Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Meet agronomic requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

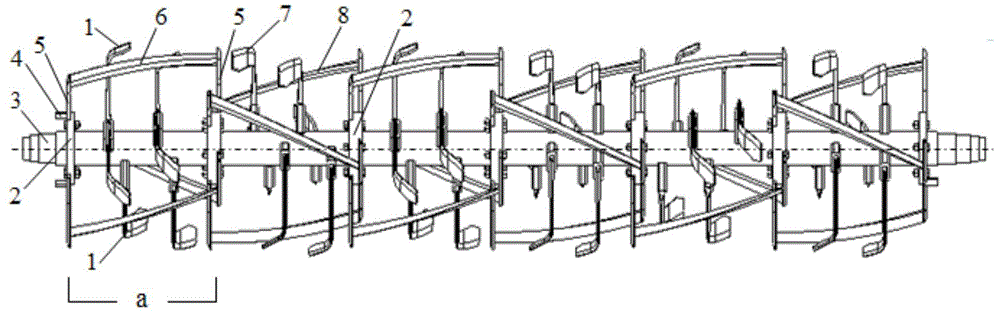

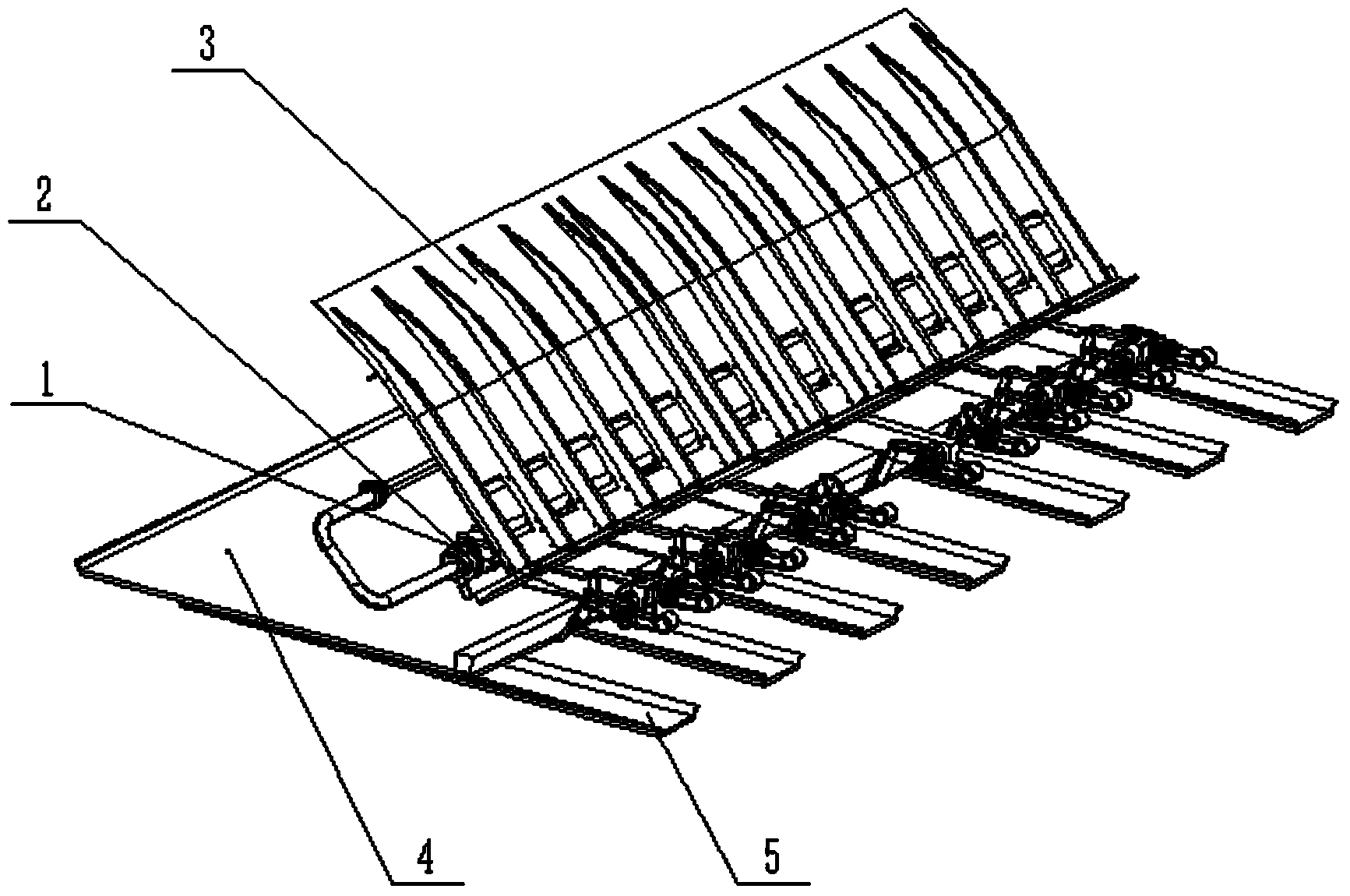

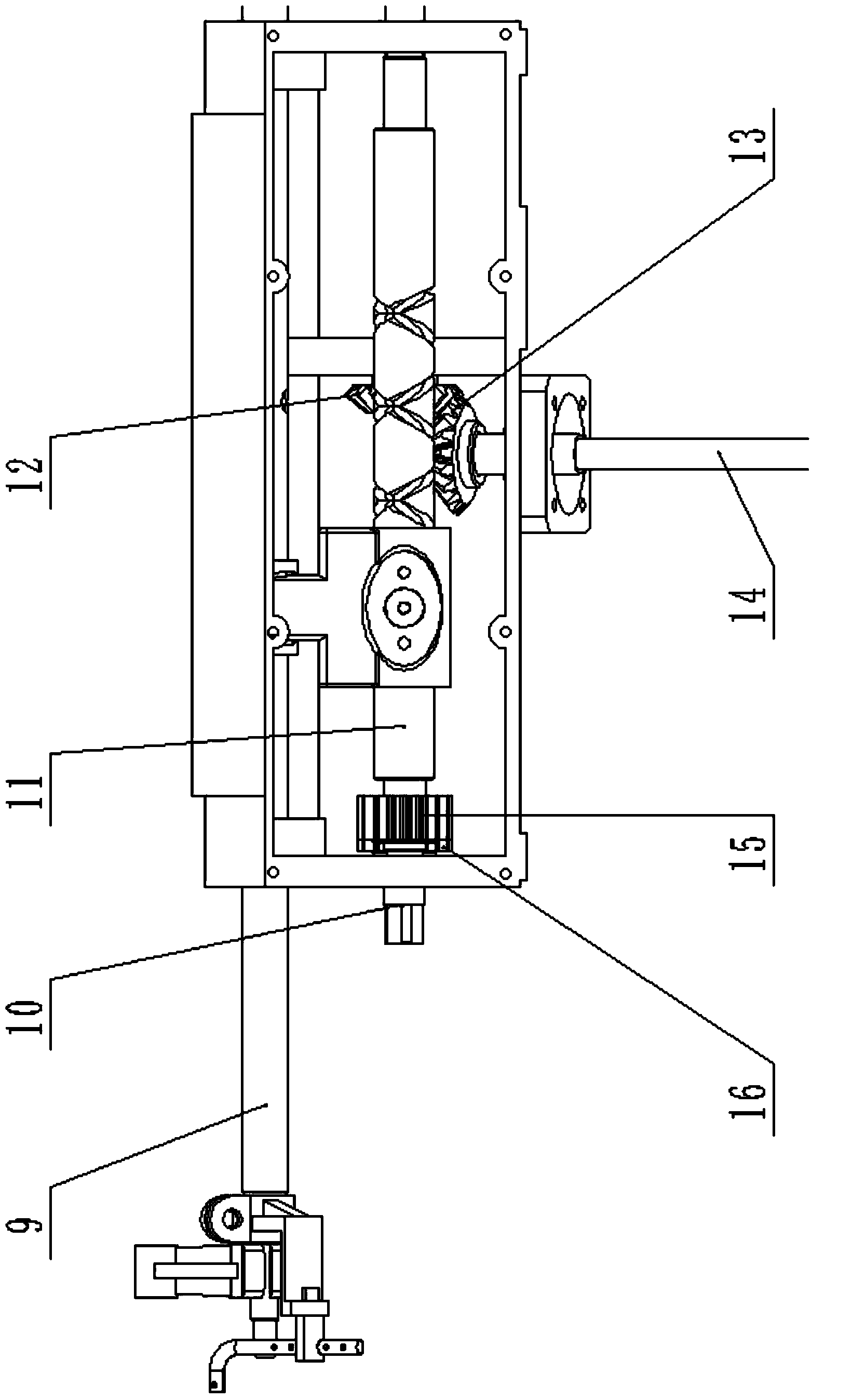

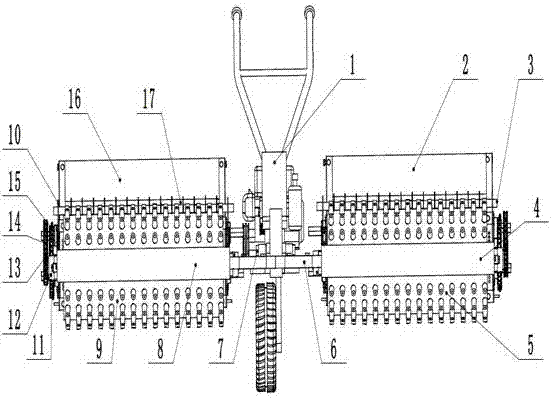

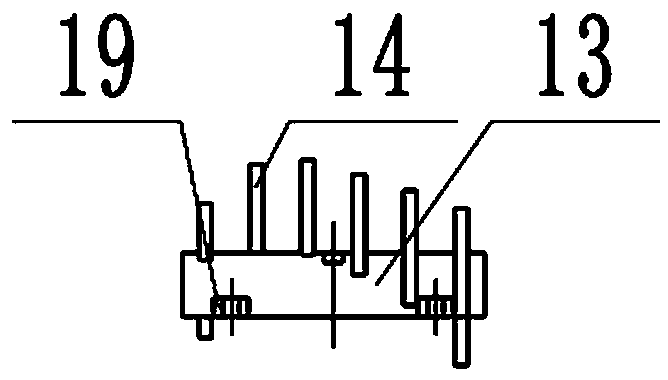

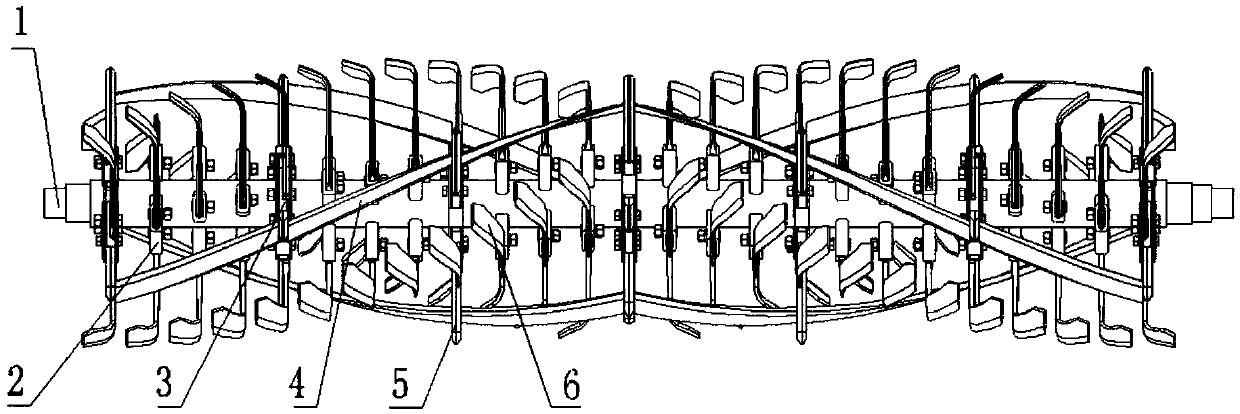

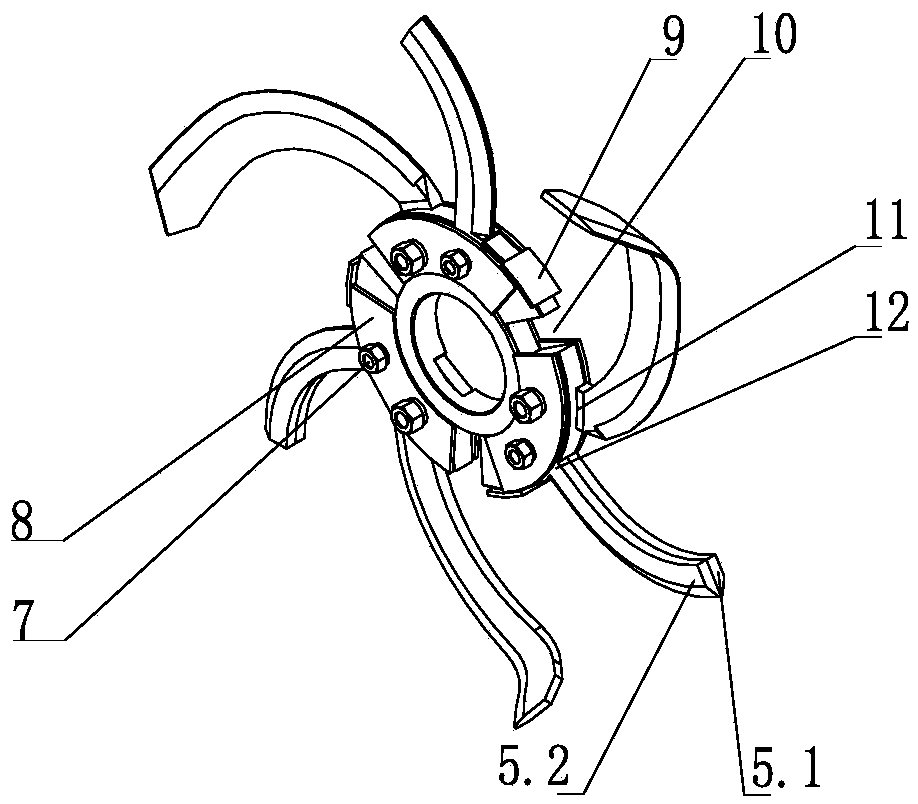

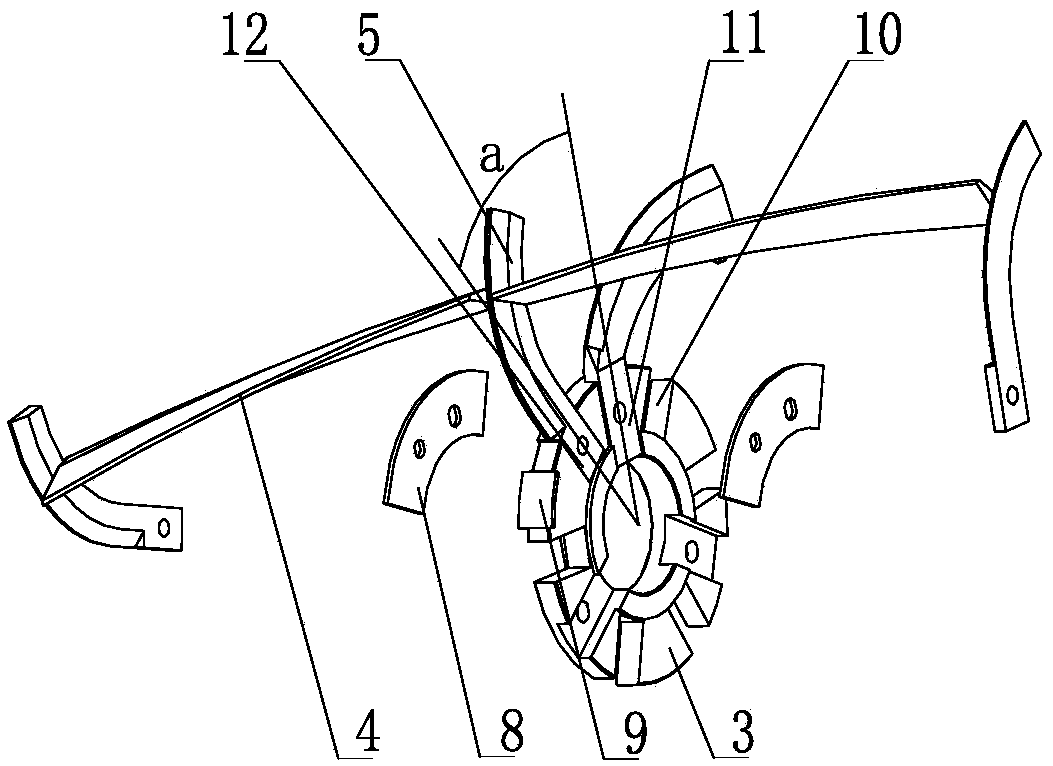

Combined straw mulching rotary tillage knife roller

InactiveCN104303717AAvoid entanglementEasy to operateCrop conditionersMowersHigh energyAgricultural engineering

The invention discloses a combined straw mulching rotary tillage knife roller. Operating tools of the conventional rotary tiller and a rotary tillage straw mulching machine are reasonably combined to realize a farmland tillage function of the conventional rotary tiller and a high-stubble straw mulching function of the rotary tillage straw mulching machine by virtue of a knife roller, so that the problems of undiversified function, complex structure, high energy consumption, narrow application range and the like of the conventional knife roller are solved. According to the technical scheme, the combined straw mulching rotary tillage knife roller comprises a knife shaft and a plurality of knife roller units arranged on the knife shaft, wherein each knife roller unit comprises a knife plate, spiral cross knives, a rotary blade and curved knives; the knife plates are arranged on the knife shaft; a plurality of curved knives are uniformly distributed on the knife plates; 2 to 3 spiral cross knives are uniformly connected to the curved knives between every two adjacent knife plates; 1 to 3 rotary blades are arranged on the knife shaft between every two adjacent spiral cross knives. The combined straw mulching rotary tillage knife roller is simple in structure, wide in application range, high in operating efficiency and low in energy consumption, and has the farmland tillage and high-stubble straw mulching functions.

Owner:HUAZHONG AGRI UNIV

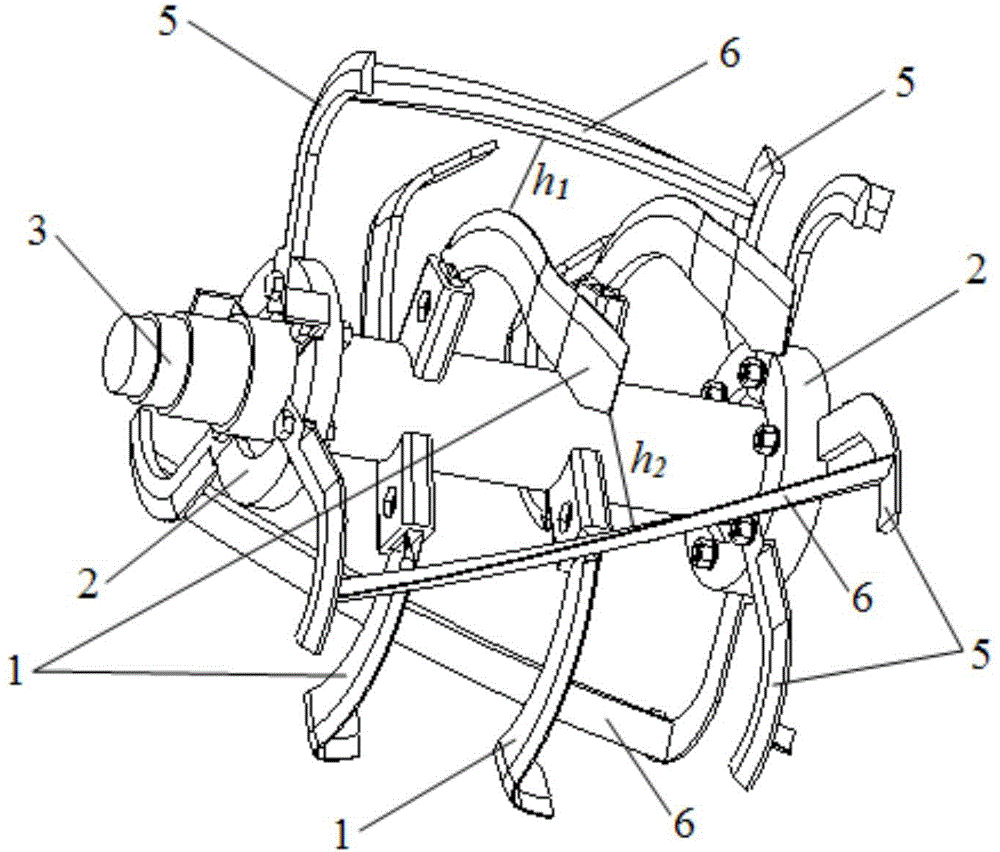

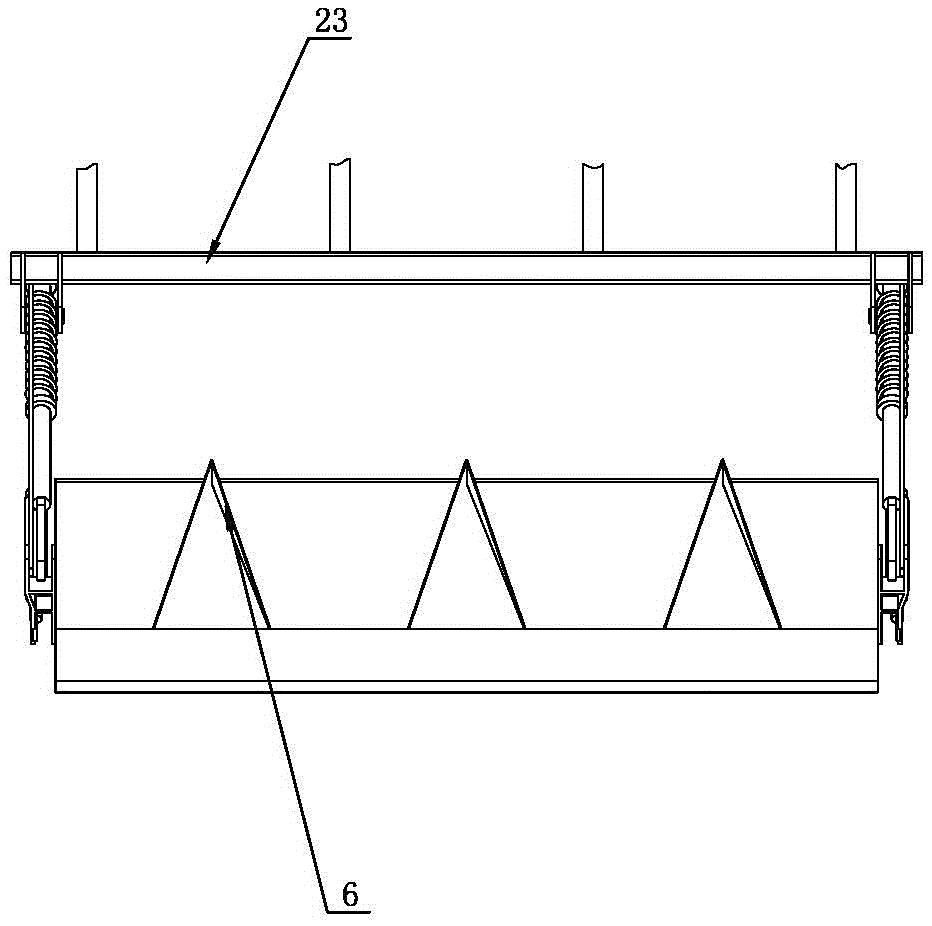

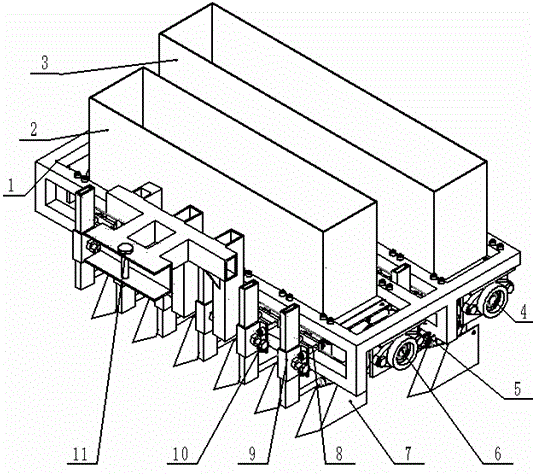

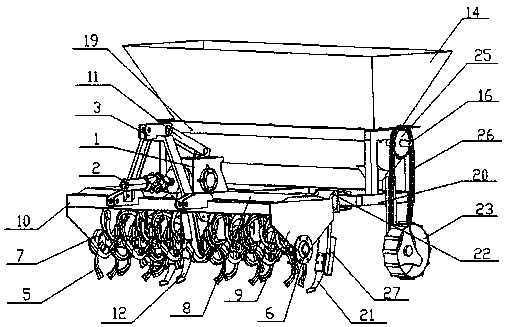

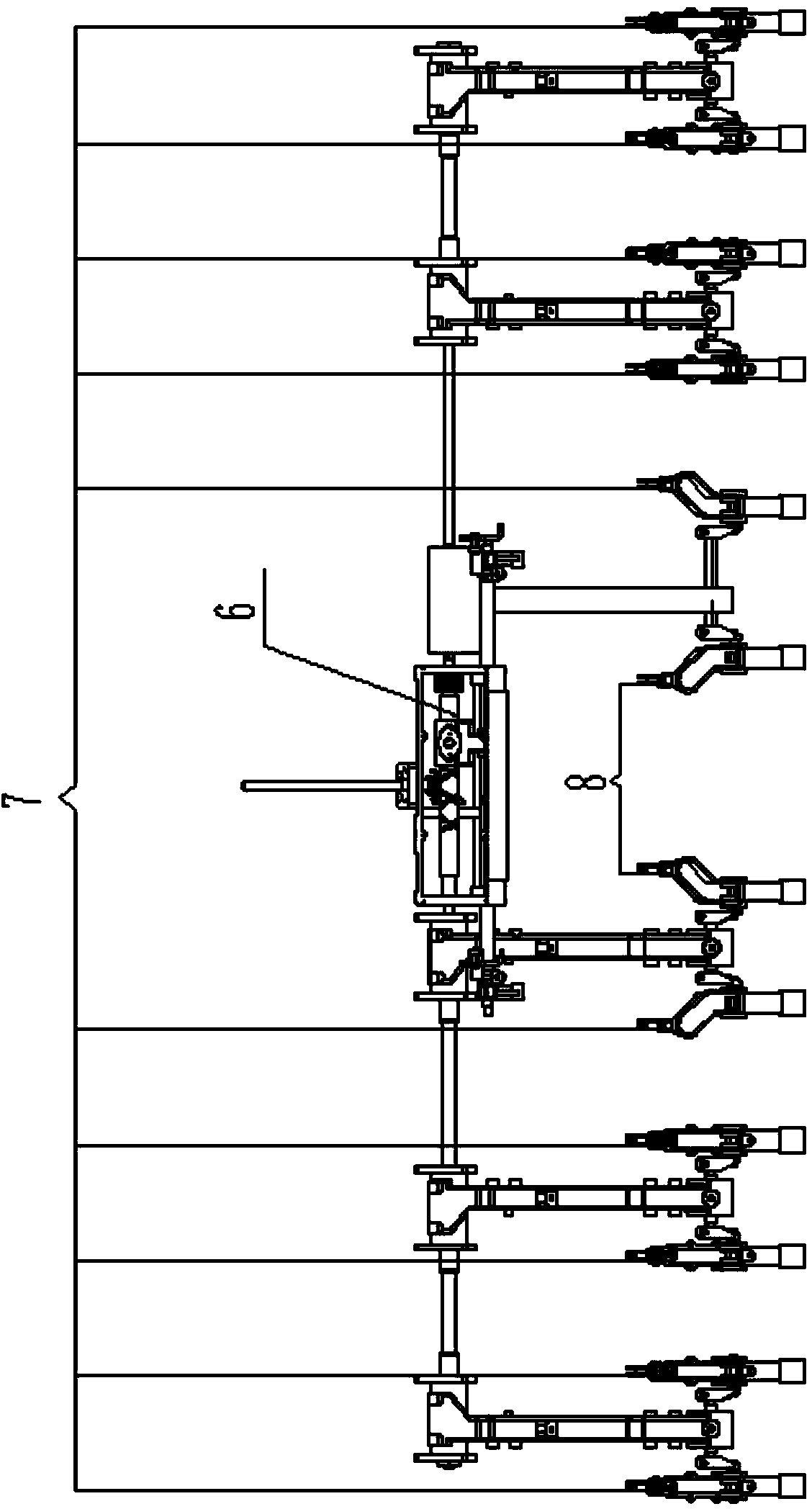

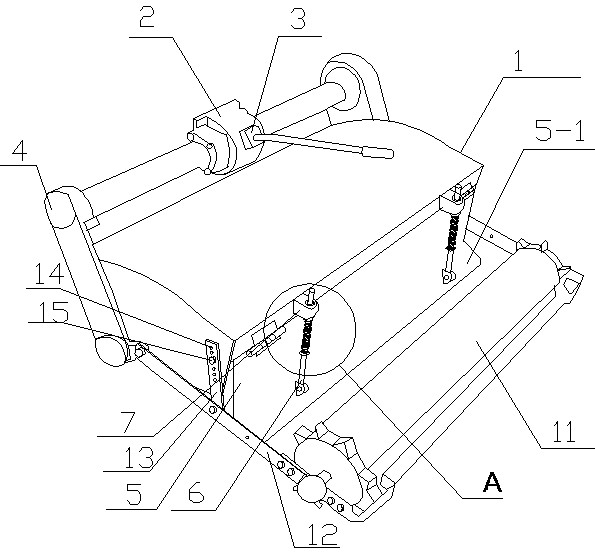

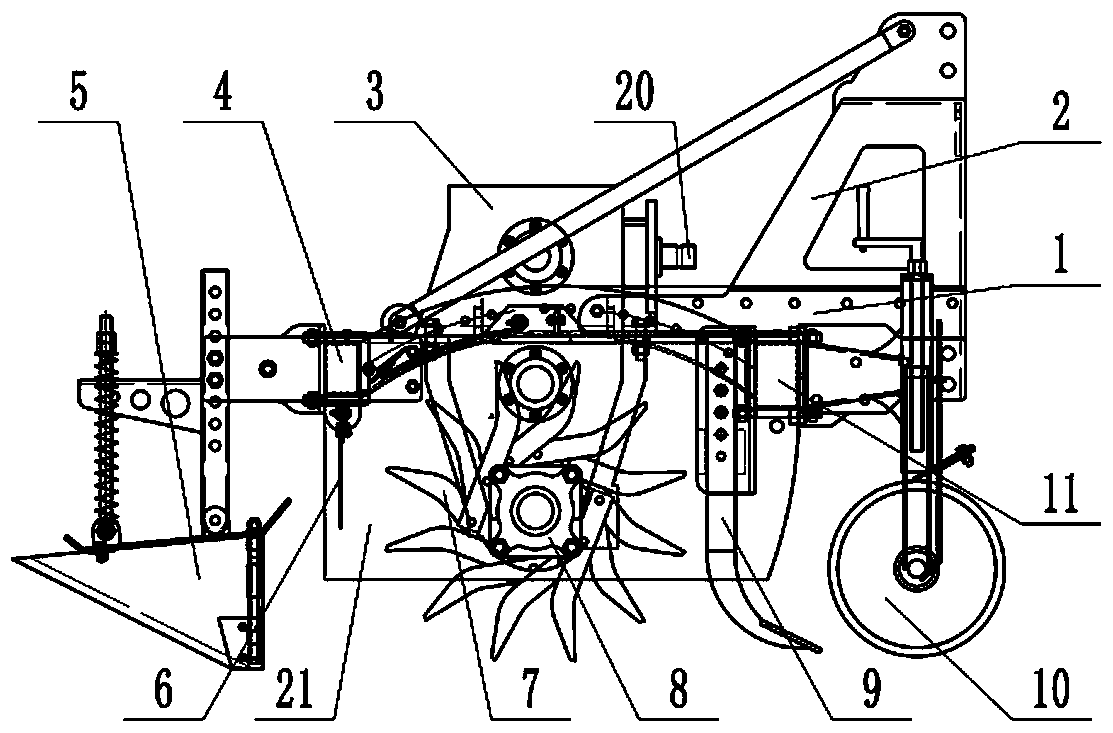

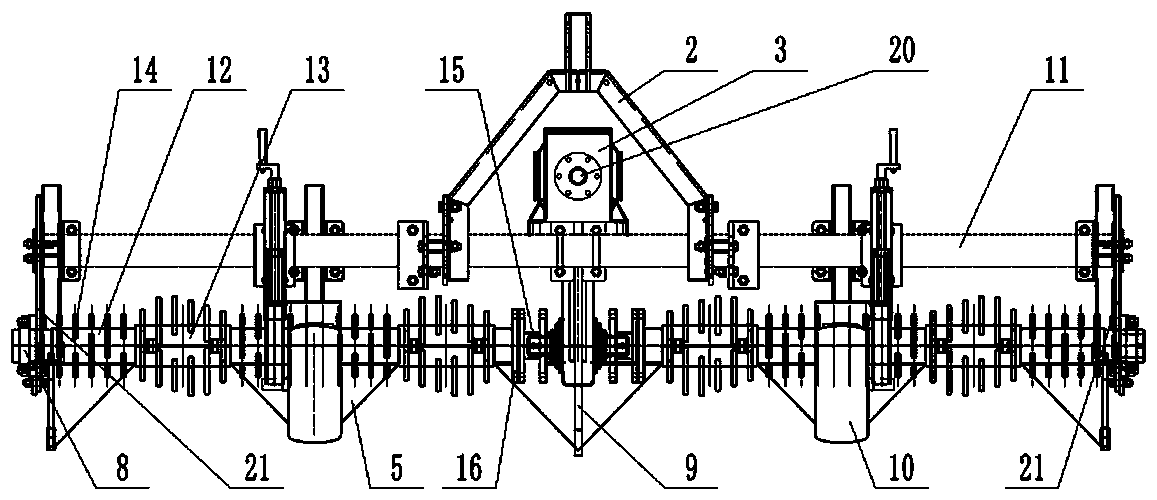

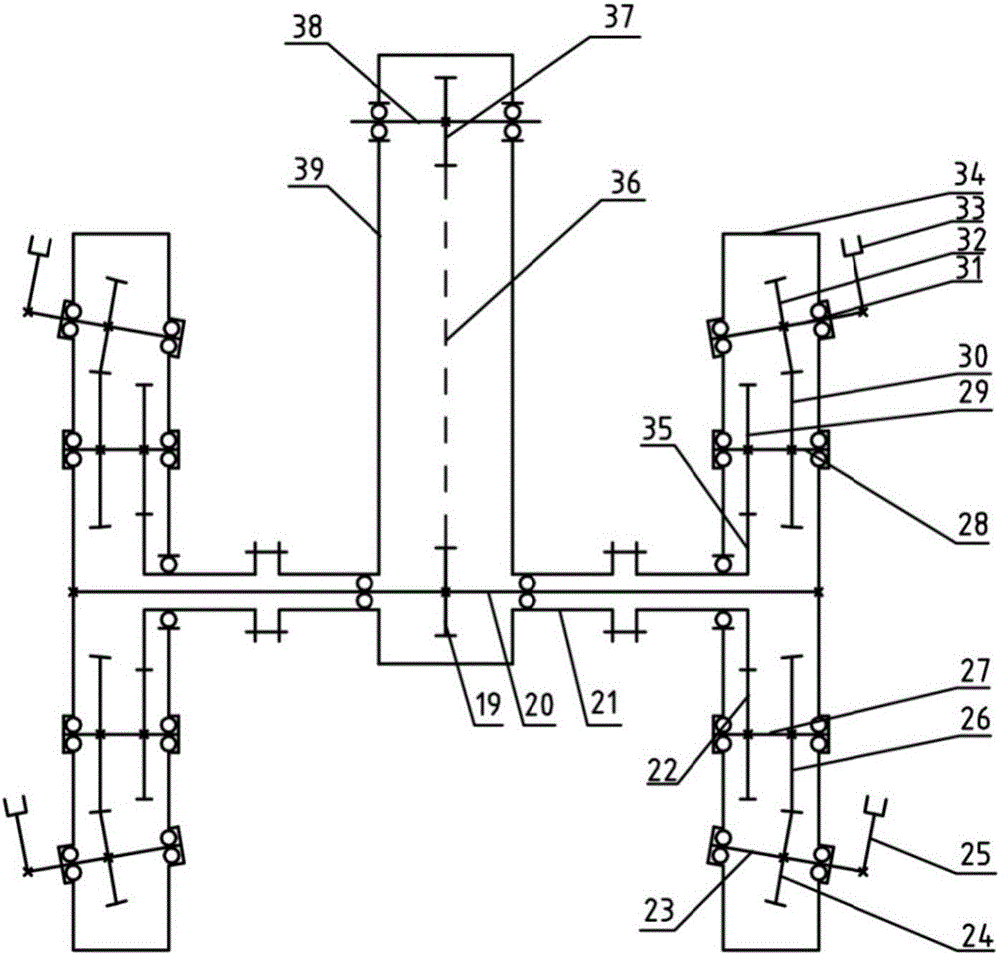

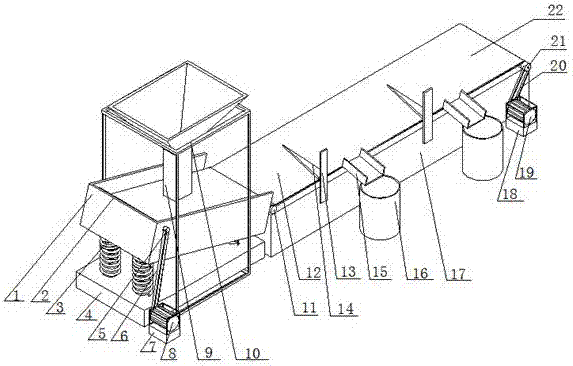

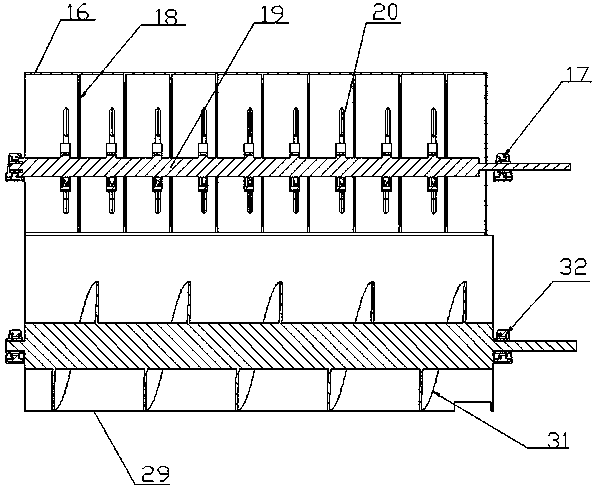

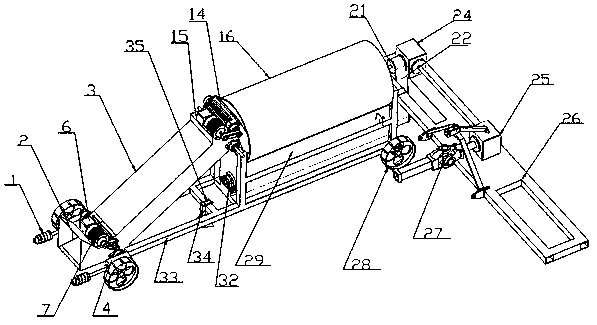

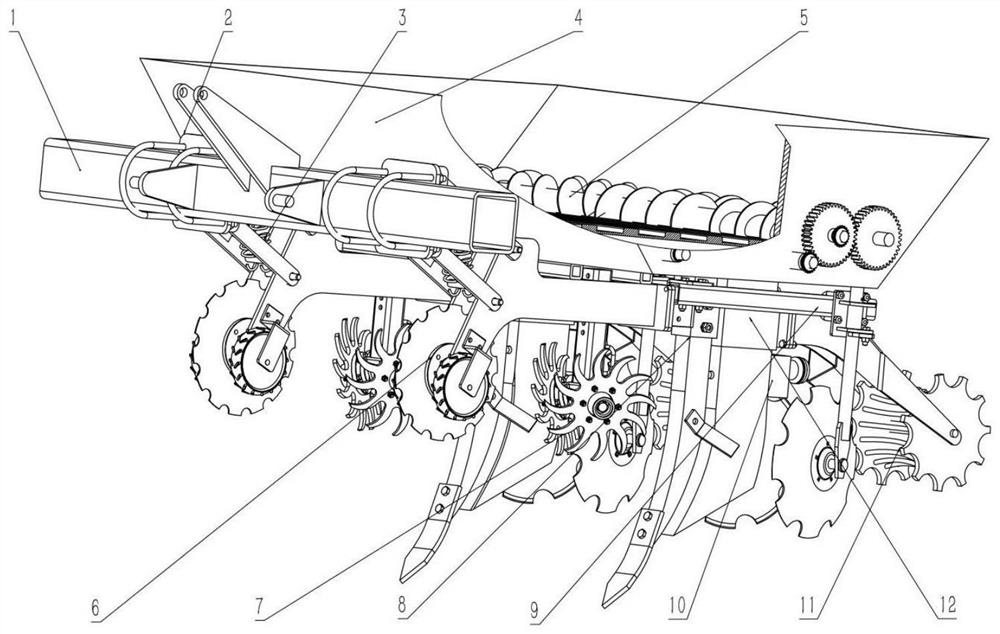

Stubble-cleaning, subsoiling, rotary-tilling and ridge-forming combine operating machine

ActiveCN106034425AMeet agronomic requirementsSpadesPloughsAgricultural engineeringAgricultural machinery

The invention provides a stubble-cleaning, subsoiling, rotary-tilling and ridge-forming combine operating machine and belongs to the field of agricultural machinery. The combine operating machine comprises a machine frame, an intermediate transmission case, a stubble cleaning knife shaft, a rotary tilling knife shaft and a subsoiling device, wherein the rotary tilling knife shaft is arranged behind the stubble cleaning knife shaft, the lower margin of rotation circumference of a rotary tilling knife is lower than that of a stubble cleaning knife, the subsoiling device is arranged on the machine frame between the rotary tilling knife shaft and the stubble cleaning knife shaft, the machine frame behind the rotary tilling knife shaft is connected with a ridge-height-adjustable ridge forming device, the ridge forming device comprises a crossbeam and a ridge forming frame, the crossbeam is connected with a ridge height adjusting frame, the ridge height adjusting frame comprises a supporting plate, a connecting plate is arranged on the supporting plate, the supporting plate is hinged with a connecting rack, the connecting rack is hinged with the ridge forming frame, the connecting plate is connected with a moving member which can do rectilinear movement, the moving member is hinged with the ridge forming frame through the connecting rack, a furrowing plate is arranged at the bottom side of the ridge forming frame, the ridge forming frame comprises a ridge forming plate, and the ridge forming plate is arranged behind the furrowing plate. According to the stubble-cleaning, subsoiling, rotary-tilling and ridge-forming combine operating machine, the adjustment on ridge height is achieved so as to meet the requirements of different crops, and the efficiency of farming is increased.

Owner:江苏银涛智能装备有限公司

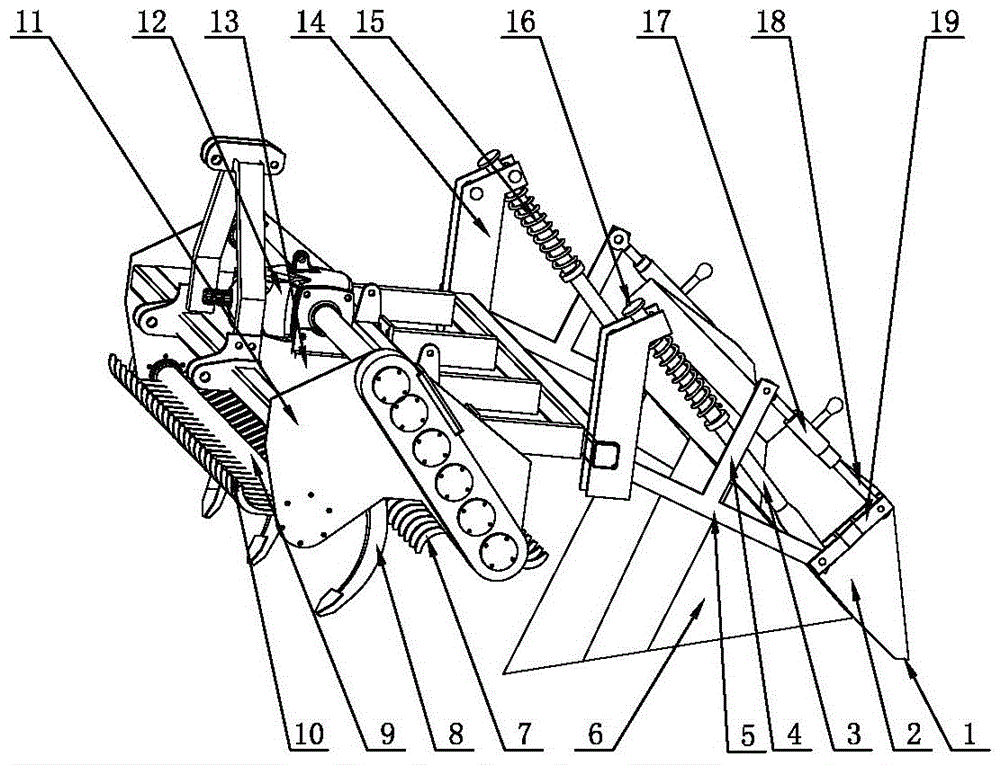

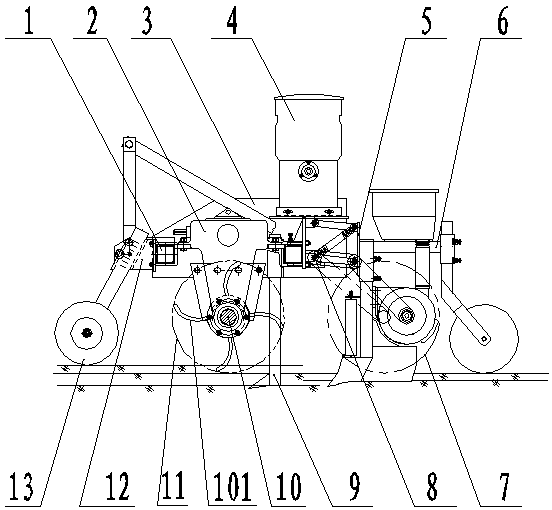

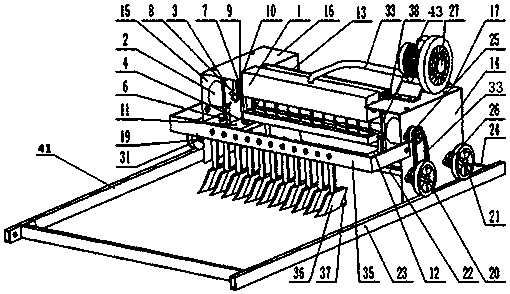

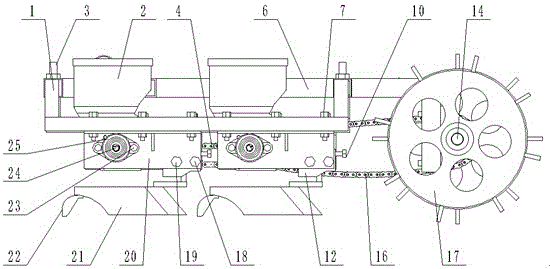

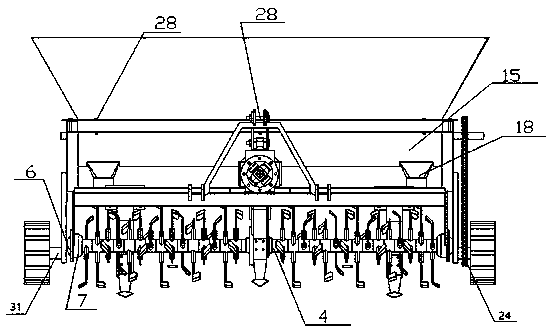

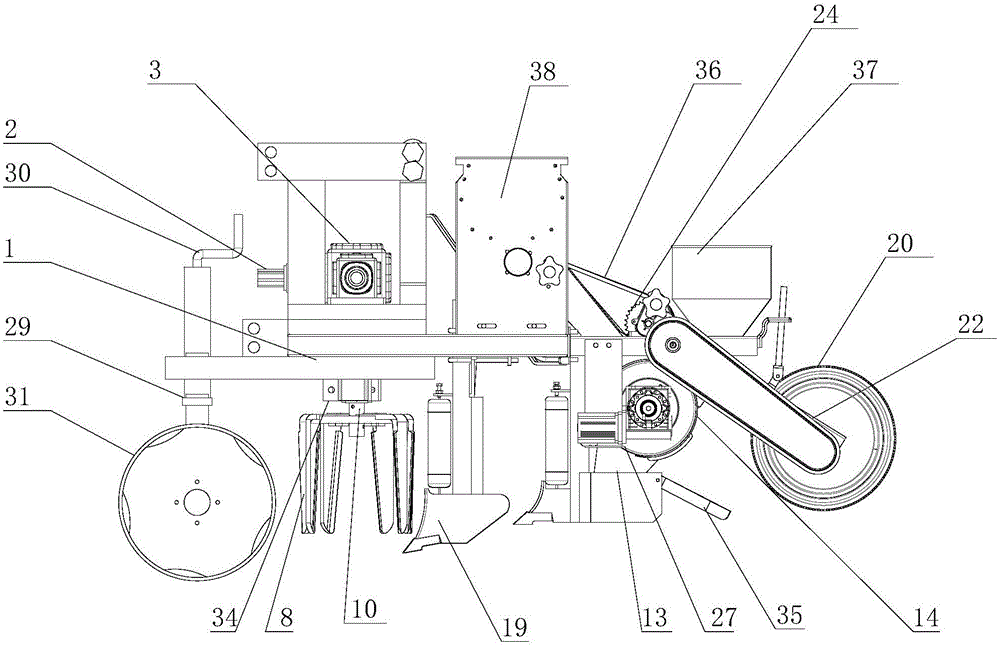

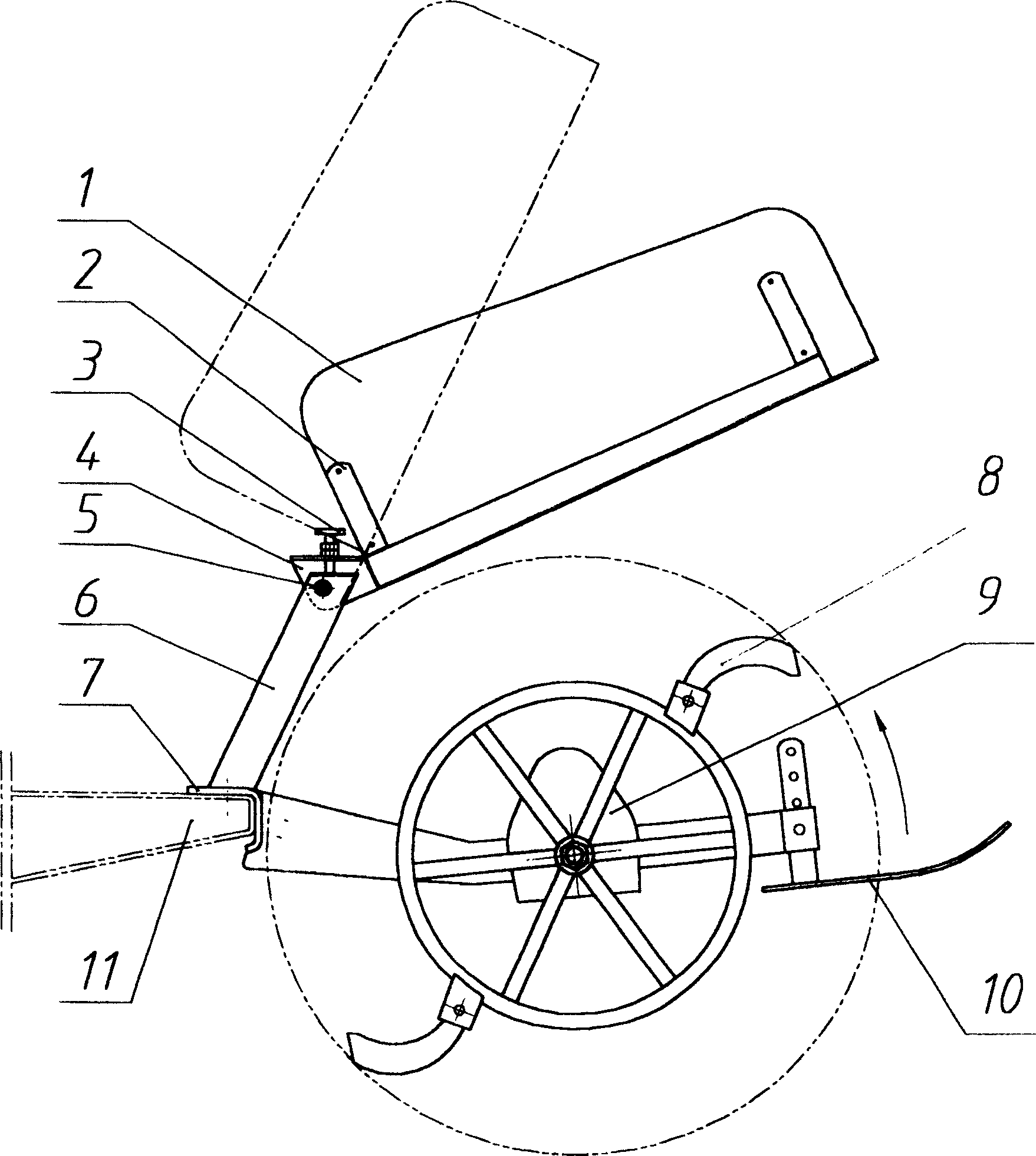

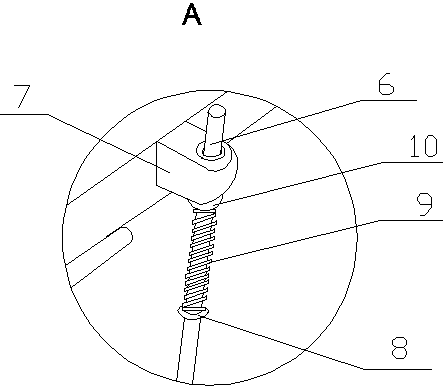

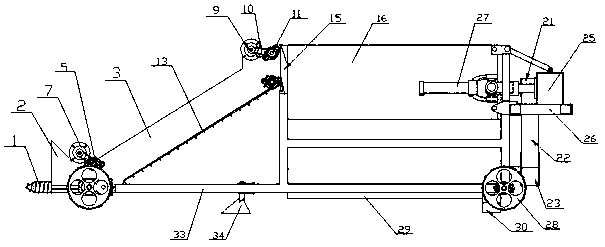

Summer cotton precision no-tillage planter capable of realizing seedling strip cleaning

InactiveCN104335726AAvoid pollutionIncrease temperatureSpadesPloughsAgricultural engineeringEarth surface

The invention provides a summer cotton precision no-tillage planter capable of realizing seedling strip cleaning. The planter comprises a frame; a depth wheel is installed on a depth wheel fixing sleeve; a speed changing box is fixed at the front part of the frame; a fertilizer box is fixed at the rear part of the frame; side plates are respectively arranged on two sides of the frame; a grass and stubble cleaning rotary tillage mechanism is installed between the two side plates; a fertilizer applicator is fixed on the rear beam of the frame; multiple groups of profiling seeding pressing single bodies are also connected with the rear part of the rear beam of the frame; a transmission six-edge shaft is installed on an auxiliary fixing device on the rear side of the rear beam of the frame through a bearing; a transmission land wheel is connected with a transmission six-edge shaft bracket through a shaft sleeve. The planter can perform summer cotton precision no-tillage direct seeding on earth surface covered with stubble after wheat harvest, can accomplish stubble cleaning, grass cleaning, shallow rotary tillage, fertilization, seeding and pressing operation at a time, is beneficial to racing against farming season, has good grass and stubble cleaning and soil crushing effects, can guarantee the seeding depth uniformity, meets agronomic requirements of summer cotton seeding, and is reasonable and novel in whole, high in adaptability, economical and reliable.

Owner:滨州市农业机械化科学研究所

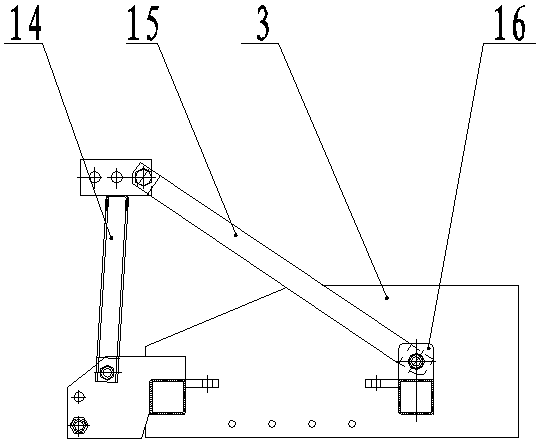

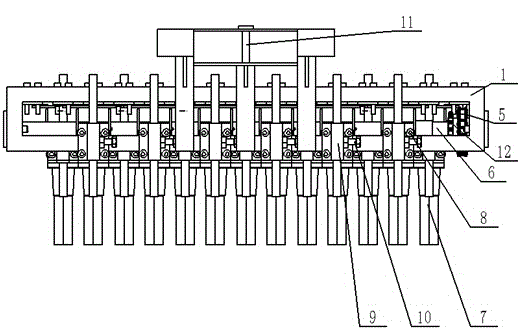

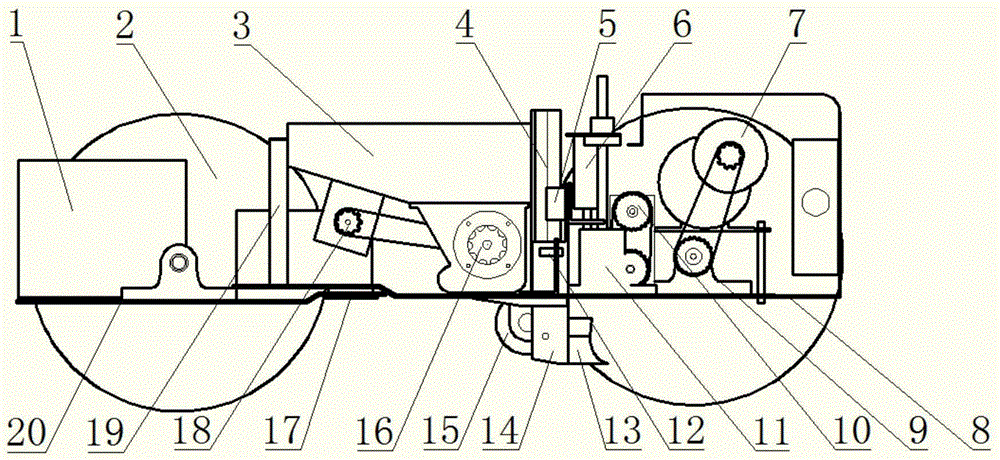

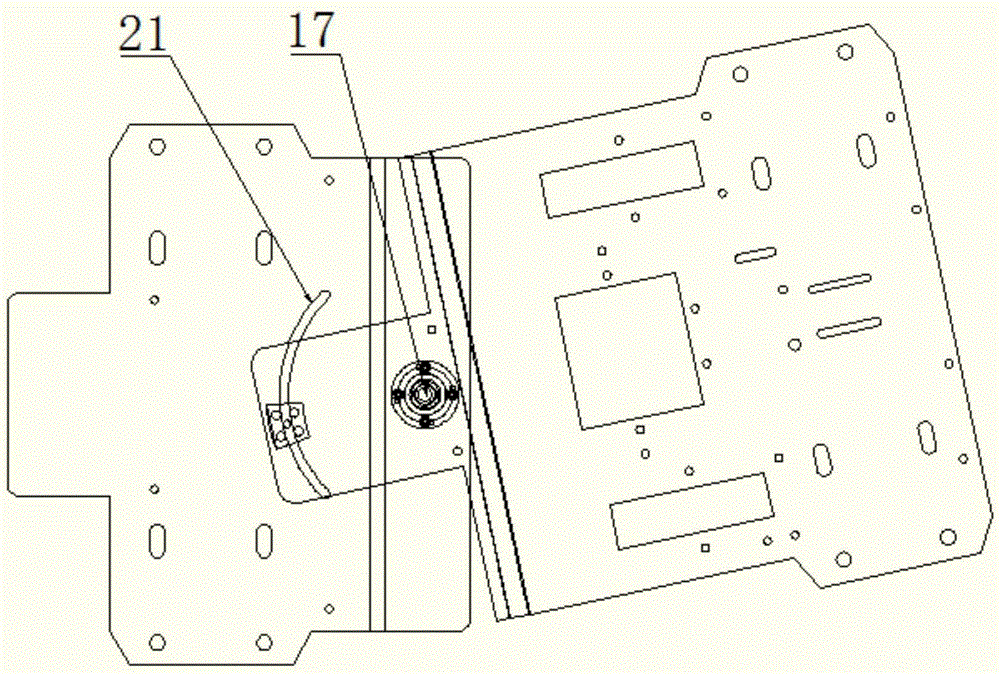

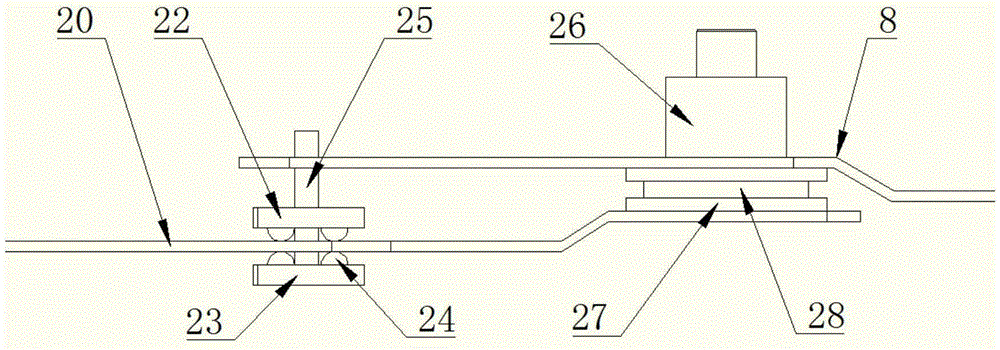

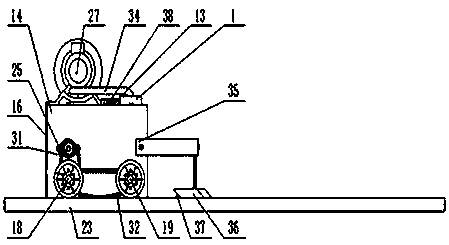

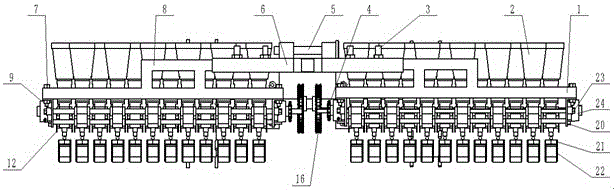

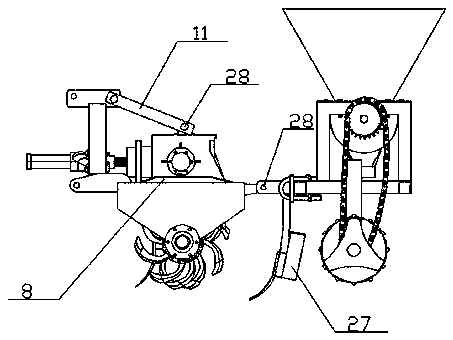

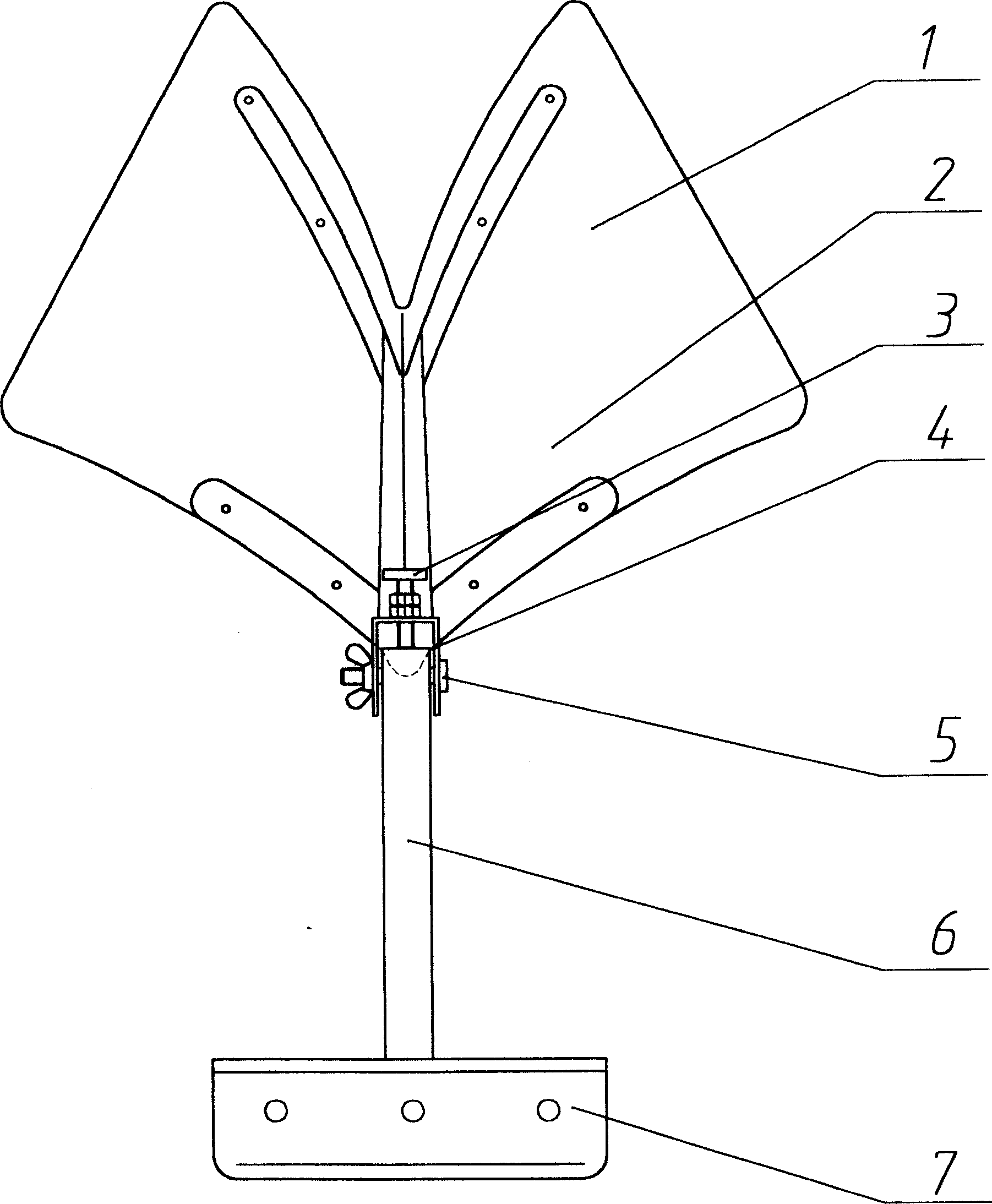

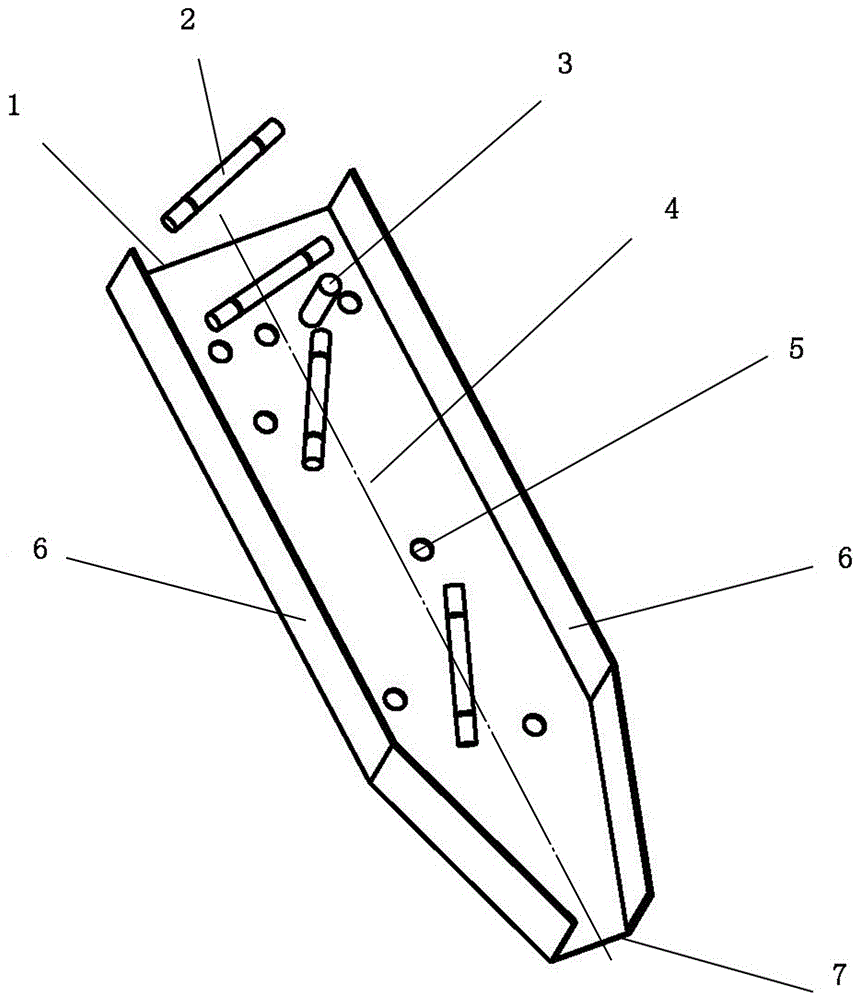

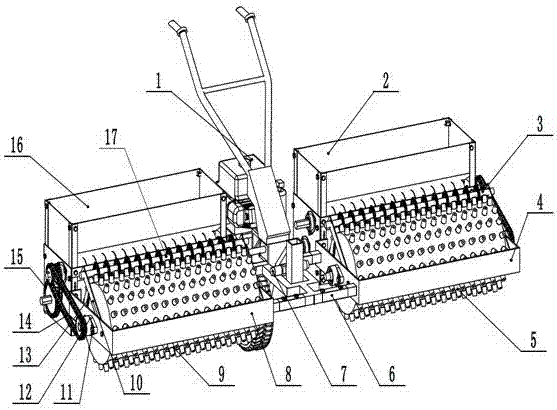

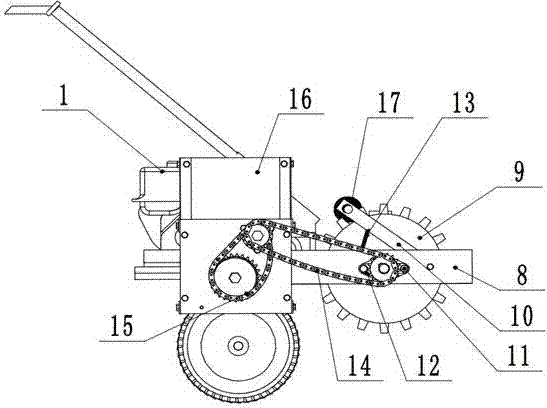

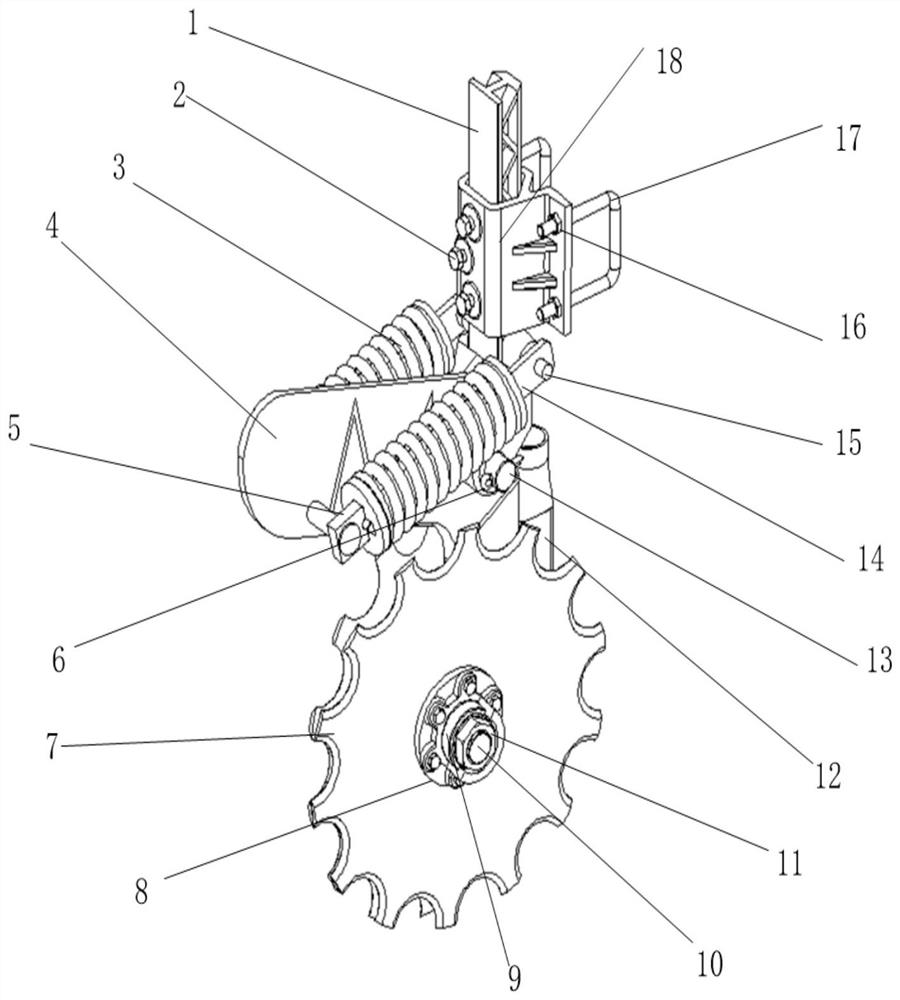

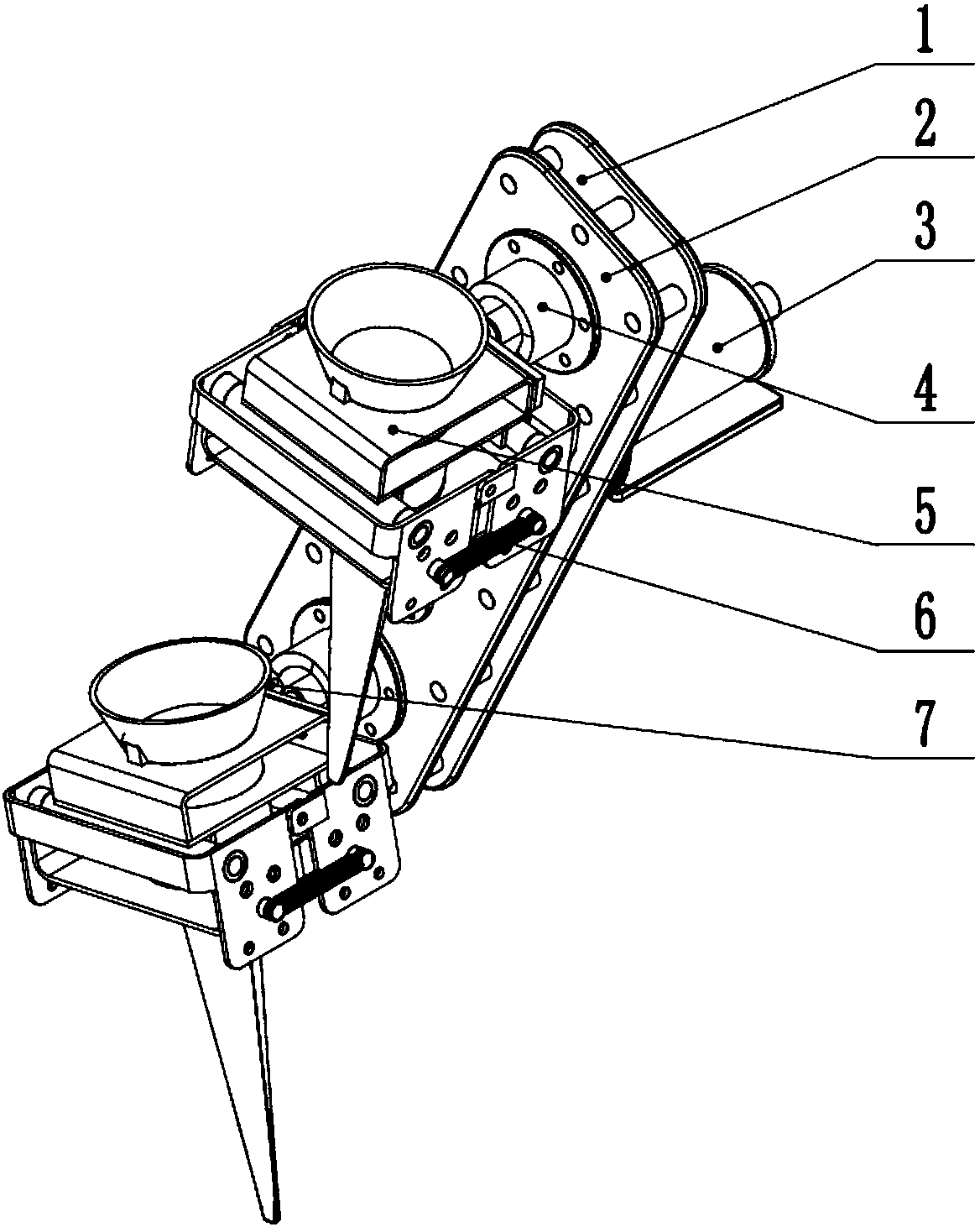

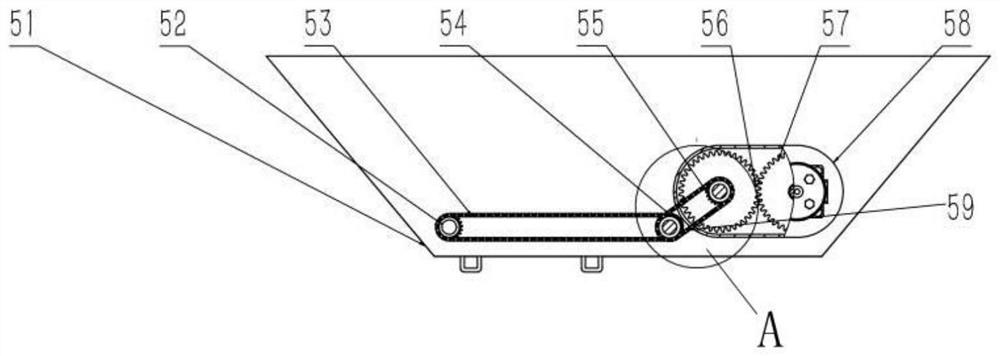

Precision pseudo-ginseng seeding machine

ActiveCN104541691ARealize fine amount of seedingSowing speedClimate change adaptationSeed depositing seeder partsAgricultural engineeringUltimate tensile strength

The invention relates to a precision pseudo-ginseng seeding machine and belongs to the field of agricultural machinery. The precision pseudo-ginseng seeding machine comprises a rack, a seed box I, a seed box II, a seed sowing device driving mechanism I, a seed sowing device transmission mechanism, a seed sowing device driving mechanism II, a ditching device, a ditching device fixing bolt, a ditching device fixing pipe, a ditching device fixing bolt, a connecting pin, a power input chain wheel, a seed sowing device, a seed sowing device fixing bolt and a seed sowing device connecting plate. The precision pseudo-ginseng seeding machine has the advantages that precise and small-amount seed sowing on pseudo-ginseng seeds is realized, and seeding speed is greatly increased; precision pseudo-ginseng seeding is used for replacing manual dibble seeding, so that pseudo-ginseng planting level is improved; agricultural mechanization of the pseudo-ginseng planting industry is realized, agricultural labour productivity can be greatly improved, labour intensity is reduced, production cost is reduced, and the quality and market competiveness of a pseudo-ginseng product are improved; and the precision pseudo-ginseng seeding machine is reasonable in structural design, good in operation quality, high in operation efficiency, reliable in operation and high in universalization degree, and agricultural requirements of the pseudo-ginseng planting industry can be completely met.

Owner:KUNMING UNIV OF SCI & TECH

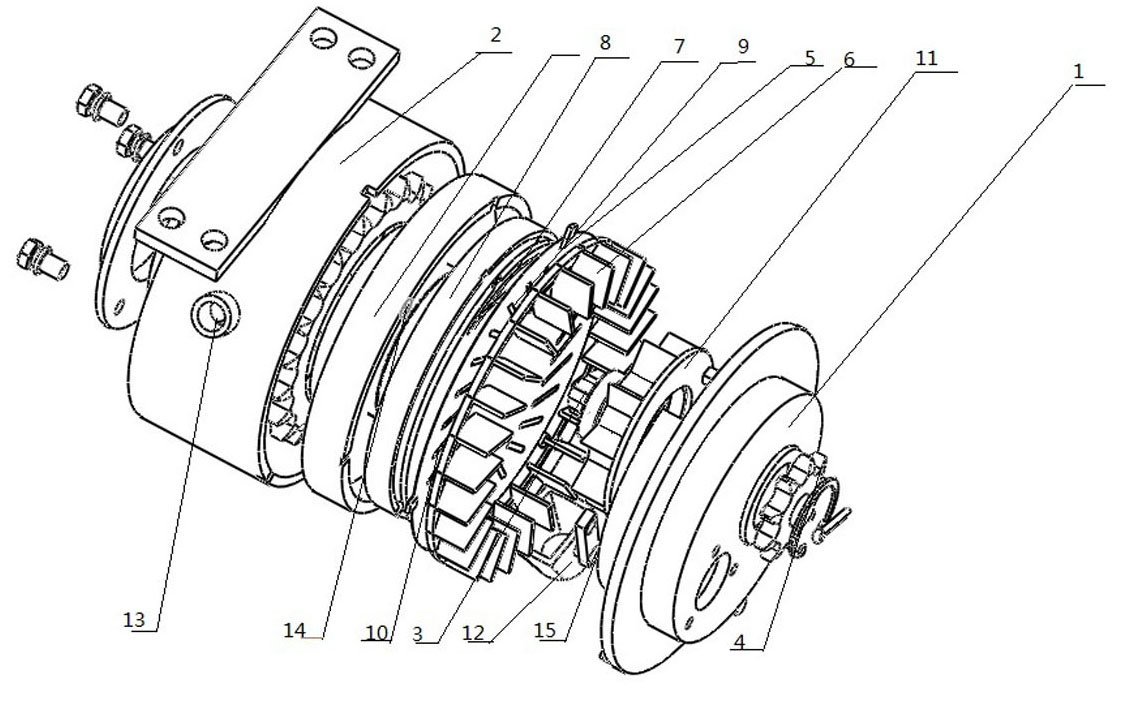

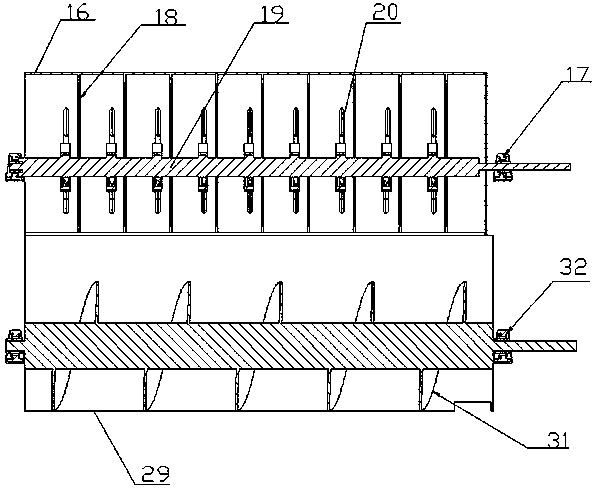

High-speed multifunctional precise-amount seed-metering device

InactiveCN102027827AReasonable and reliable structural designGuaranteed suction performanceSeed depositing seeder partsImpellerSowing

The invention discloses a high-speed multifunctional precise-amount seed-metering device, which solves the problem that the seed fetching performance is poor, seeds cannot be accurately sowed and sowing seed type is limited when the traditional seed-metering device sows at a high speed. A driving gear, a slanting slideway disc and an annular seed discharging impeller are sequentially fixed from the back to the front on a rotary shaft; a flow dividing disc is arranged behind the slanting slideway disc; a vacuum chamber seat is fixed behind the flow dividing disc; a plurality of radial slotted holes are uniformly distributed on the edge of the slanting slideway disc; the flow dividing disc is provided with a parabolic slotted hole communicated with the radial slotted holes; a speed accelerating wheel eccentric with the seed discharging impeller is arranged in the centre of the seed discharging impeller; a seed discharging port and a rotation speed sensor which swing left and right are respectively arranged on the lower part of a seed discharging shell and on the inner wall of the seed discharging shell corresponding to the seed discharging impeller; a photoelectric sensor used for detecting seed loss is arranged on the inner wall of a front end cover; and a hall sensor used for detecting the seed quality is arranged on the seed discharging port. The high-speed multifunctional precise-amount seed-metering device has a reasonable and reliable structural design, guarantees the seed absorption performance of the slanting slideway disc and meets the requirements on precise amount and precise sowing.

Owner:王曦

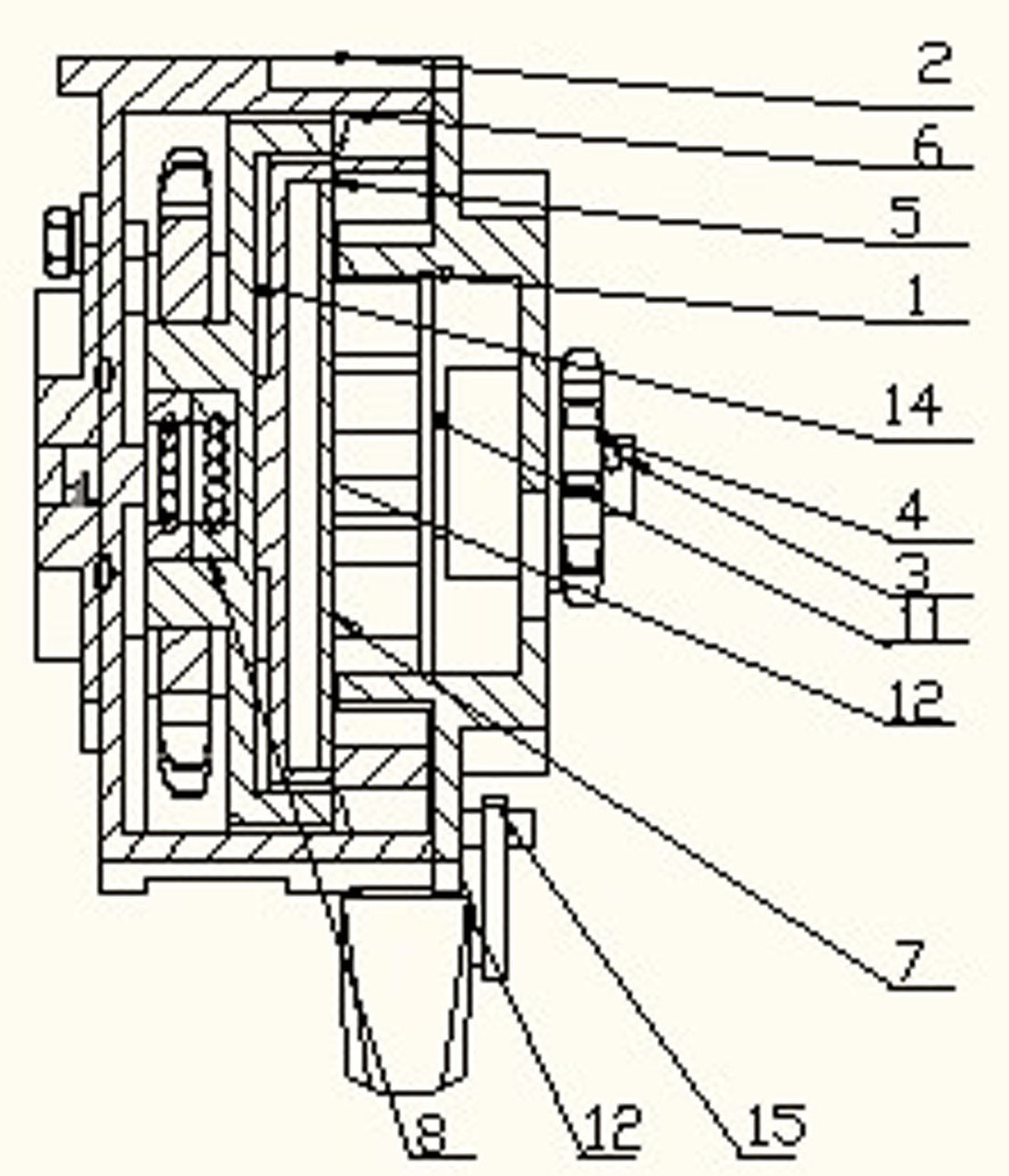

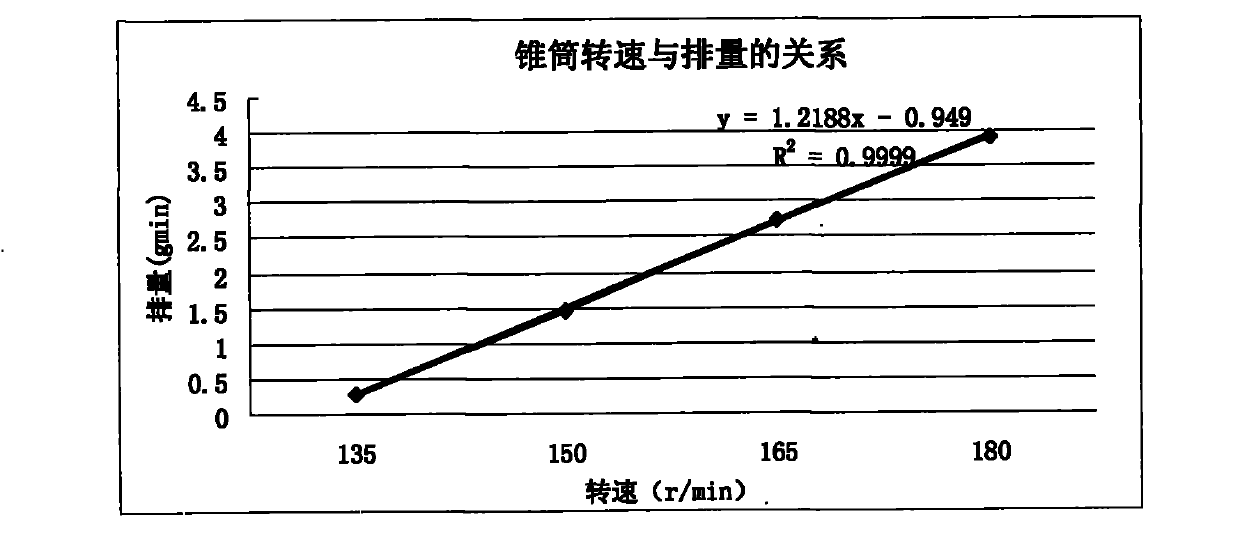

Centrifugal centralized type rape precise seed metering device

InactiveCN102550182ASimple structureThe number of sowing rows is adjustableSeed depositing seeder partsSeederAgricultural science

The invention belongs to the field of seeding machines in agricultural machinery, and aims to provide a centrifugal centralized type rape precise seed metering device. The centrifugal centralized type rape precise seed metering device has the beneficial effects that seeds are supplied by one seed box in a centralized manner, the effect that one seeding metering device can meter a plurality of rows of seeds can be realized by means of a centrifugal force, the structure is simple, and the seeds are not damaged; and the seed output is uniform, and the seed output quantity is adjustable, so that the agricultural demands of rape planting in different areas can be satisfied. Meanwhile, different crop seeds can be seeded through replacing and configuring an outer taper cylinder with different seed output structural forms, and different numbers of rows can be seeded through configuring different numbers of seed output tubes. The centrifugal centralized type rape precise seed metering device has the beneficial effects that the seeding efficiency is improved, the whole structure of the seeding machine is simplified, and the universality of the seeding machine is improved.

Owner:HUAZHONG AGRI UNIV

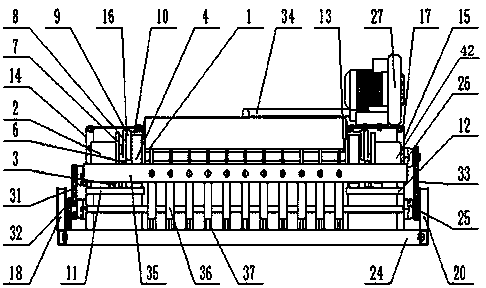

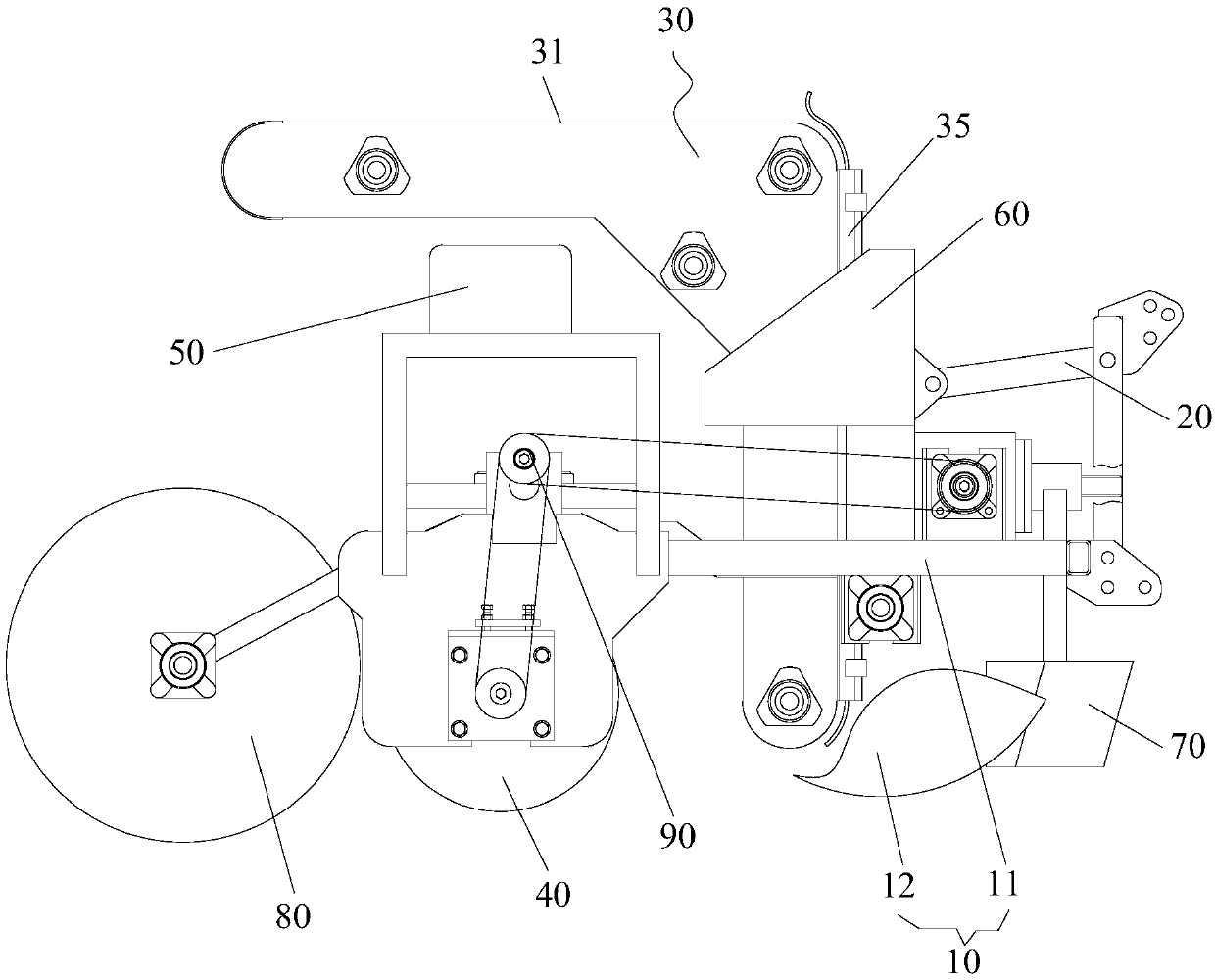

Self-propelled rice direct-seeding machine

ActiveCN105379480AMeet agronomic requirementsReduce labor intensityPlantingAgriculture gas emission reductionAgricultural engineeringDrive motor

The present invention relates to a self-propelled rice direct-seeding machine including a chassis, a bow steering device, a walking device, a seeding device and a tilling depth adjusting device, the chassis comprises a front chassis and a rear chassis, and the front chassis and the rear chassis are connected via a steering connection seat for bow steering. An arc guide rail mechanism comprises an arc guide groove installed on the rear chassis and a clamping device installed on the front chassis; the clamping device comprises an upper clamping sheet, a lower clamping sheet, a fastening shaft and balls; the walking device comprises two drive motors, four wheels, a bearing seat, a main shaft and other parts, the seeding device comprises a seed box, a seed arrangement tank, a planetary speed reducing stepper motor, a seed arrangement guide tube, a furrow opener, a ground wheel and a furrow opener lifting mechanism, and the self-propelled rice direct-seeding machine is provided with a copying device, and can better control seeding depth.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

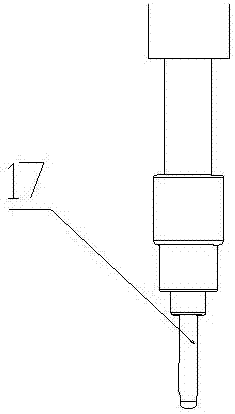

Factory needle-like suction pseudo-ginseng seeder

PendingCN108174658APrecision seedingSowing speedSeed depositing seeder partsBroadcast seedersSeederAgricultural engineering

The invention relates to a factory needle-like suction pseudo-ginseng seeder, which belongs to the field of an agricultural machine. The needle-like suction pseudo-ginseng seeder comprises a seed metering device, a swing cylinder I, a swing cylinder seat I, a slide block seat, a slide block, a limited pillar I, a limited pillar II, a rocking bar I, a rocking bar II, a rotating shaft, a pedestal I,a pedestal II, a seed case, a protective cover I, a protective cover II, a cover plate I, a cover plate II, a walking wheel I, a walking wheel II, a walking wheel III, a walking wheel IV, a walking wheel connection shaft, a track I, a track II, a mounted bearing I, a mounted bearing II, a negative pressure machine, a motor, a gas insulation board, a sprocket wheel, a chain I, a chain II, a chainIII, an inhalation pipeline, a trench digging rack, an opening share, a seed-induction pipe, an angle iron, a slide block rod, a seed-discharging needle, a guide rail II, a swing cylinder II, and a swing cylinder seat II. The seeder realizes accurate sowing during factory pseudo-ginseng sowing work, increases sowing speed, reduces labor intensity, increases the pseudo-ginseng quality, reduces cost, has the advantages of reasonable structure and high efficiency, and can satisfy the agronomic requirement for a factory pseudo-ginseng plantation industry.

Owner:KUNMING UNIV OF SCI & TECH

Front-profiling type pseudo-ginseng sower

ActiveCN105052314ARealize fine amount of seedingSowing speedSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringMarket competition

The invention relates to a front-profiling type pseudo-ginseng sower and belongs to the field of agricultural machinery. The front-profiling type pseudo-ginseng sower comprises a left rack, seeding apparatus mechanisms, set screws, secondary drive mechanisms, a hinge pin, a profiling rack, side plate connecting bolts, a right side rack, side plates I, furrow opener fixing bolts, position adjusting screws, seeding apparatus mounting brackets, a land wheel I, a land wheel shaft, UCP205 bearings, primary drive mechanisms, a land wheel II, supporting shafts I, supporting shafts II, side plates II, furrow openers, soil covering devices, fixing bolts, seeding shafts and UCP202 bearings. Small-quantity and accurate seeding of pseudo-ginseng seeds is realized, and the sowing speed is greatly improved; the plantation level of pseudo-ginseng is improved; the labor intensity is reduced, the production cost is reduced, and the quality and the market competition capacity of pseudo-ginseng products are improved. The structural design is reasonable, the operation quality is good, the operation efficiency is high, the operation is reliable, the universalization degree is high, and the agriculture requirements of the pseudo-ginseng industry is completely met.

Owner:KUNMING UNIV OF SCI & TECH

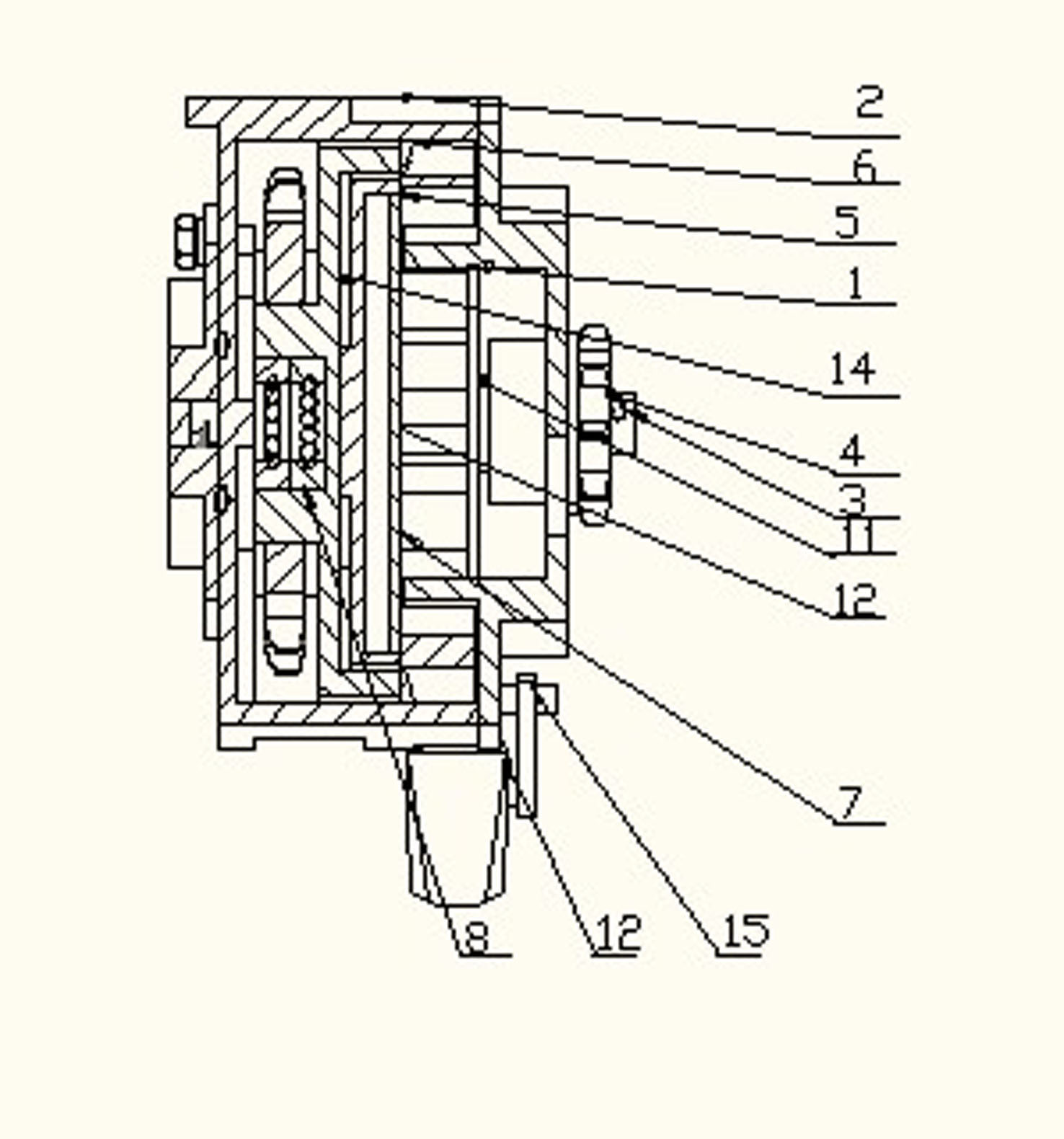

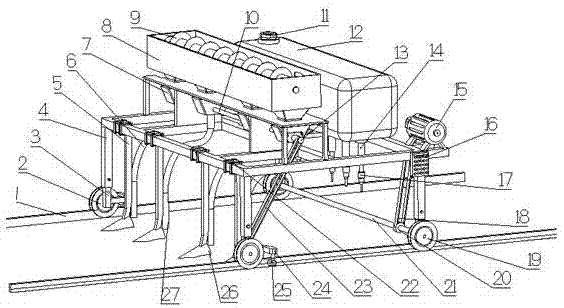

Track type solid-liquid integral pseudo-ginseng fertilizer applicator

InactiveCN107509413AEasy to operateImprove economic efficiencyPlantingFertiliser distributersGreenhouseAgricultural engineering

The invention relates to a track type solid-liquid integral pseudo-ginseng fertilizer applicator, and belongs to the technical field of agricultural machinery. The fertilizer applicator comprises a track walking system, a trenching device, a solid fertilizer applying system, and a liquid fertilizer applying system. The track walking system is arranged on the front side and rear side of a frame. The trenching system is arranged on the lower-front end of the frame. The solid fertilizer applying system is arranged on the middle of the frame. The liquid fertilizer applying system is arranged on the rear part of the frame. The power of the fertilizer applicator is provided by a motor arranged in the rear part of the frame. The provided fertilizer applicator can apply solid and liquid fertilizers at a time, the degree of automation is high, and the fertilization effect is good. The fertilizer applicator adopts a track walking system, solves the problem of fertilization of crops in a green house, and can apply solid and liquid fertilizers at the same time. The fertilizer applicator has high efficiency, fully guarantees the application of fertilizers, has multiple functions, solves the problems of large labor strength, high labor cost, and great damage of chemical agents to human body during the fertilizer applying process, has a wide market prospect, and is suitable for popularization and application.

Owner:KUNMING UNIV OF SCI & TECH

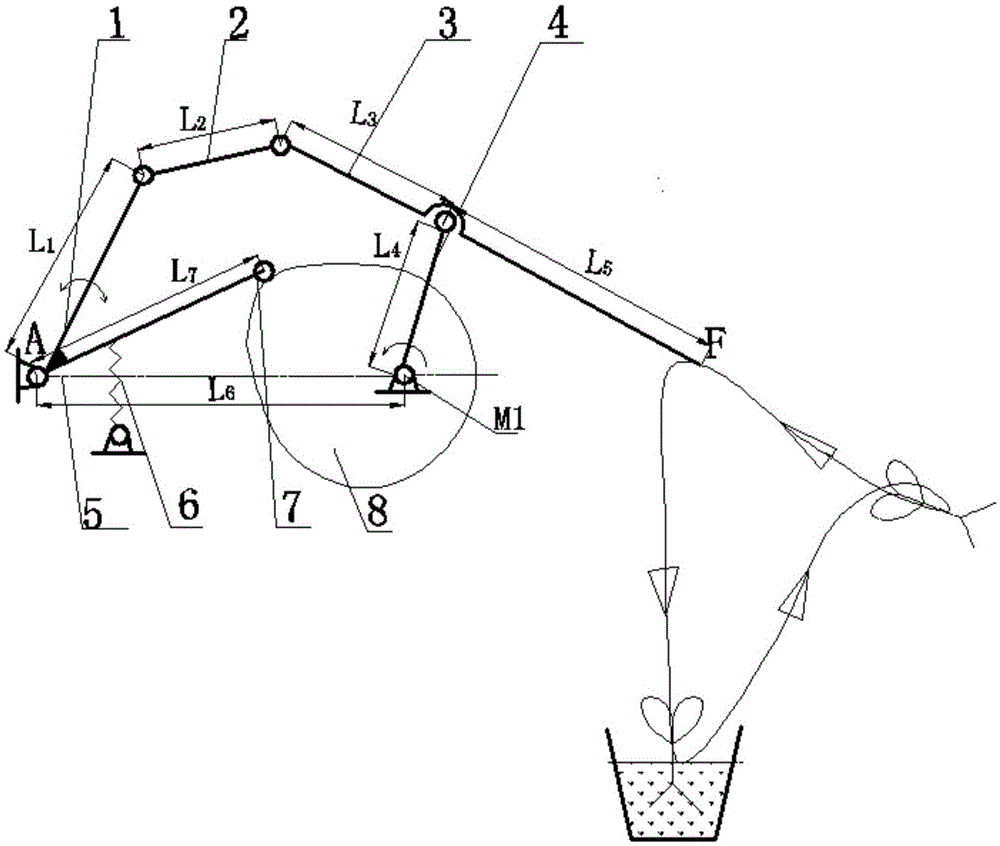

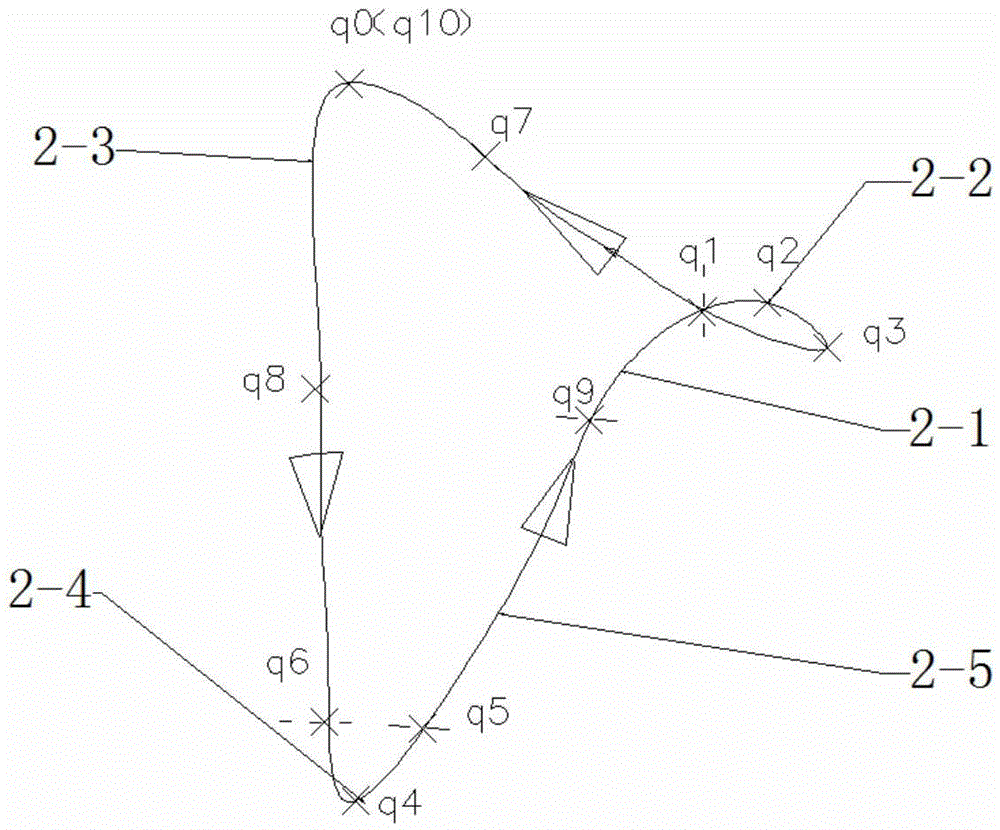

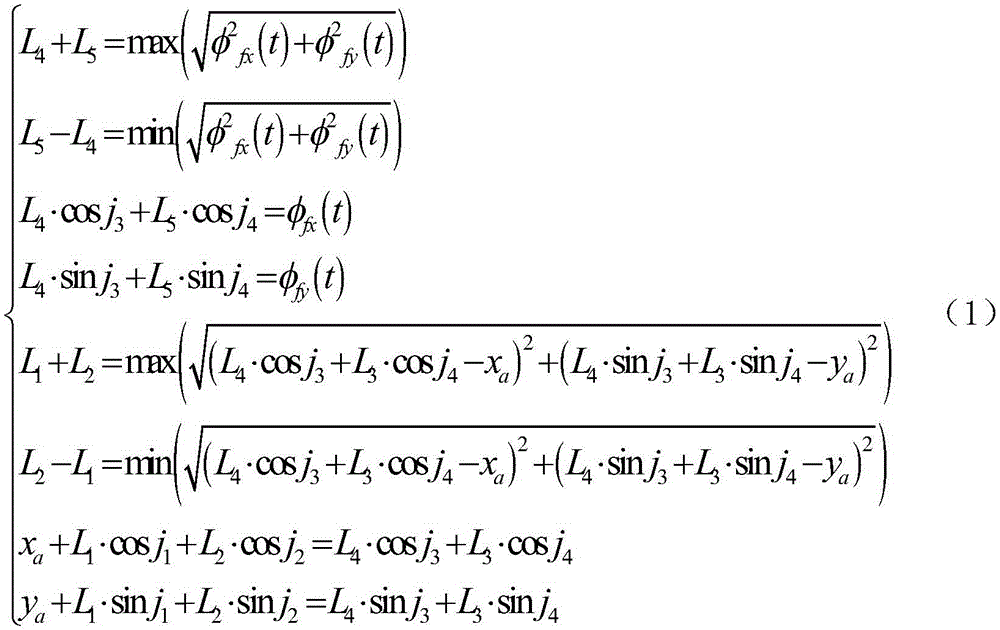

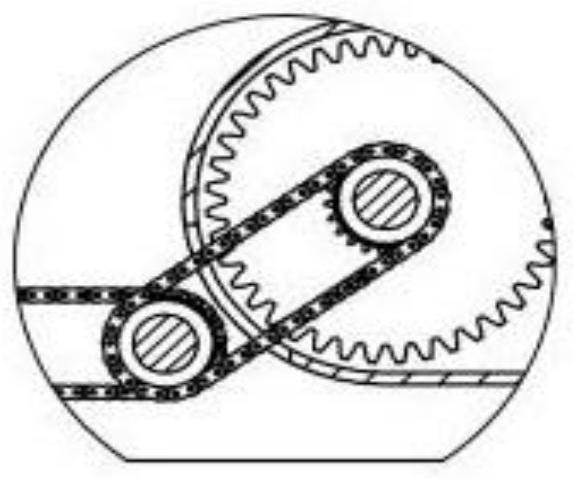

Cam-crank-rocker combined flower transplanting mechanism and design method thereof

ActiveCN105519290AMeet the agronomic requirements for transplantingMeet agronomic requirementsTransplantingMathematical modelEngineering

The invention discloses a cam-crank-rocker combined flower transplanting mechanism and a design method thereof. A planetary gear transplanting mechanism is limited in flexibility of realizing a trajectory; and a rod mechanism with a double-ring-buckle trajectory is difficult in design and parameter regulation. According to the mechanism provided by the invention, one ends of a cam and a crank are both hinged with a frame through a camshaft; the other end of the crank is hinged with the central part of a second connecting rod; a forked swing rod comprises a bottom-end-welded oscillating rod and a cam swing rod; two ends of a spring are separately connected with the forked swing rod and the frame; a roller is hinged with the top end of the cam swing rod and constitutes a cam pair with the cam; the top end of the oscillating rod is hinged with one end of a first connecting rod; and the other end of the first connecting rod is hinged with one end of the second connecting rod. The design method provided by the invention is as follows: the cam is reversely solved with a mathematical model of a single-ring-button trajectory formed by the terminal point of the free end of the second connecting rod, a coordinate of the hinge joint of the forked swing rod and the frame, and known conditions of rod lengths. According to the invention, through changing of the profile of the cam to control the movement law of a rocker, the single-ring-buckle trajectory is realized, and the mechanism is simple.

Owner:南通希芸园林科技有限公司

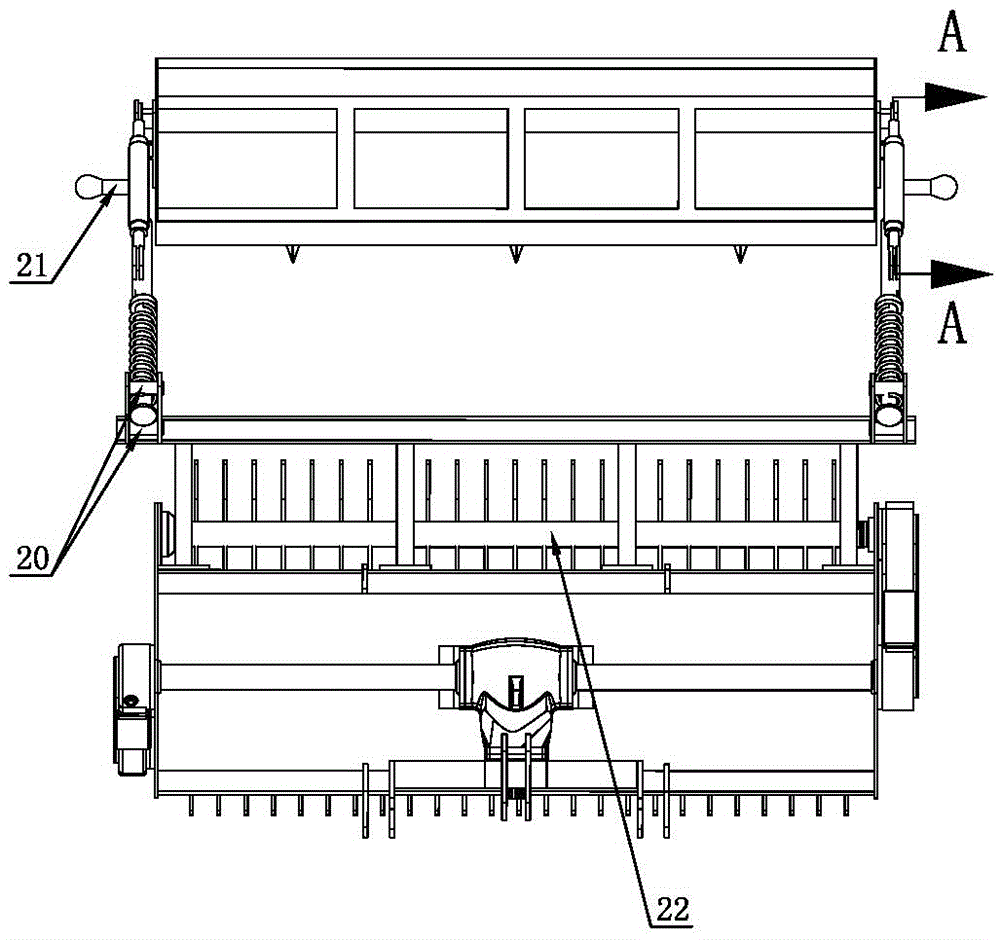

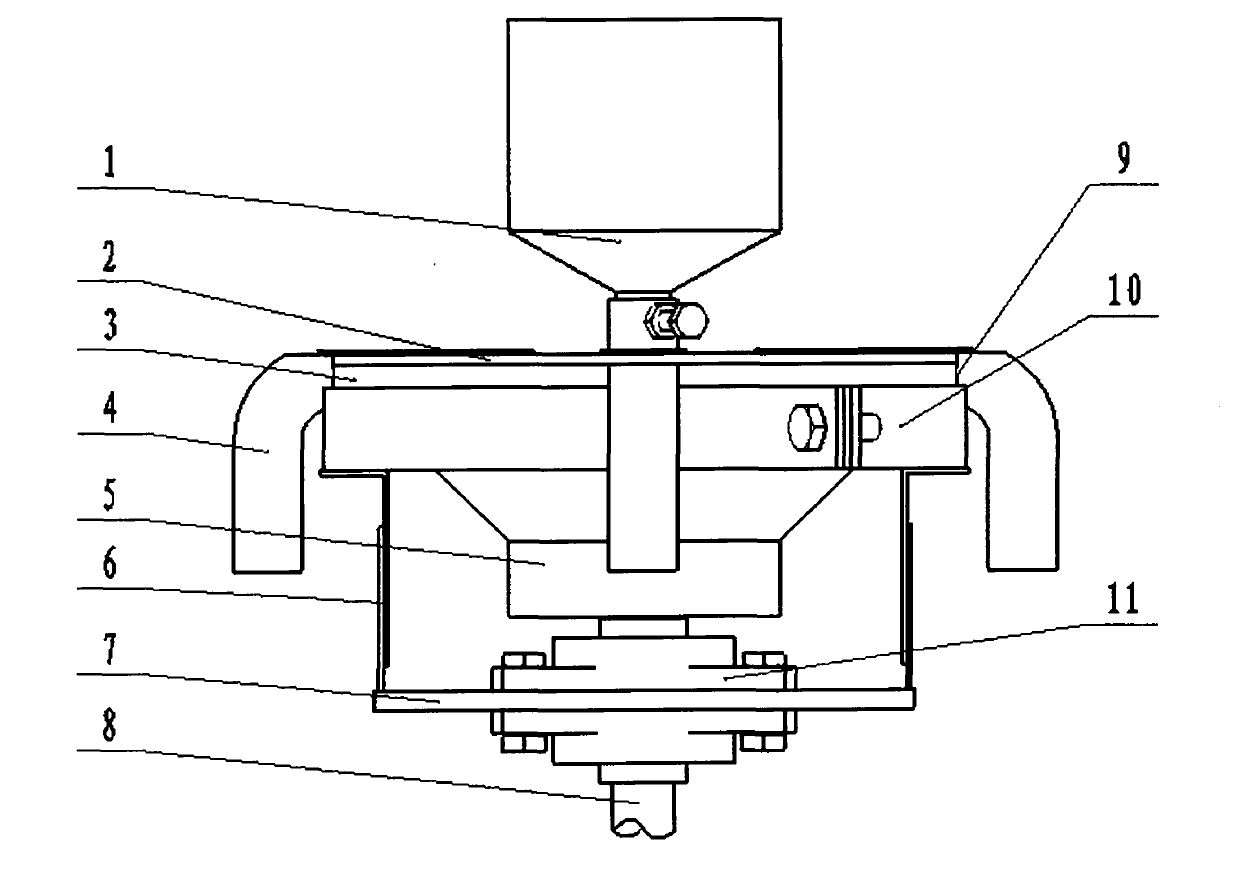

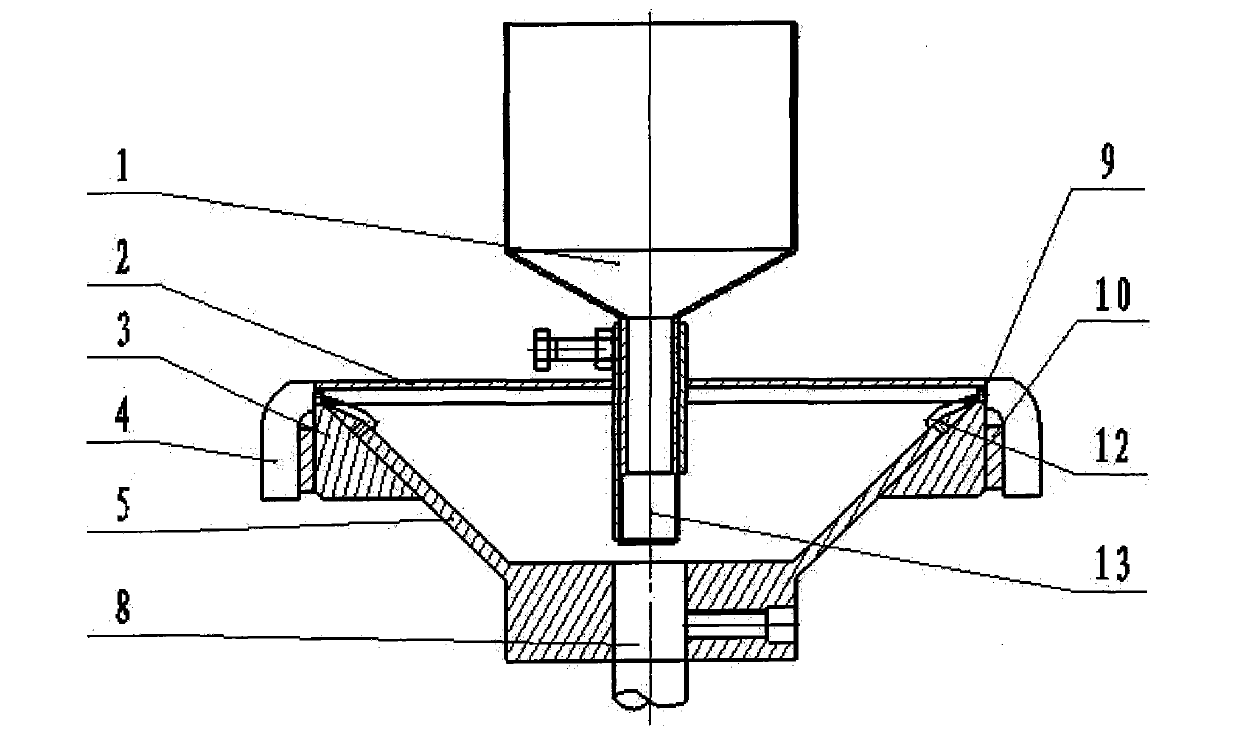

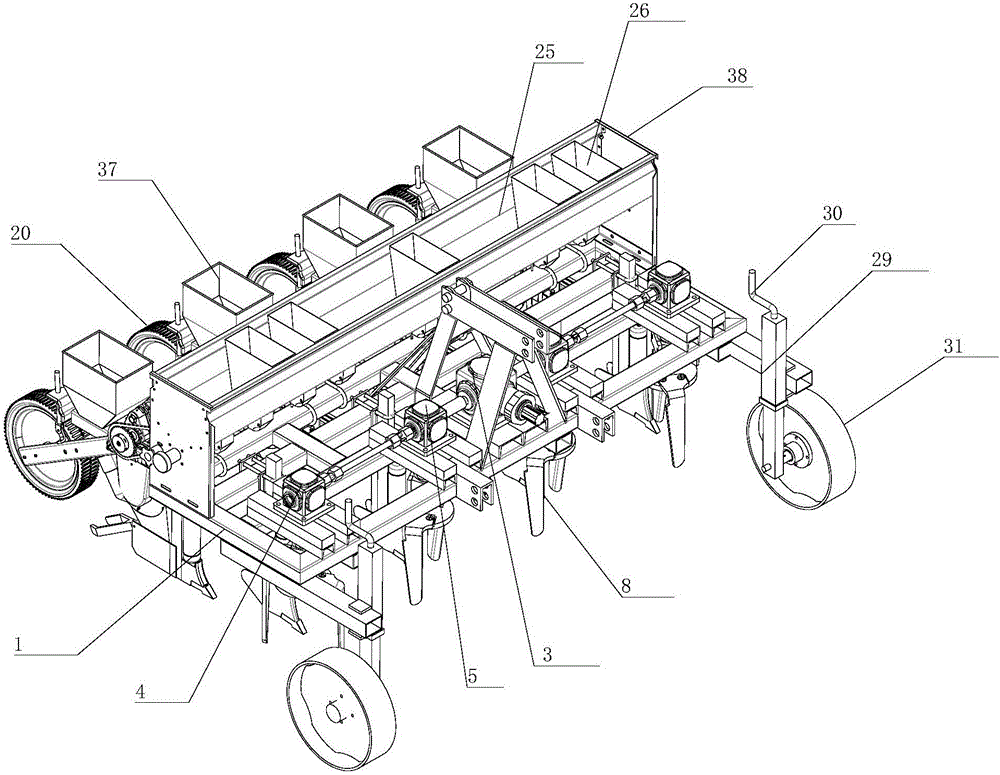

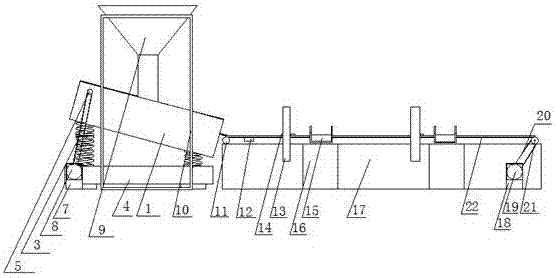

Rotary cultivation, deep loosening and fertilizer application machine

InactiveCN108605450AMeet agronomic requirementsSimple structureSpadesPloughsSpiral bladeAgricultural engineering

The invention relates to a rotary cultivation, deep loosening and fertilizer application machine, and belongs to the technical field of agricultural machinery. The rotary cultivation, deep loosening and fertilizer application machine comprises a framework, a fertilizer discharge mechanism, a land wheel transmission system, a deep loosening mechanism and a rotary cultivation mechanism. A deep loosening shovel can be inserted in the earth surface, and accordingly farmlands can be deeply loosened; a land wheel can be driven to rotate when a tractor advances, a driven chain wheel on a fertilizer discharge shaft can be driven by a driving chain wheel on the land wheel via a chain, accordingly, the fertilizer discharge shaft can rotate, fertilizers can be discharged, can be rotationally conveyedto two ends of a fertilizer discharge barrel via two reverse spiral blades, fall into conical discharge funnels, can be connected into a fertilizer application pipe on the deep loosening shovel by fertilizer pipes and can be applied to the deeply loosened farmlands, and accordingly rotary cultivation, deep loosening and fertilizer application operation can be completely carried out. The rotary cultivation, deep loosening and fertilizer application machine has the advantages that the rotary cultivation, deep loosening and fertilizer application machine is simple in structure, high in efficiency and generalization degree, good in operation quality and reliable in operation, the time can be saved, rotary cultivation, deep loosening and fertilizer application can be simultaneously completelycarried out, the agronomic requirements on the agricultural product planting industry can be completely met by the rotary cultivation, deep loosening and fertilizer application machine, and the problem of high labor cost can be solved by the aid of the rotary cultivation, deep loosening and fertilizer application machine to a great extent.

Owner:KUNMING UNIV OF SCI & TECH

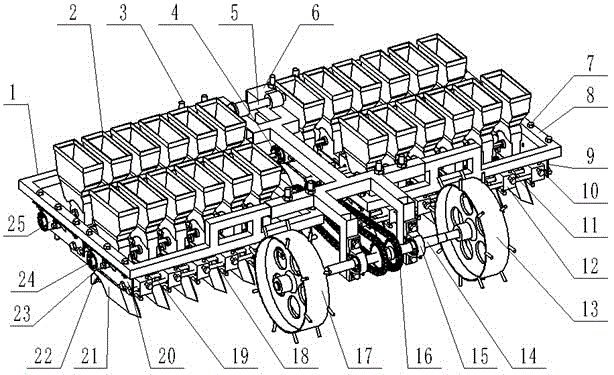

No-tillage electronic control corn compound planter

ActiveCN105815010AImprove work efficiencySolve the grass problemAgriculture gas emission reductionPlant protectionUniversal jointControl system

The invention provides a no-tillage electronic control corn compound planter. The planter comprises a rack, a stirring knife cleaning mechanism and a seeding mechanism, wherein the stirring knife cleaning mechanism comprises a spline input shaft, a speed reducer, a single-output commutator, a dual-output commutator, a universal joint, a universal joint connecting shaft, a vertical rotary stirring knife, a cutter head and a cutter shaft; the spline input shaft is in transmission connection with the speed reducer; the speed reducer and the double-output commutator are in transmission connection; one end of the universal joint connecting shaft is connected with the universal joint; the other end of the universal joint connecting shaft is connected with the double-output commutator; the universal joint is connected with the single-output commutator; the speed reducer, the double-output commutator and the single-output commutator are in transmission connection with the cutter shaft; the cutter shaft is connected with the cutter head; the vertical rotary stirring knife is connected with the cutter head; and the seeding mechanism comprises a control system assembly, a seeding apparatus assembly, a seeding apparatus shaft, a seeding pipe and a seeding coulter assembly. The no-tillage electronic control corn compound planter can stably work under the no-tillage operation condition; and accurate seeding and retest operation can also be achieved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

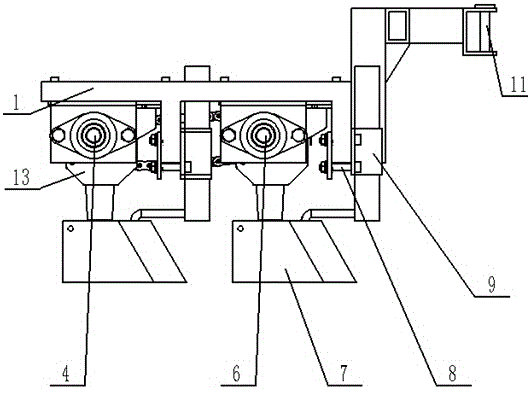

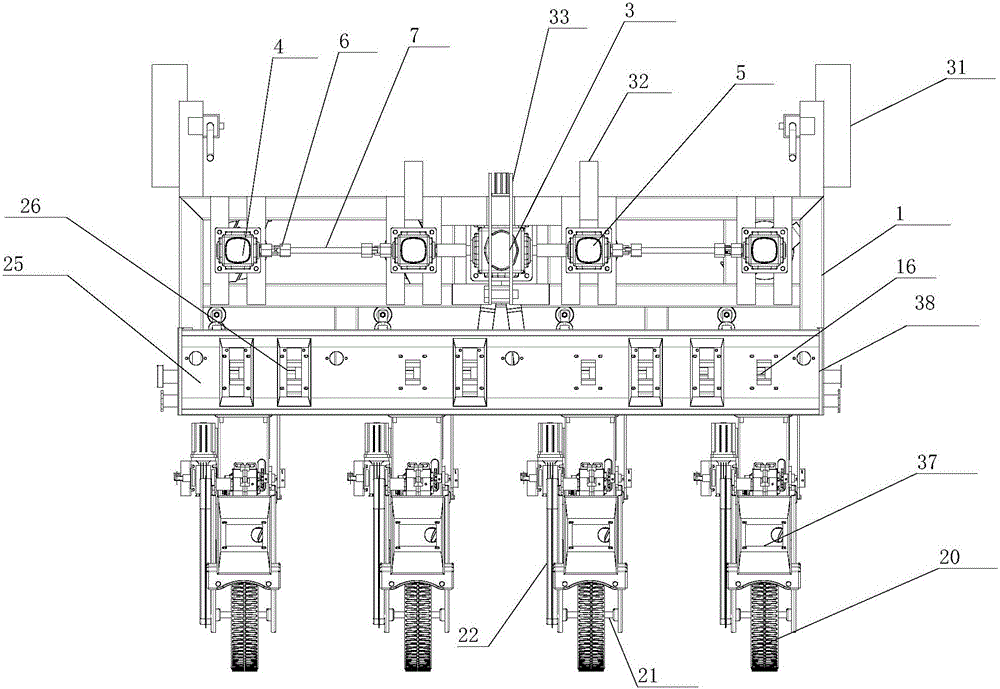

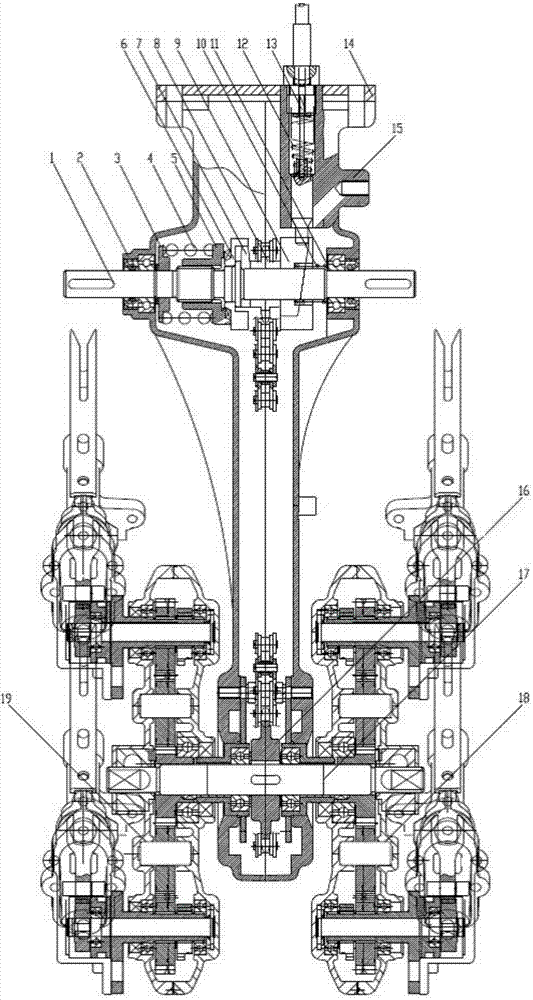

Rice transplanter for simultaneously transplanting male parents and female parents for seed production of hybrid rice and synchronous rice transplanting method for rice transplanter

InactiveCN103444328AGuaranteed agronomic requirementsGuaranteed simultaneous planting operationsTransplantingTransplanting

The invention discloses a rice transplanter for simultaneously transplanting male parents and female parents for the seed production of hybrid rice. The rice transplanter consists of a transplanting mechanism, a box moving mechanism, a longitudinal rice seedling conveying mechanism, a rice seedling box, a rice seedling boat, a tail plate and a power drive device; the transplanting mechanism comprises 12 rice seedling transplanting arms, including 10 female parent rice seedling transplanting arms and 2 male parent rice seedling transplanting arms; the female parent rice seedling transplanting arms are distributed on the two sides, and the space between adjacent female parent rice seedling transplanting arms is 177 mm; the space on one sides of the male parent rice seedling transplanting arms is 238 mm, the space on the other sides of the male parent rice seedling transplanting arms is 300 mm, the space between two male parent rice seedling transplanting arms is 291 mm; each time of transverse movement distance of the rice seedling box is 20 mm; each time of rice seedling conveying distance of the longitudinal rice seedling conveying mechanism is 18 mm; the transplanting work of male parent rice seedlings and female parent rice seedlings is finished by simultaneously transmitting power to the male parent rice seedling transplanting arms and the female parent rice seedling transplanting arms and simultaneously conveying the rice seedlings in the transverse direction and the longitudinal direction via the power drive device. By adopting the rice transplanter, labor intensity can be reduced greatly, rice transplanting efficiency can be improved, farming season can be saved, production cost can be reduced, and the problems of labor shortage, unstable seed quality and the like are solved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

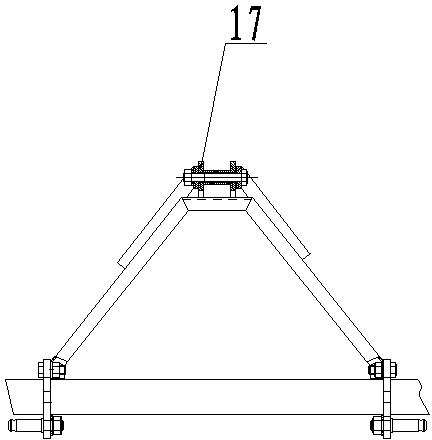

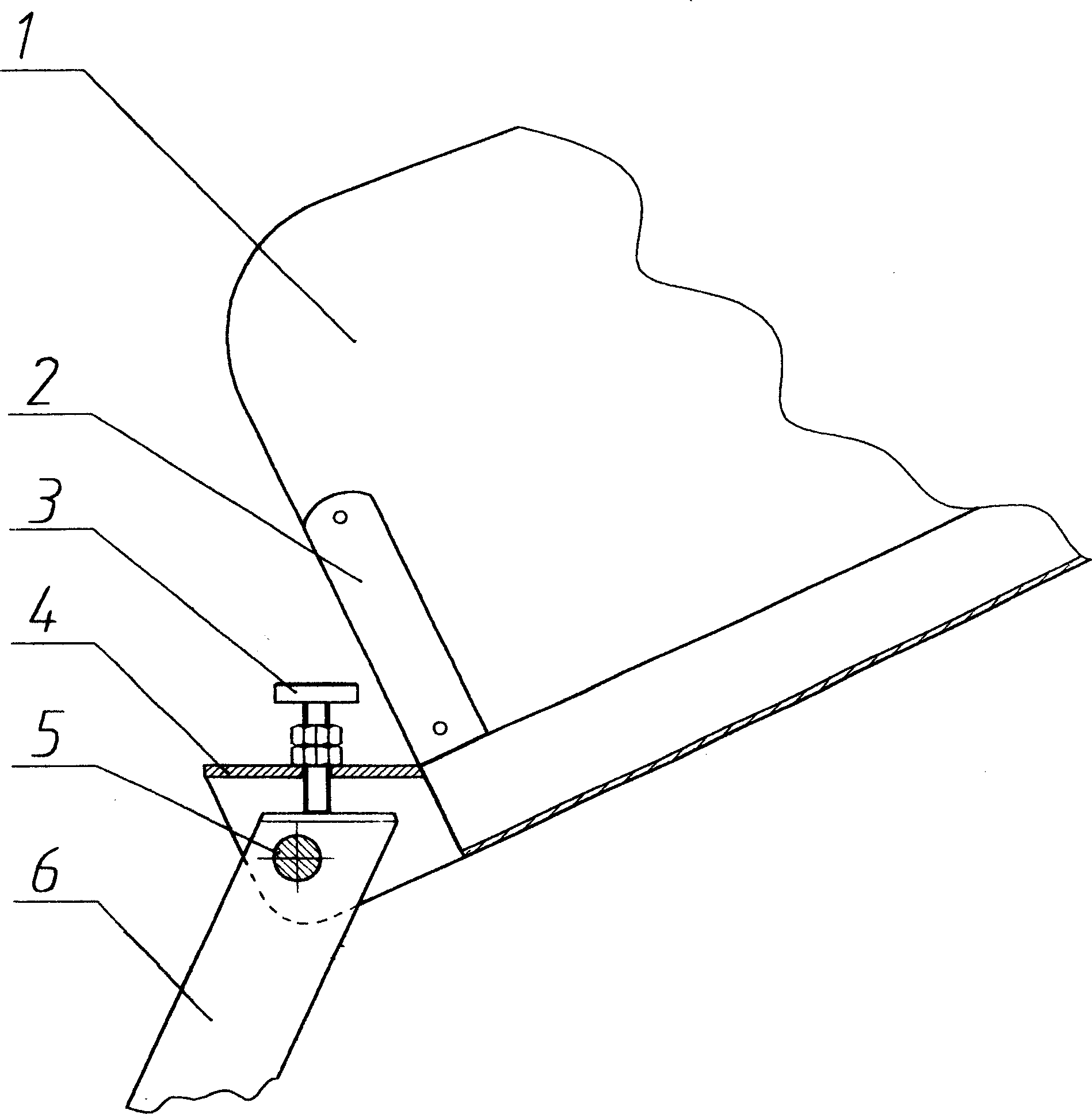

Soil divider of ditching machine

InactiveCN1596575AGood strengthSaving clayPlantingFurrow making/coveringTractorAgricultural machinery

An earth divider for the ditch digger which is installed to front end of a walking tractor is arranged above the cutting wheel of ditch digger, and has V-shaped earth dividing plate and supporting rod whose top end is connected to said earth dividing plate via hinge-locking mechanism on which a regulator is set up.

Owner:葛玉明

Stubble cleaning rotary cultivator

InactiveCN104272900AUniform sizeHigh densitySpadesPloughsAgricultural engineeringAgricultural machinery

The invention discloses a stubble cleaning rotary cultivator and relates to agricultural machinery. The stubble cleaning rotary cultivator comprises a machine body, a hooking device, a power device and a chain drive device; a flattening device is arranged on the back part of the machine body and comprises a mud guard; the lower part of the mud guard is provided with a bent part; a back beam of the machine body is provided with support rod seats; support rods are inserted into the support rod seats; a limiting gasket and a baffle are arranged on the rod body of each support rod below the corresponding support rod seat in a sleeving manner; a reset spring is arranged on the rod body of each support rod between the corresponding limiting gasket and baffle; a suppressing roller is arranged behind the mud guard; the middle of each connecting plate is provided with a depth adjusting plate; each depth adjusting plate is provided with adjusting holes; the left side wall and the right side wall of the machine body are respectively provided with an adjusting bolt matched with the depth adjusting plates; the adjusting bolts are inserted into the adjusting holes. The stubble cleaning rotary cultivator is light in weight, wide in application range and good in flattening effect.

Owner:YANGZHOU HUIMIN AGRI MACHINERY CO LTD

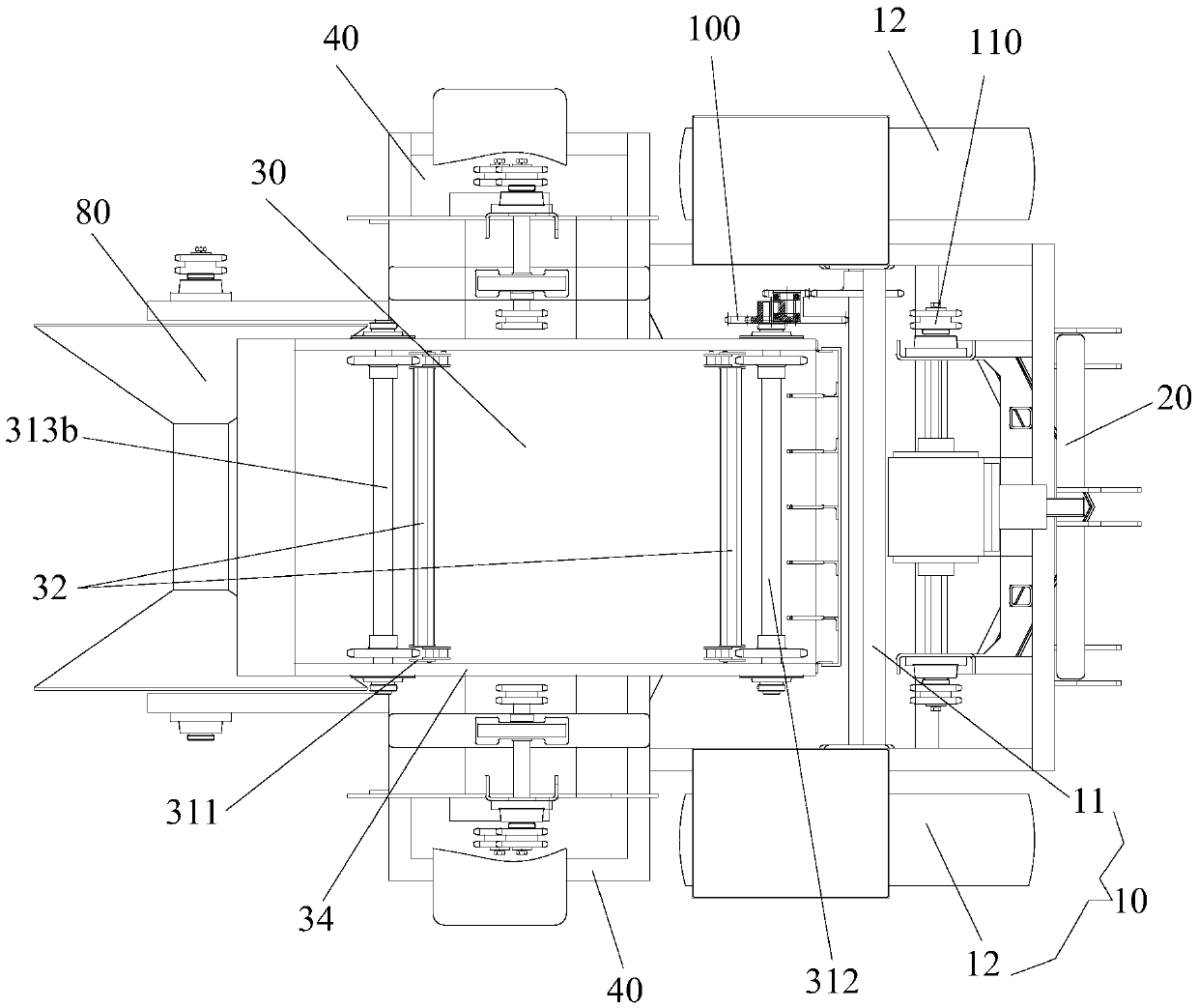

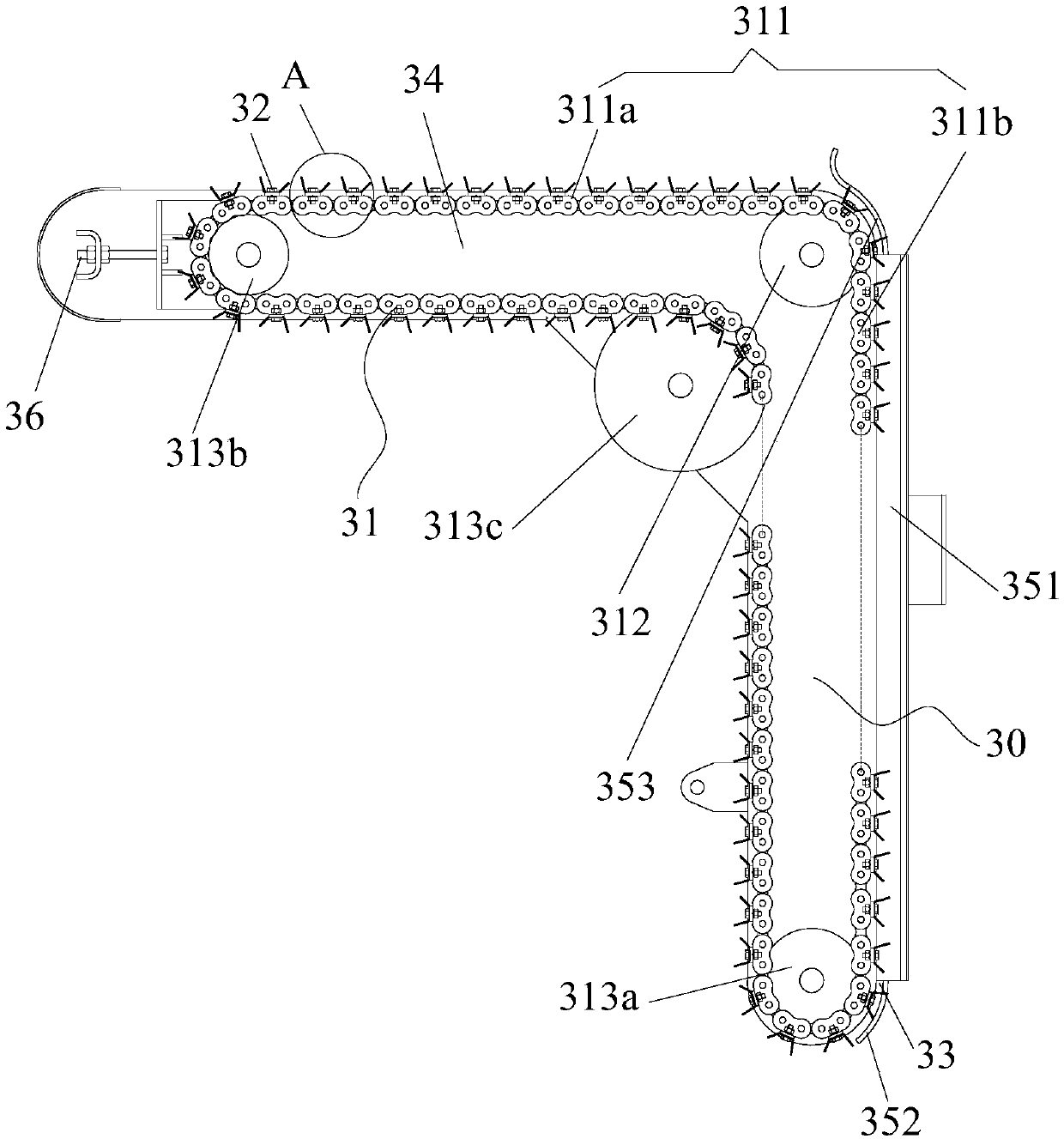

Sugarcane seed section guiding delivery device of sugarcane planter

PendingCN106105523ASolve the problem of change of directionMeet agronomic requirementsPlantingEngineering

Owner:广西农业机械研究院有限公司

Transplanting and ridging equipment

PendingCN109618576AAchieve plantingAchieve standardizationSpadesPloughsEngineeringMechanical engineering

The invention provides transplanting and ridging equipment. The transplanting and ridging equipment comprises a frame assembly, a transplanting device and a ridging structure. The frame assembly comprises a frame body and a ground wheel arranged on the frame body. A hanging structure used for being connected with a dragging device is arranged on the frame assembly. The transplanting device is arranged on the frame body, and comprises a conveying assembly and multiple mounting parts arranged on the conveying assembly, the mounting parts are used for containing transplanted seedlings, the groundwheel is connected with the conveying assembly to drive the conveying mechanism to move in the preset direction, and the conveying assembly drives the mounting parts and the transplanted seedlings tomove to a seedling outlet of the transplanting device to enable the seedlings to fall to a seedbed through the seedling outlet. The ridging structure is arranged on the frame body and located behindthe seedling outlet in the advancing direction of the frame assembly, and then the transplanted seedlings falling on the seedbed are ridged. The problems that in the prior art, the planting time is long, the planting efficiency is low, the seedling discharge quantity and the row spacing cannot be standardized, and the labor intensity of workers is increased are effectively solved.

Owner:宁夏益草农业科技有限公司 +1

Front precision planter for notoginseng

InactiveCN107046881AAchieve precision seedingImprove work efficiencySeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringBrush device

The invention discloses a front precision planter for notoginseng, and belongs to the field of agricultural machinery. The front precision planter comprises a walking tractor, a first seeding apparatus mechanism, a first soil brushing device, a right side rack, a first indentation mechanism, a main rack, a left side rack, a second indentation mechanism, a soil brushing device bracket, a plummer block, a first-level transmission mechanism, a second-level transmission mechanism, a second seeding apparatus mechanism and a second soil brushing device, wherein the walking tractor and the main rack are connected through a hinge pin; the left side rack and the right side rack are respectively fixed on the left side and the right side of the main rack; the first soil brushing device and the first indentation mechanism are fixed on the right side rack; the second soil brushing device and the second indentation mechanism are fixed on the left side rack; the first seeding apparatus mechanism is fixed on the rear end of the right side rack; the second seeding apparatus mechanism is fixed on the rear end of the left side rack; the first indentation mechanism is connected with the first seeding apparatus mechanism through the first-level transmission mechanism; the second indentation mechanism is connected with the second seeding apparatus mechanism through the first-level transmission mechanism. The front precision planter has the advantages of compact structure, high operation efficiency and high reliability, and the planting requirement of notoginseng is met.

Owner:KUNMING UNIV OF SCI & TECH

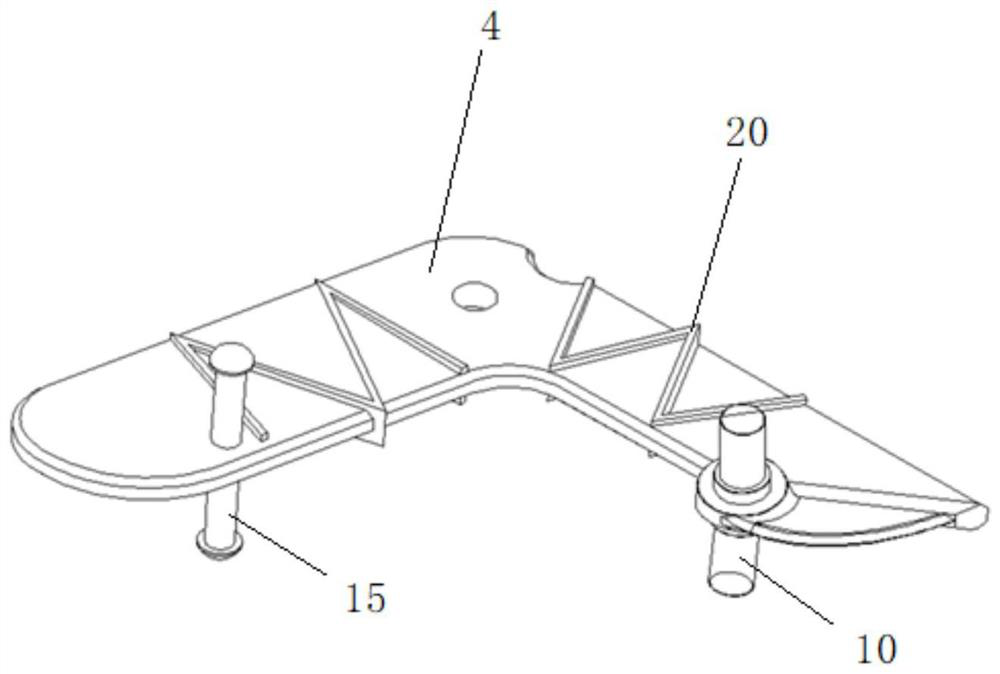

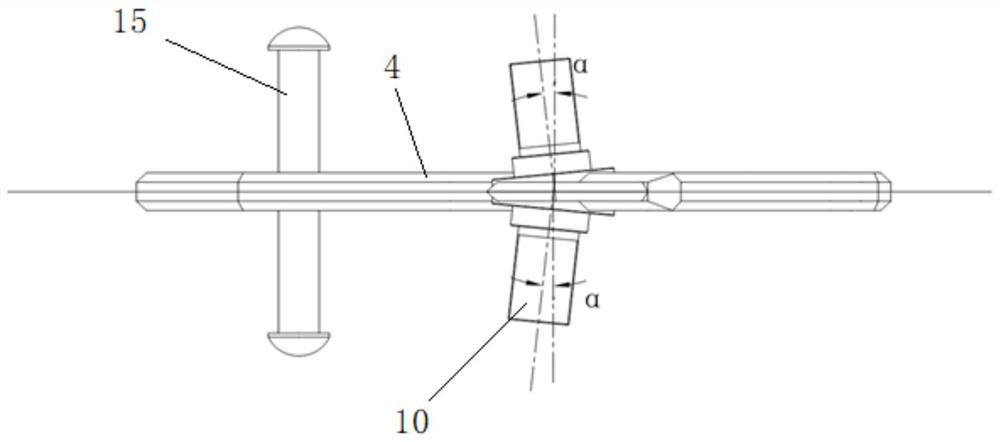

Fertilizing and ditching device suitable for sticky and wet soil operation

PendingCN113207364ASimple structureEasy to installPlantingFurrow making/coveringSoil scienceAgricultural engineering

The invention discloses a fertilizing and ditching device suitable for sticky and wet soil operation, and belongs to the field of agricultural machinery. According to the fertilizing and ditching device suitable for sticky and wet soil operation, the problems that bonding and blocking occur, the working efficiency is low, and the straw stubble cutting-off capacity is weak when an existing fertilizing and ditching device of a corn no-tillage machine works in sticky and wet soil are solved. The fertilizing and ditching device suitable for sticky and wet soil operation is characterized in that the corner part of a turnover rack is hinged to the lower end of a fixing and height adjusting mechanism, a transverse plate part of the turnover rack is provided with a stretching shock absorber, the upper end of the stretching shock absorber is hinged to the fixing and height adjusting mechanism, the lower end of the stretching shock absorber is hinged to the front end of the transverse plate part of the turnover rack, and a vertical plate part of the turnover rack is provided with a fixing screw rod; an included angle is formed between the axis of the fixing screw rod and the vertical line of the vertical plate part of the turnover rack, two curved-surface opening disc furrow openers are mounted on the fixing screw rod, soil facing surfaces are attached to form a straight line, and the soil facing angle is 0 degree. The fertilizing and ditching device suitable for sticky and wet soil operation has the advantages of being small in penetrating angle, good in straw stubble cutting-off capacity, good in soil dredging capacity and soil bonding prevention capacity and significant to soil conservation farming.

Owner:NORTHEAST FORESTRY UNIVERSITY

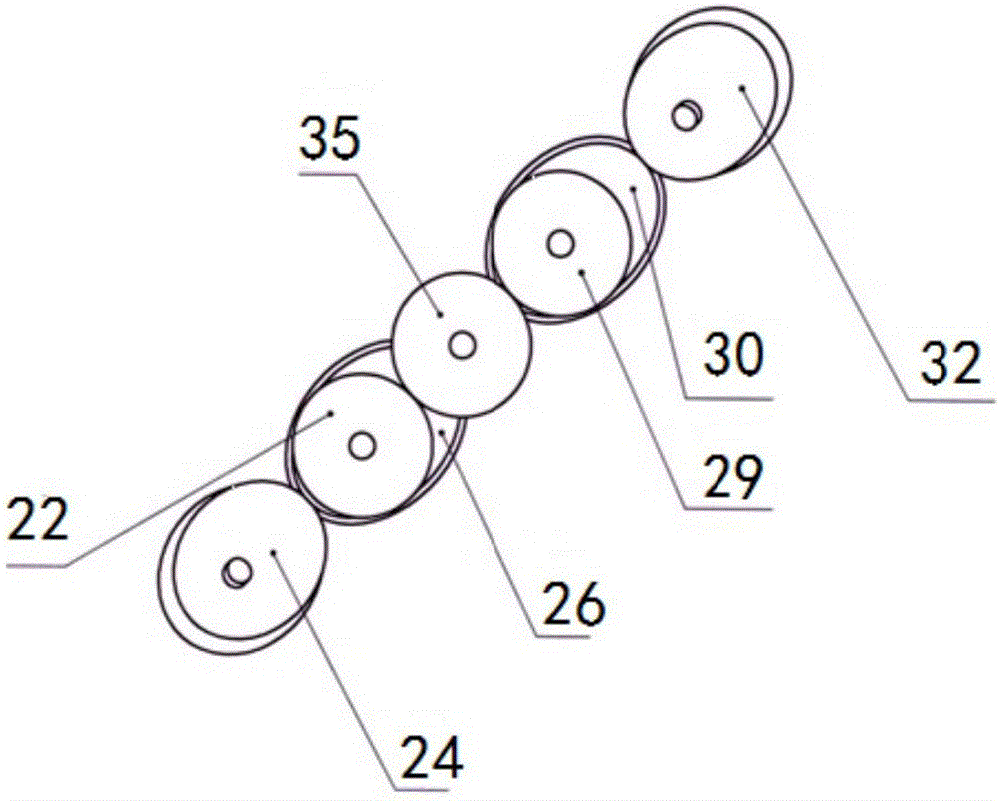

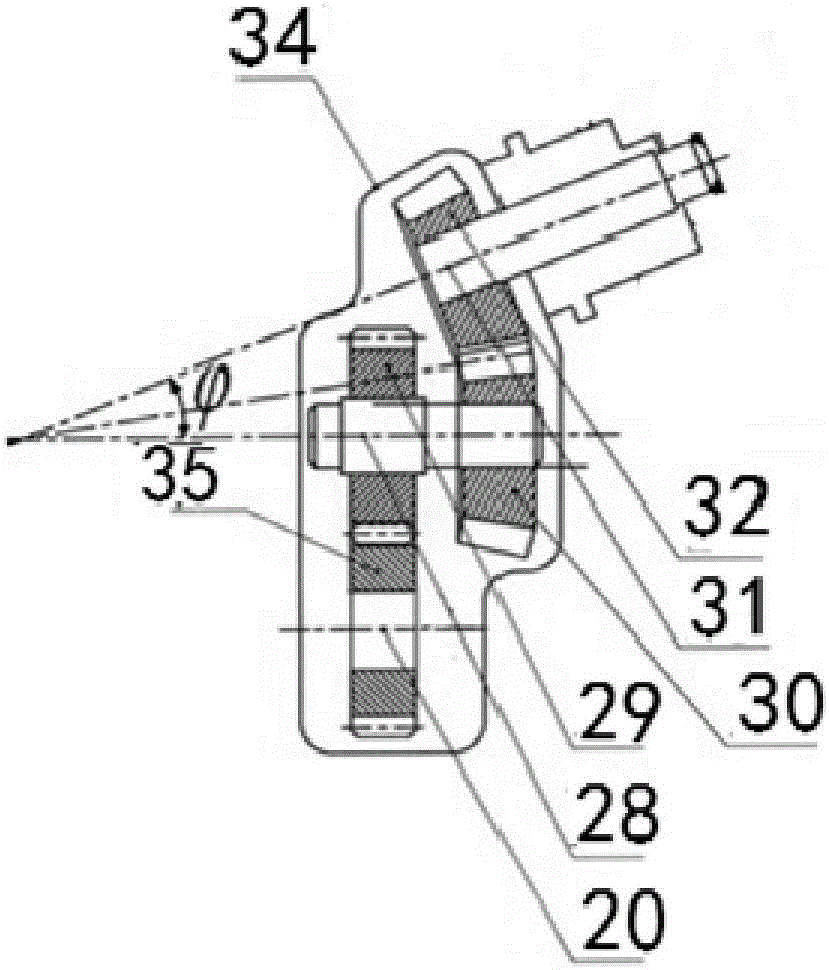

Deep pruning machine for tea trees

The invention relates to a deep pruning machine for tea trees and belongs to the technical field of agriculture and forestry machinery. The machine comprises a rack which is supported on a crawler-type chassis, the rack extends backwards to form a handrail, and the front end of the rack is hinged to a cutter rack through upper and lower swing rods to form a parallelogram mechanism; the cutter rackis provided with a left droop-shaped rotary-cut cutter set and a right droop-shaped rotary-cut cutter set which are driven by a power source, each rotary-cut cutter set is provided with a set of disccutters of which the diameters are gradually reduced from top to bottom, and the edges of the adjacent cutters of the left rotary-cut cutter set and the right rotary-cut cutter set are overlapped. The tea trees can be cut into multiple segments through the droop-shaped left rotary-cut cutter set and the droop-shaped right rotary-cut cutter set, ground attachment cutting can be basically achievedin theory, accumulation and blocking of branches are avoided, the agricultural technology requirement of deep pruning can be practically met, the crawler-type chassis runs smoothly, the tea trees cannot be damaged, and therefore various defects of the prior art are overcome.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Power-driven ridging cultivator

PendingCN110226375AImprove lodging resistanceMeet the agronomic requirements of plantingSpadesPloughsScarificationEngineering

The invention discloses a power-driven ridging cultivator. The power-driven ridging cultivator comprises a rack, a traction suspension bracket, a gearbox, a rear beam, a ridging ploughshare, a soil hacking cutter, a deep scarification shovel, land wheels, a front beam, cutter shafts, cutter holders, side plates and a drive mechanism; ridging is performed before soybean, corn or potatoes are sown,inter-cultivation is performed one week after deep scarification or 20-30 days after sowing, rice seedlings cannot be damaged, earthing-up cultivation operation is performed, and mechanical weeding isrealized while inter-cultivation is performed. After inter-cultivation operation is performed, soil is loosened and ventilated, the light area of a ridge body is enlarged, the appearance of the ridgebody is smooth and tidy, the tuber storage capability of a ridge surface is increased, the lodging-resistant capability of soybeans and corn is improved, exposure of green tubers of potatoes is avoided, growth and development of the tubers are facilitated, and the excellent yield-increasing effect is realized. The power-driven ridging cultivator can meet agronomic requirements of planting of potatoes, soybeans and corn; compared with conventional methods, the power-driven ridging cultivator has the advantages that the dosage of a herbicide is reduced, the production cost is substantially reduced, and the working efficiency is improved.

Owner:赵东明

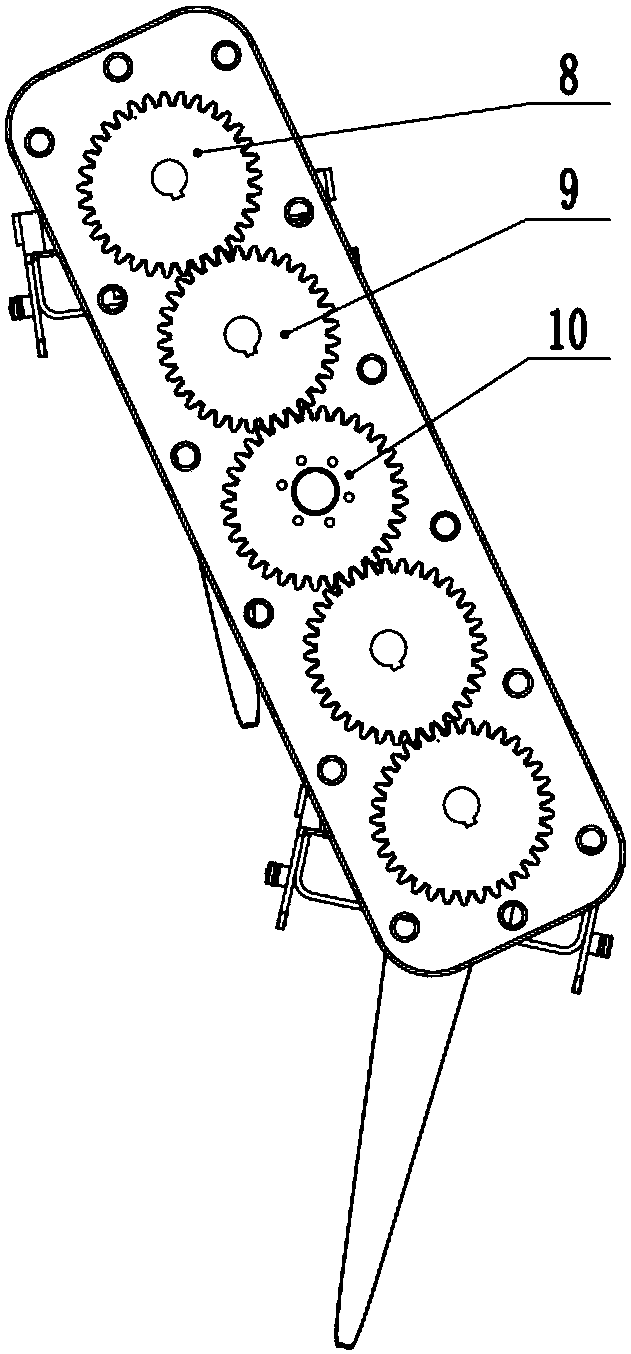

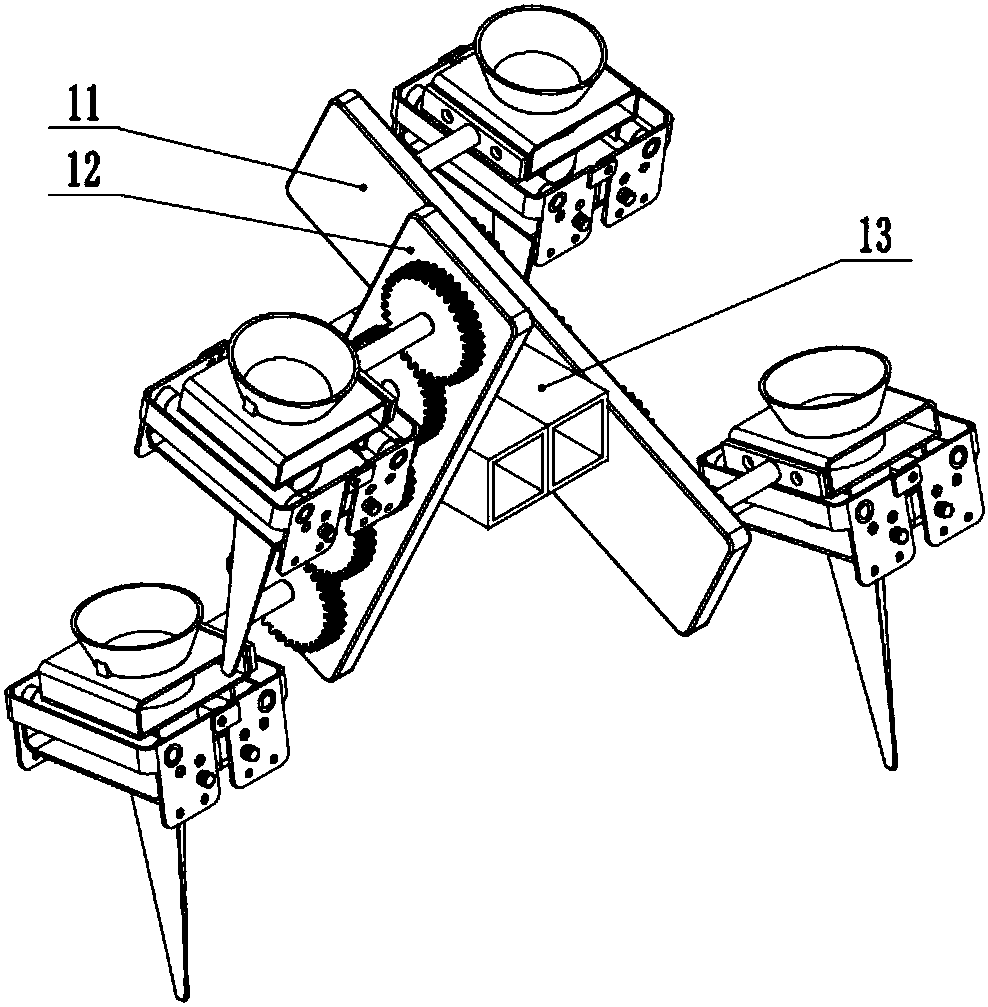

Coaxial double-bar ejection-type cylindrical gear-elliptical bevel gear planetary system wide-narrow row seedling slinging mechanism

PendingCN106717366AReduce labor costsIncrease the ejection linkTransplantingAgriculture gas emission reductionCamEngineering

The invention discloses a coaxial double-bar ejection-type cylindrical gear-elliptical bevel gear planetary system wide-narrow row seedling slinging mechanism. The seedling slinging mechanism comprises a gear box. A central cylindrical gear, upper, lower and middle cylindrical gears, upper, lower and middle elliptical bevel gears and upper and lower planetary elliptical bevel gears are supported in the gear box. Upper and lower transplanting arms are coaxially connected to the upper and lower planetary elliptical bevel gears. A hollow loop bar is slidably arranged in the housing of the transplanting arm. A solid push bar is slidably arranged in the hollow loop bar. A double contour line cam, a shifting fork and a triggering machine are hinged to the interior of the housing of the transplanting arm. The outer end of the hollow loop bar is provided with a seedling taking mechanism. The cylindrical gear-elliptical bevel gear as a transmission mechanism cooperates with the coaxial double-bar ejection-type transplanting arm so that different wide-narrow row seedling slinging agronomic requirements are satisfied and the technical gap of a seedling slinging machine is filled.

Owner:ZHEJIANG FORESTRY UNIVERSITY

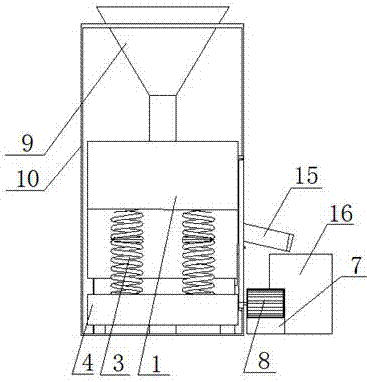

Radix notoginseng seedling grader

The invention relates to a radix notoginseng seedling grader and belongs to the technical field of agricultural machines. The radix notoginseng seedling grader comprises a sorting device I and a grading device II. The sorting device I drives a screening work table to vibrate by means of vertical motion of a vibrating spring. The grading device II comprises gravity sensors, grading rods, a grading working table and a conveyor belt. The conveyor belt of the grading working table is provided with the grading rods. The gravity sensors are arranged below the conveyor belt and above the grading working table. The grading rods are arranged on the conveyor belt at intervals. The front of each grading rod is provided with one gravity sensor. A discharging port and a collecting box are arranged between every two grading rods. The gravity sensors and the grading rods are connected with a control device. The radix notoginseng seedling grader can classify seedlings better, thus, soil and labor force can be utilized conveniently, transplanted radix notoginseng grows excellently, the yield is increased, standardized operation is achieved, and excellent radix notoginseng is produced.

Owner:KUNMING UNIV OF SCI & TECH

Double-planet-wheel type salvia miltiorrhiza seedling transmembrane cross-transplantation device and method

PendingCN108076752AMeet agronomic requirementsImplement featuresTransplantingDouble planetEngineering

The invention discloses a double-planet-wheel type salvia miltiorrhiza seedling transmembrane cross-transplantation device and method, solves the problem of low salvia miltiorrhiza planting efficiencyin the prior art, and has the beneficial effects of compact structure and high working efficiency. The invention adopts the scheme that a non-circular gear and planetary gear train salvia miltiorrhiza seedling transmembrane cross-transplantation mechanism comprises a non-circular gear and planetary gear train mechanism, a salvia miltiorrhiza planter and a non-circular sun wheel, wherein the non-circular gear and planetary gear train mechanism comprises a stand and a planet carrier; the planet carrier is driven by a rotary power source to rotate; the non-circular sun wheel is fixedly connectedwith the stand, and is also meshed with a non-circular planetary wheel through a middle wheel; the salvia miltiorrhiza planter is fixedly connected with the non-circular planetary wheel; a roller isarranged at the side part of the salvia miltiorrhiza planter; the roller is matched with a space cam fixedly connected with the planet carrier; the roller is fixedly connected with one side of the salvia miltiorrhiza planter; when the salvia miltiorrhiza planter is driven by the non-circular planetary wheel to rotate to the maximum stroke of the space cam, the roller opens the salvia miltiorrhizaplanter under the pushing action of the space cam to realize feeding of salvia miltiorrhiza seedlings.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

A rose branch smashing and returning machine matched with a four-wheel tractor

ActiveCN108554557BMeet the technical requirements of productionOvercome limitationsSpadesPloughsAgricultural engineeringAgricultural machinery

Owner:KUNMING UNIV OF SCI & TECH

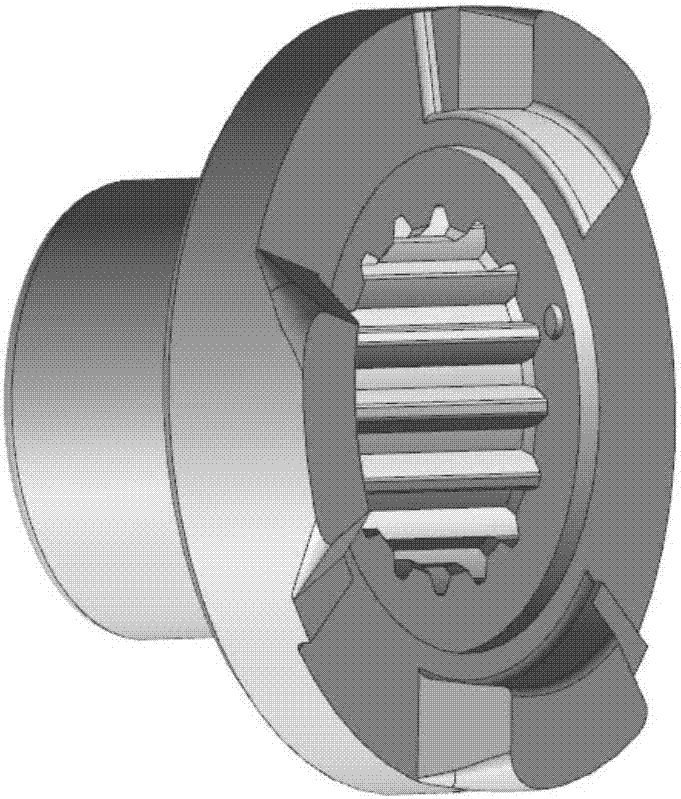

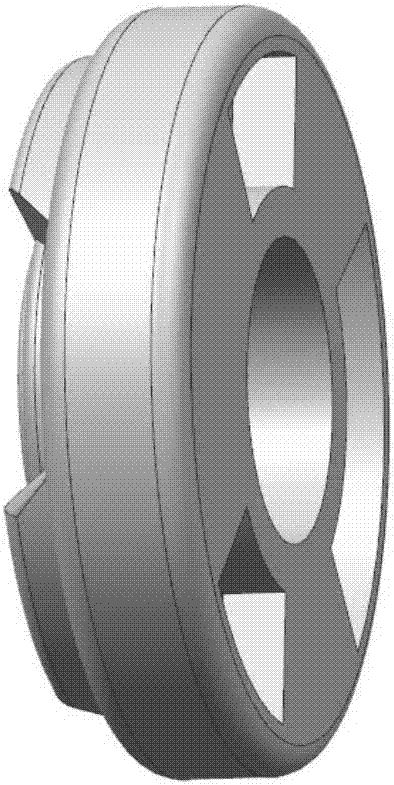

Device and method for planting rice seedlings with narrow row spacing

The invention discloses a narrow-spaced transplanting device and method for rice seedlings. According to the device, a gear box comprises a left box body and a right box body; a safety spring seat, a safety spring, a safety pressure disc, a safety clutch disc, a claw disc, a drive sprocket, a clutch disc, a clutch spring and a clutch spring seat are mounted on a drive shaft sequentially and form an integrated structure of power transmission and safety protection as well as power interruption and connection, so that the safety of a transplanting mechanism and a power transmission system is effectively protected. The drive shaft is transversely mounted at the front part of the gear box, a driven shaft is mounted at the rear part of the gear box, and the drive shaft and the driven shaft transmit power through chain transmission, accordingly, the overall structure is compact, the structure size of a power transmission system is greatly reduced, the structure of transplanting arms is optimized at the same time, and spacing between the two transplanting arms meets the agronomic requirement of transplanting of rice.

Owner:浙江小精农机制造有限公司

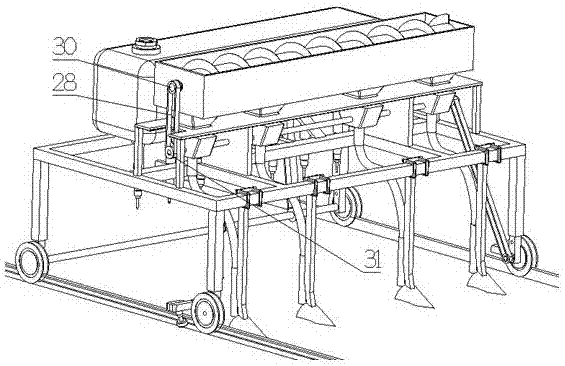

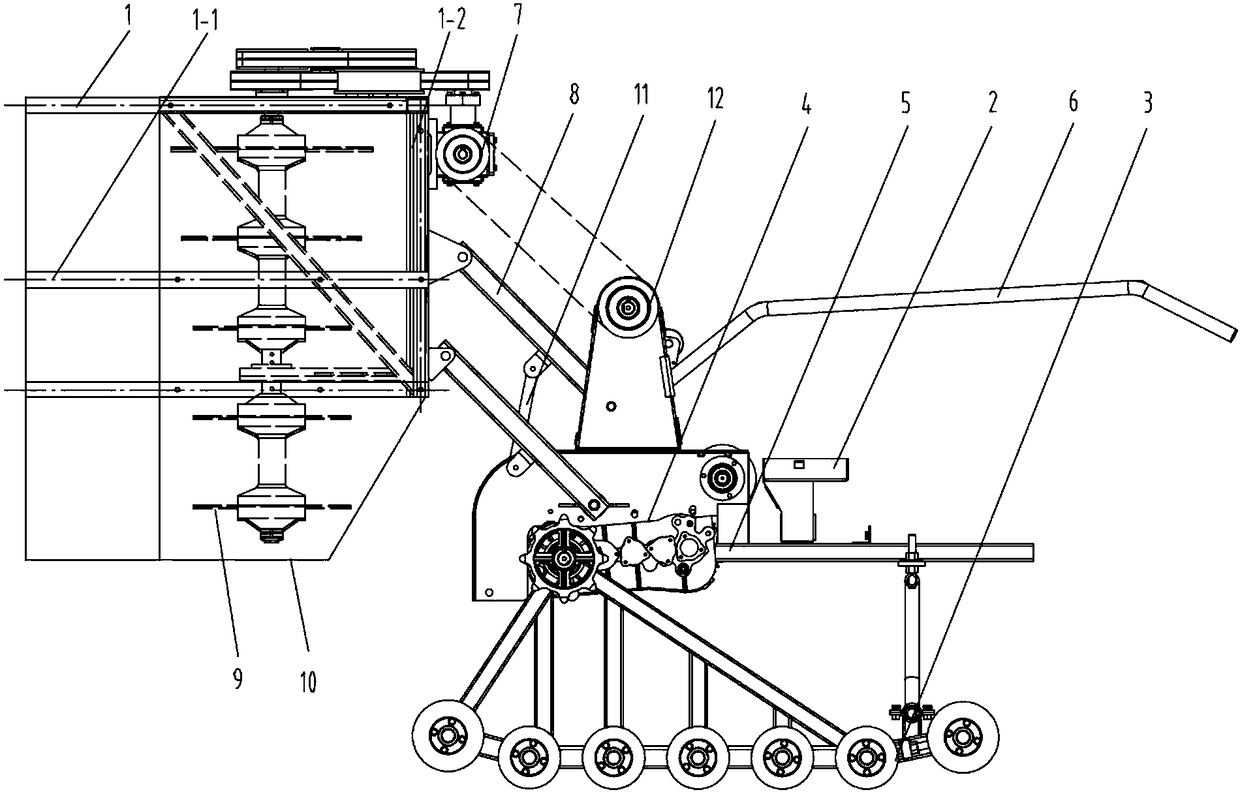

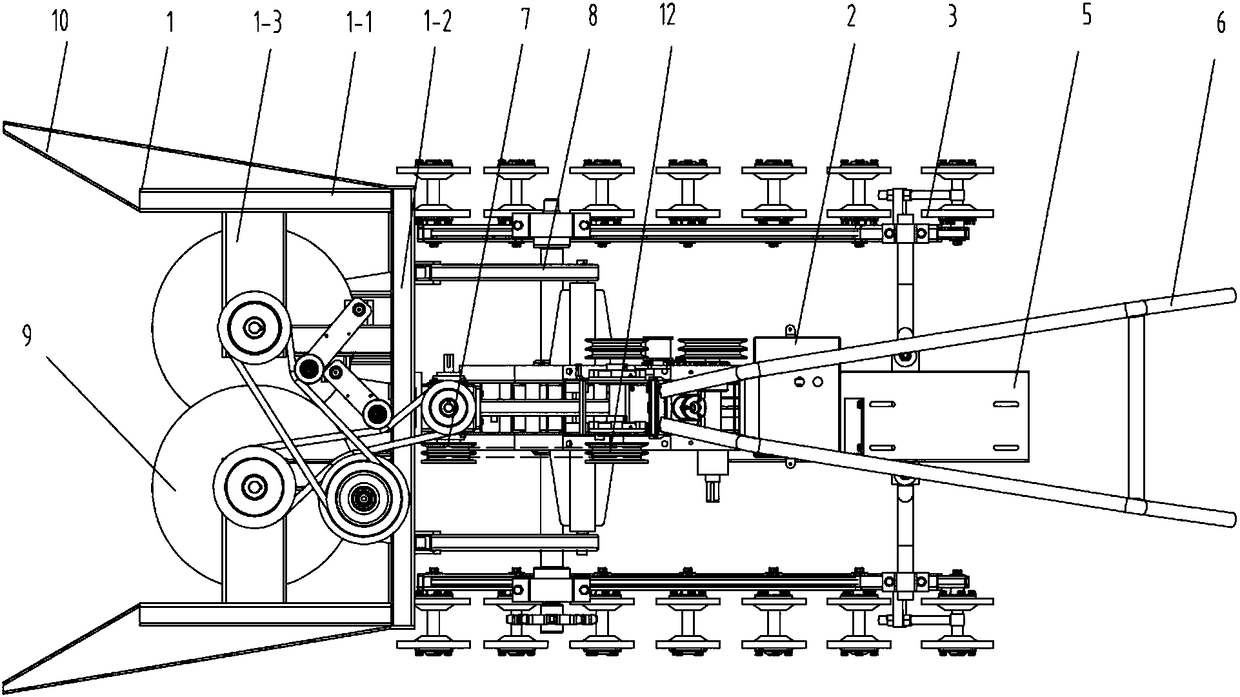

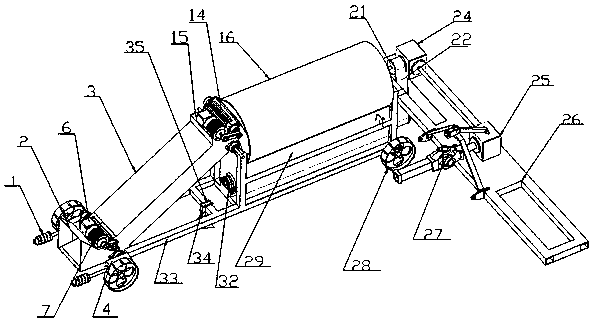

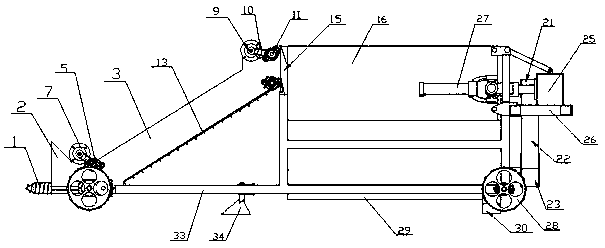

Rose branch breaking and mulching machine matched with four-wheel tractor

ActiveCN108554557AMeet the technical requirements of productionOvercome limitationsSpadesPloughsEngineeringWork quality

The invention relates to a rose branch breaking and mulching machine matched with a four-wheel tractor, and belongs to the technical field of agricultural machines. The machine comprises a feeding part, a lifting and conveying part, a breaking and discharging part, a ditching part and a power transmission part; after the rose branch shearing and laying link, the machine is pulled by the four-wheeltractor to enter the flower field work, the hurt of the rose branches to the workers is reduced to the maximum degree, collecting, breaking and mulching processes of the rose branches can be finishedat one time, and needs in the edible rose production process can be met; labor intensity is reduced, production cost is reduced, the structure is simple and reasonable, machining production, maintaining and preserving are facilitated, work quality is good, work efficiency is high, work is reliable, and the agriculture needs are completely met.

Owner:KUNMING UNIV OF SCI & TECH

Detachable flood and dry dual-purpose rotary embedded knife roller

InactiveCN106612643BCompact and reasonable layoutEven by forceCrop conditionersMowersHigh energyEngineering

Owner:HUAZHONG AGRI UNIV

A belt-shaped no-till farmyard manure deep application ridge machine

ActiveCN111328484BGood for decomposition and release of fertilizerLine spacing adjustableSpadesPloughsAgricultural engineeringFarmyard manure

The invention provides a strip-shaped no-tillage farmyard manure deep application ridging machine, which mainly includes a fertilizer box, a fertilizer transmission device and a roller extrusion fertilization device. During the process of fertilizer transportation, the fertilizer transmission device drives the roller extrusion Press fertilization device to realize two-roller differential extrusion fertilization. The invention realizes the differential extrusion of the pair of rollers to discharge fertilizer, produces mutual rubbing effect of the two rollers, can automatically clean the fertilization roller itself, and solves the problem of large amount of fertilization, high viscosity and easy adhesion and blockage of farmyard manure; When the roller rotates, it can squeeze and crush the unbroken block farmyard manure after the front treatment, which is beneficial to the decomposition of the farmyard manure and release the fertilizer effect; in addition, the stubble breaking and ditching device and the stubble cleaning device can clean the straw to both sides to form a The belt-shaped operation area prevents deep loosening and shoveling of grass, improves the quality of subsequent no-tillage sowing, and reduces the phenomenon of "drying seeds" caused by mixing straw in the ridge.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com