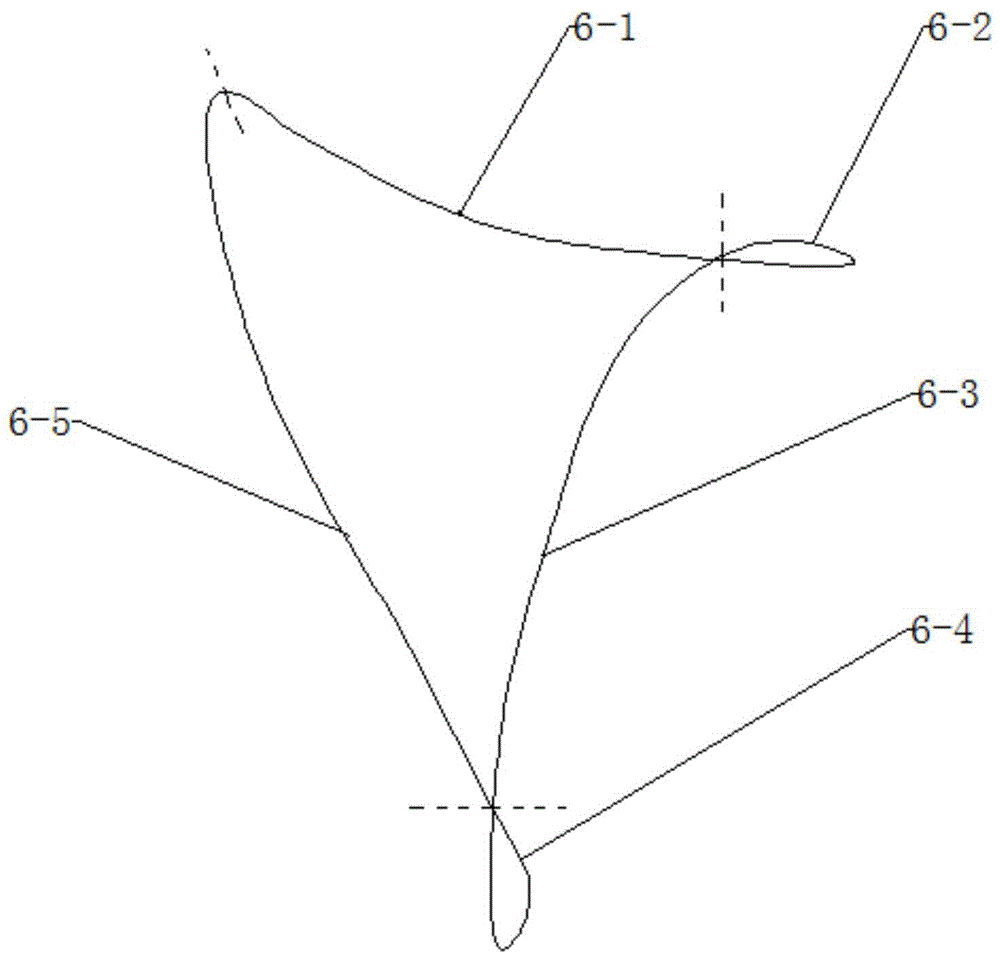

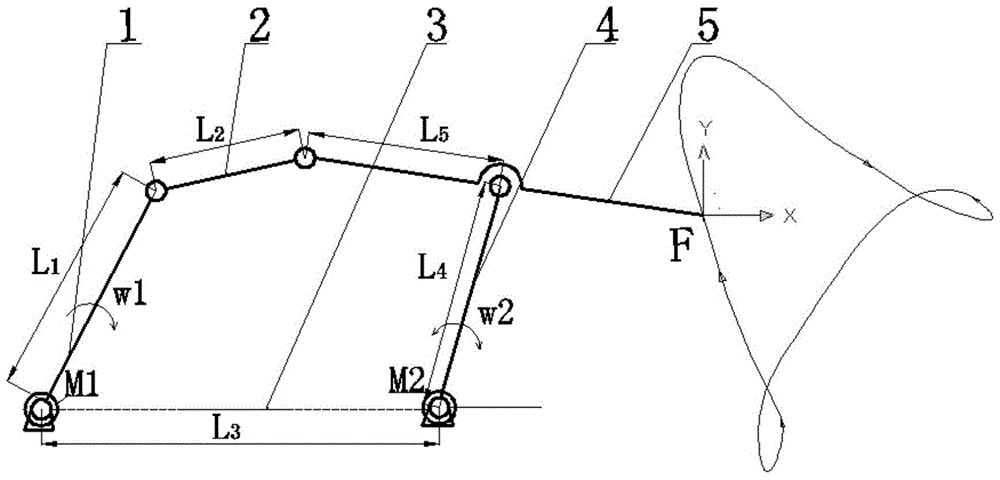

InactiveCN104641771ARealize automatic transplantingImprove flexibilityTransplantingEngineeringControl circuit

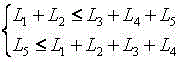

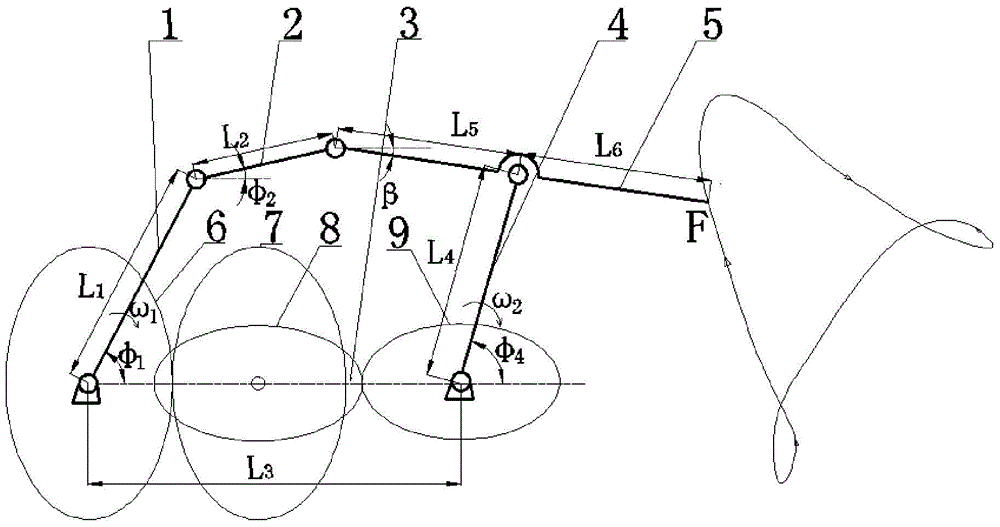

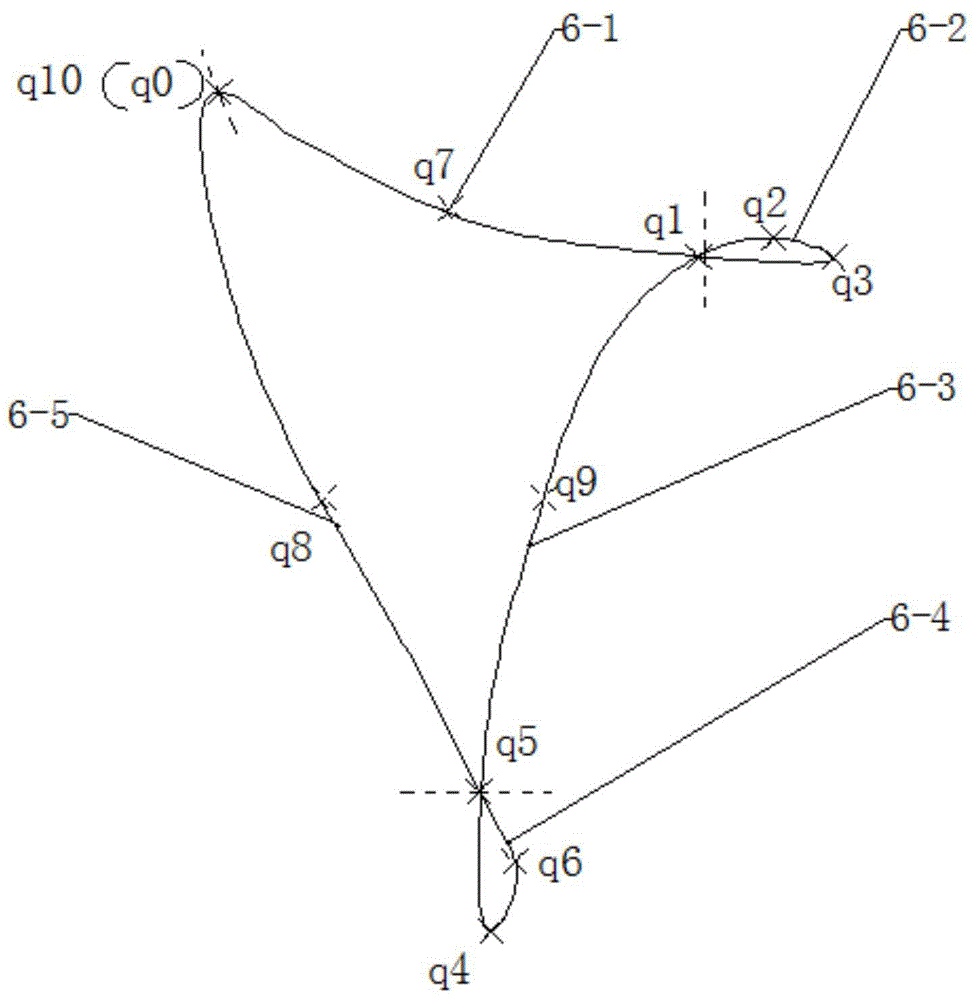

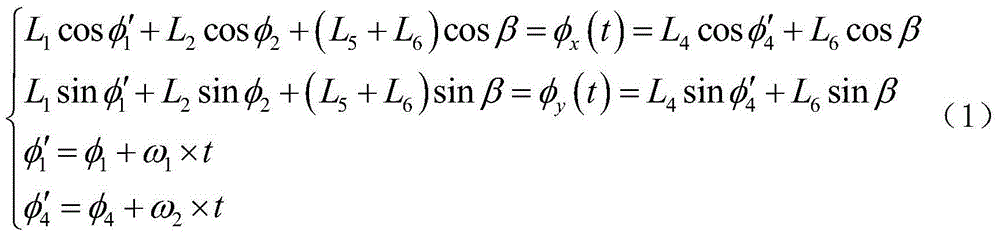

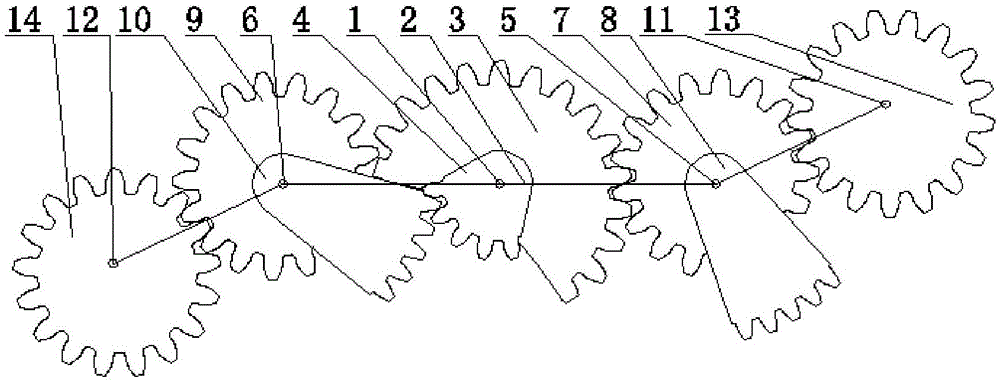

The invention discloses a design method for forming a transplanting track by using a five-rod driving mechanism with two degrees of freedom. The existing transplanting mechanism track is not suitable for transplanting flowers. According to the design method, the angular speed w1 of a first crank is set through a normal-speed motor, and a speed-adjustable motor is adjusted through a control circuit, so that the angular speed of a second crank is shown in the specification, wherein w1 is a constant value selected from 50r / min to 70r / min, and theta is a constant value selected from pi / 4 to pi / 2; the direction of the angular speed w2 meets the following change rule under the condition that the period T=2pi, namely that the direction of the angular speed w2 is kept consistent with the direction of the angular speed w1 when the time t is from 0 to T / 3 and is opposite to the direction of the angular speed w1 when the time t is from T / 3 to T, so that a double-buckle transplanting track is formed at the sharp point of the free end of a second connecting rod. The double-buckle transplanting track is achieved by using the five-rod driving mechanism with two degrees of freedom, so that not only can the transplanting tracks of flowers be achieved, but also the fully-automatic transplanting of various crops such as melons, fruits and vegetables can be realized.

Owner:ZHEJIANG SCI-TECH UNIV

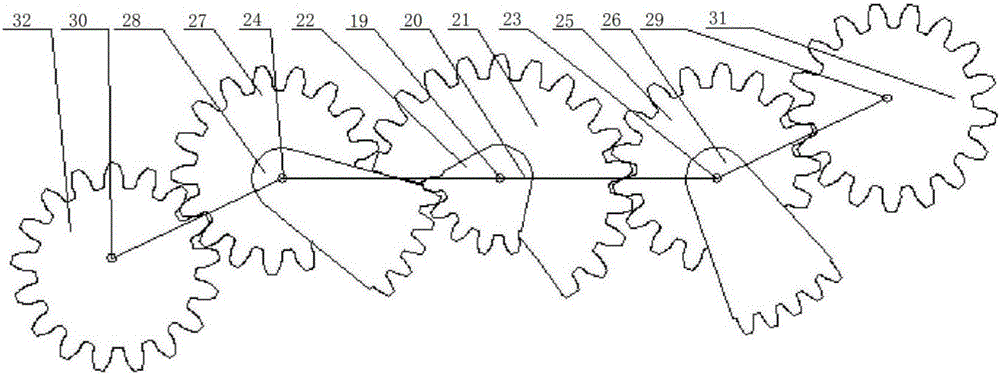

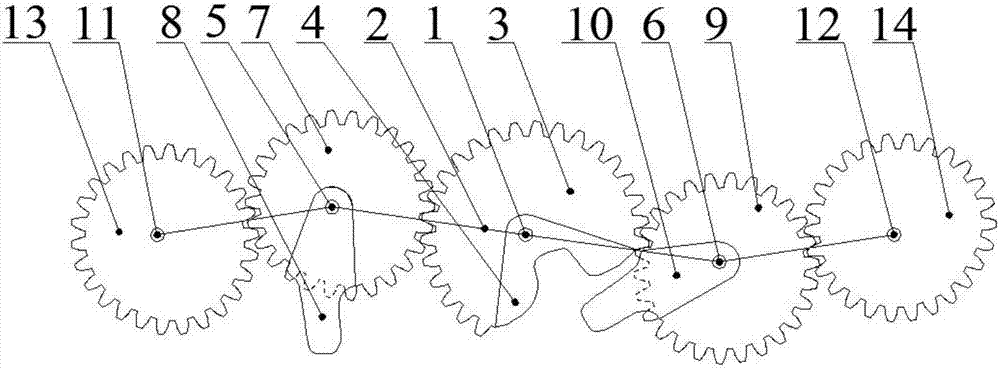

Design method for forming flower transplanting track by two-stage non-circular gear five-bar driving mechanism

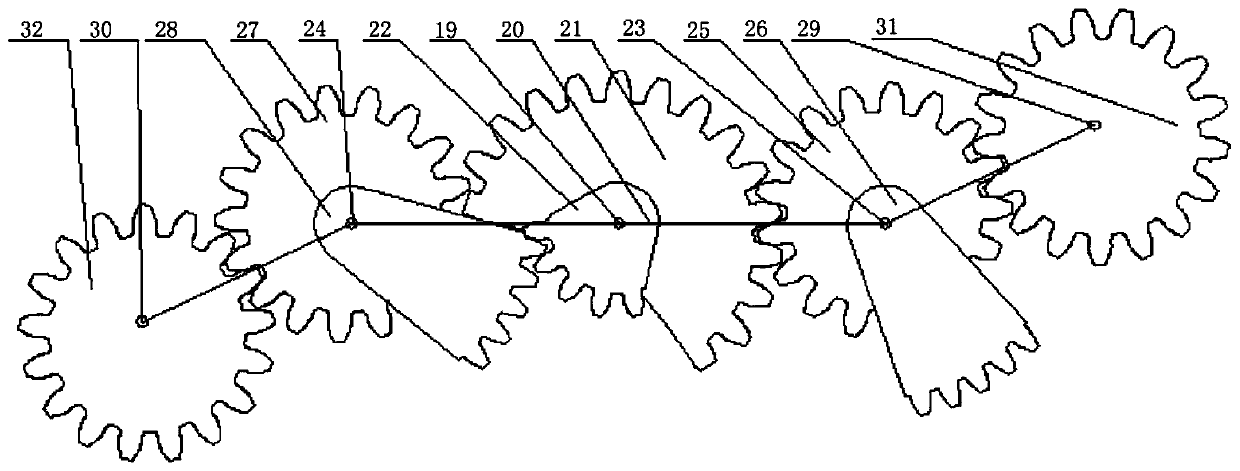

ActiveCN104657546ARealize automatic transplantingImprove flexibilityTransplantingSpecial data processing applicationsMathematical modelAngular velocity

The invention discloses a design method for forming a flower transplanting track by a two-stage non-circular gear five-bar driving mechanism. An existing transplanting mechanism track is not suitable for flower transplantation. The design method specifically comprises the following steps: firstly, constructing a two-stage non-circular gear five-bar driving mechanism, and establishing a free end point of a second connecting rod, so as to form a mathematical model of a double-buckle track; then reversely determining angular velocity change rules of a first crank and a second crank through the established mathematical model, designing a two-stage non-circular gear, and verifying whether the two-stage non-circular gear five-bar driving mechanism satisfies existence conditions of the double cranks. According to the design method, the angular velocity ratio of the first crank to the second crank is changed by adopting the two-stage non-circular gear five-bar driving mechanism, the double-buckle track is realized, so as to realize seedling taking and planting motions, the flower transplanting track can be realized, and full automatic transplantation of various crops such as fruits and vegetables can be realized.

Owner:安徽翰邦科技咨询有限公司

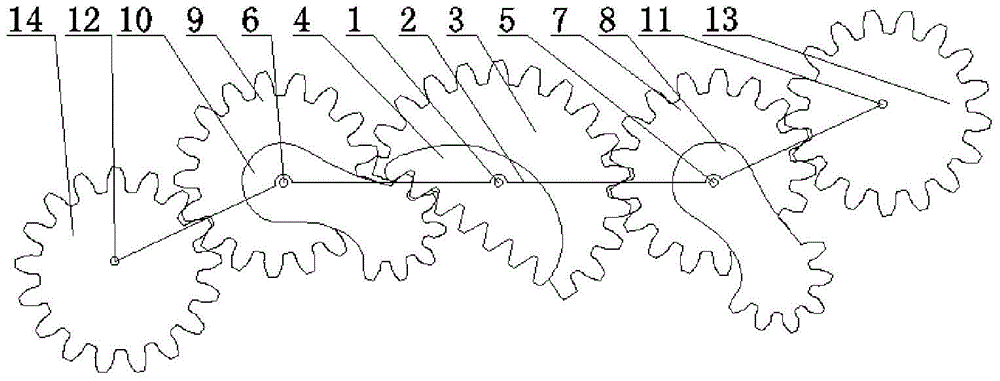

Combined incompletely eccentrically circular and non-circular gear planetary train vegetable seedling pick-up mechanism

ActiveCN105638055AMeet the agronomic requirements for transplantingOvercome stabilityToothed gearingsTransplantingAgricultural engineeringSeedling

The invention discloses a combined incompletely eccentrically circular and non-circular gear planetary train vegetable seedling pick-up mechanism. An existing pick-up mechanism gains a wide-range variation in a transmission ratio of a pick-up trajectory through a locking arc and has high transmission impact. In the mechanism, a center shaft and a planet carrier are fixed; a central incompletely eccentrically circular gear is fixed to a frame, a central incompletely non-circular gear is fixed to the central incompletely eccentrically circular gear, and both the two gears loosely sleeve the center shaft; a first middle non-circular gear is connected with a first middle shaft through splines, and a first middle incompletely non-circular gear is fixed to a first middle non-circular gear; a second middle non-circular gear is connected with a second middle shaft through splines, and a second middle incompletely non-circular gear is fixed to the second middle non-circular gear; a first planet non-circular gear is connected with a first planet shaft through splines, and a second planet non-circular gear is connected with a second planet shaft through splines; both one end of a first planet shaft and one end of the second planet shaft are fixed to a shell of a pick-up claw. This mechanism has stable transmission and low impact.

Owner:陕西专壹知识产权运营有限公司

Cam-crank-rocker combined flower transplanting mechanism and design method thereof

ActiveCN105519290AMeet the agronomic requirements for transplantingMeet agronomic requirementsTransplantingMathematical modelEngineering

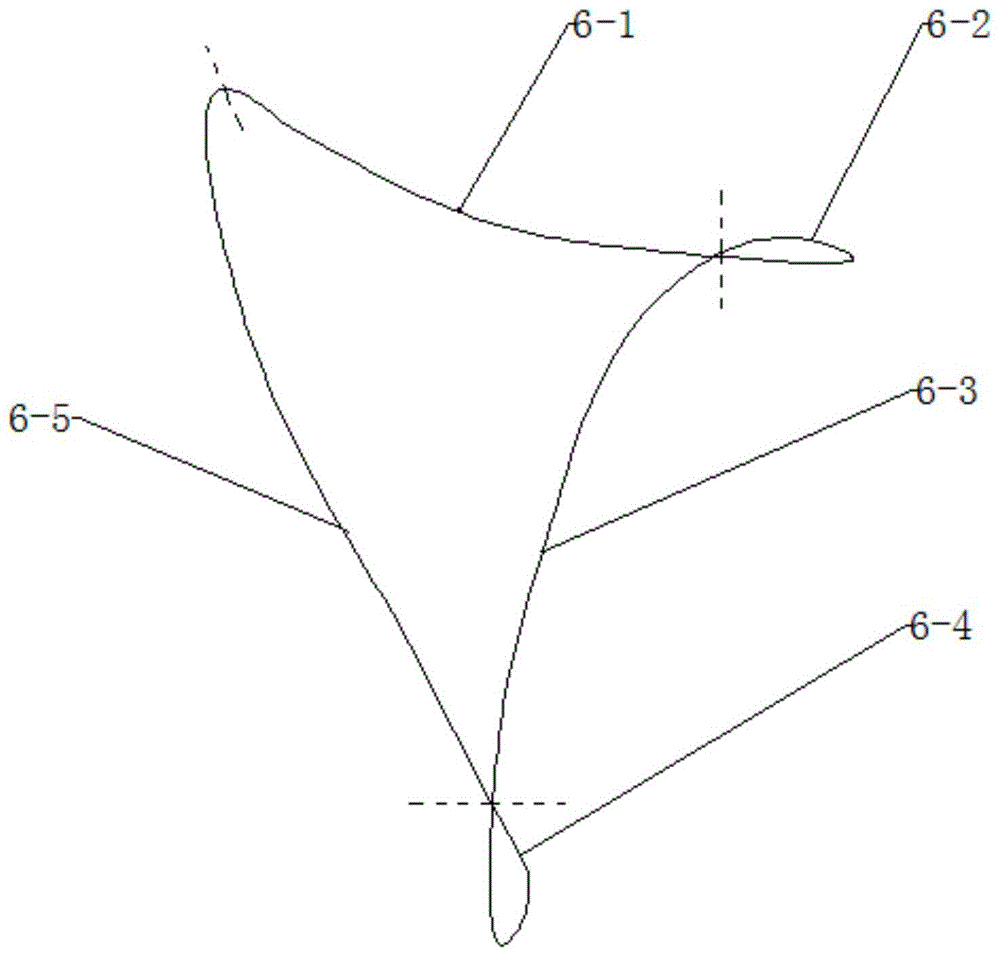

The invention discloses a cam-crank-rocker combined flower transplanting mechanism and a design method thereof. A planetary gear transplanting mechanism is limited in flexibility of realizing a trajectory; and a rod mechanism with a double-ring-buckle trajectory is difficult in design and parameter regulation. According to the mechanism provided by the invention, one ends of a cam and a crank are both hinged with a frame through a camshaft; the other end of the crank is hinged with the central part of a second connecting rod; a forked swing rod comprises a bottom-end-welded oscillating rod and a cam swing rod; two ends of a spring are separately connected with the forked swing rod and the frame; a roller is hinged with the top end of the cam swing rod and constitutes a cam pair with the cam; the top end of the oscillating rod is hinged with one end of a first connecting rod; and the other end of the first connecting rod is hinged with one end of the second connecting rod. The design method provided by the invention is as follows: the cam is reversely solved with a mathematical model of a single-ring-button trajectory formed by the terminal point of the free end of the second connecting rod, a coordinate of the hinge joint of the forked swing rod and the frame, and known conditions of rod lengths. According to the invention, through changing of the profile of the cam to control the movement law of a rocker, the single-ring-buckle trajectory is realized, and the mechanism is simple.

Owner:南通希芸园林科技有限公司

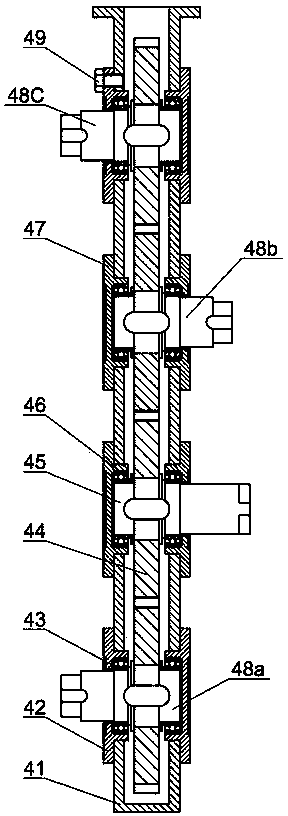

Coaxial double rod ejection type elliptical-incomplete non-circular and circular gear planetary system seedling slinging mechanism

ActiveCN106717364AMeet the agronomic requirements for transplantingReduce stabilityGearingTransplantingEllipseEngineering

The invention discloses a coaxial double rod ejection type elliptical-incomplete non-circular and circular gear planetary system seedling slinging mechanism. The mechanism comprises a planet carrier, wherein a central incomplete non-circular gear, a central incomplete circular gear, a first middle elliptical gear, a first middle incomplete circular gear, a second middle elliptical gear, a second middle incomplete circular gear, a first planet elliptical gear, a second planet elliptical gear and two seedling slinging transplanting arms are supported on the planet carrier; each of the seedling slinging transplanting arms comprises a transplanting arm housing, a hollow loop bar is slidably arranged in the transplanting arm housing, and a solid push rod is slidably arranged in the hollow loop bar; a first limiting plate, a second limiting plate and an opening and closing mechanism are arranged on the hollow loop bar; and a double outline cam, a shifting fork and a trigger are hinged in the transplanting arm housing. By adopting a layout plan of the two transplanting arms, planet carrier rotates once to fetch the seedlings and eject twice, so that the work efficiency is high; and the mechanism can be suitable for seedling slinging operations of a seedling slinging machine in a paddy field and a dry land at any rotating speeds.

Owner:ZHEJIANG FORESTRY UNIVERSITY

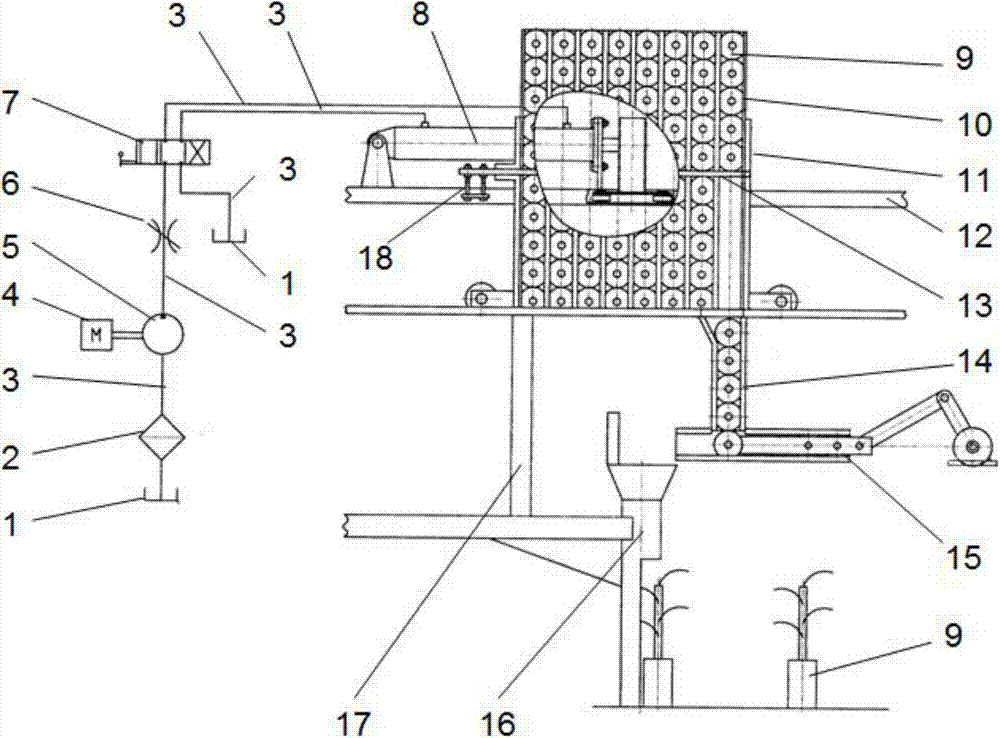

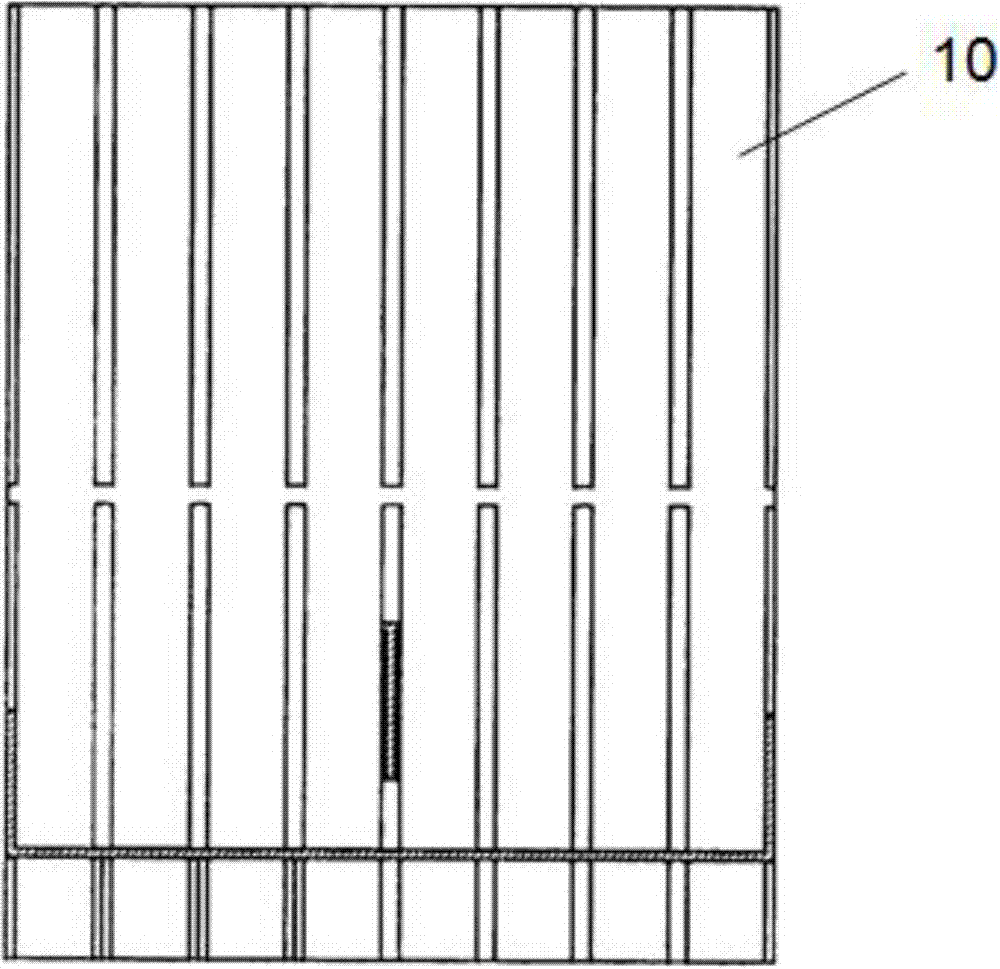

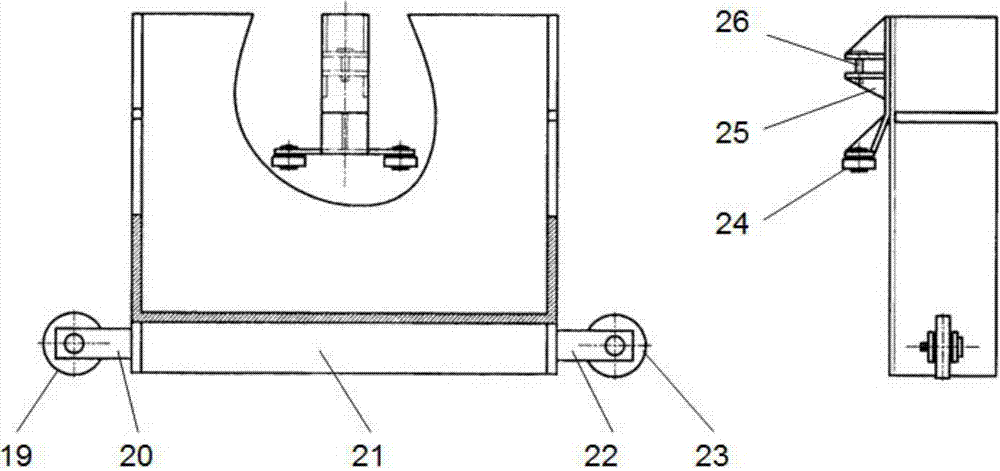

Cotton nutrition pot transplanting mechanism

InactiveCN103749053AAdjustable working speedMatch forward speedTransplantingHydraulic cylinderReciprocating motion

The invention discloses a cotton nutrition pot transplanting mechanism, comprising a hydraulic system, a primary pot feeding device, a secondary pot feeding device, a seedling planting device and the like. The core technology is that a manual direction control valve in the hydraulic system is utilized for controlling stretching of a hydraulic cylinder, so as to drive the primary pot feeding device hinged with the right end of the hydraulic cylinder to carry out right and left reciprocating motion; lower pot seedlings in a pot seedling plate are orderly fed to a vertical seedling guide tube of the secondary pot feeding device from right to left when the primary pot feeding device moves towards right; meanwhile, upper pot seedlings on the pot seedling plate orderly fall into the lower layer of the pot seedling plate from right to left; the lower pot seedlings on the pot seedling plate are orderly fed to the vertical seedling guide tube of the secondary pot feeding device from left to right when the primary pot feeding device moves towards left. The mechanism has the characteristics of being novel in structure, simple and convenient to adjust, and good in transplanting quality and the like, and has a broad application prospect.

Owner:HUAZHONG AGRI UNIV

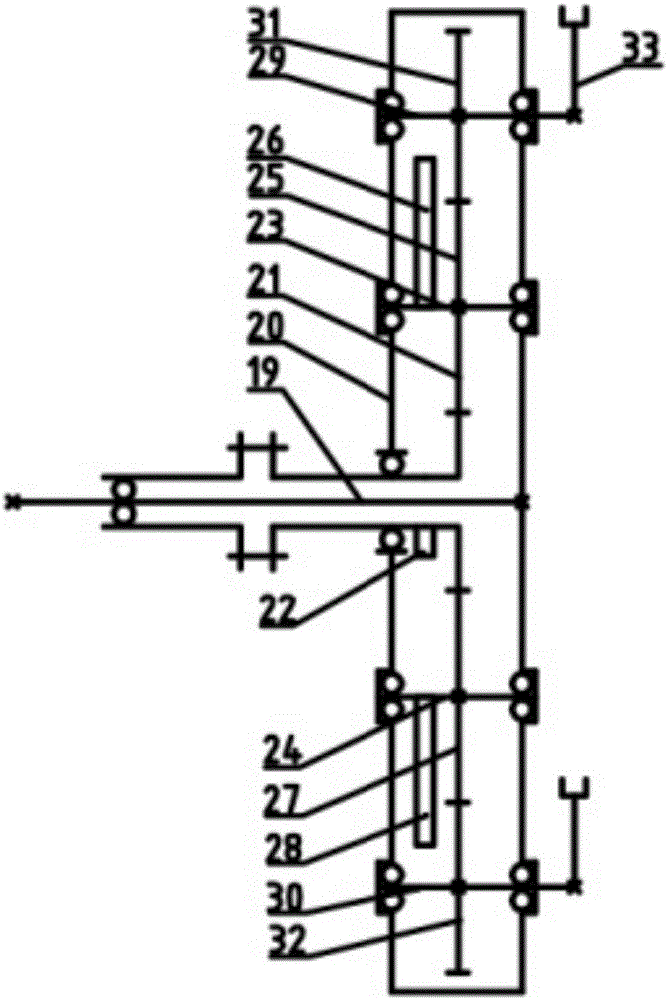

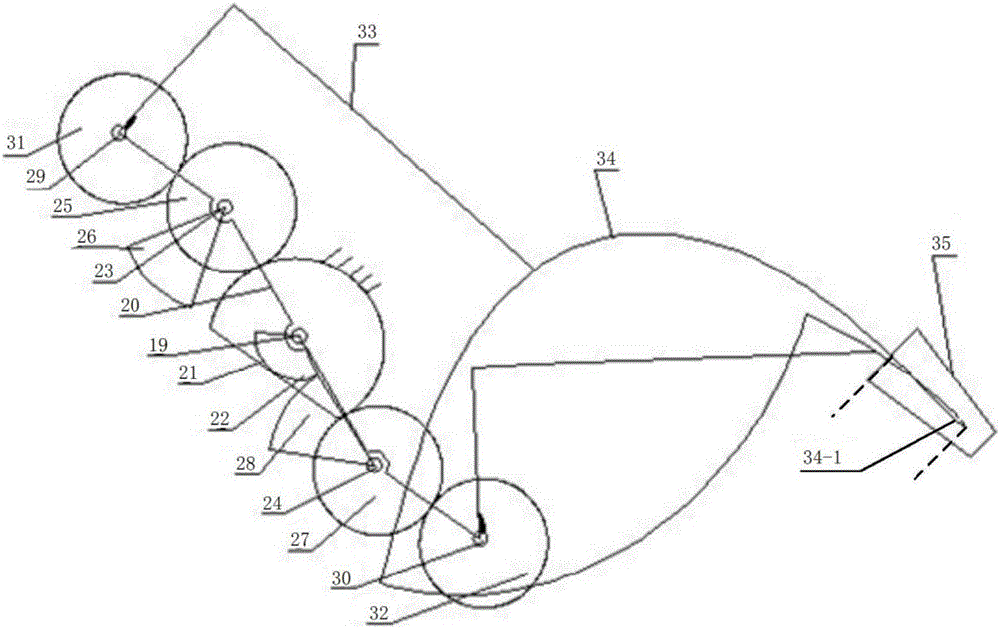

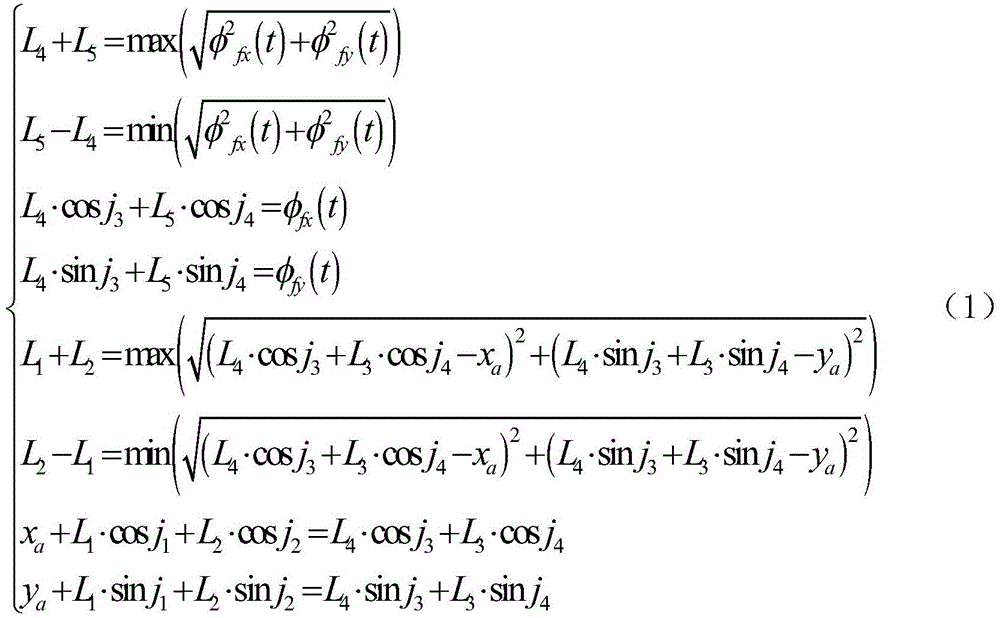

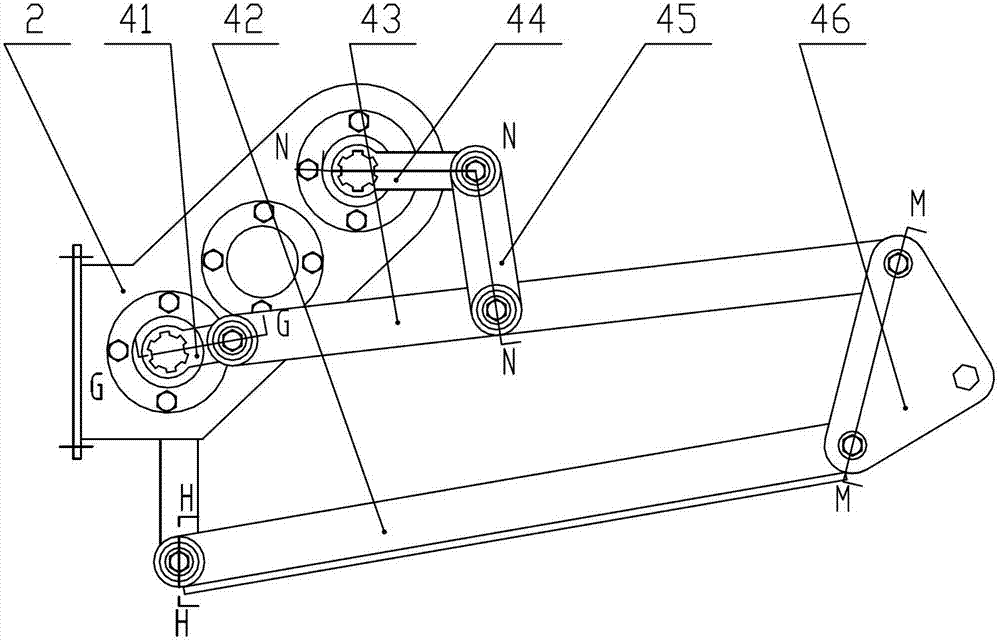

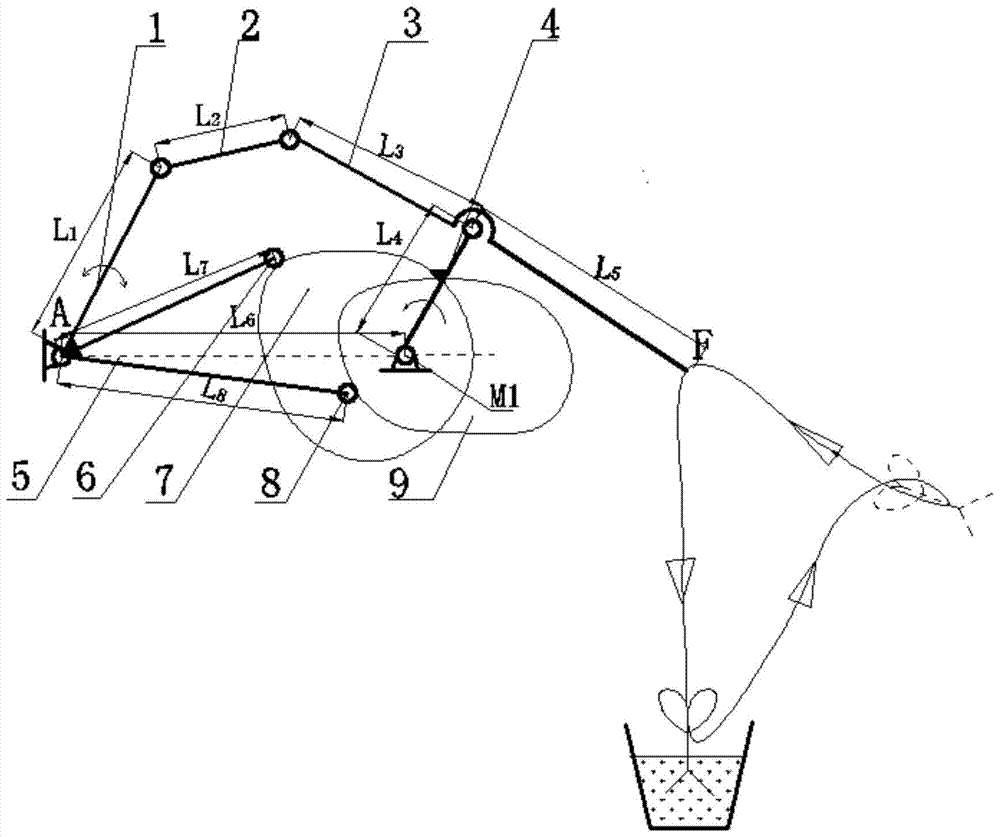

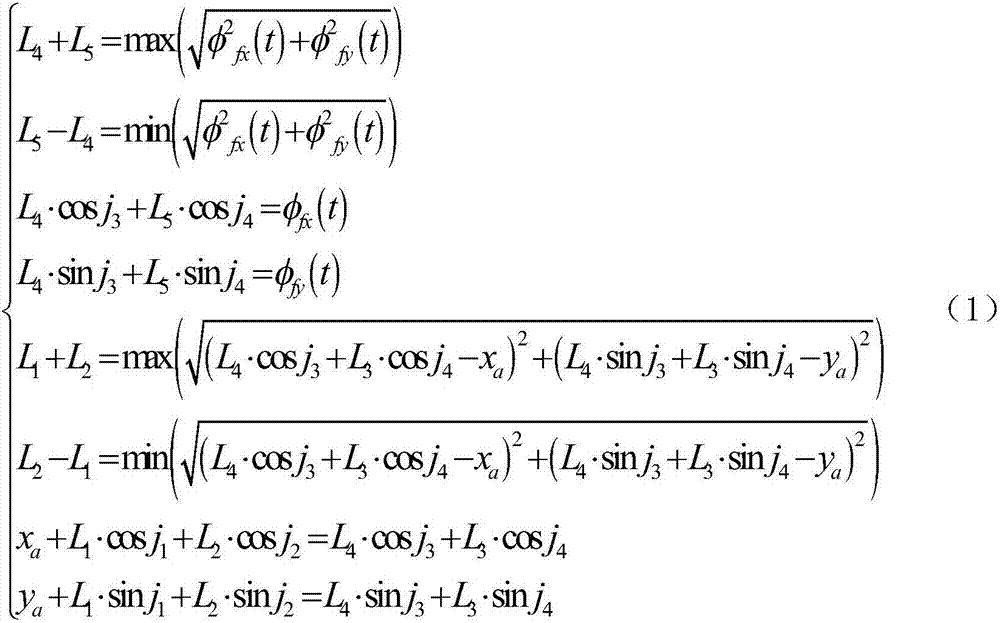

Closed-chain five-link transplanting mechanism for flowers and plants and design method therefor

ActiveCN105519289AMeet the agronomic requirements for transplantingGuaranteed direct vertical insertionTransplantingMathematical modelEngineering

The invention discloses a closed-chain five-link transplanting mechanism for flowers and plants and a design method therefor. A planetary gear train transplanting mechanism can realize flexibility restriction to trajectories; and parameters of a link mechanism with dual-snap-ring trajectories are difficult in design and adjustment. According to the mechanism disclosed by the invention, the bottom end of a first crank and the bottom end of a second crank are welded; the top end of the first crank is hinged to one end of a second link, and the top end of the second crank is hinged to the middle part of a third link; a forked swing link comprises a first swing link and a second swing link, of which bottom ends are hinged; the bottom end of the forked swing link is hinged to a rack; the other end of the second link is hinged to the top end of the first swing link; one end of a first link is hinged to the top end of the second swing link, and the other end of the first link is hinged to one end of the third link; and the other end of the third link is arranged freely. According to the design method disclosed by the invention, the length of each of rest links is determined reversely under the condition of a single-snap-ring trajectory mathematical model formed at the endpoint of the free end of the third link, coordinates of a hinged point of the forked swing link and the rack and known link length. According to the closed-chain five-link transplanting mechanism for the flowers and plants and the design method therefor, a single-snap-ring trajectory is achieved, and the mechanism is simple and easy to control.

Owner:平邑仁安中医药产业发展有限公司

Conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism and designing method thereof

ActiveCN105594356AMeet the agronomic requirements for transplantingSatisfy the uprightnessTransplantingGear systemEngineering

The invention discloses a conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism and a designing method thereof. A planet gear system transplanting mechanism is limited in realizing track flexibility, and a rod mechanism with double stirrup tracks is difficult in parameter designing and adjusting. The conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism is characterized in that one ends of a first conjugate cam, a second conjugate cam and a crank are all hinged to a rack through a cam shaft, the other end of the crank is hinged to the middle of a second connecting rod, a first cam swing rod, a second cam swing rod and a swing rod are fixedly connected, the first cam swing rod is connected with the first conjugate cam through a first roller, the second cam swing rod is connected with the second conjugate cam through a second roller, and the swing rod is hinged to the second connecting rod through a first connecting rod. The designing method includes: reversely solving the conjugate cams through a mathematic model of single stirrup tracks formed by an end point of the free end of the second connecting rod, coordinates of a hinged point of a fork-shaped swing rod and the rack and known rod length conditions. The single stirrup tracks are realized by changing profile of the conjugate cams to control movement laws of a rocker rod, and the conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism is simple.

Owner:平邑经济开发区投资发展有限公司

Tooth bar-incomplete non-circular-elliptical gear planetary system vegetable seedling-taking mechanism

ActiveCN103947345AMeet the agronomic requirements for transplantingOvercome stabilityTransplantingTransmission ratioSeedling

The invention discloses a tooth bar-incomplete non-circular-elliptical gear planetary system vegetable seedling-taking mechanism. The existing seedling-taking mechanism utilizes a locking arc to realize long-range change of a transmission ratio of a seedling-taking locus so that mechanism transmission impact is large. According to the tooth bar-incomplete non-circular-elliptical gear planetary system vegetable seedling-taking mechanism, a center shaft and a planetary carrier are fixed, a central incomplete non-circular gear and a frame are fixed, a central rack and the central incomplete non-circular gear are fixed, the central incomplete non-circular gear and the central rack sleeve the center shaft without key joint, a first middle elliptical gear is in a splined connection relationship with a first middle shaft, a first middle incomplete non-circular gear and the first middle elliptical gear are fixed, a second middle elliptical gear is connected to a second middle shaft by a spline, a second middle incomplete non-circular gear and the second middle elliptical gear are fixed, a first planetary elliptical gear and a first planetary gear shaft are connected by a spline, a second planetary elliptical gear and a second planetary gear shaft are connected by a spline, and one end of each one of the first planetary gear shaft and the second planetary gear shaft stretches out of the planetary carrier and then is fixed to the housing of a seedling-taking claw. The tooth bar-incomplete non-circular-elliptical gear planetary system vegetable seedling-taking mechanism has the advantages of stable transmission and small impact.

Owner:ZHEJIANG SCI-TECH UNIV

Combined incomplete eccentric circle - non-circular gear planetary gear train vegetable seedling picking mechanism

ActiveCN105638055BMeet the agronomic requirements for transplantingAchieve secondary transmission ratio fluctuationToothed gearingsTransplantingAgricultural engineeringSeedling

Owner:陕西专壹知识产权运营有限公司

Two-degree-of-freedom variable crank seven-bar flower transplanting mechanism

InactiveCN104686035BImprove flexibilityRealize the action of picking seedlingsTransplantingGear wheelDegrees of freedom

The invention discloses a two-degree-of-freedom variable-crank seven-link flower transplanting mechanism. The two-degree-of-freedom variable-crank seven-link flower transplanting mechanism is used for solving the problem that effects of entering a seedling planting work part at a better attitude and realizing the full automation of a flower transplanting machine are hard to guarantee due to the fact that a double crank mechanism and a planetary gear mechanism can only form one ring-buckle-shaped trajectory. According to the two-degree-of-freedom variable-crank seven-link flower transplanting mechanism, one end of a first crank is fixedly arranged on an output shaft of a first constant-speed motor; one end of a first link is hinged to the first crank, and the other end of the first link is hinged to one end of a second link; the middle part of the second link is hinged to one end of a third link, and the other end of the third link is arranged freely; a cam is fixedly arranged on a machine frame; one end of a second crank is fixedly arranged on an output shaft of a second constant-speed motor, and the other end of the second crank is connected with a sliding block through a sliding pair; a circular gear is hinged to the machine frame and is fixed together with the second crank; the sliding block is hinged to the other end of the third link and is connected with a cam slot of the cam. According to the two-degree-of-freedom variable-crank seven-link flower transplanting mechanism, double ring-buckle-shaped trajectories can be realized, so that the full automation of the flower transplanting machine is realized, and proper angle and speed for flower seedling casting and verticality of seedling planting are guaranteed.

Owner:ZHEJIANG SCI-TECH UNIV

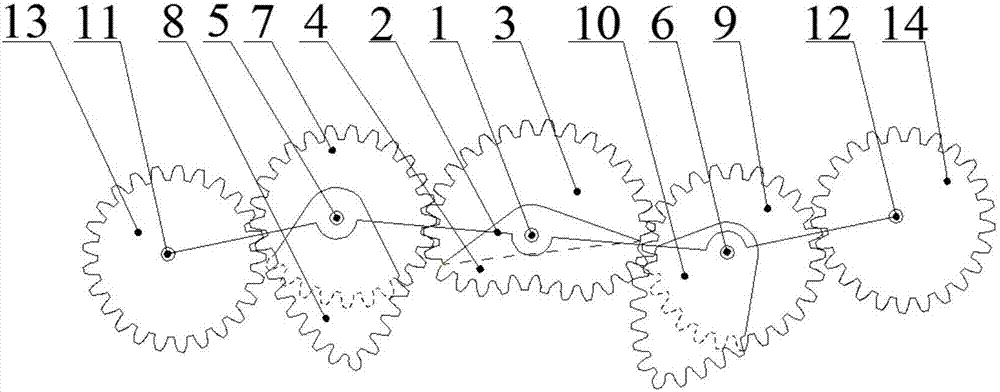

Double-crank pot clamping type transplanting mechanism for rice pot seedling transplanting machine

InactiveCN102640610BMeet the agronomic requirements for transplantingGuaranteed lateral movementTransplantingSprocketCam

The invention relates to a double-crank pot clamping type transplanting mechanism for a rice pot seedling transplanting machine and belongs to agricultural machinery. A second oval gear, a first oval gear, a driven cylindrical gear, a driving cylindrical gear and a driving chain wheel are assembled and arranged in a gear box body, wherein the driven cylindrical gear is in coaxial and fixed arrangement with the first oval gear, the driving cylindrical gear is in coaxial and fixed arrangement with the driving chain wheel, the driving cylindrical gear is engaged with the driven cylindrical gear, the first oval gear and the second oval gear are assembled, installed and engaged according to the set angle, the rotating center position parts of the first oval gear and the second oval gear are respectively and fixedly provided with a driving crank shaft and a driven crank shaft, two ends of a driving crank are respectively and fixedly connected with the driving crank shaft and a cam of a planting arm assembly according to the set angle, one end of a driven crank is fixedly installed with the driven crank shaft, the other end of the driven crank is hinged and connected with one end of a connecting rod, and the other end of the connecting rod is hinged and connected with the crank of the planting arm assembly. The double-crank pot clamping type transplanting mechanism has the advantages that the structure is simple and reasonable, the manufacture cost is low, the pot tray seedling taking and planting operation requirements are met, the operation effect is good, and the production efficiency is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Design method of closed-chain five-bar flower transplanting mechanism

ActiveCN105519289BMeet the agronomic requirements for transplantingGuaranteed direct vertical insertionTransplantingMathematical modelEngineering

Owner:平邑仁安中医药产业发展有限公司

Coaxial double-rod ejection type elliptical-incomplete non-circular and circular gear planetary system seedling throwing mechanism

ActiveCN106717364BMeet the agronomic requirements for transplantingSimple structureGearingTransplantingEllipseCam

The invention discloses a coaxial double rod ejection type elliptical-incomplete non-circular and circular gear planetary system seedling slinging mechanism. The mechanism comprises a planet carrier, wherein a central incomplete non-circular gear, a central incomplete circular gear, a first middle elliptical gear, a first middle incomplete circular gear, a second middle elliptical gear, a second middle incomplete circular gear, a first planet elliptical gear, a second planet elliptical gear and two seedling slinging transplanting arms are supported on the planet carrier; each of the seedling slinging transplanting arms comprises a transplanting arm housing, a hollow loop bar is slidably arranged in the transplanting arm housing, and a solid push rod is slidably arranged in the hollow loop bar; a first limiting plate, a second limiting plate and an opening and closing mechanism are arranged on the hollow loop bar; and a double outline cam, a shifting fork and a trigger are hinged in the transplanting arm housing. By adopting a layout plan of the two transplanting arms, planet carrier rotates once to fetch the seedlings and eject twice, so that the work efficiency is high; and the mechanism can be suitable for seedling slinging operations of a seedling slinging machine in a paddy field and a dry land at any rotating speeds.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Design method of transplanting trajectory formed by two-degree-of-freedom five-bar drive mechanism

InactiveCN104641771BRealize automatic transplantingImprove flexibilityTransplantingDegrees of freedomMelon (food)

Owner:ZHEJIANG SCI-TECH UNIV

An elliptical-incomplete non-circular and circular gear planetary vegetable seedling picking mechanism

ActiveCN103959966BMeet the agronomic requirements for transplantingSimple structureTransplantingMedial axisGear wheel

The invention discloses a vegetable seedling taking mechanism adopting planetary systems comprising elliptical, incomplete non-circular and circular gears, and aims to solve the problem of large transmission impact due to the fact that a conventional seedling taking mechanism adopts a locking arc for realizing large-range change of a transmission ratio of the seedling taking track. According to the mechanism, a center shaft is fixed with a planet carrier, a center incomplete non-circular gear is fixed with a rack, a center incomplete circular gear is fixed with the center incomplete non-circular gear, and the center shaft is freely sleeved with the center incomplete circular gear and the center incomplete non-circular gear; a first middle elliptical gear and a first middle shaft are connected through a spline, and a first middle incomplete circular gear is fixed with the first middle elliptical gear; a second middle elliptical gear is connected with a second middle shaft through a spine, and a second middle incomplete circular gear is fixed with the second middle elliptical gear; a first planetary elliptical gear is connected with a first planetary shaft through a spine, and a second planetary elliptical gear is connected with a second planetary shaft through a spine; and one end of the first planetary shaft and one end of the second planetary shaft both extend out of the planet carrier to be fixed with a casing of one seedling taking claw. According to the mechanism, the transmission is stable, and the impact is small.

Owner:ZHEJIANG SCI-TECH UNIV

Design method of flower transplanting mechanism with cam crank rocker combination

ActiveCN105519290BMeet the agronomic requirements for transplantingMeet agronomic requirementsTransplantingMathematical modelEngineering

Owner:南通希芸园林科技有限公司

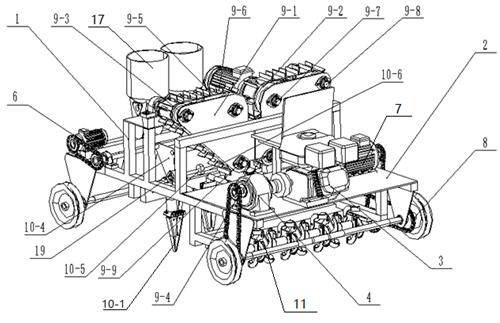

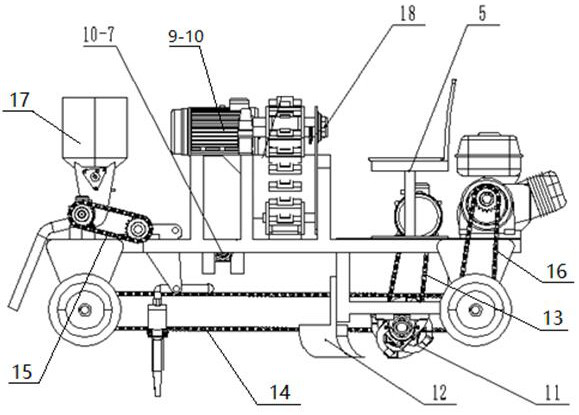

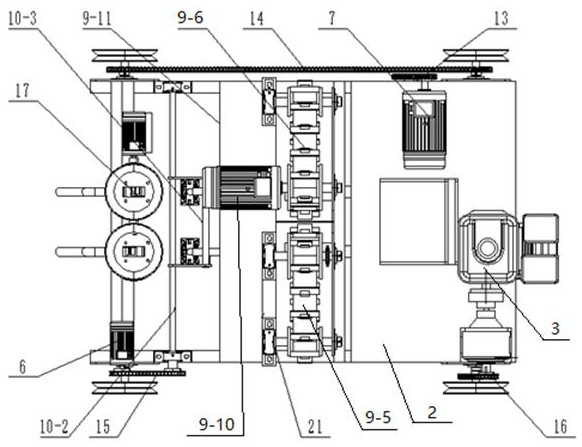

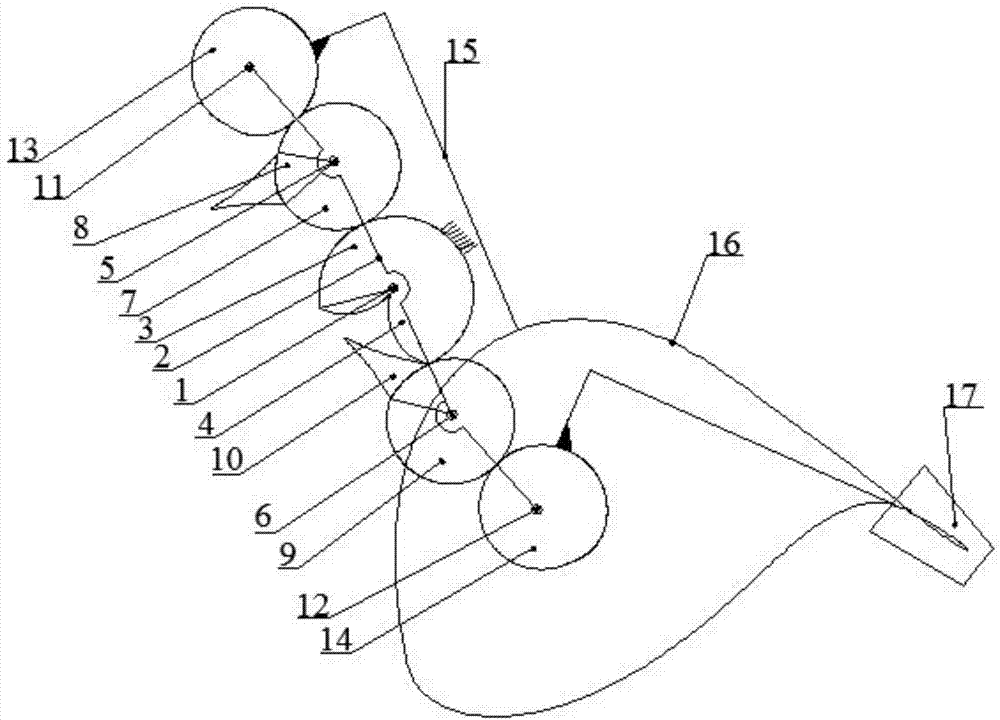

Industrial pseudo-ginseng transplanter

ActiveCN113575061AMeet the agronomic requirements for transplantingUniform spacingTransplantingAgricultural scienceAgricultural engineering

The invention relates to an industrial pseudo-ginseng transplanter, and belongs to the field of agricultural machinery. The industrial pseudo-ginseng transplanter comprises a rack (1), a rack upper plate (2), a gasoline engine (3), a speed reducer (4), a motor II (7), traveling wheels (8), a seedling conveying device, a transplanting device, a rotary tillage device (11), a furrow opener (12), a chain wheel transmission mechanism I (13), a chain wheel transmission mechanism II (14), a chain wheel transmission mechanism IV (16) and a fertilizing device (17). The industrial pseudo-ginseng transplanter can achieve mechanical transplanting of pseudo-ginseng, is compact in whole machine structure and suitable for the transplanting process of industrial planting of pseudo-ginseng, and the whole pseudo-ginseng transplanting process can be completed by one person. The seedling conveying device and the transplanting device are combined, it can be guaranteed that line spacing, plant spacing and depth of transplanted seedlings are consistent, the transplanting efficiency and the transplanting qualification rate are improved, the labor intensity of farmers is reduced, and the industrial pseudo-ginseng transplanter has important significance on standardized planting of pseudo-ginseng and income increasing of the farmers.

Owner:KUNMING UNIV OF SCI & TECH

Transplanting mechanism capable of implementing continuous perpendicular planting

The invention discloses a transplanting mechanism capable of implementing continuous perpendicular planting. The translating mechanism comprises a transmission box, a planting arm assembly, a planter and a cam starting mechanism, wherein the transmission box is fixed on a stander; three output shafts, an input shaft and two hanging shafts are arranged on the transmission box; the first output shaft, the second output shaft and the two hanging shafts are arranged on one side of the transmission box and are used for hanging the planting arm assembly and driving the planting arm assembly; the third output shaft and the input shaft are arranged on the other side of the transmission box; the third output shaft is used for mounting and driving the cam starting mechanism; the input shaft is connected with an output shaft of a planter handpiece; the planting arm assembly consists of a four-rod mechanism, a five-rod mechanism and two parallel mechanisms; the planter is hung on the planting arm assembly through a square shaft. The transplanting mechanism disclosed by the invention is compact in structure, has the advantages of low seedling injury rate, low seedling leakage rate, low seedling burying rate, low seedling exposure rate and high seedling growth rate and can completely meet an agriculture requirement on oilseed rape transplanting.

Owner:HUNAN AGRICULTURAL UNIV

Design method of transplanting trajectory formed by two-degree-of-freedom variable-crank five-bar drive mechanism

InactiveCN104641770BRealize automatic transplantingSimple organizationTransplantingMathematical modelDegrees of freedom

The invention discloses a design method for forming a transplanting track by using a length-variable crank five-rod driving mechanism with two degrees of freedom. The existing transplanting mechanism track is not suitable for transplanting flowers. The design method comprises the following concrete steps of firstly, establishing the five-rod driving mechanism with a changing crank, and establishing a mathematic model of a double-buckle transplanting track formed at the end point of the free end of a second connecting rod; then, carrying out reverse solving of the length changing rule of a first crank through the established mathematic model, and calculating the sliding speed of a sliding sleeve on the first crank; and finally, checking whether the five-rod driving mechanism with the changing crank meets the existing condition of double cranks. The double-buckle transplanting track is achieved by using the five-rod driving mechanism with the changing crank, so that not only can the transplanting tracks of flowers be achieved, but also the fully-automatic transplanting of various crops such as melons, fruits, vegetables and flowers can be realized.

Owner:ZHEJIANG SCI-TECH UNIV

Design method of flower transplanting trajectory formed by two-stage non-circular gear five-bar drive mechanism

ActiveCN104657546BRealize automatic transplantingImprove flexibilityTransplantingSpecial data processing applicationsMathematical modelAngular velocity

The invention discloses a design method for forming a flower transplanting track by a two-stage non-circular gear five-bar driving mechanism. An existing transplanting mechanism track is not suitable for flower transplantation. The design method specifically comprises the following steps: firstly, constructing a two-stage non-circular gear five-bar driving mechanism, and establishing a free end point of a second connecting rod, so as to form a mathematical model of a double-buckle track; then reversely determining angular velocity change rules of a first crank and a second crank through the established mathematical model, designing a two-stage non-circular gear, and verifying whether the two-stage non-circular gear five-bar driving mechanism satisfies existence conditions of the double cranks. According to the design method, the angular velocity ratio of the first crank to the second crank is changed by adopting the two-stage non-circular gear five-bar driving mechanism, the double-buckle track is realized, so as to realize seedling taking and planting motions, the flower transplanting track can be realized, and full automatic transplantation of various crops such as fruits and vegetables can be realized.

Owner:安徽翰邦科技咨询有限公司

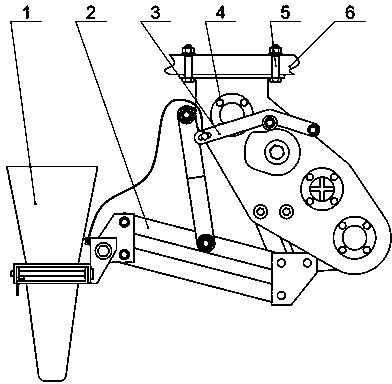

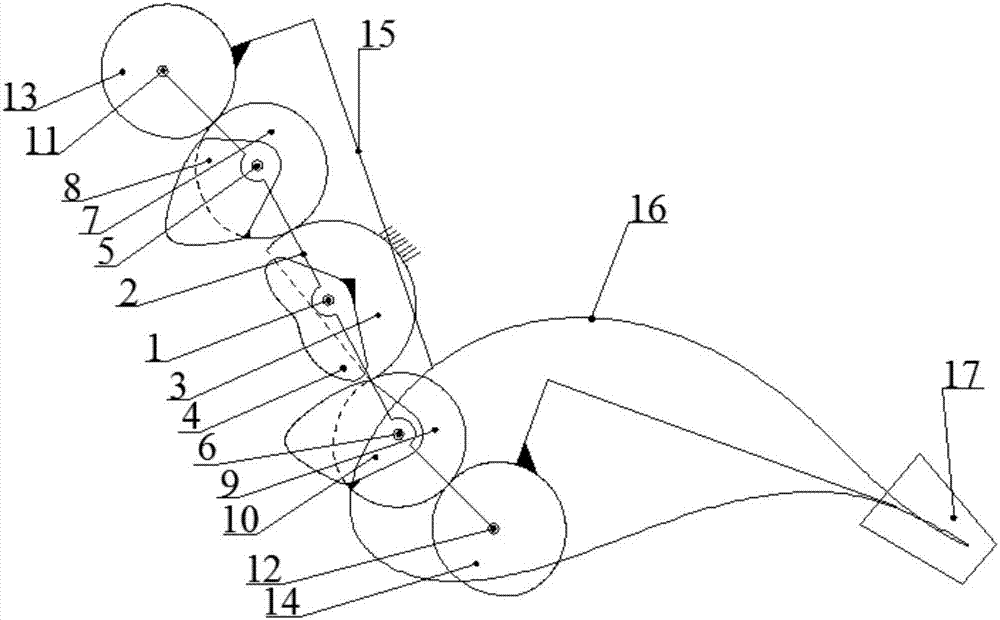

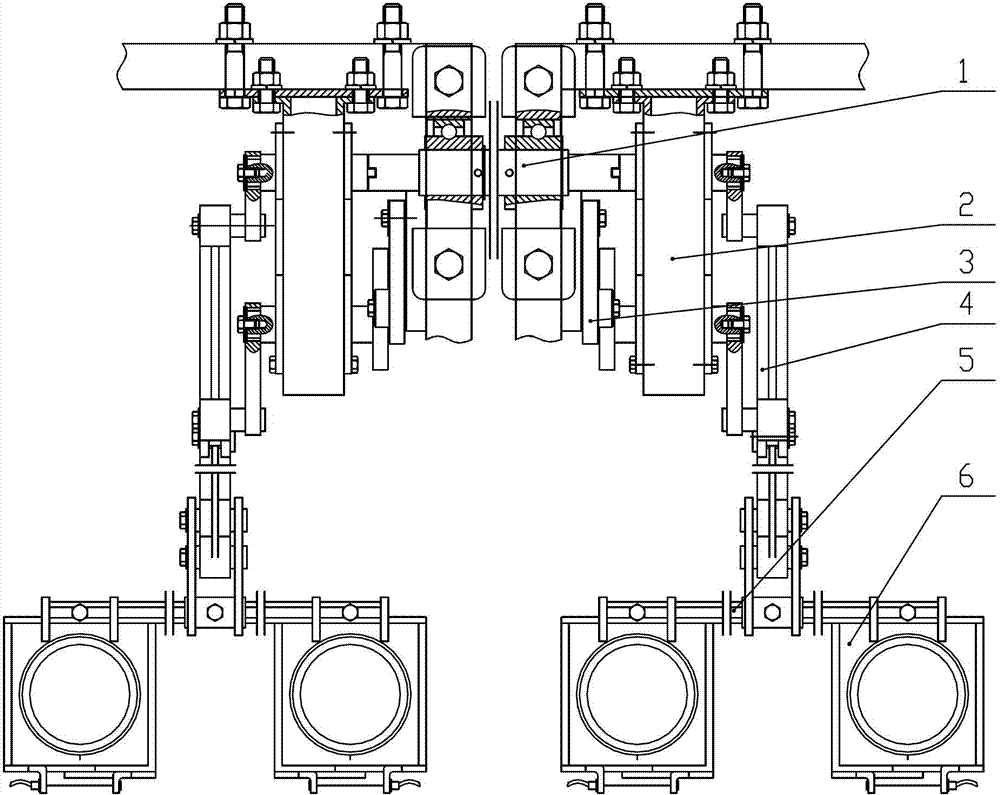

Planting mechanism of front inserted-type oilseed rape transplanter

The invention discloses a planting mechanism of a front inserted-type oilseed rape transplanter. The planting mechanism of the front inserted-type oilseed rape transplanter comprises speed reduction boxes, cam opening mechanisms, planting arm components and planters, wherein the speed reduction boxes are installed on the input shafts of the planters. The planting mechanism of the front inserted-type oilseed rape transplanter is characterized in that the two speed reduction boxes are symmetrically installed at two ends of the planters; each speed reduction box is provided with three output shafts; two output ends at one sides of the speed reduction boxes are connected with the planting arm components, and the output ends at the other sides of the speed reduction boxes are connected with the cam opening mechanisms; the tail ends of the planting arm components are symmetrically provided with two planters through shafts; and the planters are controlled to drop seedlings by the cam opening mechanisms. The device completes the functions of punching synchronously in four lines and transplanting oilseed rape seedlings once; the front inserted-type arrangement ensures that the whole machine is more compact, and reduces the planting leakage rate; and the mechanism has the characteristics of low seedling damage ratio, low seedling embedment ratio and low seedling leakage ratio, high seedling erecting ratio, conforming to the agricultural technology requirement of oilseed rape transplanting and the like.

Owner:HUNAN AGRICULTURAL UNIV

Single-degree-of-freedom non-circular gear variable crank seven-bar flower transplanting mechanism

InactiveCN104663088BImprove flexibilityRealize the action of picking seedlingsTransplantingGear wheelSingle degree of freedom

Owner:ZHEJIANG SCI-TECH UNIV

A rack-incomplete non-circular-elliptical gear planetary system vegetable seedling picking mechanism

ActiveCN103947345BMeet the agronomic requirements for transplantingSimple structureTransplantingEllipseMedial axis

Owner:ZHEJIANG SCI-TECH UNIV

Single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism

InactiveCN104686036AImprove flexibilityRealize the action of picking seedlingsTransplantingSingle degree of freedomGear wheel

The invention discloses a single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism. The single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism is used for solving the problem that effects of entering a seedling planting work part at a better attitude and realizing the full automation of a flower transplanting machine are hard to guarantee due to the fact that a double crank mechanism and a planetary gear mechanism can only form one ring-buckle-shaped trajectory. According to the single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism, a first crank is hinged to one end of a first link; the other end of the first link is hinged to one end of a second link; one end of a third link is hinged to the middle part of the second link, and the other end of the third link is hinged to a sliding block; the sliding block is connected with a second crank through a sliding pair; a driving circular gear is fixed together with the first crank; a driven circular gear is hinged to a machine frame and is engaged with the driving circular gear; a cam is fixedly arranged on the machine frame; the second crank is fixed with the driven circular gear; the sliding block is connected with a sliding slot of the cam through a cam pair. According to the single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism, double ring-buckle-shaped trajectories can be realized, so that the full automation of the flower transplanting machine is realized, and proper angle and speed for flower seedling casting and verticality of seedling planting are guaranteed.

Owner:ZHEJIANG SCI-TECH UNIV

Concave tooth-incomplete eccentric circle-non-circular gear planetary system vegetable seedling picking mechanism

ActiveCN105746059BMeet the agronomic requirements for transplantingIdeal seedling trajectoryTransplantingAgricultural engineeringSeedling

The invention discloses a concave tooth-incomplete eccentric circle-non-circular gear planetary system vegetable seedling taking mechanism. A conventional seedling taking mechanism adopts a locking arch or a rack-incomplete non-circular transmission mechanism to achieve the purpose that the transmission ratio of a seedling taking track is greatly varied, the locking arch has large transmission impact, and the rack-incomplete non-circular transmission mechanism is not ideal in transmission ratio variation range. A central shaft of the concave tooth-incomplete eccentric circle-non-circular gear planetary system vegetable seedling taking mechanism is fixed together with a planet carrier; a central incomplete eccentric circle-non-circular gear is fixed together with a rack; central concave teeth are fixed together with the central eccentric circle-non-circular gear and are all arranged on the central shaft in a sleeving manner; a first middle circle-non-circular gear is connected with a first intermediate shaft spline; a first convex tooth is fixed with the first middle circle-non-circular gear; a second middle circle-non-circular gear is connected with a second intermediate shaft spline; second convex teeth are fixed with the second middle circle-non-circular gear; a first planetary circle-non-circular gear is connected with a first planetary shaft spline; a second planetary circle-non-circular gear is connected with a second planetary shaft spline; one end of each of a first planetary shaft and a second planetary shaft is fixed with a shell of a seedling taking claw. The concave tooth-incomplete eccentric circle-non-circular gear planetary system vegetable seedling taking mechanism is stable in transmission and small in impact.

Owner:陕西专壹知识产权运营有限公司

Design Method of Conjugate Cam-Crank-Rocker Combination Flower Transplanting Mechanism

ActiveCN105594356BMeet the agronomic requirements for transplantingSatisfy the uprightnessTransplantingGear systemEngineering

The invention discloses a conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism and a designing method thereof. A planet gear system transplanting mechanism is limited in realizing track flexibility, and a rod mechanism with double stirrup tracks is difficult in parameter designing and adjusting. The conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism is characterized in that one ends of a first conjugate cam, a second conjugate cam and a crank are all hinged to a rack through a cam shaft, the other end of the crank is hinged to the middle of a second connecting rod, a first cam swing rod, a second cam swing rod and a swing rod are fixedly connected, the first cam swing rod is connected with the first conjugate cam through a first roller, the second cam swing rod is connected with the second conjugate cam through a second roller, and the swing rod is hinged to the second connecting rod through a first connecting rod. The designing method includes: reversely solving the conjugate cams through a mathematic model of single stirrup tracks formed by an end point of the free end of the second connecting rod, coordinates of a hinged point of a fork-shaped swing rod and the rack and known rod length conditions. The single stirrup tracks are realized by changing profile of the conjugate cams to control movement laws of a rocker rod, and the conjugate cam, crank and rocker rod combined flower-plant transplanting mechanism is simple.

Owner:平邑经济开发区投资发展有限公司

Single-degree-of-freedom circular gear variable crank seven-bar flower transplanting mechanism

InactiveCN104686036BImprove flexibilityRealize the action of picking seedlingsTransplantingSingle degree of freedomEngineering

The invention discloses a single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism. The single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism is used for solving the problem that effects of entering a seedling planting work part at a better attitude and realizing the full automation of a flower transplanting machine are hard to guarantee due to the fact that a double crank mechanism and a planetary gear mechanism can only form one ring-buckle-shaped trajectory. According to the single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism, a first crank is hinged to one end of a first link; the other end of the first link is hinged to one end of a second link; one end of a third link is hinged to the middle part of the second link, and the other end of the third link is hinged to a sliding block; the sliding block is connected with a second crank through a sliding pair; a driving circular gear is fixed together with the first crank; a driven circular gear is hinged to a machine frame and is engaged with the driving circular gear; a cam is fixedly arranged on the machine frame; the second crank is fixed with the driven circular gear; the sliding block is connected with a sliding slot of the cam through a cam pair. According to the single-degree-of-freedom circular-gear variable-crank seven-link flower transplanting mechanism, double ring-buckle-shaped trajectories can be realized, so that the full automation of the flower transplanting machine is realized, and proper angle and speed for flower seedling casting and verticality of seedling planting are guaranteed.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com