Light-level foamed internal wall brick and its manufacturing method

A production method and technology for wall bricks, which are applied in building components, sustainable waste treatment, solid waste management, etc., can solve the problems of easy cracking, heavy brick weight, and high labor intensity for wall building and handling, so as to reduce self-pressure , The effect of convenient construction and labor-saving handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The embodiments will be further described in detail below in conjunction with the accompanying drawings.

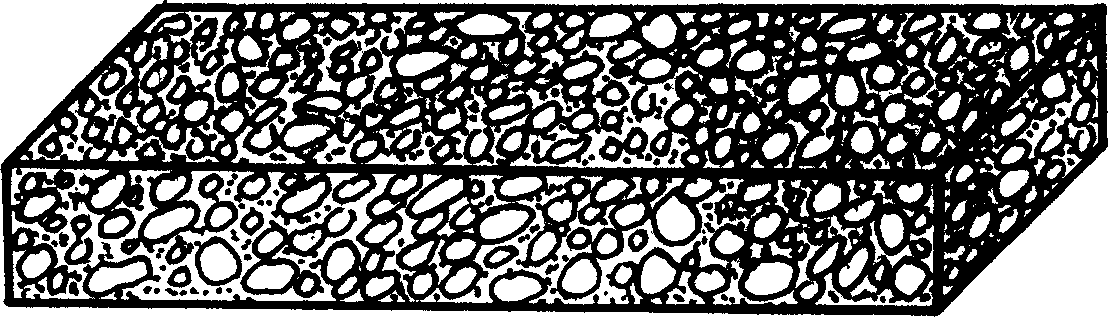

[0008] refer to figure 1 , light-weight foamed interior wall bricks, the shape is cube, similar to ordinary fired bricks, the whole includes a number of air holes formed by sintered foaming irregularly distributed inside, as the interior wall partition wall material. Its production method is to burn crystal glass-like blocks from industrial waste cinders, and the weight ratio is 74-64% after crushing; waste soil is used as one of the raw materials, accounting for 15-25% by weight; mixed with coke The weight ratio of the particles is 10%; the weight ratio of the tackifier is 1%, the mixture is evenly mixed, pressed in a special machine to form a billet, and fired in an ordinary sintered brick kiln with an open flame. When sintering, the temperature in the kiln should be controlled at 1000°C-1200°C. After foaming into a block, it should be placed in the kiln at a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com