A kind of nanoscale Pickering emulsion type fracturing fluid and its preparation method

A Pickering emulsion, nano-level technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult molecular weight control, low solid content of aqueous solution, high transportation cost, and achieve excellent surface activity reduction function, Good sand suspending ability and simple liquid dispensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

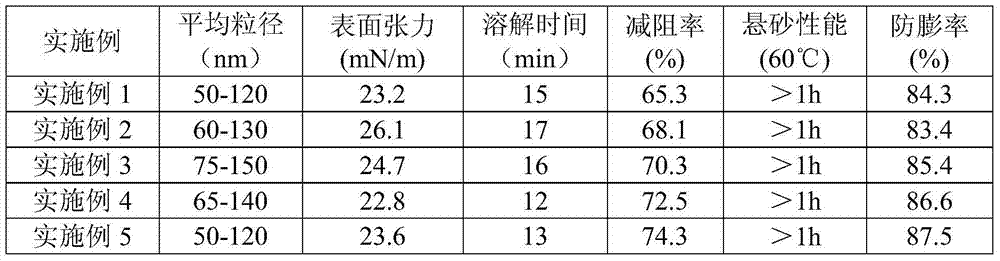

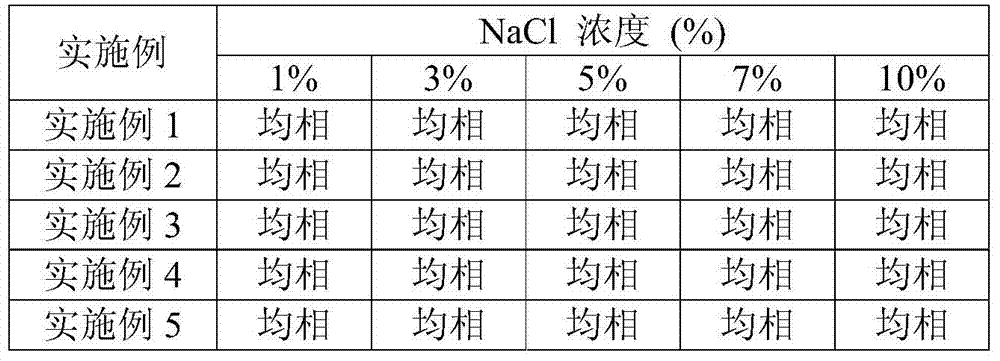

Examples

Embodiment 1

[0036] This example provides a method for preparing nanoscale Pickering emulsion type fracturing fluid, which is specifically carried out through the following steps:

[0037] (1) Preparation of water phase

[0038] 15 parts by weight of acrylamide, 1 part by weight of methacryloyloxyethyltrimethyl ammonium chloride, 1 part by weight of octyl alcohol polyoxyethylene ether maleic acid diester, 1 part by weight of polyvinyl alcohol 15 parts by weight of ammonium sulfate are mixed, dissolved in 50 parts by weight of deionized water, stirred and dissolved to form an aqueous phase evenly.

[0039] (2) Preparation of oil phase

[0040] Dissolve 1 part by weight of Span-80 and 1 part by weight of Tween-80 emulsifier in 50 parts by weight of white mineral oil, stir and dissolve to form an oil phase evenly.

[0041] (3) Preparation of nanoscale Pickering emulsion fracturing fluid

[0042]The above-mentioned prepared water phase and oil phase are mixed and stirred uniformly to obtain...

Embodiment 2

[0044] This example provides a method for preparing nanoscale Pickering emulsion type fracturing fluid, which is specifically carried out through the following steps:

[0045] (1) Preparation of water phase

[0046] 20 parts by weight of N,N-dimethylacrylamide, 2 parts by weight of dimethyl diallyl ammonium chloride, 3 parts by weight of octyl alcohol polyoxyethylene ether maleic acid monoester, 2 parts by weight of Polyethylene glycol, 18 parts by weight of magnesium sulfate are mixed, dissolved in 50 parts by weight of deionized water, stirred and dissolved to form an even water phase.

[0047] (2) Preparation of oil phase

[0048] Dissolve 1 part by weight of OP-10 and 1 part by weight of Tween-80 emulsifier in 60 parts by weight of toluene, stir and dissolve to form an oil phase evenly.

[0049] (3) Preparation of nanoscale Pickering emulsion fracturing fluid

[0050] The above-mentioned prepared water phase and oil phase were mixed and stirred uniformly to obtain a pri...

Embodiment 3

[0052] This example provides a method for preparing nanoscale Pickering emulsion type fracturing fluid, which is specifically carried out through the following steps:

[0053] (1) Preparation of water phase

[0054] 24 parts by weight of 2-methacrylamide, 5 parts by weight of diethyl diallyl ammonium chloride, 3 parts by weight of nonylphenol polyoxyethylene ether maleic acid monoester, 2 parts by weight of polyethylene Diol and 20 parts by weight of potassium sulfate are mixed, dissolved in 60 parts by weight of deionized water, stirred and dissolved to form a water phase evenly.

[0055] (2) Preparation of oil phase

[0056] Dissolve 1 part by weight of OP-10 and 2 parts by weight of Span-80 emulsifier in 60 parts by weight of heptane, stir and dissolve to form an oil phase evenly.

[0057] (3) Preparation of nanoscale Pickering emulsion fracturing fluid

[0058] Mix the above-mentioned prepared water phase and oil phase and stir evenly to obtain a primary mixed liquid. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com