Stubble-cleaning, subsoiling, rotary-tilling and ridge-forming combine operating machine

A composite operation and deep loosening technology, applied in agricultural machinery and implements, agriculture, shovels, etc., can solve problems such as reducing the resistance of rotary tiller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

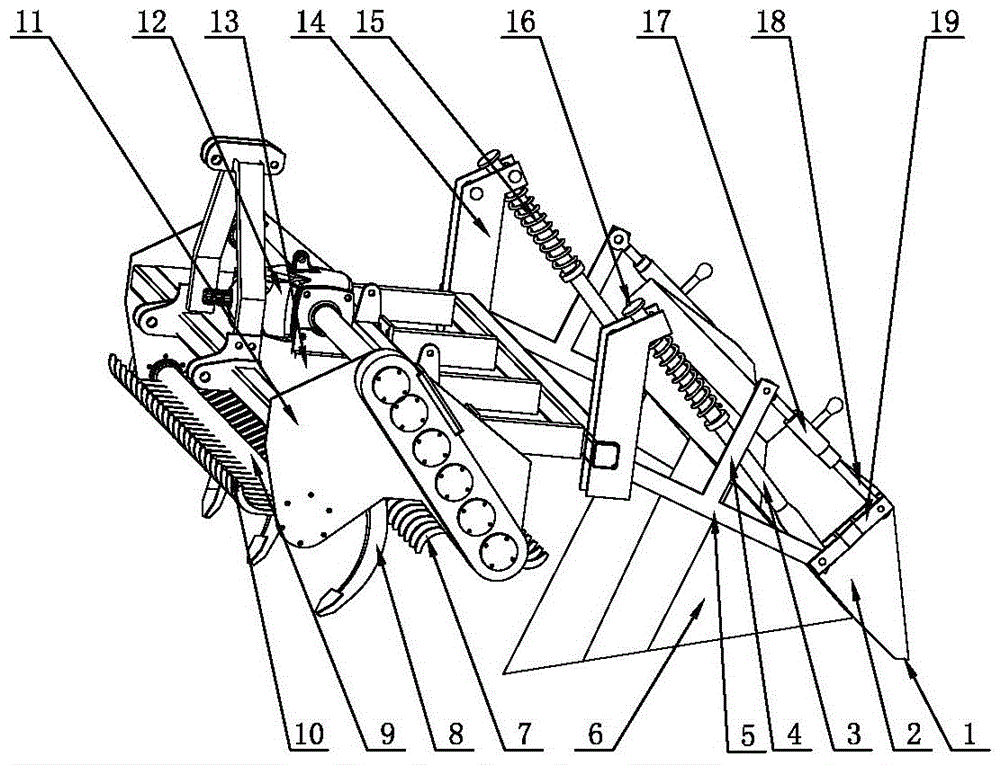

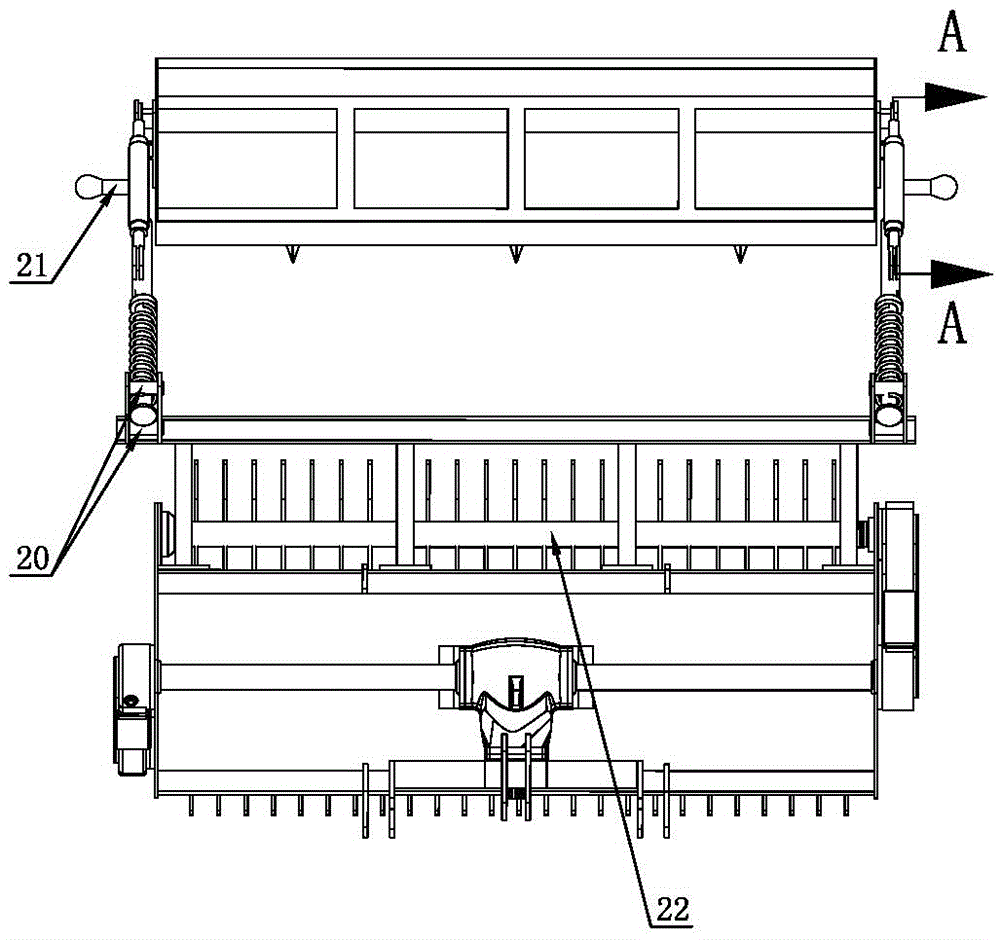

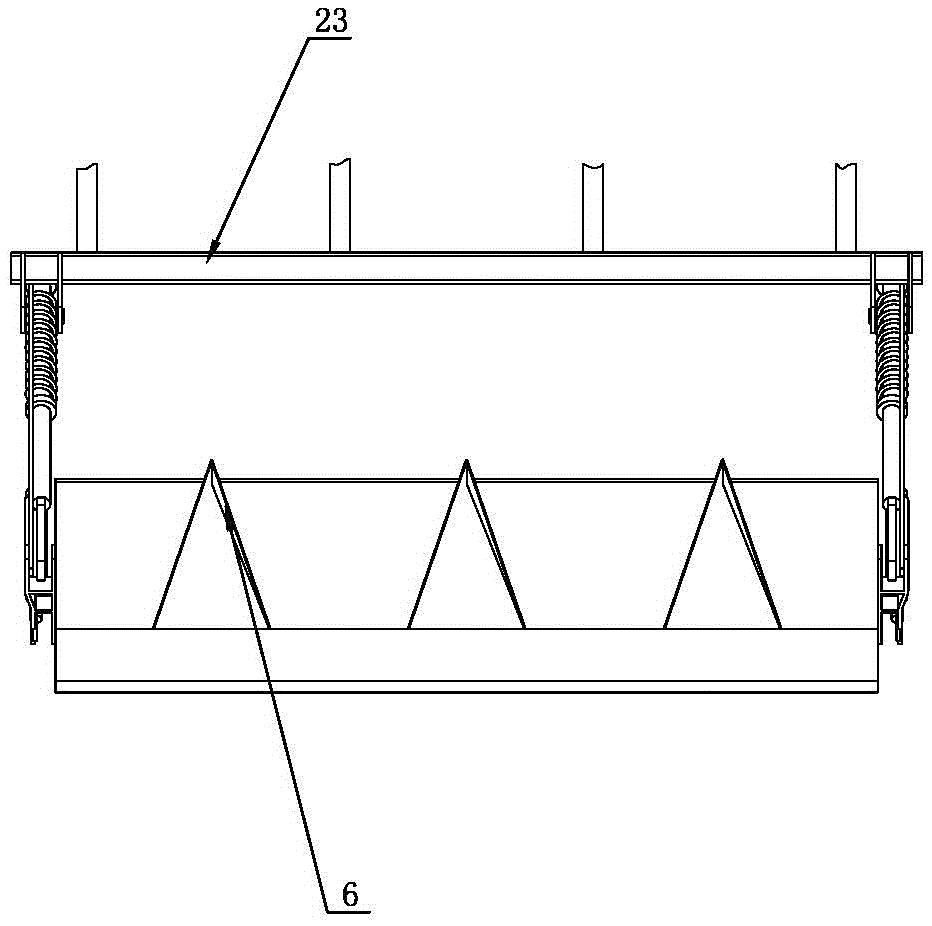

[0028] like Figure 1~5 Shown is a stubble removal subsoiling rotary tillage and ridge-riding compound operation machine, including a frame 13, an intermediate transmission box 12, a stubble removal cutter shaft 9, a rotary tiller cutter shaft 23 and a subsoiling device, a stubble removal cutter shaft 9 and a rotary tiller cutter shaft 23 are respectively connected with the middle transmission box 12 transmission, a number of stubble knives 10 are arranged on the stubble knife shaft 9, a number of rotary tiller knives 7 are arranged on the rotary tiller shaft 23, a subsoiling device is installed on the frame 13, subsoiling The device comprises a mounting base 24 and a subsoiling shovel 8, the mounting base 24 is connected with the subsoiling shovel 8, the rotary tiller shaft 23 is arranged behind the stubble cutter shaft 9, and the lower edge of the rotary circle of the rotary tiller 7 is smaller than that of the stubble cutter 10. The lower edge of the rotary circle is low, a...

Embodiment 2

[0031] like Figure 6~8 The shown stubble removal, subsoiling, rotary tillage and ridge forming compound operation machine is different from Embodiment 1 in that the moving part includes an oil cylinder 35, which is connected to the connecting plate 4, and the piston rod 34 of the oil cylinder 35 passes through the connecting frame 19 Hinged with the ridging frame 2, the lower sides of the two ends of the beam 22 are respectively connected with measuring devices, the measuring devices include a bushing 31, and the middle and lower parts of the bushing 31 and the bottom of the bushing 31 are provided with second limiters extending inwards of the bushing. Position side 36, bushing 31 is connected with a travel shaft that can move in the vertical direction, and the top side of the travel shaft is connected with a distance measuring sensor 38 through a connecting seat 37, and the head of the distance measuring sensor 38 is facing the second limit side 36 , the lower side of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com