Patents

Literature

33results about How to "Saving clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass carbon matrix environment-friendly brick and making method

InactiveCN107324773AGood environmental protection functionIncrease profitCeramic materials productionClaywaresBiomass carbonToxic gas

The invention discloses a biomass carbon matrix environment-friendly brick and a making method. The biomass carbon matrix environment-friendly brick is characterized by comprising the following components (in percentage by weight): 35-45% of biological black carbon, 55-65% of an earth material and 1-3% of molding aids, wherein the brick is made by treating the earth material, mixing with the biological black carbon, molding, drying and roasting; the biological black carbon is biological black carbon granules or powder ash made of biomasses via high-temperature carbonization; the earth material comprises 15-35% of clay, 15-25% of shale powder ash, 15-25% of coal gangue powder ash and 15-25% of coal ash; the 1-3% of molding aids comprise bentonite, fulvic acid powder and tapioca flour. The making method comprises the following steps: performing high-temperature carbonization on various types of biomass straw so as to obtain biological black carbon granules or powder ash; grinding shale, coal gangue and coal residues into a powder material; uniformly mixing with the clay and the molding aids; making bricks by using a brick making machine, drying, and sintering. Due to adoption of a biomass black carbon material, the biomass carbon matrix environment-friendly brick is capable of adsorbing toxic gases as a whole for a long time, is light and environmentally friendly, and is capable of purifying indoor polluted air and lowering cost.

Owner:湖北金日生态能源股份有限公司

Fly ash foamed plastic particle insulating and waterproof material, and manufacturing method thereof

The invention relates to a fly ash foamed plastic particle insulating and waterproof material, and a manufacturing method thereof. The material is composed of raw materials of: cement, test-proved 32.5 ordinary Portland cement, quick lime containing 80 to 85% of CaO, polystyrene foamed plastic particles with a granularity of 4 to 8mm, and fly ash. Fly ash, quick lime and cement are placed in a mixer according a certain ratio, and are mixed for 0.5 to 5 minutes, such that a cementing material is manufactured. A proper amount of a cementing material, polystyrene foamed plastic particles and water are added to the obtained cementing material. A foaming agent and a water-proofing agent are added to the obtained mixture, and the mixture is stirred for 0.5 to 5 minutes, such that foamed slurry is manufactured. The foamed slurry is used for casting within 30 to 60 minutes. A cast surface is compacted and smoothed, and is maintained moisturized for 12 to 72 hours, such that an insulating and waterproof plate is manufactured. The surface of the plate is then processed through a surface spraying treatment 3 to 5 times by using a hydrophobic agent with intervals of 1 to 3 hours. The material provided by the invention has advantages of low density, high strength, good heat insulation, good waterproof performance, and low manufacturing cost. With the invention, wastes such as fly ash and foamed plastic particles can be reused, and a large amount of clay is saved.

Owner:新疆生产建设兵团第五建筑工程有限责任公司

Method for preparing building block sintered from oil field mud

InactiveCN1528530ALarge amount of processingEffective consumptionSolid waste disposalCeramic shaping apparatusSludgeMetallurgy

The invention relates to a method to sinter building block by mud in oil field, including the steps: 1), batching: according to weight ratio, clay 20-80, mud 20-80, and additional auxiliary material 0.1-30% of the total weight of the clay and mud, where the content of the soluble salt is below 0.5% of the total weight; 2) mixing: two modes: one, dry or wet mixing; two, wet mixing; 3), ageing: 1-7 days; 4), molding: adopting half-dry pressing or dry pressing, where the molding pressure is greater than 4.0MPa; 5), drying; 6), sintering: placing the dried preparation into the high temperature furnace for baking, wherein the sintering temperature 800-1200 deg.C, preserving heat for 1-3 hours in the high temperature region and then cooling with the furnace to obtain the products.

Owner:WUHAN UNIV OF TECH

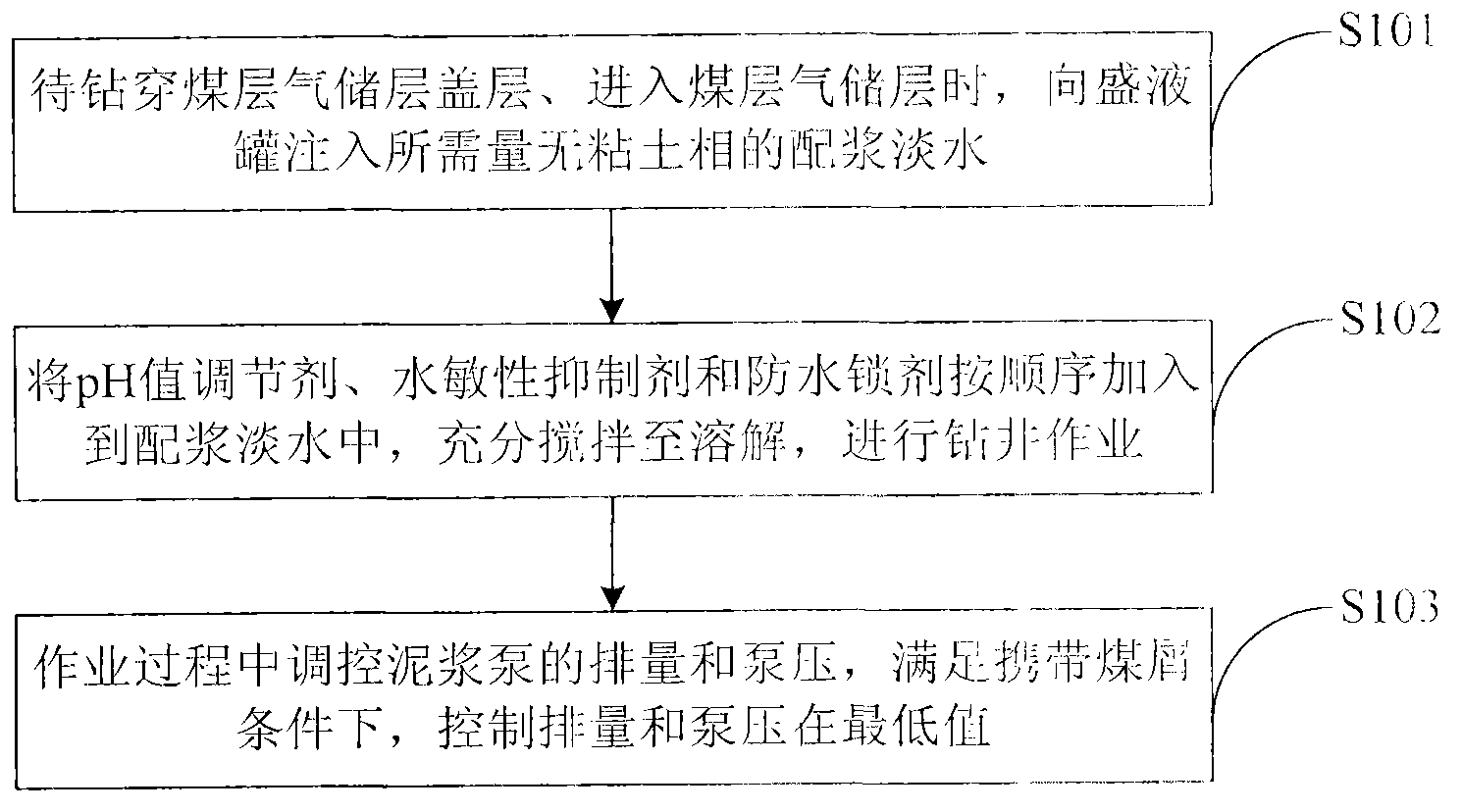

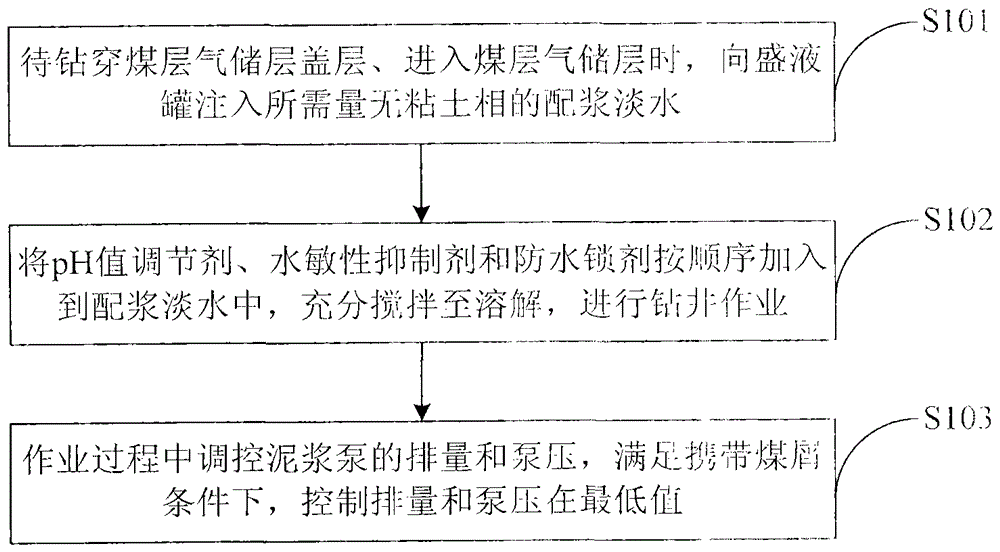

Drilling fluid capable of protecting coal bed methane reservoir

InactiveCN103194189AEffective protectionAvoid damageDrilling compositionMaterial analysisClay mineralsAdditive ingredient

The invention discloses a drilling fluid capable of protecting a coal bed methane reservoir. The drilling fluid comprises the following ingredients in percentage by weight: 100 parts of fresh water, 0.1-0.3 part of pH value modifier, 0.5-10 parts of water-sensitivity inhibitor, and 0.1-1 part of waterproof blocking agent. For the drilling fluid, the density is 1.01-1.08g / cm<3>, the pH value ranges 8 to 10, the expansion rate reduction ratio is greater than or equal to 60%, the contact angle reduction rate is greater than or equal to 50%, the hygroscopic-state recovery rate of the core permeability is greater than or equal to 85%, the dry-state recovery rate is greater than or equal to 95%, the coal powder landberra volume reduction rate is greater than or equal to 15%, clay-free phase does not exist, the damage to the coal bed methane reservoir caused by same-phase invasion can be furthest reduced, the hydration of the clay mineral in coal petrography can be effectively prevented, water blocking is reduced, the coal bed methane can be forced to be desorbed from the surface of the coal petrography, the coal bed methane reservoir can be effectively protected, the stability of the coal bed well wall can be retained, the practicability is strong, and the stronger popularization and application values can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Process method for preparing bricks by using papermaking sludge

InactiveCN102503361ASolve processing problemsCause harmCeramic materials productionCeramicwareBrickWater volume

The invention relates to a process method for preparing bricks by using papermaking sludge, and relates to the field of papermaking sludge treatment in papermaking industry. The process method comprises the following steps of: 1, putting the papermaking sludge into a sterilizing treatment pond, and adding water into the sterilizing treatment pond, wherein a ratio of water volume to the weight of the papermaking sludge is 2:1; 2, introducing disinfection gas into the sterilizing treatment pond to perform sterilizing disinfection; 3, drying the papermaking sludge subjected to gas sterilizing disinfection; 4, stirring and mixing 15 to 25 mass parts of dried papermaking sludge with 10 to 15 mass parts of coal cinder and 60 to 85 mass parts of clay uniformly in a stirring pond; and 5, extruding the mixture of the coal cinder, the clay and the papermaking sludge to form blank strips, cutting to form brick blanks, drying, and sintering the brick blanks at the sintering temperature of between 600 and 700 DEG C. The process method for preparing the bricks by using the papermaking sludge has smaller harm to human bodies and environment.

Owner:QUANZHOU HUAXIANG PAPER IND

Lithium slag hollow brick and making method thereof

The invention discloses a lithium slag cored brick. The brick is made by using the following raw materials, by weight, 20-30 parts of fly ash, 20-25 parts of lithium slag, 10-15 parts of coal slag, 15-17 parts of lime, 2-4 parts of gypsum, 10-15 parts of light calcium powder, 10-15 parts of self made concrete, 4-6 parts of attapulgite, 2-3 parts of cement clinker, 8-10 parts of an aluminum phosphate solution with the concentration of 4-5%, 1-2 parts of alumina, 1-2 parts of nanometer carbon powder, 5-8 parts of a quartz fiber, 0.2-0.5 parts of glycerol and 18-20 parts of water. The hollow brick made in the invention has the advantages of light weight, high strength, clay saving, fuel saving, improvement of the heat and sound insulation performances of the brick, realization of recycling of the lithium slag, reduction of the pollution to environment, and changing of wastes into valuables.

Owner:WUHE DINGSHUN NEW BUILDING MATERIAL

Light-level foamed internal wall brick and its manufacturing method

InactiveCN1676808ATake advantage ofRelieve stressConstruction materialSolid waste managementC constantAgricultural engineering

The invention refers to a method of making the new-type architecture wall-body material, especially the light froth inner-wall brick which used to the inner wall material. The character of the method is that in the brick there are many air holes formed by the sinter froth anomalistic distributed. The manufacture method is that in the industry waste cinder the block grain which is burned to crystal vitreous body shape accounts for 64%-74% after the smashing according to weight ratio, the waste earth accounts for 15-25%, cock grain accounts for 10%, add-adhesive accounts for 1%, mixes evenly, and then pressed to the flan at the special-purpose machine, open fire burns it in the ordinary agglutinates brick kiln, froth to cock grain when controlling the temperature in the agglutinate 1000-1200 deg. C constant temperature for 10-20 hours in the agglutinate, cut the bricks to the just size to the needs of the inner-wall after the natural cooling. The brick is a new-type wall-body material; its weight is only 1 / 5 of the ordinary agglutinate brick. It recycles waste, and lower the cost is also suitable to do building material of the wall, it has the characters that the transporting reduces effort, the construction is convenient, and protects the cultivated land resources, favorable country advantage people.

Owner:毛光辉

Composite gel material taking bulk solid waste as raw material and preparation method thereof

The invention discloses a composite gel material taking bulk solid waste as a raw material. The composite gel material is prepared from the following raw materials in parts by weight: 40-50 parts of iron tailings, 5-10 parts of blast furnace slag, 10-20 parts of fly ash, 20-30 parts of desulfurized fly ash, 20-30 parts of carbide slag and 0.05-0.14 part of an activating agent. According to the invention, a large amount of industrial bulk solid waste can be consumed, environmental pollution can be reduced, a large amount of fertile farmland clay is saved, waste is turned into wealth, and high-efficiency utilization of the industrial bulk solid waste is realized; and the composite gel material is simple in production process, low in cost and high in quality.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Multi-solid-waste large-mixing-amount utilization method

The invention discloses a multi-solid-waste large-mixing-amount utilization method, and belongs to the field of building material preparation; the multi-solid-waste large-mixing-amount utilization method is a utilization method of iron tailings, alkaline residues, fly ash and other solid wastes, and comprises the following specific steps: step 1, solid waste crushing: crushing iron ore waste rocks, grading according to 4.75 mm, using the crushed iron ore waste rocks with the particle size of more than 4.75 mm as coarse aggregates, and using the crushed iron ore waste rocks with the particle size of less than 4.75 mm as fine aggregates for later use; crushing iron tailings until the particle size is not greater than 2 mm for later use, and not treating alkaline residues for later use; step2, utilizing the treated solid waste for preparing any one of clinker, cement, concrete and baking-free bricks. The method has the beneficial effects that a large amount of various solid wastes including alkaline residues, coal ash, iron tailings and iron ore waste rocks can be consumed, the solid waste mixing amount is increased, raw materials are saved, the solid waste accumulation pressure is relieved, environmental pollution is reduced, large pieces of fertile farmland clay are saved, waste is turned into wealth, meanwhile, the urban ecological environment is maintained, and the balance state of the ecological environment is kept.

Owner:张延年

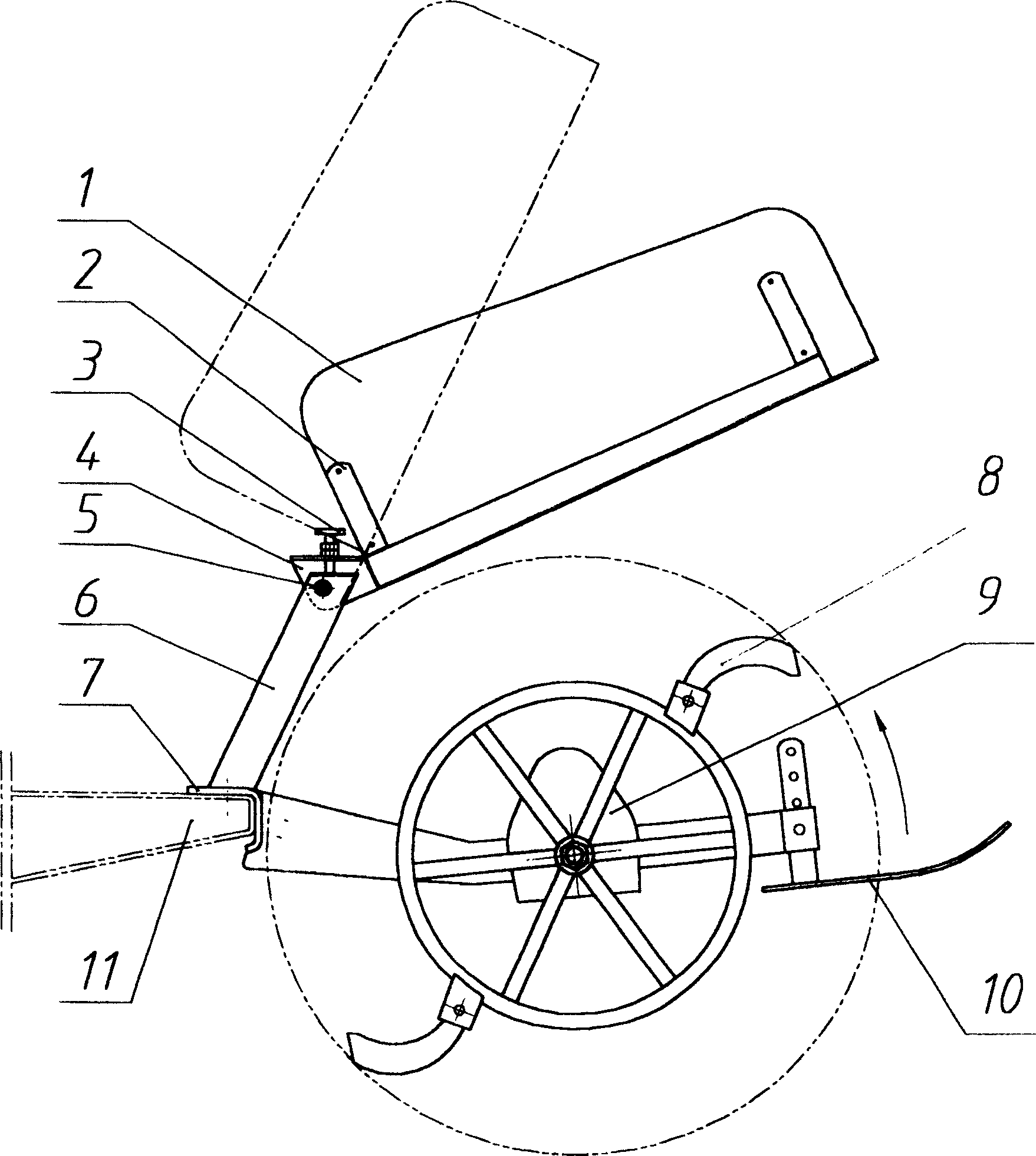

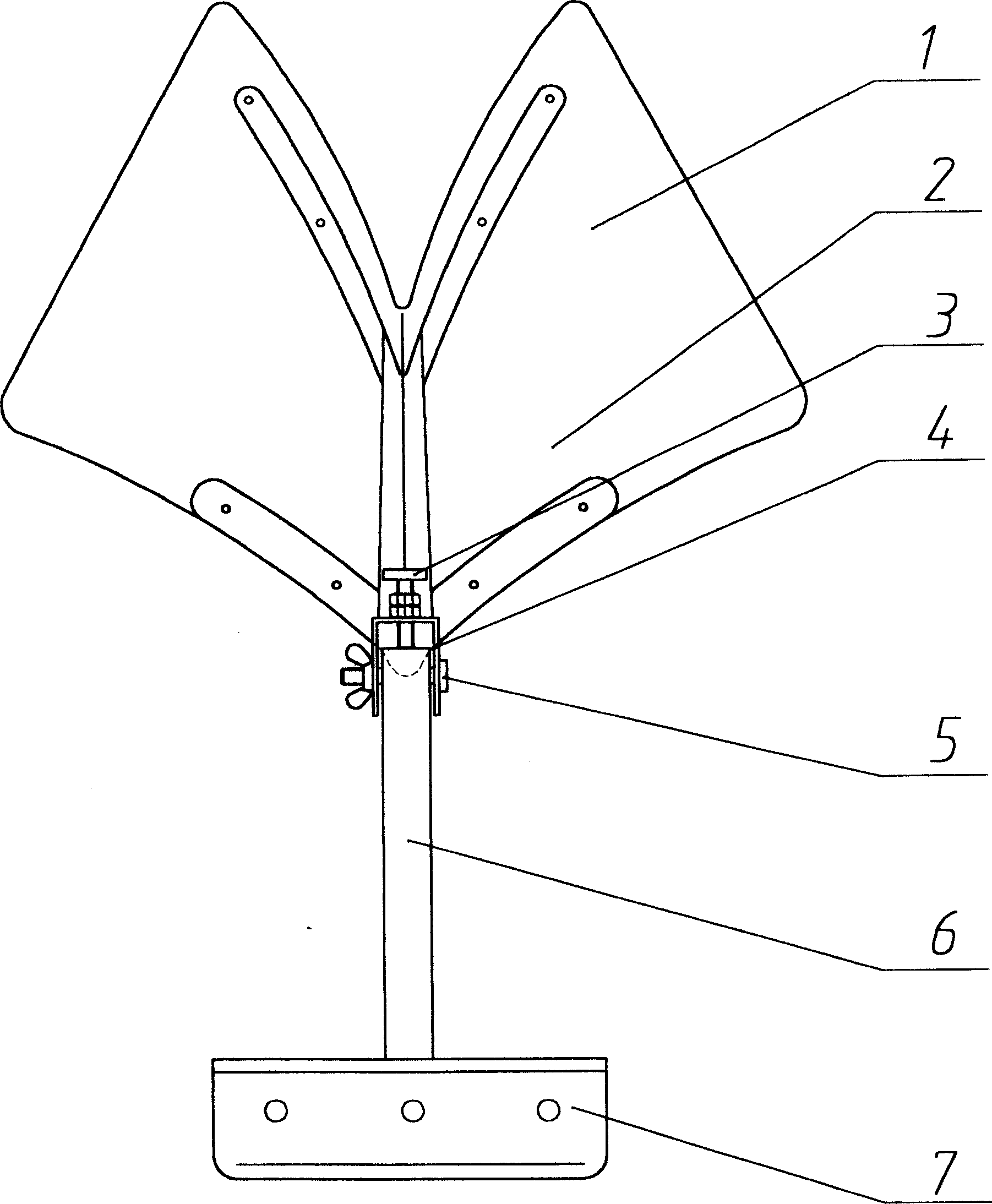

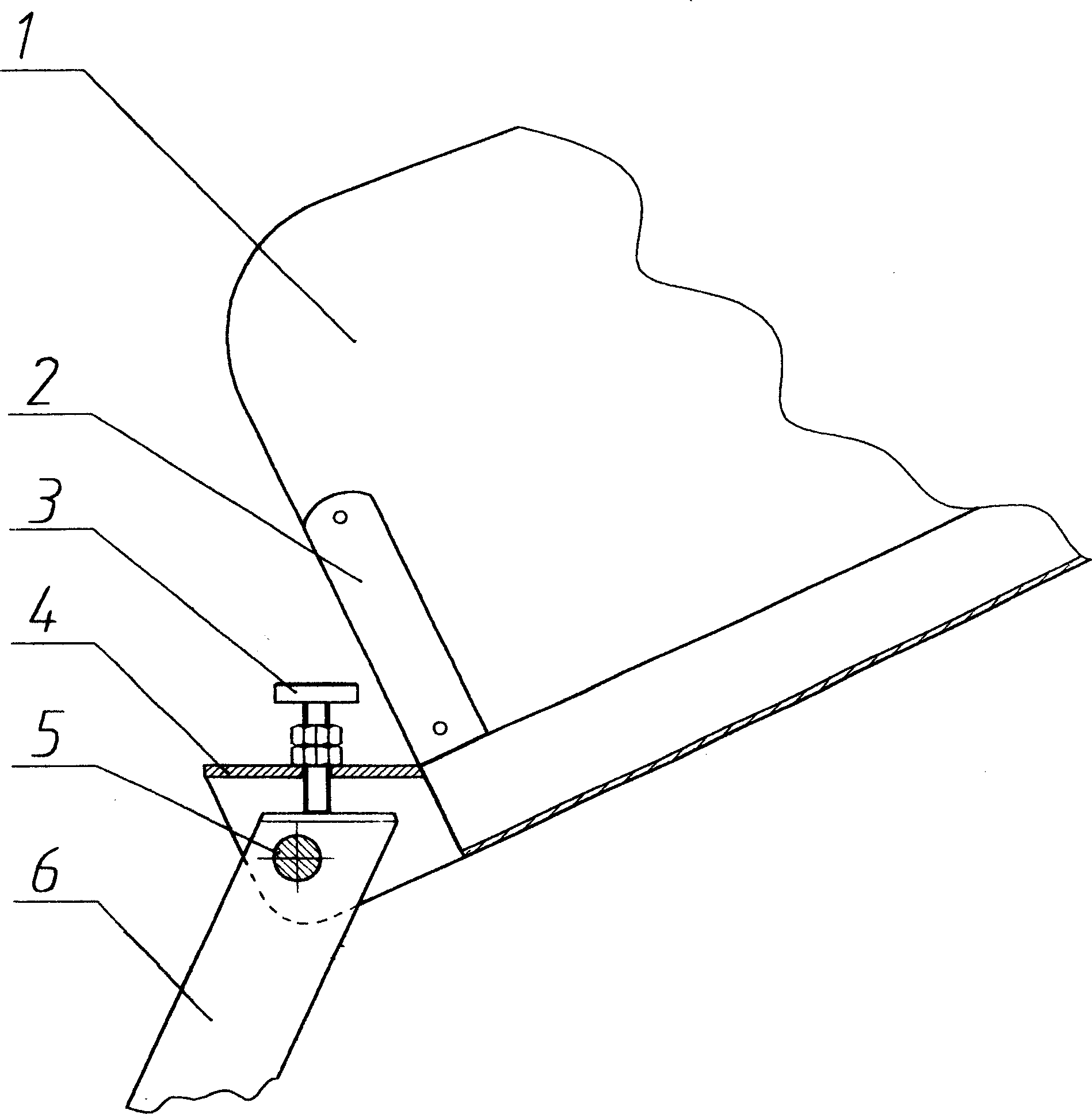

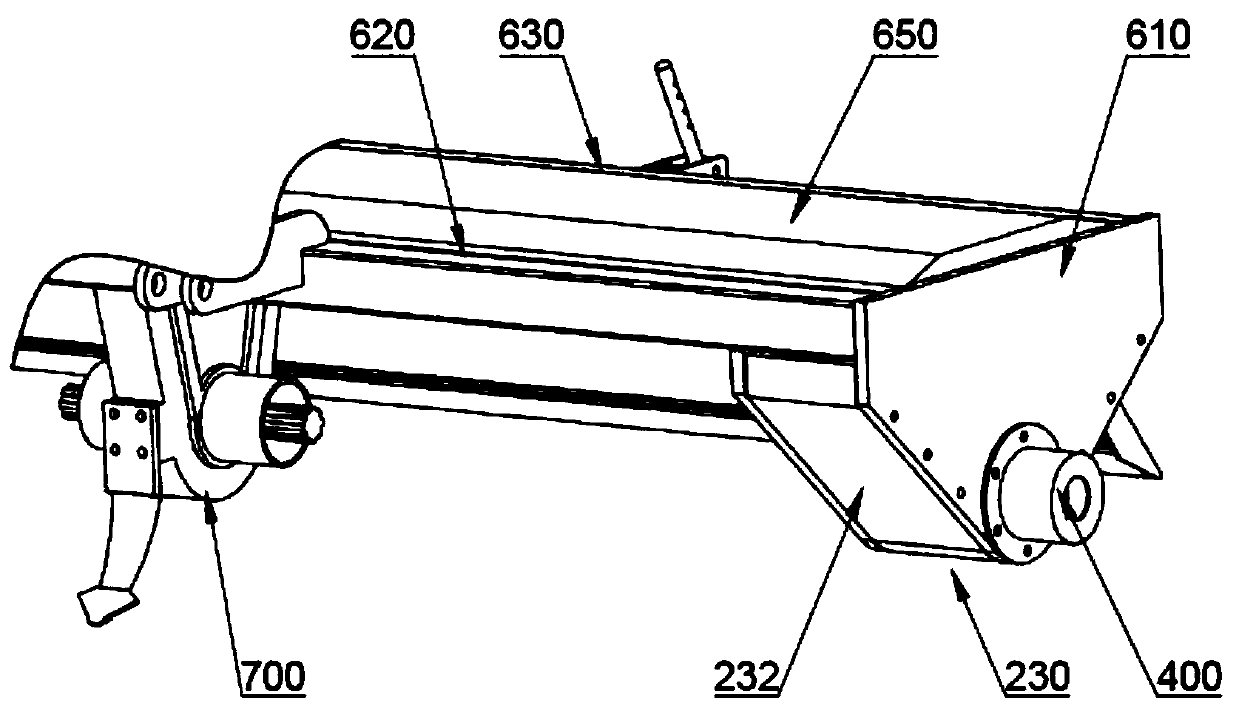

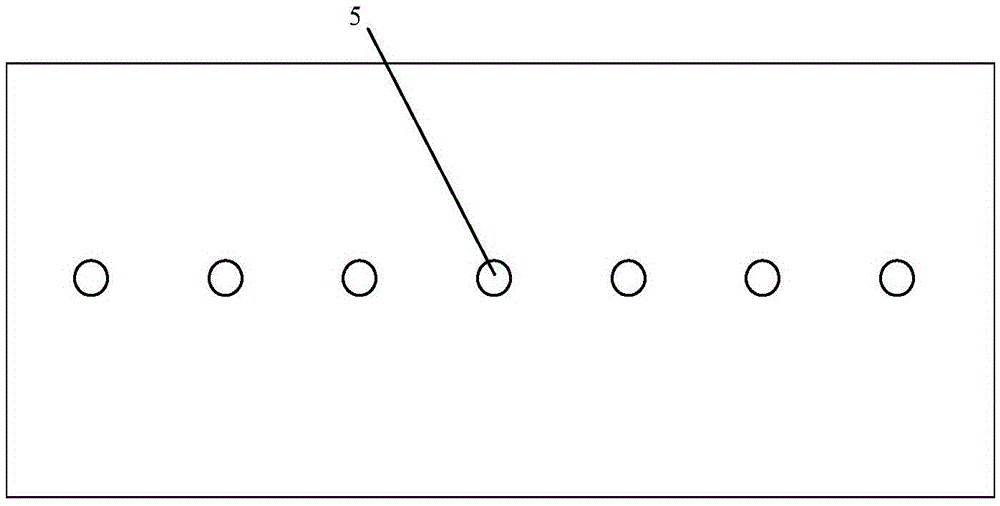

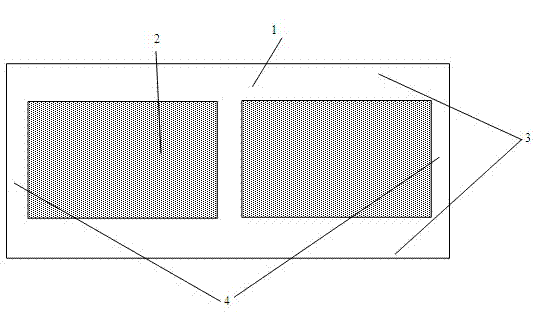

Soil divider of ditching machine

InactiveCN1596575AGood strengthSaving clayPlantingFurrow making/coveringTractorAgricultural machinery

An earth divider for the ditch digger which is installed to front end of a walking tractor is arranged above the cutting wheel of ditch digger, and has V-shaped earth dividing plate and supporting rod whose top end is connected to said earth dividing plate via hinge-locking mechanism on which a regulator is set up.

Owner:葛玉明

Alkaline residue cement superfine powder and preparation method thereof

InactiveCN108863118AImprove performanceQuality improvementCement productionChemical industryPolymer science

The invention discloses alkaline residue cement superfine powder. The alkaline residue cement superfine powder is prepared by the following steps: uniformly mixing 98 to 99 percent by mass of waste alkaline residue discharged after production of industrial crystal soda in salt chemical industry and 1 to 2 percent by mass of chlorine remover with stirring; curing and drying at 100 DEG C; grinding the mixture into cement superfine powder with a specific surface area of greater than 400 to 500m<2> / kg. The alkaline residue cement superfine powder can replace 40 to 50 percent of cement products, improves the performance of cement products, can advance the setting time of cement by 20 to 40 minutes, increases the hydration strength of cement by 8 to 12mpa, increases the specific surface area by100 to 150m<2> / kg, reduces the water consumption of cement by 15 to 30 percent, increases the wear resistance of cement by 10 to 15 times, increase the compatibility of cement products by 100mm, increases the hourly output of a cement table by 20 to 30 tons, directly lowers the cost of cement by 80 yuan / ton, and protects the environment from secondary pollution.

Owner:淮安市水泥厂有限公司 +1

Energy-dissipation speed-reduction anti-collision guardrail for purifying air and processing method thereof

InactiveCN104264608AReduce pollutionSaving clayGas treatmentDispersed particle separationEngineeringPollution

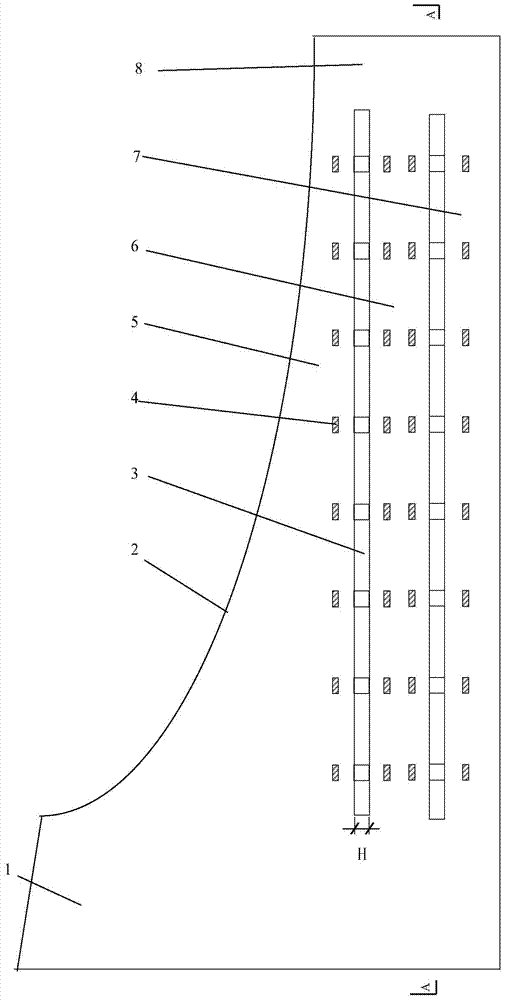

The invention relates to an air-purifying energy-dissipation speed-reduction anti-collision guardrail and a processing method thereof. The guardrail comprises a sleeper beam, a first-layer speed-reduction anti-collision curved plate, a second-layer speed-reduction anti-collision surface plate, a support plate, energy-dissipation ventilating cavities, a top beam and energy-dissipation flexible steel rings, wherein an anti-collision curved surface is arranged on the outer side of the first-layer speed-reduction anti-collision curved plate, a vertical facade is arranged on the inner side of the first-layer speed-reduction anti-collision curved plate, the area of the section gradually reduces from bottom to top, the sections of the second-layer speed-reduction anti-collision surface plate and the support plate are both rectangular, and the energy-dissipation ventilating cavities are respectively formed among the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate; the upper ends and the lower ends of the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate are respectively connected through the sleeper beam and the top beam, the plate bodies of the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate are respectively connected through the energy-dissipation flexible steel rings, and a plurality rows of ventilating holes are formed in the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate. The air-purifying energy-dissipation speed-reduction anti-collision guardrail reduces the environmental pollution, absorbs and degrades a large quantity of harmful substances in the air, effectively reduces the pollution, and purifies the air.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for preparing building block sintered from oil field mud

InactiveCN1212900CLarge amount of processingEffective consumptionSolid waste disposalCeramic shaping apparatusSludgeMetallurgy

The invention relates to a method to sinter building block by mud in oil field, including the steps: 1), batching: according to weight ratio, clay 20-80, mud 20-80, and additional auxiliary material 0.1-30% of the total weight of the clay and mud, where the content of the soluble salt is below 0.5% of the total weight; 2) mixing: two modes: one, dry or wet mixing; two, wet mixing; 3), ageing: 1-7 days; 4), molding: adopting half-dry pressing or dry pressing, where the molding pressure is greater than 4.0MPa; 5), drying; 6), sintering: placing the dried preparation into the high temperature furnace for baking, wherein the sintering temperature 800-1200 deg.C, preserving heat for 1-3 hours in the high temperature region and then cooling with the furnace to obtain the products.

Owner:WUHAN UNIV OF TECH

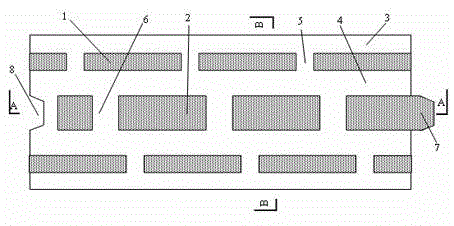

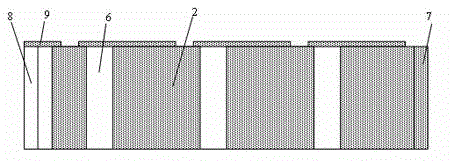

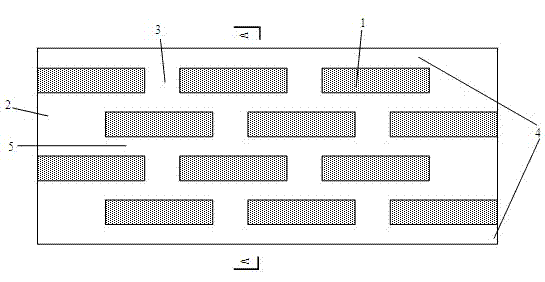

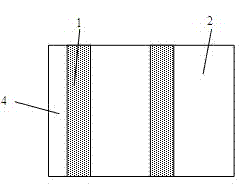

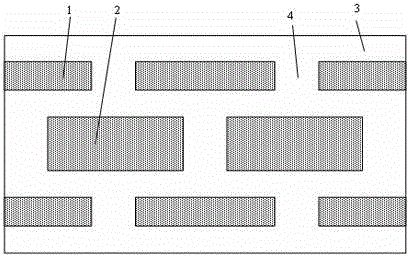

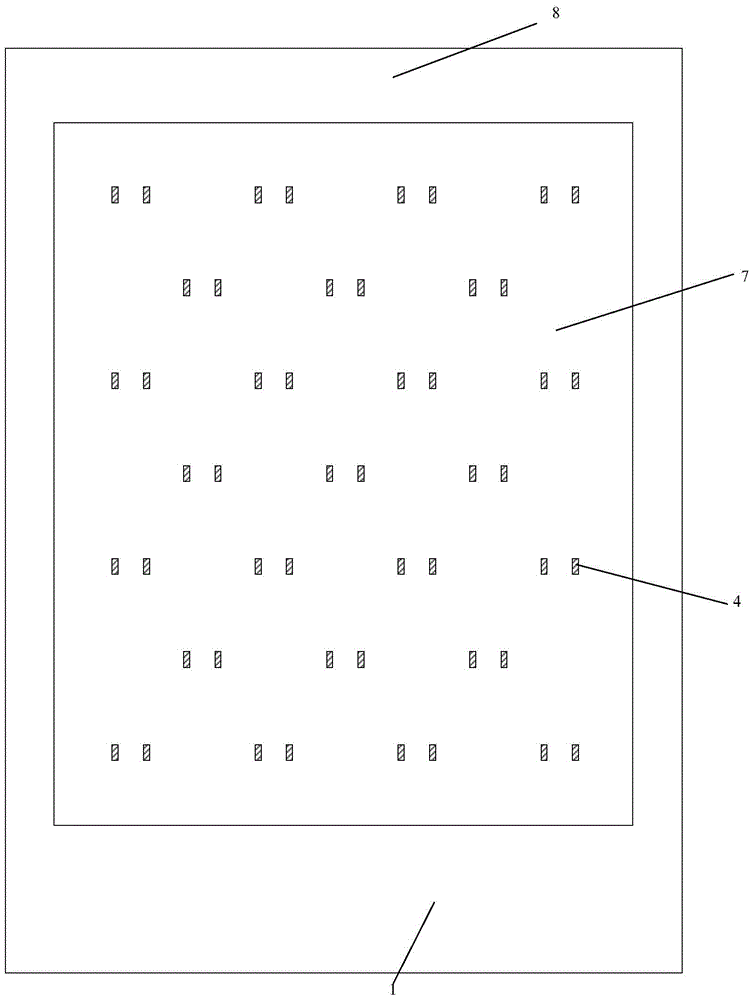

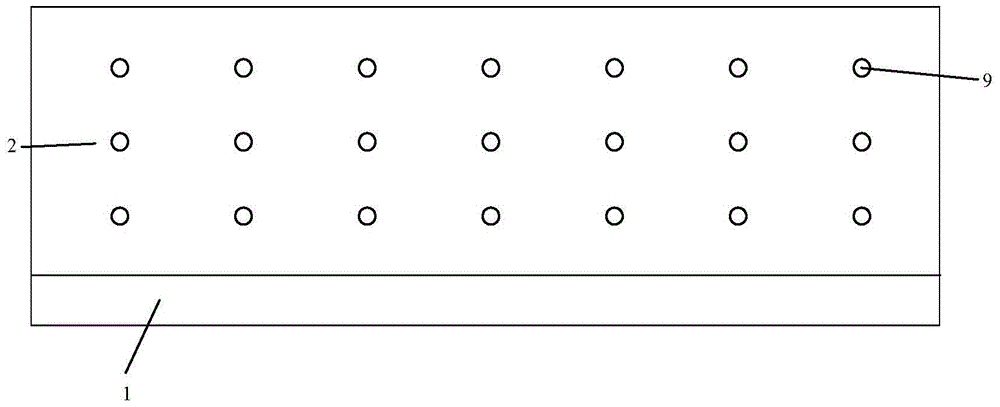

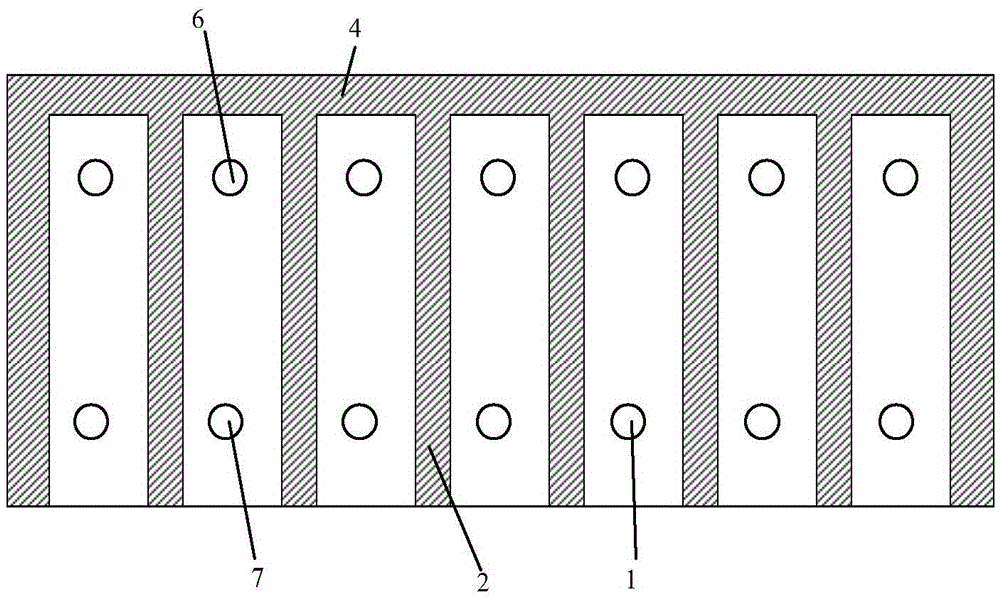

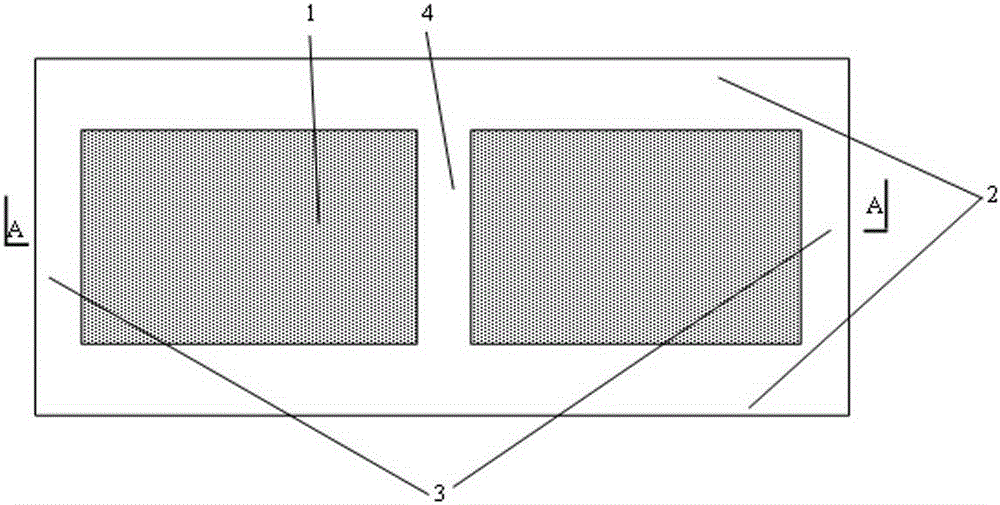

Industrial waste residue self-insulation raw soil building block without heat bridge and preparation method thereof

InactiveCN102912927AReduce pollutionGood energy saving effectConstruction materialClimate change adaptationInsulation layerThermal bridge

The invention discloses an industrial waste residue self-insulation raw soil building block without a heat bridge. The industrial waste residue self-insulation raw soil building block comprises insulation boards on both sides, wherein a side rib is formed between the adjacent insulation boards on both sides, a middle rib is formed between the middle adjacent insulation boards, the side ribs and the middle ribs in different layers are staggered, the outer sides of the insulation boards on both sides are raw soil protection layers, and raw soil layers are arranged between the insulation boards on both sides and the middle insulation boards; the building block is outwards extended from the middle insulation board on one end of the building block so as to form a vertical mortar joint extension insulation layer, a vertical mortar joint heat bridge blocking groove matched with the vertical mortar joint extension insulation layer is arranged on the other end of the building block, and the insulation boards on both sides and the middle adjacent insulation boards are outwards extended to form a horizontal vertical mortar joint extension insulation layer. According to the invention, a large amount of industrial waste residues can be consumed to produce an energy-saving building wall material, so that the environmental pollution is reduced, vast fertile farmland clay is saved, the waste is changed into wealth, and a large amount of fuel coal is saved. Furthermore, the energy-saving capacity of the building is improved, the thermal insulation effect is enhanced, and the industrial waste residue self-insulation raw soil building block has the advantages of durability, safety and flame resistance, and capability of effectively blocking sound.

Owner:SHENYANG JIANZHU UNIVERSITY

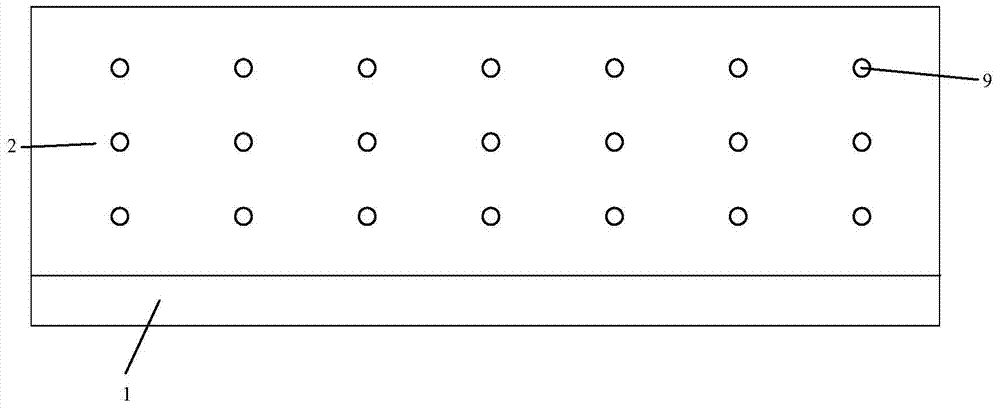

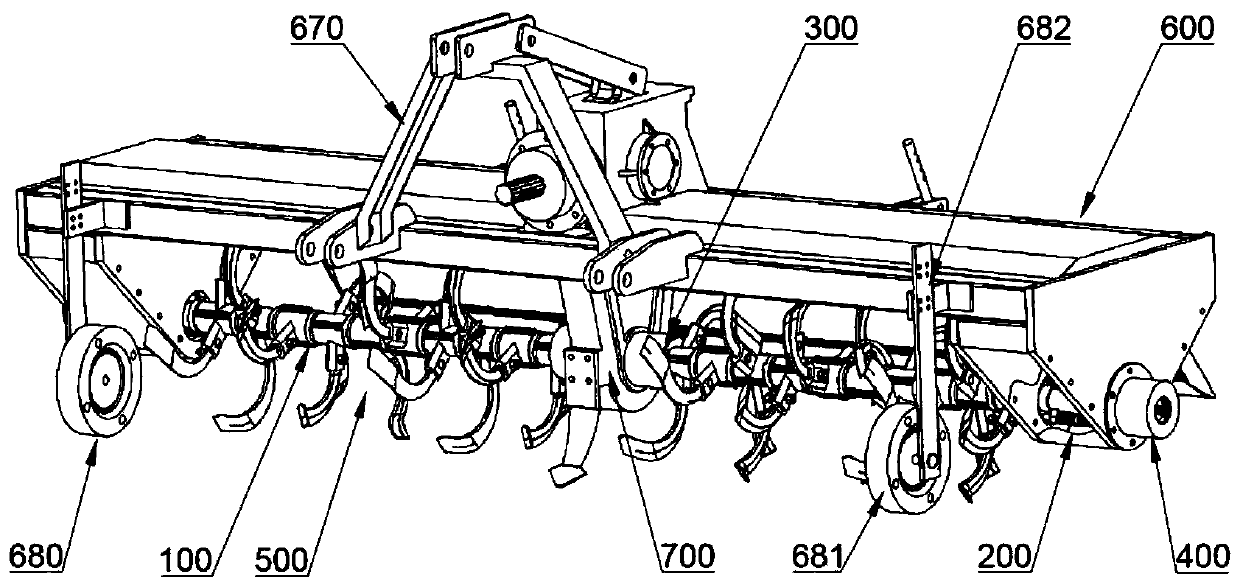

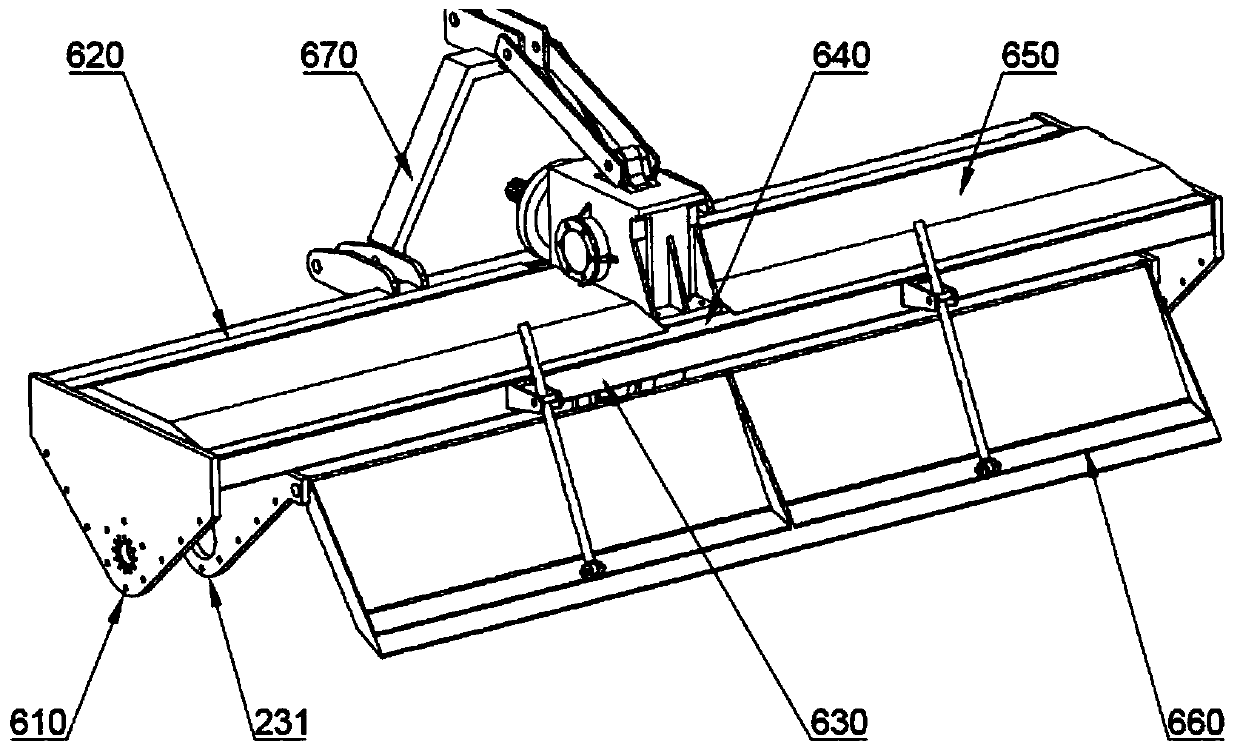

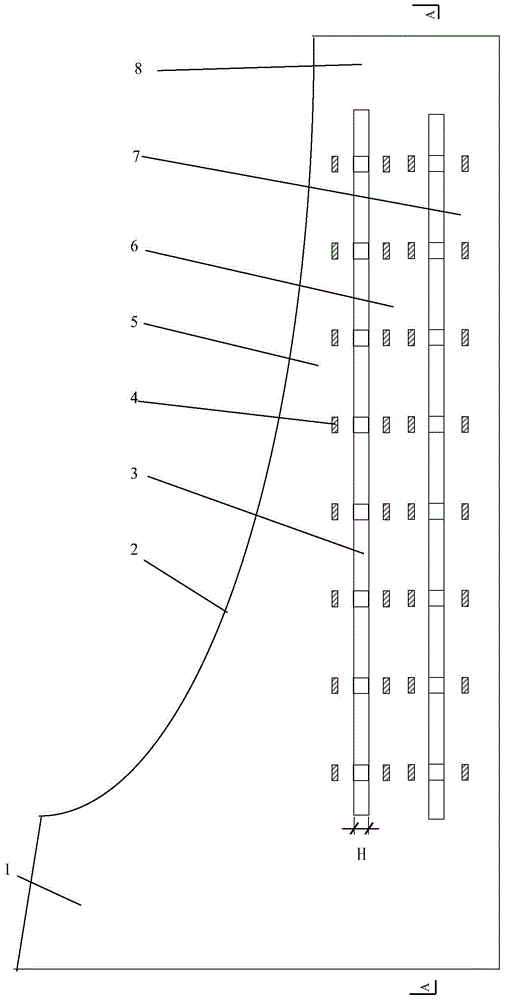

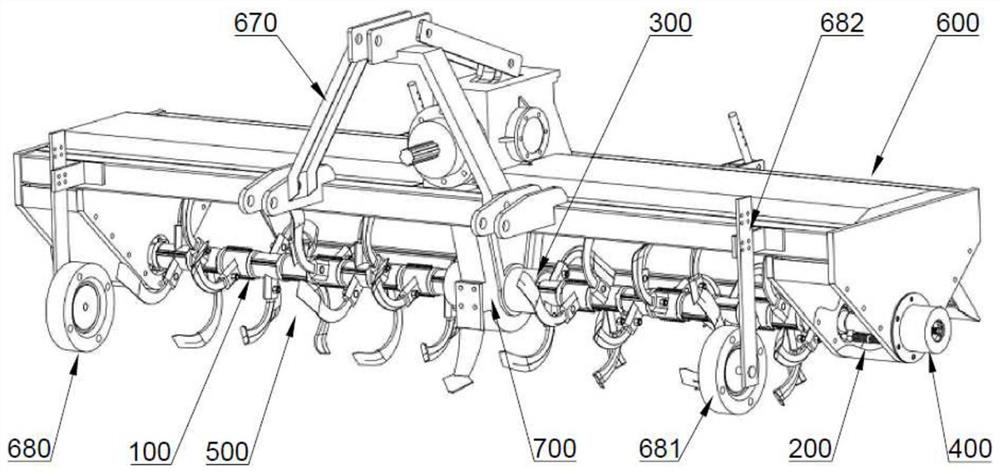

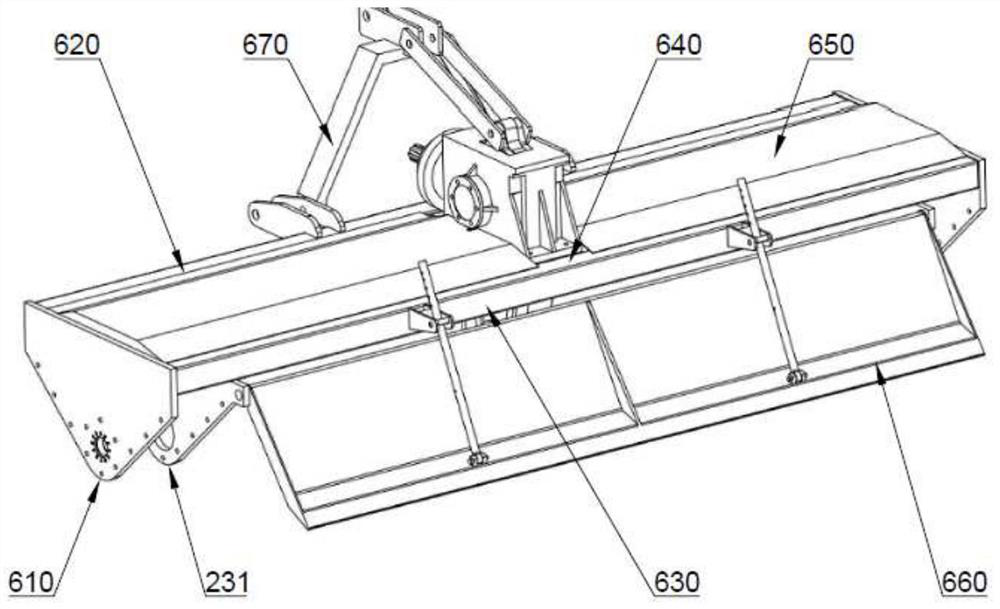

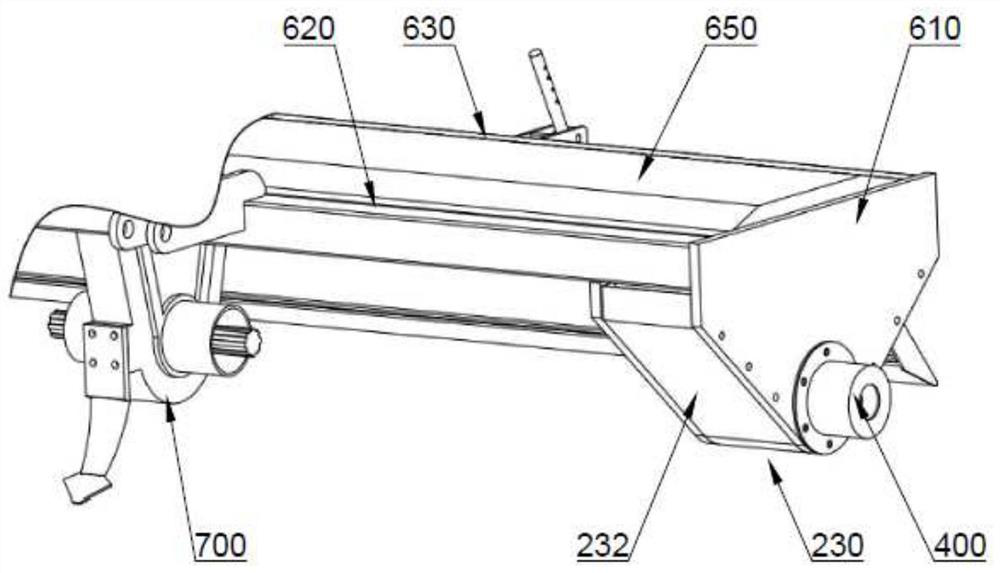

Rotary blade roller anti-sticking and anti-twining device based on resonance excitation and rotary cultivator with rotary blade roller anti-sticking and anti-twining device

ActiveCN111448854ALow retrofit costSaving clayTilling equipmentsConvex structureStructural engineering

The invention discloses a rotary blade roller anti-sticking and anti-twining device based on resonance excitation. The rotary blade roller anti-sticking and anti-twining device comprises an anti-sticking and anti-twining blade set, a resonance source device, a buffering device and a resonance adjusting device. The anti-sticking and anti-twining blade set is formed by connecting a plurality of soilscrapers and a plurality of anti-twining cutters, and can integrally move along the axial direction of the cutter shaft; the resonance source device comprises a resonance single body and a concave-convex oscillation starting device. Each resonance single body comprises a first support, a resonance shaft and a resonance spring arranged on the resonance shaft in a sleeving mode. A concave-convex sliding surface is arranged on the surface of the concave-convex oscillation starting device around the cutter shaft; one end of the resonance shaft is connected with the anti-sticking and anti-twiningblade set, and the other end of the resonance shaft clings to the concave-convex sliding surface; and the resonance adjusting device adopts a lead screw nut mechanism to adjust the concave-convex structure of the concave-convex sliding surface. The invention further provides a rotary cultivator with the rotary blade roller anti-sticking and anti-twining device. Vibration is generated by utilizingthe rotating power of the knife roll, an additional driving source is not needed, the problems of clay and winding can be solved in real time, and the rotary tillage operation efficiency is improved.

Owner:HUAZHONG AGRI UNIV

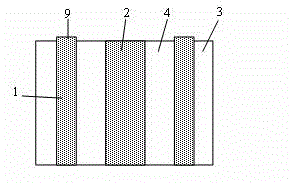

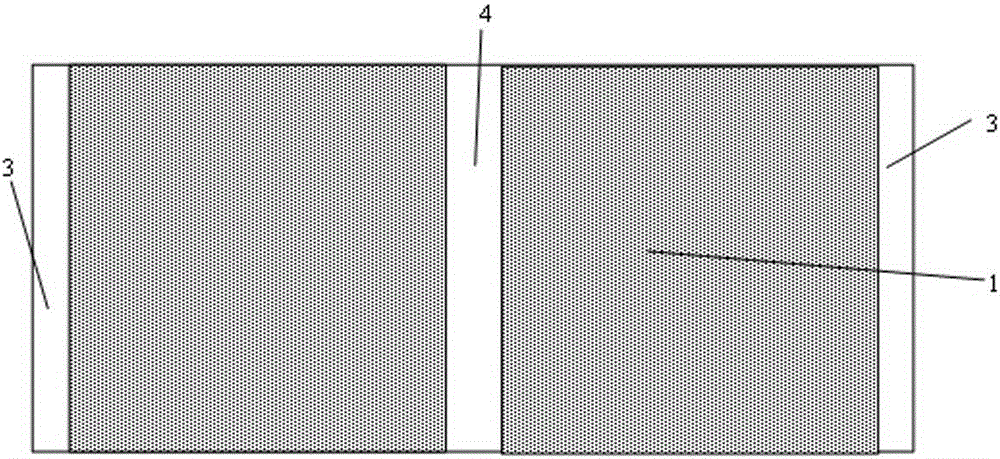

Staggered floor dense rib insulation immature soil building block

InactiveCN102926498AReduce pollutionSaving clayConstruction materialClimate change adaptationInsulation layerNon-ferrous extractive metallurgy

The invention provides a staggered floor dense rib insulation immature soil building block. The staggered floor dense rib insulation immature soil building block mainly comprises an insulation layer, an immature soil layer, an insulation plate middle rib, an immature soil protecting layer and an internal immature soil layer, and is characterized in that each insulation layer is separated by the insulation plate middle ribs which are staggered respectively; the thermal coefficient of the insulation layer is less than 0.06; the immature soil layer consists of industrial residue, clay, a plant fiber, a fire retardant and a mould inhibitor, and a plasticizer, an early strength agent and an antifreeze agent in a certain proportion are added according to the physical condition; and the industrial residue can be coal ash, residue in steel mills, smelting residue in non-ferrous metals smelting works, chemical waste gypsum and chemical lime. The staggered floor dense rib insulation immature soil building block has the advantages that a great amount of agricultural waste and industrial residue can be consumed, energy-saving building wall materials are produced, the environmental pollution is reduced, a large amount of clay in fertile farmland can be saved, waste is changed into wealth, a great amount of fuel coal can be saved, the energy-saving capacity of buildings is greatly improved, and the thermal insulating effect is enhanced, is durable, safe, fireproof and sound-proof, is convenient in construction, high in speed, high in building efficiency, low in weight of blocks and low in cost, and can be used for saving materials.

Owner:SHENYANG JIANZHU UNIVERSITY

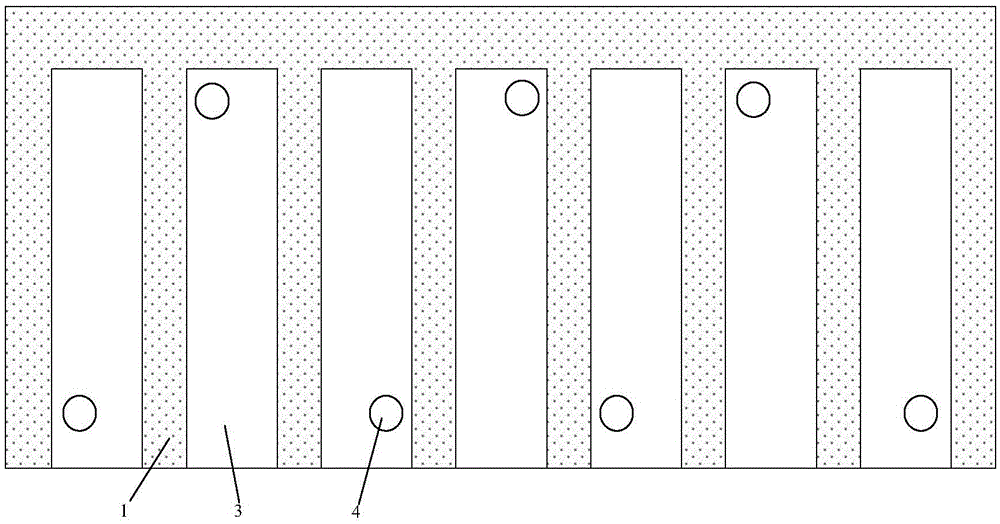

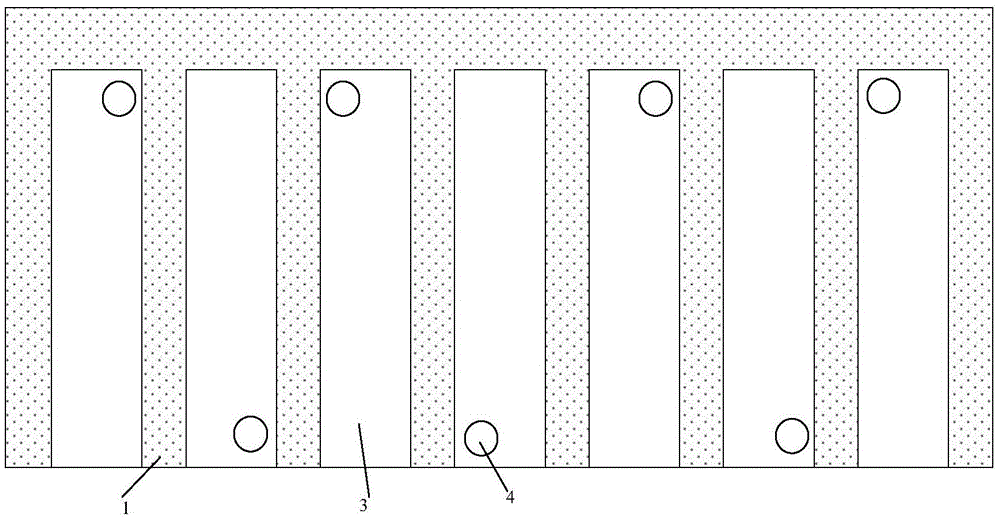

Thermal-bridge-free thermal insulation building block made of straw and raw soil and producing method thereof

InactiveCN102912926AReduce pollutionSaving clayConstruction materialClimate change adaptationEnvironmental resource managementThermal insulation

The invention relates to a thermal-bridge-free thermal insulation building block made of straw and raw soil. The building block comprises intermediate thermal insulation blocks, lateral thermal insulation blocks, raw soil layers and midribs. Thicknesses of the intermediate thermal insulation blocks are twice of those of lateral thermal insulation blocks. The midribs are formed between the adjacent thermal insulation blocks on a same layer, and the midribs on adjacent layers are staggered mutually. The lateral thermal insulation blocks stretch to the outer edges at two ends of the building block. The heights of the thermal insulation blocks are identical to the height of the building block. The thermal-bridge-free thermal insulation building block made of straw and raw soil and a producing method thereof have the advantages that a great many agricultural wastes can be consumed to produce energy-saving building wall materials, so that not only environmental pollution can be reduced, lots of fertile farmland clay is saved, wastes are turned into wealth, and lots of bunker coal can be saved. The energy-saving capacity of buildings is improved greatly, the thermal insulation effect is enhanced, and the building block is durable, safe, fire proof and effective in sound insulation. The construction is convenient, the speed is fast, the building efficiency is high, materials are saved, the building block weight is light, and the cost is low.

Owner:SHENYANG JIANZHU UNIVERSITY

Sintered brick suitable for being prepared from waste paper and paper-making sludge and preparation method of sintered bricks

The invention relates to a sintered brick suitable for being prepared from waste paper and paper-making sludge and a preparation method of the sintered bricks. The preparation method comprises the following steps: 1) performing pretreatment on the waste paper and paper-making sludge with a bactericide; 2) mixing 70-85 parts by weight of clay, 10-25 parts by weight of waste paper and paper-making sludge after pretreatment and 5-10 parts by weight of coal cinder; and 3) extruding the obtained mixture to form billets, cutting to form green bricks, drying, and then sintering the green bricks at the sintering temperature of 1000-1100 DEG C.

Owner:蒋华

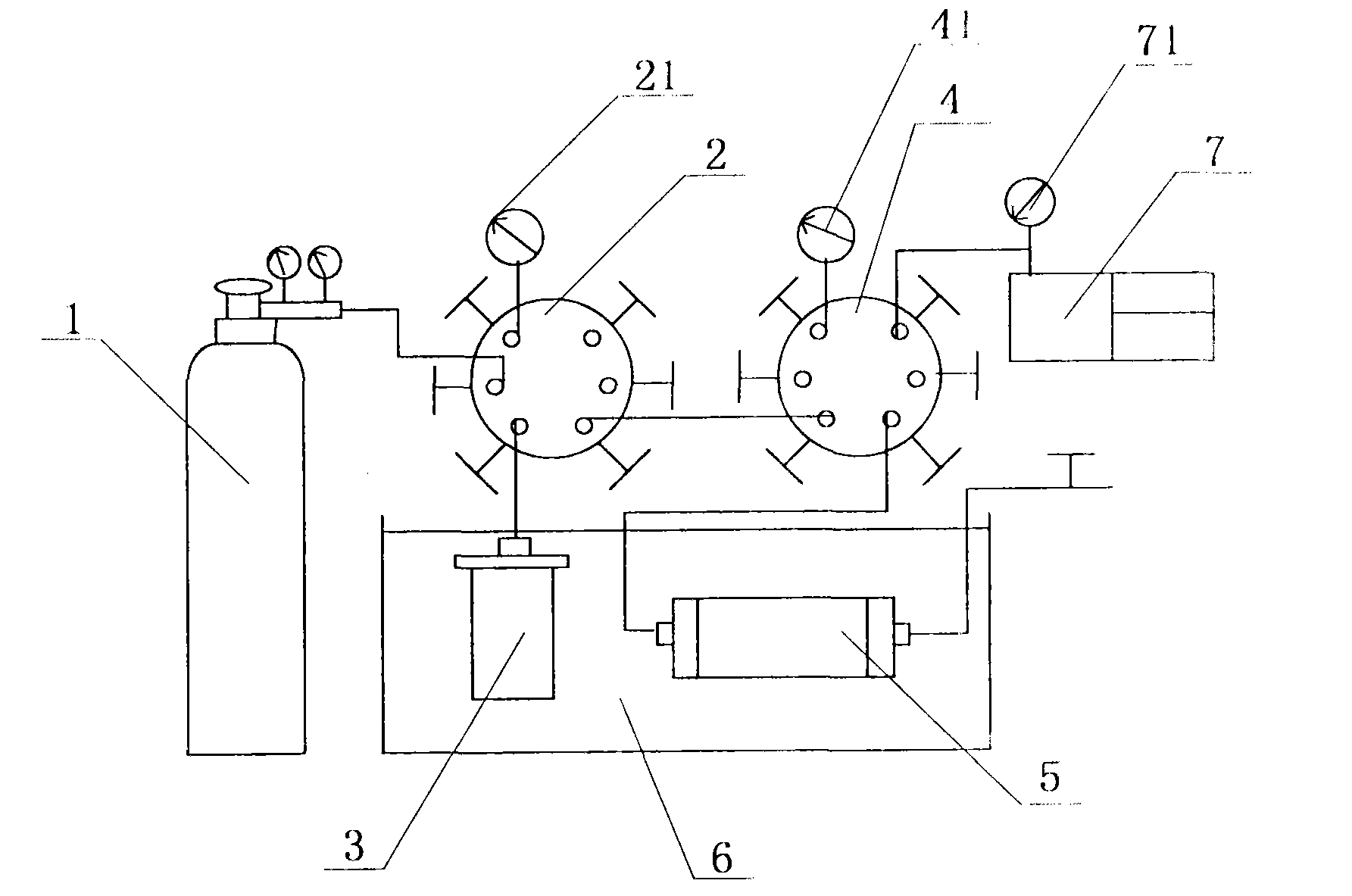

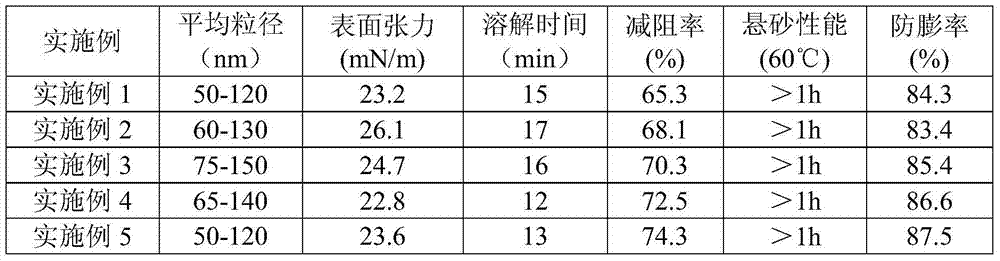

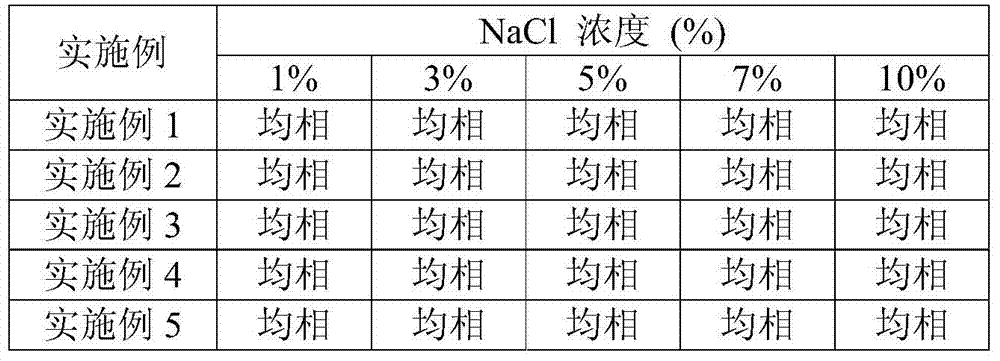

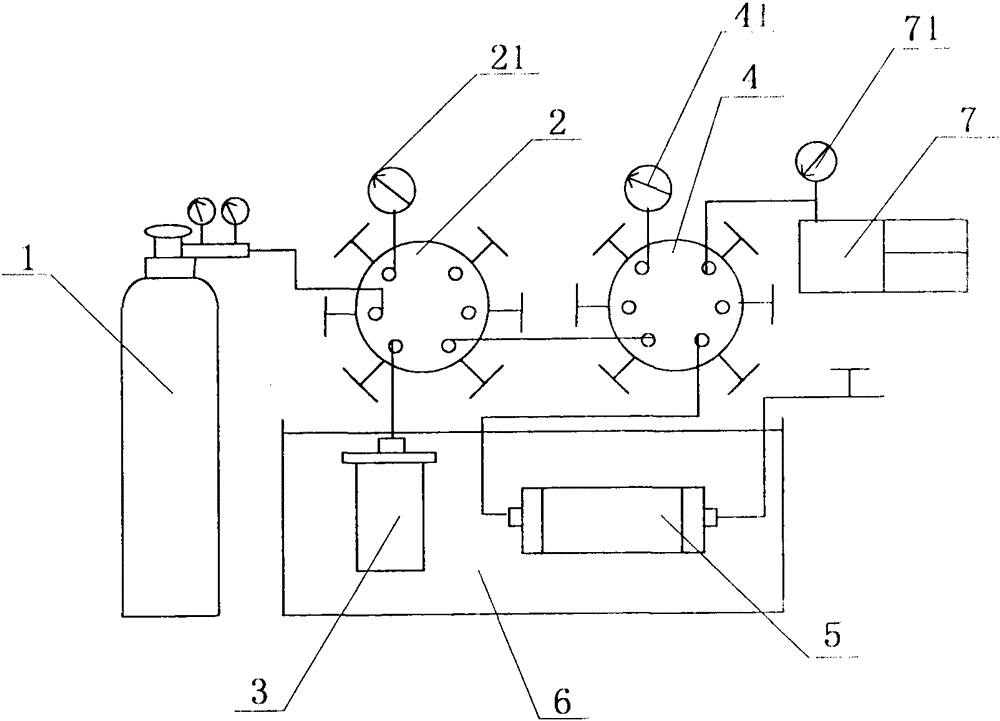

A kind of nanoscale Pickering emulsion type fracturing fluid and its preparation method

The invention provides nanoscale Pickering emulsion type fracturing fluid and a preparing method thereof. The method includes the steps that a water-soluble monomer, two functional monomers, water-soluble polymeric emulsifier and inorganic salt are mixed and dissolved in deionized water to form a water phase; oil-soluble emulsifier and oil are mixed to form an oil phase; the water phase and the oil phase are mixed and heated, nitrogen is introduced, nano particles and an initiating agent are added to initiate polymerization, high-speed dispersion is combined with high-pressure homogenization or high-pressure microjet to disperse a mixed solution into dispersion fluid, the dispersion fluid is diluted to prepare the nanoscale Pickering emulsion type fracturing fluid. The fracturing fluid has good capacity of reducing resistance, aiding discharge, stabilizing clay, suspending sand and reducing surface activity, can effectively reduce usage of clay stabilizer and a discharge aiding agent, reduces operation cost, shortens work time and improves the fracturing efficiency. The stability of the fracturing fluid is effectively improved by the introduced nano particles.

Owner:PETROCHINA CO LTD

Energy-dissipating deceleration anti-collision guardrail for purifying air and processing method thereof

InactiveCN104264608BReduce pollutionSaving clayGas treatmentDispersed particle separationHazardous substanceEngineering

The invention relates to an air-purifying energy-dissipation speed-reduction anti-collision guardrail and a processing method thereof. The guardrail comprises a sleeper beam, a first-layer speed-reduction anti-collision curved plate, a second-layer speed-reduction anti-collision surface plate, a support plate, energy-dissipation ventilating cavities, a top beam and energy-dissipation flexible steel rings, wherein an anti-collision curved surface is arranged on the outer side of the first-layer speed-reduction anti-collision curved plate, a vertical facade is arranged on the inner side of the first-layer speed-reduction anti-collision curved plate, the area of the section gradually reduces from bottom to top, the sections of the second-layer speed-reduction anti-collision surface plate and the support plate are both rectangular, and the energy-dissipation ventilating cavities are respectively formed among the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate; the upper ends and the lower ends of the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate are respectively connected through the sleeper beam and the top beam, the plate bodies of the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate are respectively connected through the energy-dissipation flexible steel rings, and a plurality rows of ventilating holes are formed in the first-layer speed-reduction anti-collision curved plate, the second-layer speed-reduction anti-collision surface plate and the support plate. The air-purifying energy-dissipation speed-reduction anti-collision guardrail reduces the environmental pollution, absorbs and degrades a large quantity of harmful substances in the air, effectively reduces the pollution, and purifies the air.

Owner:SHENYANG JIANZHU UNIVERSITY

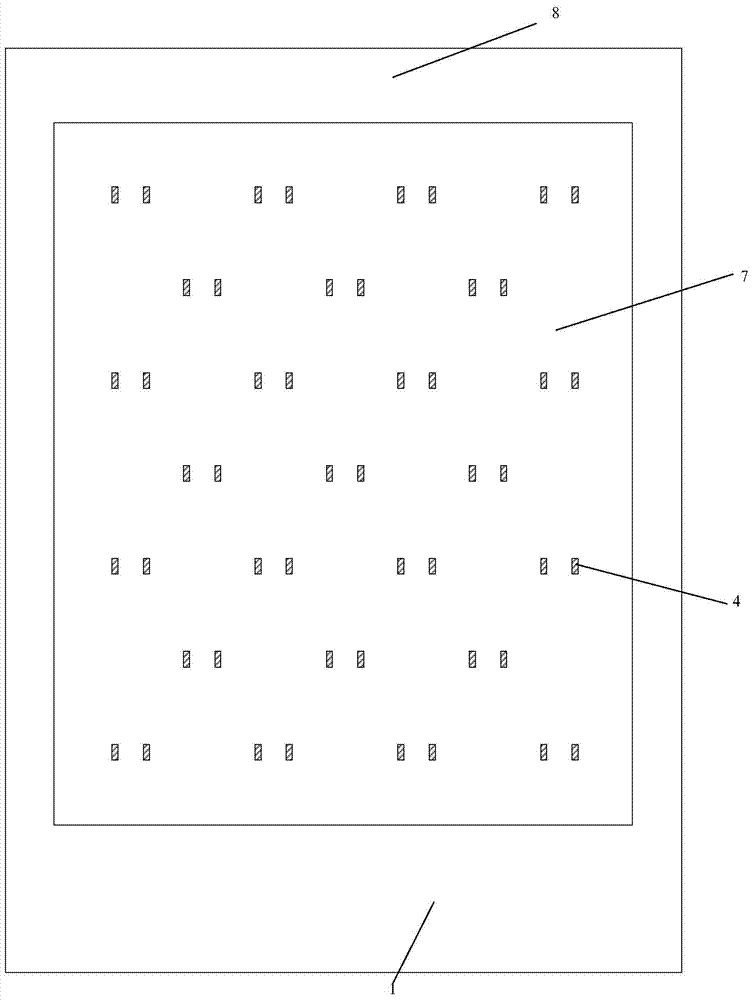

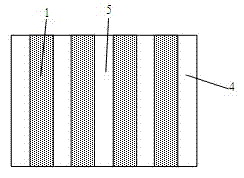

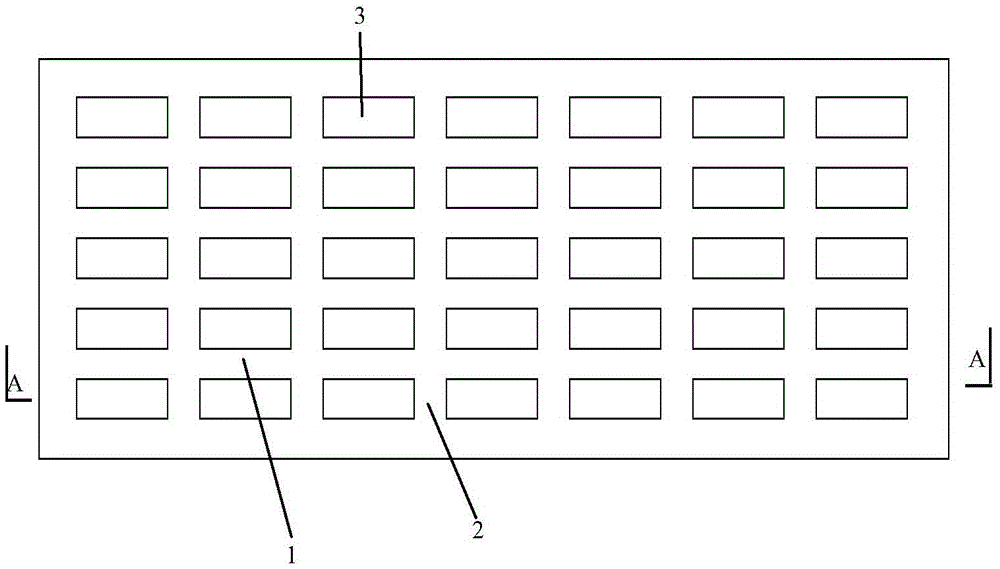

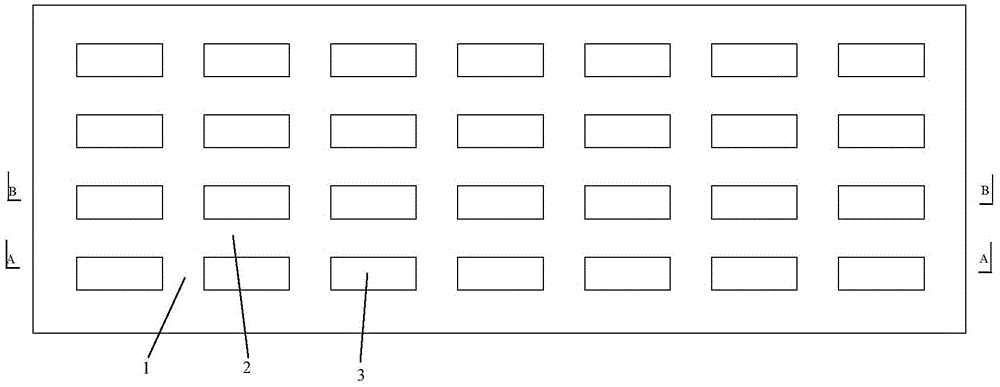

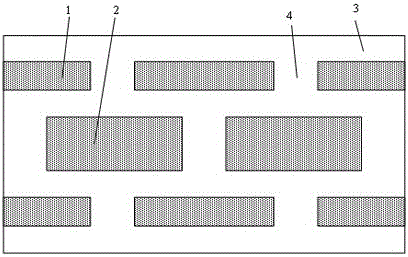

A coal gangue block for air purification and its processing method

InactiveCN104499633BReduce pollutionSaving claySolid waste managementBuilding componentsArchitectural engineeringEngineering

The invention relates to a coal gangue building block for purifying air and a processing method of the coal gangue building block, and belongs to the technical field of construction building blocks. One end of the building block is top-sealed; a plurality rows and columns of cavities are formed along the other end of the building block; longitudinal ribs and transverse ribs are respectively formed in adjacent cavities; middle vent holes are formed in the longitudinal ribs of every other two rows; upper vent holes and lower vent holes are formed in the longitudinal ribs of each row adjacent to the middle vent holes. According to the coal gangue building block, a great amount of industrial wastes can be consumed to produce building wall materials, the environment pollution can be reduced, a great deal of fertile farmland clay can be saved, the wastes can be turned into wealth, harmful substances in air can be greatly absorbed and degraded, and the coal gangue building block is not only an effective method for efficiently utilizing resources, but also capable of effectively reducing pollution and purifying air.

Owner:SHENYANG JIANZHU UNIVERSITY

A composite gel material using bulk solid waste as raw material and its preparation method

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Water-permeable, air-permeable, air-purifying concrete curbstone and processing method thereof

InactiveCN104264564BReduce pollutionSaving claySolid waste managementPaving gutters/kerbsHazardous substanceToxic industrial waste

Owner:SHENYANG JIANZHU UNIVERSITY

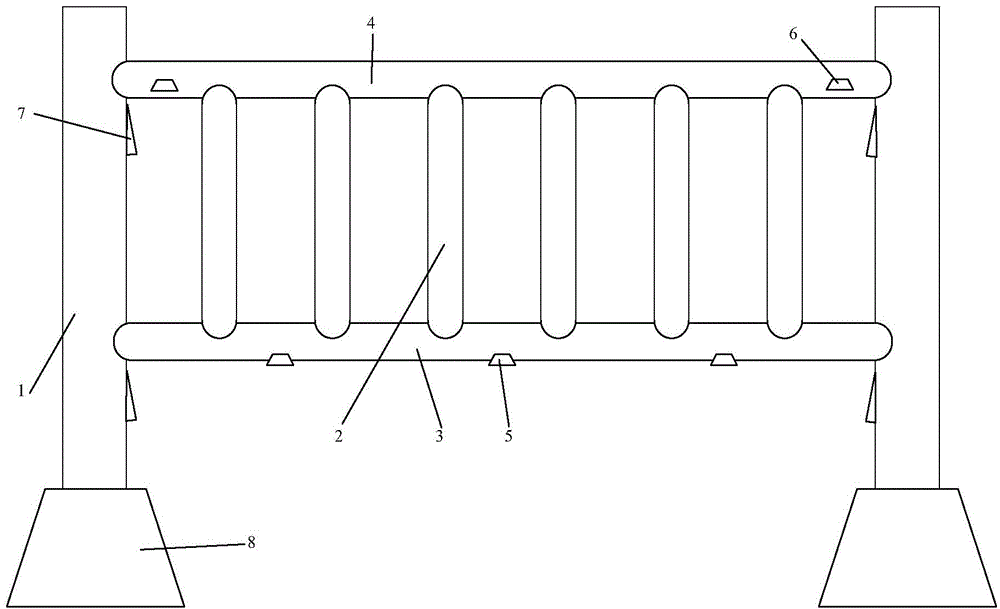

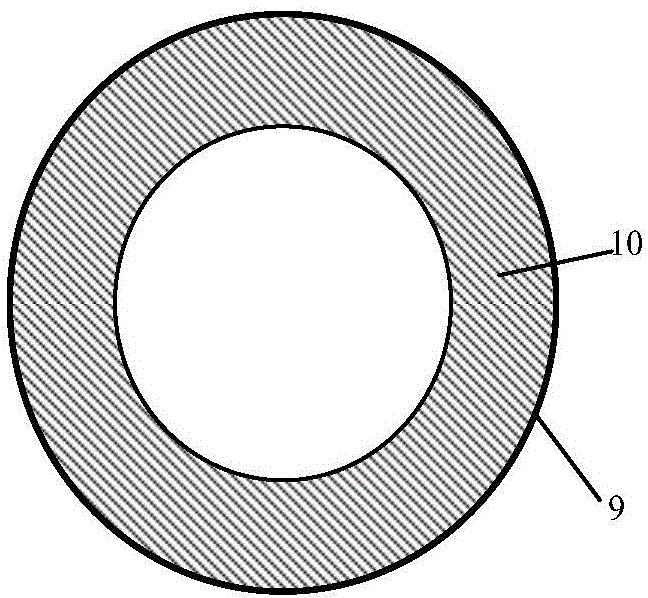

Thin-walled lightweight road barrier for air purification and manufacturing method thereof

ActiveCN104314024AReduce pollutionSaving claySolid waste managementWater-setting substance layered productVertical barEngineering

The invention relates to a thin-walled lightweight road barrier for air purification, comprising a barrier frame composed of vertical posts, a plurality of vertical bars, a lower cross bar, an upper cross bar and a base. The vertical bars are disposed in parallel between the upper cross bar and the lower cross bar; each vertical post is provided with two post vents, arranged at the parts, in connection with the upper cross bar and the lower cross bar, of the vertical post respectively; the lower portion of the lower cross bar is provided with a plurality of lower cross bar vents; the sides of two ends of the upper cross bar are provided with upper cross bar vents between the vertical bars; the lower cross bar vents, the upper cross bar vents and the post vents all open down; each vent is provided with a waterproof breathable cap. The thin-walled lightweight road barrier for air purification has the advantages that a great amount of industrial waste can be consumed, environmental pollution is reduced, clay of fertile lands is greatly saved, waste is turned into wealth, a great amount of harmful matters in air are absorbed and degraded, efficient utilization of resources is achieved, pollution is effectively reduced, and air is purified.

Owner:响水科迪混凝土制品有限公司

Production process of water-permeable, air-permeable and air-purifying pavement bricks

The invention provides a production process of a water-permeable and air-permeable paving brick capable of purifying air and belongs to the technical filed of transportation facilities. The production process comprises the following steps of adding higher than 10% of high-titanium dry slag into industrial waste slag, coal gangue and zeolite, adding 1% of sodium carbonate and 2.5% of water glass, uniformly stirring, calcining, adding a low-temperature binder, stirring, carrying out compression molding and then calcining into microporous honeycomb with capillary through holes. By the production process, a lot of industrial wastes can be consumed to produce the water-permeable and air-permeable paving brick capable of purifying air, the environmental pollution can be reduced, the large fertile farmland clay is saved, the waste is changed into treasure, harmful substances in the air can be largely absorbed and degraded, the production process is an effective way to achieve efficient utilization of resources and meanwhile, the pollution can be effectively reduced and the air is purified.

Owner:SHENYANG JIANZHU UNIVERSITY

Resonant Excited Rotary Tiller Roller Anti-sticking Device and Rotary Tiller Equipped with the Same

ActiveCN111448854BLow retrofit costSaving clayTilling equipmentsConvex structureStructural engineering

The invention discloses an anti-sticking device for rotary cultivator blade rollers based on resonance excitation, which includes an anti-sticking knife set, a resonance source device, a buffer device and a resonance adjustment device; the anti-sticking knife set consists of a plurality of soil scrapers It is connected with multiple anti-winding knives and can move along the axial direction of the cutter shaft as a whole; the resonance source device includes a resonance unit and a concave-convex vibration device; the resonance unit includes a first support, a resonance shaft and a sleeve A resonant spring on the resonant shaft; the surface of the concave-convex vibrating device is provided with a concave-convex sliding surface around the cutter shaft; one end of the resonant shaft is connected with the anti-stick wrapping knife group, and the other end is close to the concave-convex sliding surface; The resonance adjustment device uses a screw nut mechanism to adjust the concave-convex structure of the concave-convex sliding surface. The present invention also provides a rotary tiller equipped with the above-mentioned rotary tiller roll anti-sticking device. The invention utilizes the rotating power of the knife roller to generate vibration without an external drive source, can solve the problem of clay and entanglement in real time, and improves the efficiency of the rotary tillage operation.

Owner:HUAZHONG AGRI UNIV

Coal gangue thermal insulation raw soil block and preparation method thereof

InactiveCN102926499BReduce pollutionSaving clayConstruction materialSolid waste managementInsulation layerThermal insulation

This invention provides a coal gangue thermal insulation raw soil block. The coal gangue thermal insulation raw soil block is composed of a thermal insulation layer, an inner and outer protective layer, an end protective layer and a middle rib. The thickness of the thermal insulation layer is 140-160mm; The thickness of the protective layer is 60~70mm; the thickness of the end protective layer and the middle rib is 50~60mm. The effect and advantage of the invention is that it can consume a large amount of agricultural and forestry waste and coal gangue to produce energy-saving building wall materials, which can not only reduce environmental pollution, save a large area of fertile land clay, turn waste into treasure, but also save a large amount of fuel coal. Greatly improve the energy-saving capacity of buildings, enhance the effect of thermal insulation, durable, safe and fireproof, and effective sound insulation. The construction is convenient, the speed is fast, the masonry efficiency is high, the material is saved, the blocks are light in weight, and the cost is low.

Owner:SHENYANG JIANZHU UNIVERSITY

Straw raw soil thermal insulation block without thermal bridge and preparation method thereof

InactiveCN102912926BReduce pollutionSaving clayConstruction materialClimate change adaptationEnvironmental resource managementHeat conservation

Owner:SHENYANG JIANZHU UNIVERSITY

Self-insulation immature soil building block adopting industrial and agricultural waste

The invention provides a self-insulation immature soil building block adopting industrial and agricultural waste. The self-insulation immature soil building block mainly comprises an immature soil protection layer mainly containing industrial waste, an immature soil insulation layer mainly containing agricultural waste as a main material, and the like, and is characterized in that a production material comprises industrial waste residue, clay, agricultural waste, a fire-proofing agent, a mildew preventive and the like, a certain proportion of plasticizer, early strength agent and antifreeze agent can be added; the industrial waste residue can be coal ash, waste residue from a steel mill, smelting slag from a nonferrous metal smelting plant, chemical waste gypsum, chemical lime, building rubbish and the like; and the agricultural waste can be crop straws such as rice straws, cone stalks and sorghum stalks. The self-insulation immature soil building block has the advantages and the effects that a large quantity of forestry and agricultural residues and industrial waste residue can be consumed, an energy-saving building wall body material is produced, environment pollution can be reduced, fertile farmlands and clay can be saved, waste is turned into wealth, and a plurality of quantity of fuel coal can be saved. The energy saving capacity of a building is greatly improved, the insulation and heat isolation effect is enhanced, the durability and the safety are achieved, fire is prevented, and sound is effectively isolated. The self-insulation immature soil building block has the advantages of convenience in construction, high speed, high construction efficiency, material saving, light weight and low cost.

Owner:SHENYANG JIANZHU UNIVERSITY

A drilling fluid for protecting coalbed methane reservoirs

InactiveCN103194189BEffective protectionAvoid damageDrilling compositionMaterial analysisClay mineralsAdditive ingredient

The invention discloses a drilling fluid capable of protecting a coal bed methane reservoir. The drilling fluid comprises the following ingredients in percentage by weight: 100 parts of fresh water, 0.1-0.3 part of pH value modifier, 0.5-10 parts of water-sensitivity inhibitor, and 0.1-1 part of waterproof blocking agent. For the drilling fluid, the density is 1.01-1.08g / cm<3>, the pH value ranges 8 to 10, the expansion rate reduction ratio is greater than or equal to 60%, the contact angle reduction rate is greater than or equal to 50%, the hygroscopic-state recovery rate of the core permeability is greater than or equal to 85%, the dry-state recovery rate is greater than or equal to 95%, the coal powder landberra volume reduction rate is greater than or equal to 15%, clay-free phase does not exist, the damage to the coal bed methane reservoir caused by same-phase invasion can be furthest reduced, the hydration of the clay mineral in coal petrography can be effectively prevented, water blocking is reduced, the coal bed methane can be forced to be desorbed from the surface of the coal petrography, the coal bed methane reservoir can be effectively protected, the stability of the coal bed well wall can be retained, the practicability is strong, and the stronger popularization and application values can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com