Combined straw mulching rotary tillage knife roller

A rotary tiller roller and combined technology, which is applied in the field of combined straw returning rotary tiller roller, can solve the problems of high manufacturing cost, high operation efficiency, and only applicable to paddy field operations, etc., so as to reduce energy consumption and operation cost, increase the standardization degree, and reduce the effect of going to the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

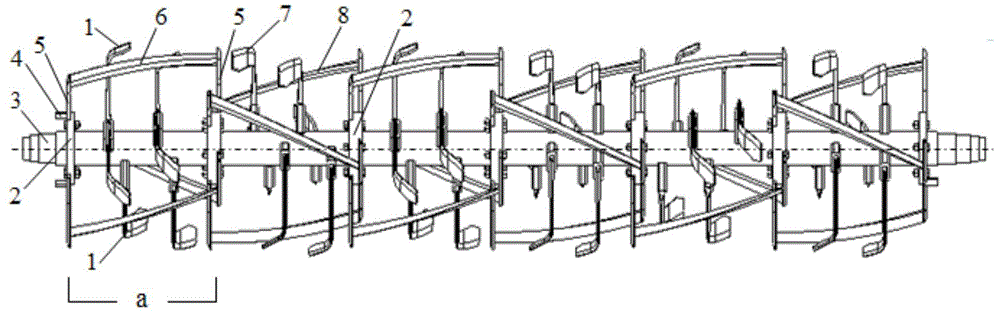

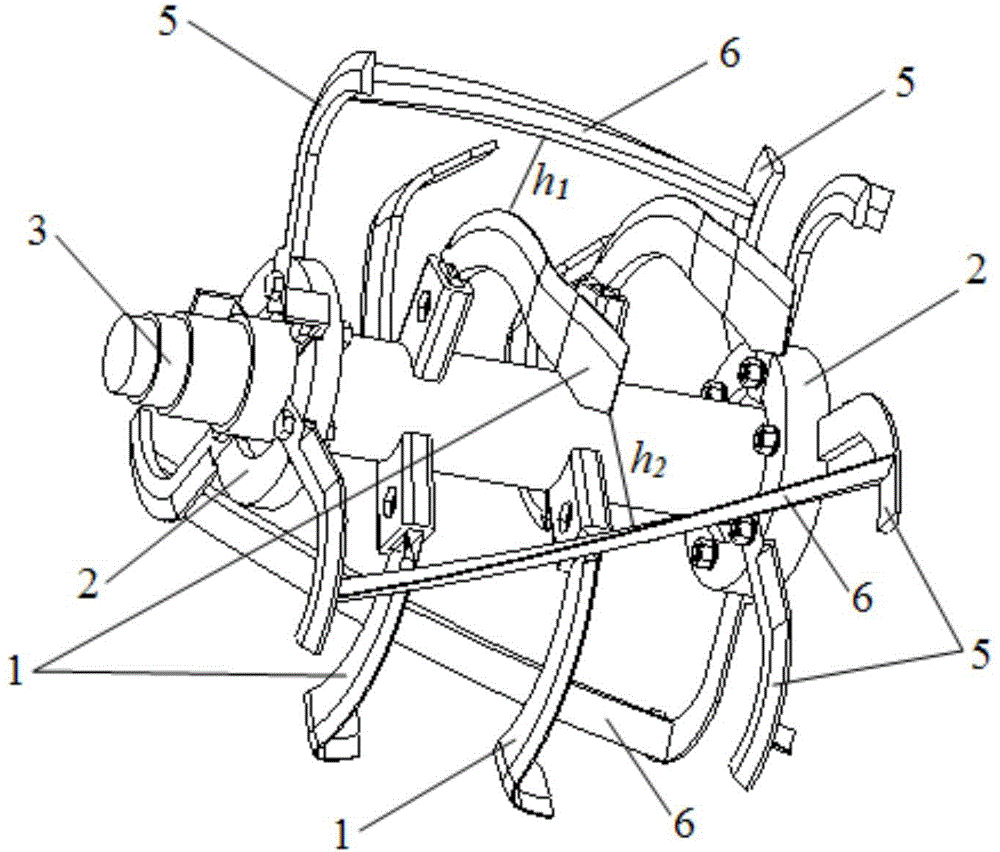

[0032] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0033] see figure 1 and figure 2 ,

[0034] The technical solution includes a cutter shaft 3 and a plurality of cutter roller units a installed on the cutter shaft 3, the cutter roller unit a includes a cutter head 2, a spiral horizontal knife, a rotary cultivating knife and a machete 5, and the cutter head 2 is installed On the cutter shaft 3, a plurality of scimitars 5 are evenly distributed along the circumferential direction on the cutter head 2, and the scimitars 5 of two adjacent cutter heads 2 are evenly connected by 2-3 helical lines along the circumferential direction of the cutter shaft. 2-3 spiral horizontal knives; in the same knife roller unit a, two rotary tiller knives are arranged on the knife shaft 3 between two adjacent spiral horizontal knives, and the cutter head of the rotary tiller is composed of two adjacent Protrude from the gap between the spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com