Industrial waste residue self-insulation raw soil building block without heat bridge and preparation method thereof

An industrial waste slag and self-insulation technology, which is applied in climate change adaptation, building materials, etc., can solve the problems that there are no patents for the invention of raw soil blocks, and achieve the effect of enhancing thermal insulation effect, convenient construction, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

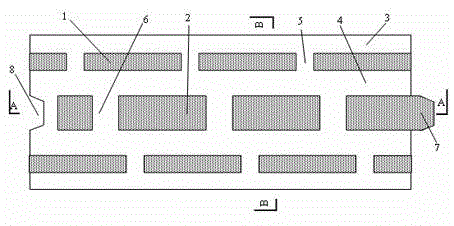

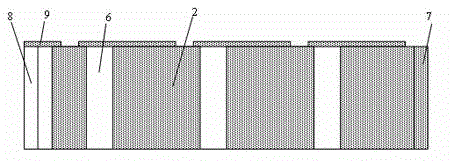

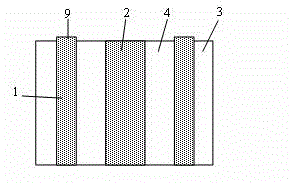

[0023] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

[0024] Such as Figure 1-3 As shown, a thermal bridge-free industrial waste slag self-insulating raw soil block of the present invention includes two side insulation boards 1, a middle insulation board 2, a raw soil protection layer 3, a raw soil layer 4, side ribs 5, and middle ribs 6. The two side insulation boards 1 are arranged on both sides of the middle insulation board 2, side ribs 5 are formed between adjacent two side insulation boards 1, middle ribs 6 are formed between adjacent middle insulation boards 2, different layers The side ribs 5 and the middle ribs 6 are arranged in a staggered manner, the outer sides of the insulation boards 1 on both sides are the raw soil protection layer 3, and the raw soil layer 4 is between the insulation boards 1 on both sides and the middle insulation board 2; The middle insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com