Energy-dissipation speed-reduction anti-collision guardrail for purifying air and processing method thereof

A technology for air purification and anti-collision guardrails, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve air pollution and other problems, achieve the effects of reducing pollution, reducing environmental pollution, and protecting life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

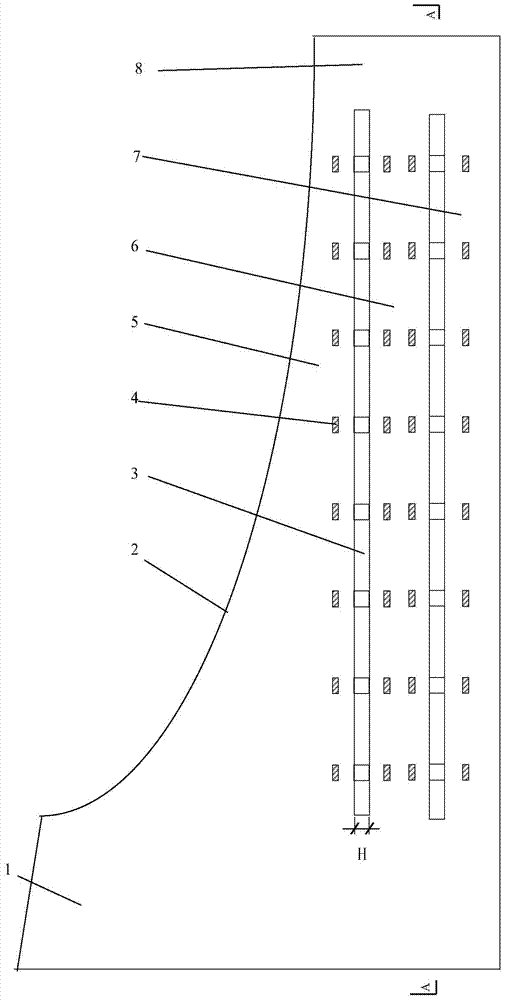

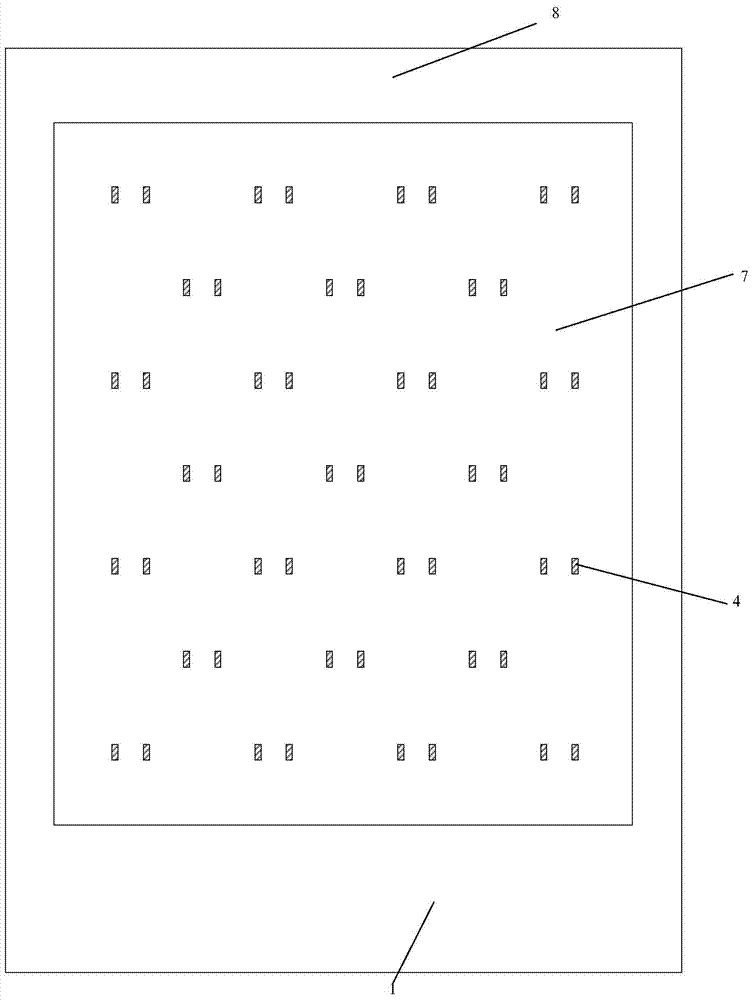

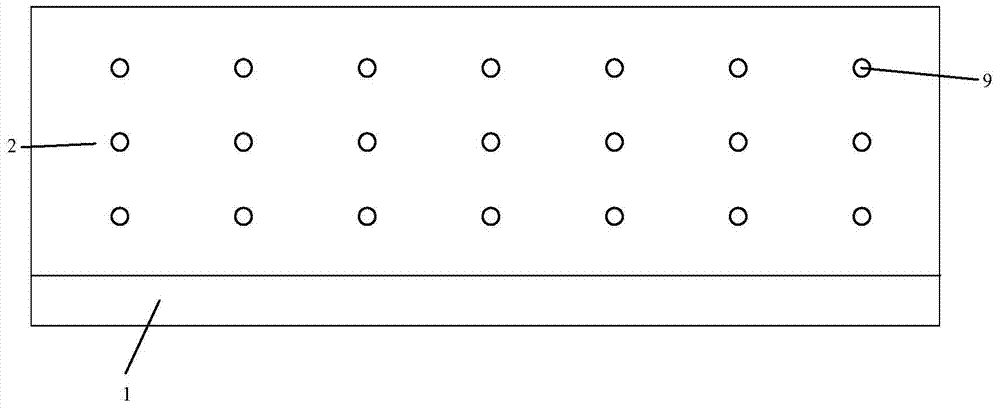

[0035] Embodiment 1: as Figure 1~Figure 3 As shown, the present invention includes a corbel 1, a first-floor deceleration and anti-collision curved panel 5, a second-floor deceleration and anti-collision flat panel 6, a support plate 7, an energy-dissipating ventilation cavity 3, a top beam 8 and an energy-dissipating soft steel ring 4, The outer side of the first layer of deceleration and anti-collision curved panel 5 is an anti-collision curved surface 2, and the inner side is a vertical facade, and its section gradually decreases from bottom to top; Rectangular; between the first layer of deceleration and anti-collision curved panels 5, the second layer of deceleration and anti-collision flat panels 6 and the support plate 7, energy-consuming ventilation cavities 3 are respectively arranged, and the first and second floors of deceleration and anti-collision flat panels 5, 6 and The upper and lower ends of the support plate 7 are respectively connected by the corbel 1 and t...

Embodiment 2

[0042] Embodiment 2: The difference from Embodiment 1 is that the thickness H of the energy-dissipating ventilation cavity 3 in this embodiment is 30 mm.

[0043] In the masonry method of this example block:

[0044] Step 1: Burn zeolite powder with a particle size of 2mm at 550°C for 1 hour;

[0045] Step 2: Add high-titanium heavy slag containing more than 10% titanium dioxide, the mass ratio of zeolite powder to high-titanium heavy slag is 2:1, and heat to 700°C for 2 hours;

[0046] The third step: the mixture of the second step, Portland cement, coarse sand, and gravel are evenly stirred, and the parts by weight of each component are respectively: the mixture of the second step: 20, Portland cement: 80, Coarse sand: 250, gravel 300, mix into concrete according to the water-cement ratio of 0.2, and pour the energy-dissipating and decelerating anti-collision guardrails for air purification.

Embodiment 3

[0047] Embodiment 3: The difference from Embodiment 1 is that the thickness H of the energy-dissipating ventilation cavity 3 in this embodiment is 25 mm.

[0048] In the masonry method of this example block:

[0049] Step 1: Burn zeolite powder with a particle size of 0.5mm at 500°C for 2 hours;

[0050] Step 2: Add high-titanium heavy slag containing more than 10% titanium dioxide, the mass ratio of zeolite powder to high-titanium heavy slag is 2:1, and heat to 600°C for no less than 2 hours;

[0051] The third step: the mixture of the second step, Portland cement, coarse sand, and gravel are stirred evenly, and the parts by weight of each component are: the mixture of the second step 50, Portland cement 100, coarse sand 250, gravel 300, mixed into concrete according to the water-cement ratio of 0.25, and pouring energy dissipation deceleration anti-collision guardrails for air purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com