Power-driven ridging cultivator

A cultivator and power technology, applied in agricultural machinery and implements, shovels, plows, etc., to reduce the dosage of herbicides, loosen the soil, and expand the light-receiving area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

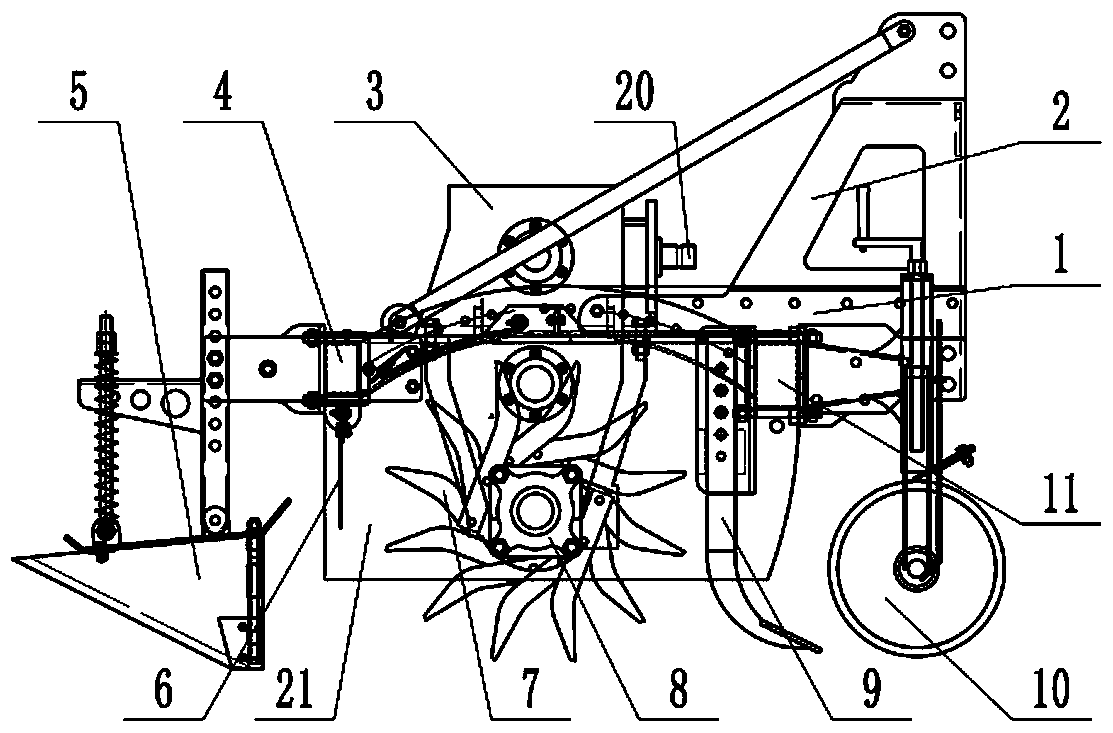

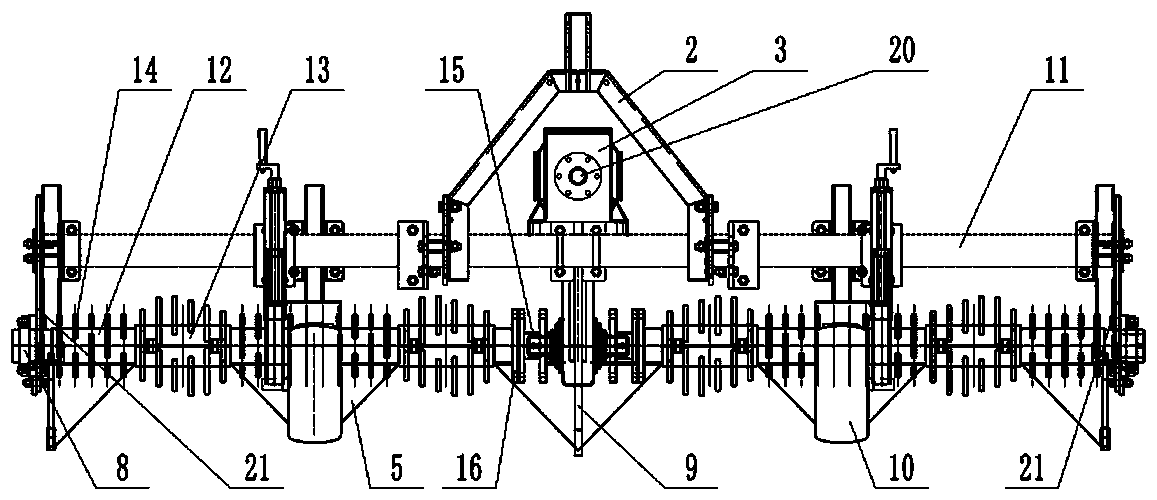

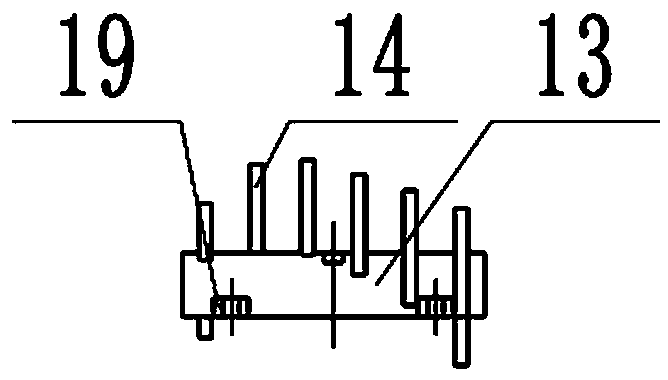

[0018] As shown in the figure, the present invention is a power ridging cultivator, comprising: a frame 1, a traction suspension frame 2, a gearbox 3, a rear beam 4, a ridging share 5, a soil breaking knife 7, a subsoiling shovel 9, a ground Wheel 10, front beam 11, cutter shaft 12, cutter seat 14, side plate 21 and transmission mechanism; it is characterized in that: the traction suspension frame 2 is fixedly arranged above the front end of the frame 1, and the gearbox 3 is fixedly arranged on the frame 1 Above the middle position, the front of the frame 1 is provided with a front beam 11, a ground wheel 10 is fixedly installed at the front ditch position on the front beam 11, and a subsoiling shovel 9 is fixedly installed at the back ditch position on the front beam 11; 1 is provided with a rear beam 4 at the rear of the rear beam 4, and a ridge share 5 is installed on the rear of the rear beam 4. Side plates 21 are fixedly arranged on both sides of the frame (1), and bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com