Detachable flood and dry dual-purpose rotary embedded knife roller

A dual-use, detachable technology, applied in applications, agricultural machinery and implements, agriculture, etc., can solve the problems of complicated arrangement of rotary tillers, straws that cannot be buried in the ploughing layer, and horizontal helical knives that cannot be disassembled. , to reduce the power consumption of the paddy field, improve the working efficiency, and reduce the vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further explained:

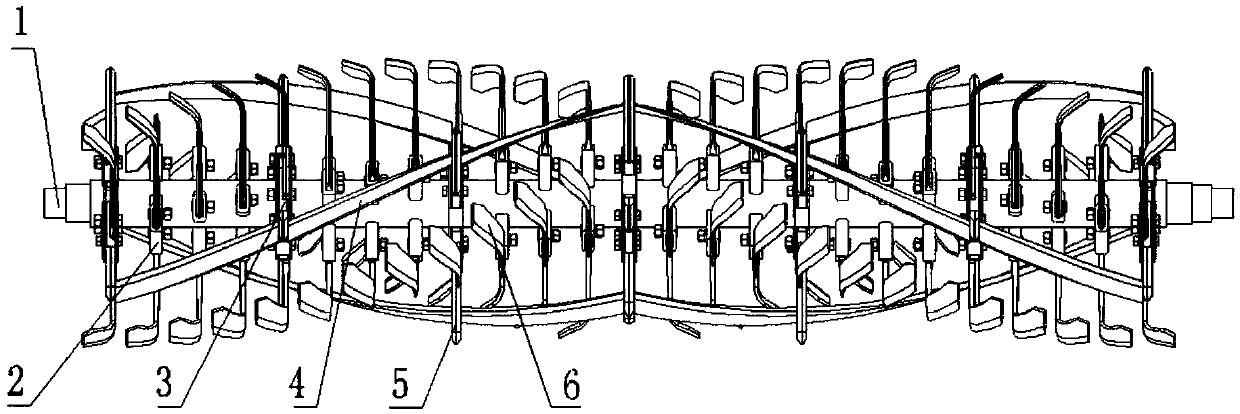

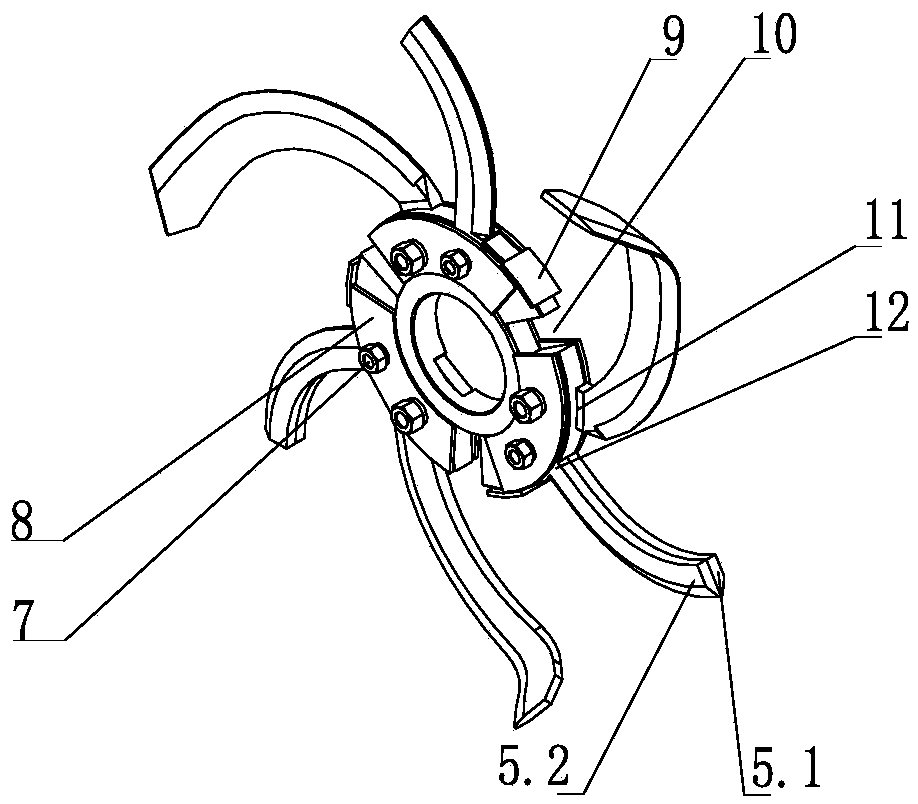

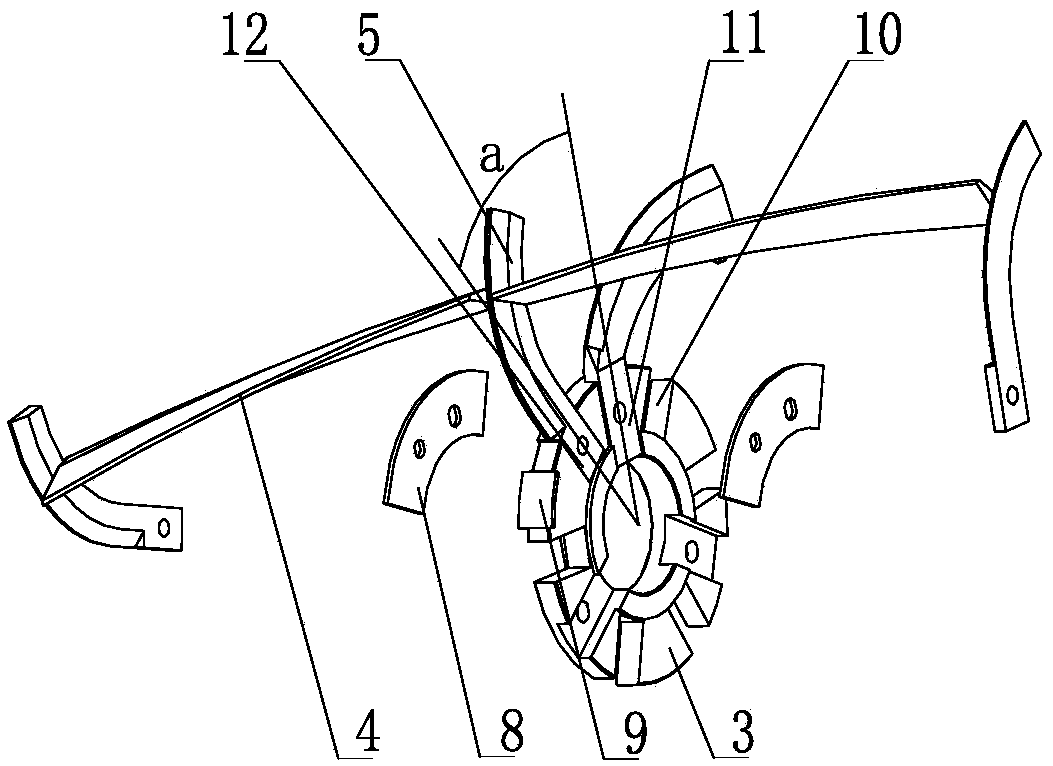

[0034] see figure 1 , figure 2 and image 3 , the cutter roll of the present invention comprises a cutter shaft 1 and a cutter, with the center line of the cutter shaft 1 being the center line of symmetry, the cutters on both sides of the cutter shaft 1 are symmetrically arranged, and the rotary tiller blades 6 on both sides of the cutter shaft 1 are rotated in opposite directions, That is, the rotary tiller 6 in the right-handed direction is installed on the left side of the knife shaft, and the rotary tiller 6 in the left-handed direction is installed on the right side of the knife shaft. The cutter includes a spiral horizontal knife 4, a machete set 5 and a rotary tiller 6, and the machete set 5 is composed of two closely fitted machetes 5.1, 5.2. A plurality of cutter heads 3 are housed on the described cutter shaft 1, and a plurality of cutter holders 2 (9 cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com