Stubble cleaning rotary cultivator

A technology of rotary tiller and stubble removal, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of not being able to meet the standards and agronomic requirements, unstable operation quality, poor leveling effect, etc. Wide, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

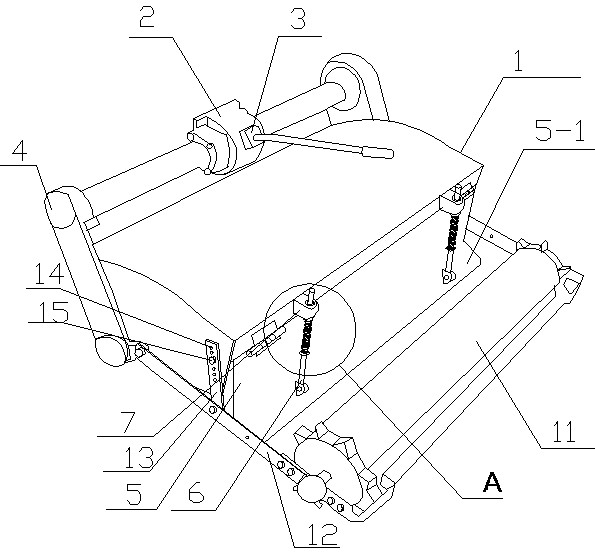

[0009] like figure 1 , 2 As shown, the present invention includes a body 1, a hitch 2, a power unit 3, and a chain transmission 4, and the power unit 3 drives the rotary tiller through the chain transmission 4.

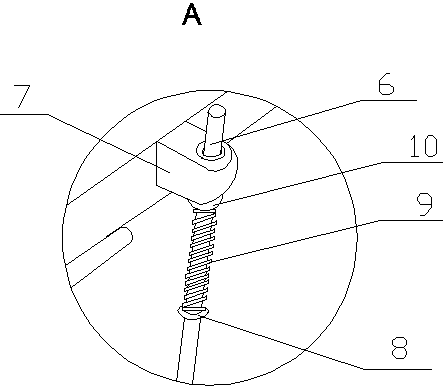

[0010] A leveling device is arranged at the rear portion of the body 1, and the leveling device includes a fender 5, the upper end of the fender 5 is hinged with the rear beam of the body 1, and the bottom of the fender 5 has a bending portion 5-1, which is placed on the rear beam of the body 1. Two support rod seats 7 are arranged on the top, and support rods 6 are respectively inserted in each support rod seat 7, and the lower end of each support rod 6 is respectively fastened with the bending part 5-1 of the fender 5 by bolts; On the rod body of the support rod 6 below each support rod seat 7, the spacer 8 and the baffle plate 10 are respectively sleeved, and on the body of the support rod 6 between each group of spacer spacers 8 and the baffle plate 10, respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com