Patents

Literature

95results about How to "Improve masonry efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

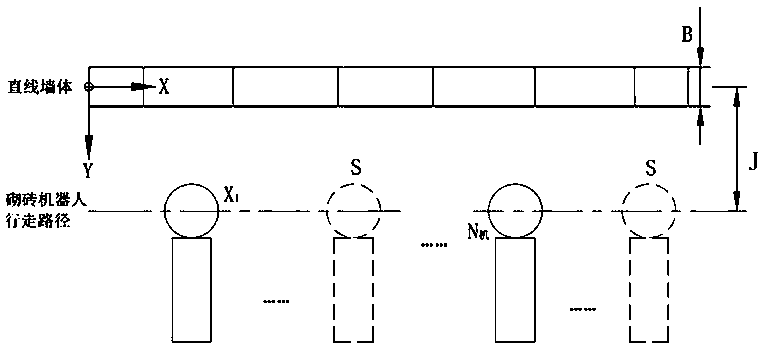

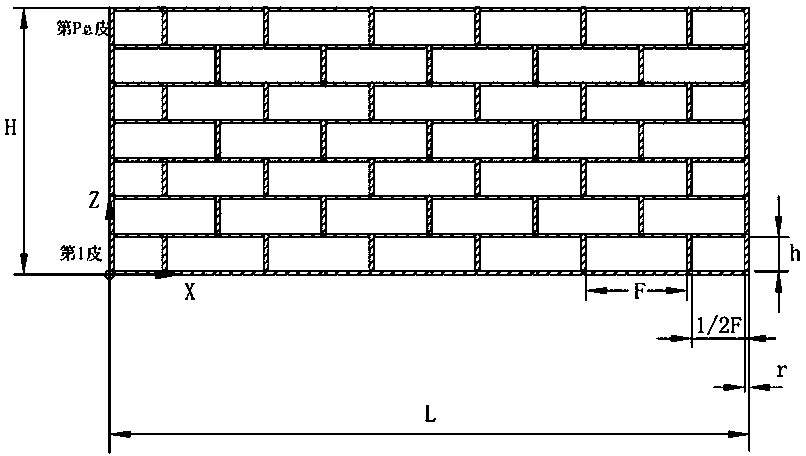

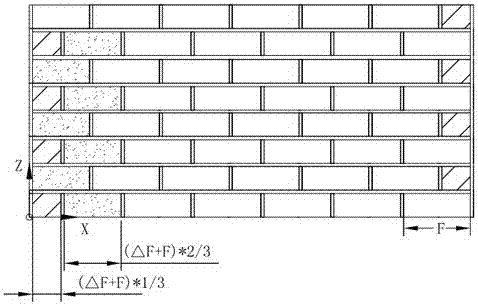

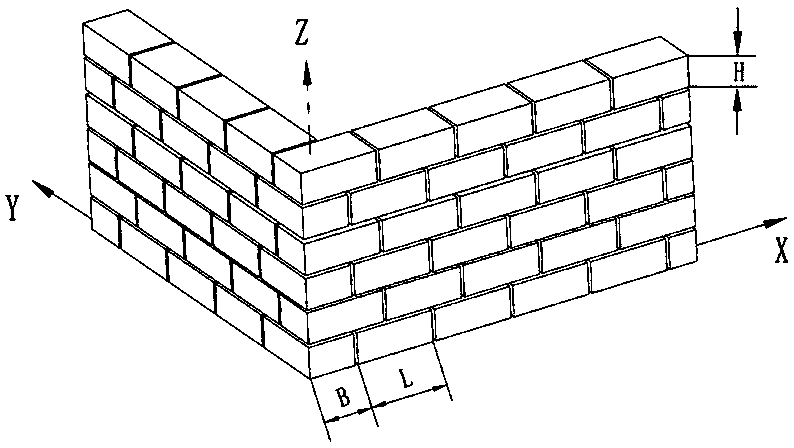

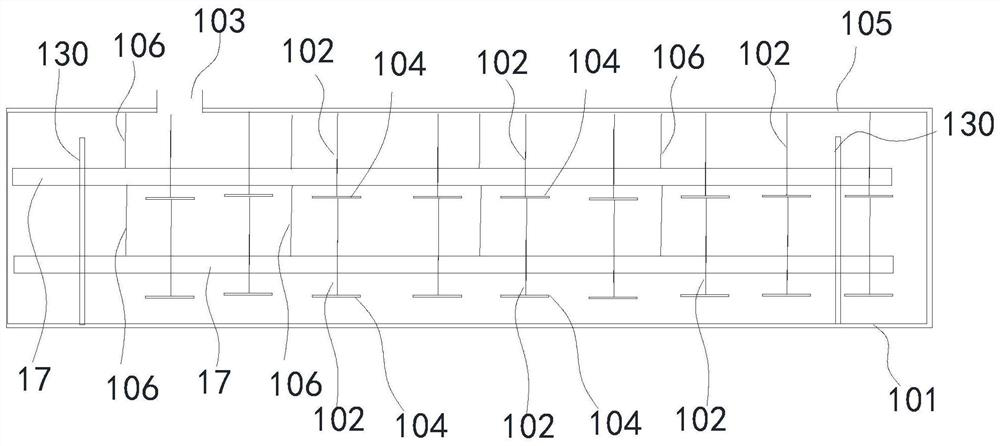

Masonry algorithm of bricking robot linear wall and taking plasticity of mortar into consideration

The invention discloses a masonry algorithm of a bricking robot linear wall and taking plasticity of mortar into consideration. The masonry algorithm comprises the following steps that a, a datum coordinate system is determined; b, the number of bricks and an arrangement mode of each brick are calculated; c, the coordinate position of each brick is calculated; d, The distance J between a linear track and a wall center line is determined; e, the mortar plastic time is determined, the number N of needed bricking robots is calculated, the number NS of bricked bricks of each standing posture of each robot is calculated, and the distance S between the adjacent standing postures is calculated; f, the number N of the needed bricking robots is calculated according to the mortar plastic time; and g, the bricking order of each robot is set up, an action command is sent to a programming control system, so that the programming control system implements corresponding action to conduct masonry of the linear wall. According to the masonry algorithm, By taking mortar plasticity condition into consideration, masonry is achieved through the multiple robots, the number of the bricked bricks of each robot is determined, the brick clamping and bricking processes are completed in the plasticity time of the mortar, the practicability is high, and the overall masonry efficiency is improved.

Owner:HUAWAY IOT TECH

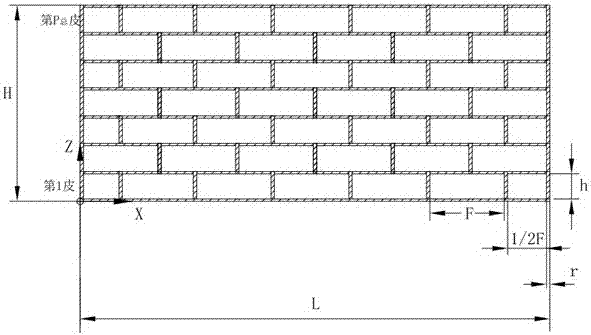

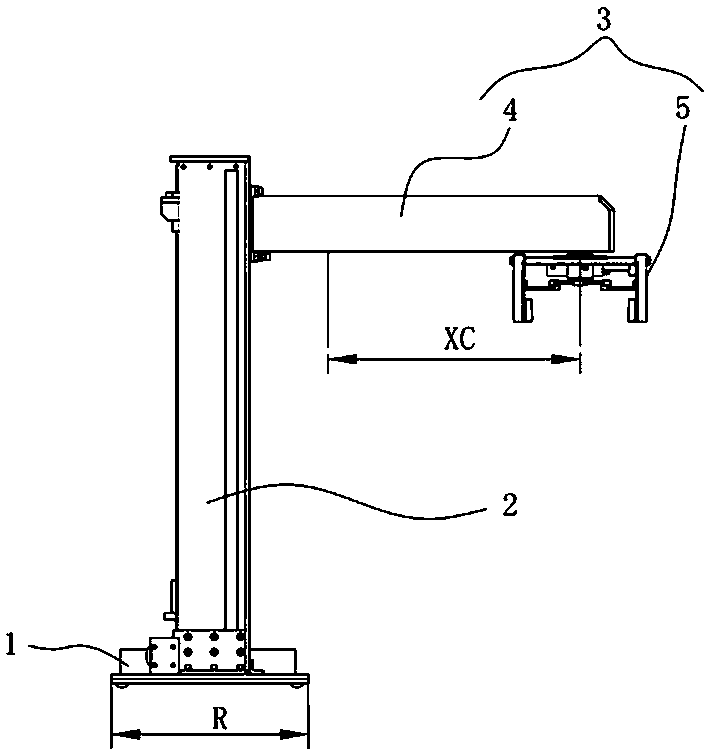

Masonry algorithm of straight wall of bricklayer robot

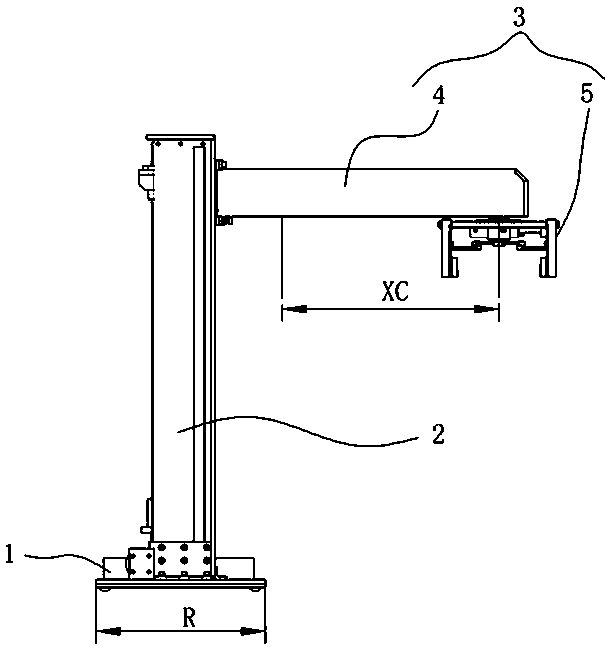

ActiveCN107357294AAccurate locationAccurate calculationBuilding material handlingPosition/course control in two dimensionsBrickControl system

The invention discloses a masonry algorithm of a straight wall of a bricklayer robot. The algorithm is implemented as follows: step a, determining a reference coordinate system; step b, calculating a standing posture position of a robot; step c, calculating a brick taking position; step d, calculating the number of layers of bricks, the number of bricks in each layer, and a central point coordinate of each brick; and step e, calculating a masonry track and sending an action instruction to a program control system to enable the system to perform a corresponding action so as to realize construction of a straight wall body. According to the invention, the brick taking position moves synchronously with a bricklayer robot; the standing posture coordinate of the bricklayer robot, the brick taking position coordinate, and the coordinate of each brick of the wall body are built, so that positions of brick clamping and brick laying become accurate. Therefore precise calculation is realized and the overall masonry quality and efficiency are improved.

Owner:HUAWAY IOT TECH

Self-flow castable for filling back seam of side wall of aluminium electrolytic bath

The invention discloses a self-flow castable capable of filling a seam between a shell and a side wall brick of an electrolytic bath, is designed special for an aluminium electrolytic bath and mainly comprises the following components: a carborundum material, a high alumina material, silica micropowderl, aluminium oxide powder and a calcium aluminate cement. The carborundum raw material used by the self-flow castable has high purity, high SiC content, relatively good bath electrolyte erosion resistance and compression strength; high heat conduction coefficients can eliminate a thermal barrierbetween the bath shell and the side wall brick and are favourable for promoting the forming of a side wall brick furnace upper; and good fluidity can guarantee that the castable uniformly fill the seam. Through the features, the self-flow castable can effectively prolong the service lives of the aluminium electrolytic bath and the side wall brick, is not limited by a construction space in castingconstruction, can quickly cast and is not fired at a high temperature in a production process. Therefore, the self-flow castable is a high-efficiency, energy-saving and environment-friendly refractory material.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

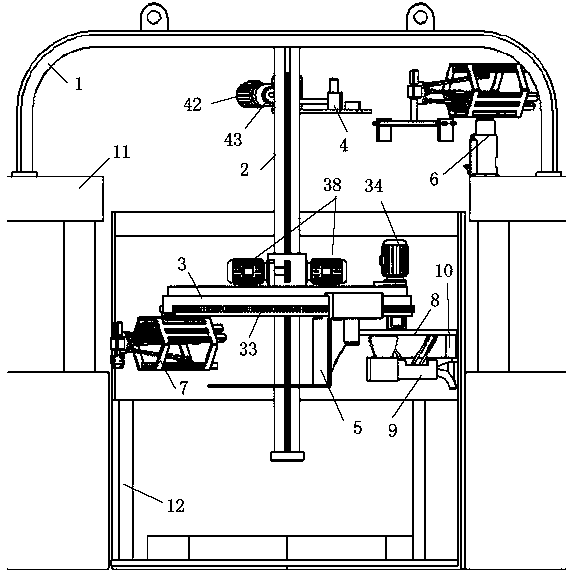

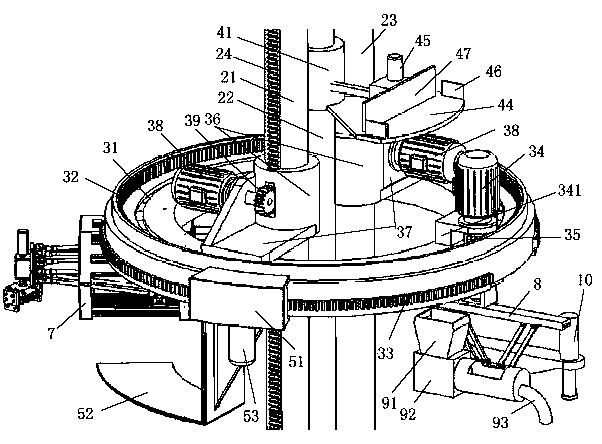

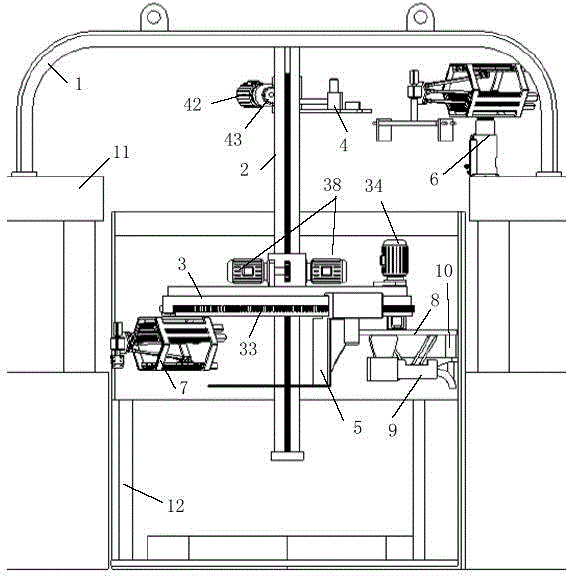

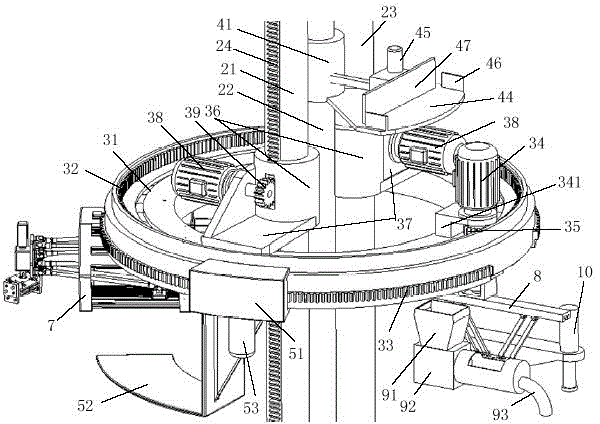

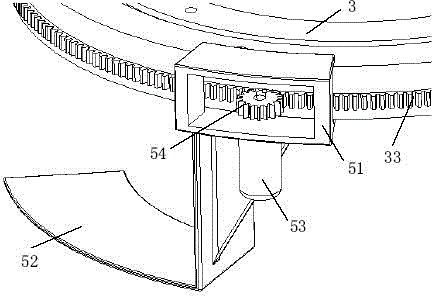

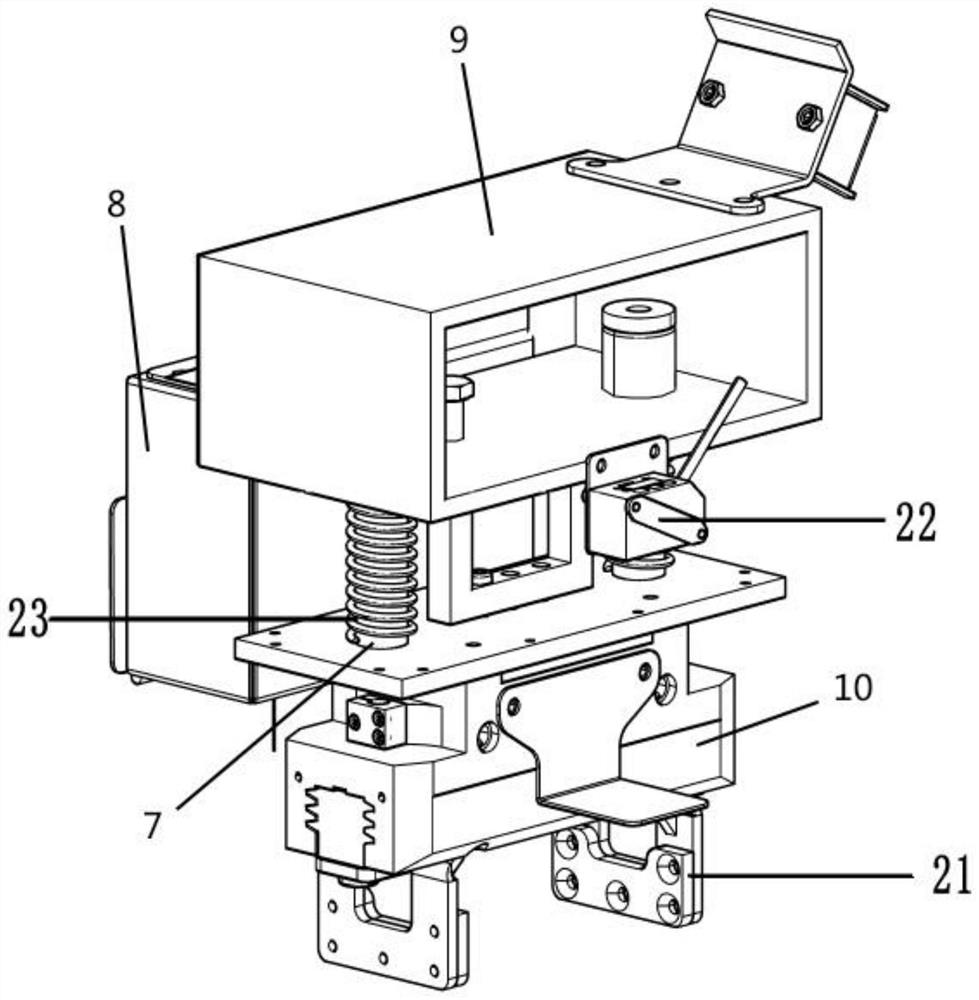

Device for building steel ladle working lining

ActiveCN103406527AConvenient automatic masonryGuarantee the accuracy of masonryMelt-holding vesselsBrickBraced frame

The invention discloses a device for building a steel ladle working lining. The bottom face of a supporting framework of the device is arranged on a steel ladle foundation in an erected mode and located above a steel ladle, the top end of a telescopic stand column set is vertically arranged in the center of the top face of the supporting framework and extends into the steel ladle, a rotation lifting platform and a brick lifting disc are arranged on the telescopic stand column set and lift along the telescopic stand column set, the brick lifting disc is arranged at the outer edge of the rotation lifting platform and rotates along the rotation lifting platform, a brick building mechanical arm and a pouring posture adjusting mechanism are fixedly arranged at the outer edge of the rotation lifting platform in a spaced mode, the tail end of the pouring posture adjusting mechanism moves horizontally within a vertical surface in a two-dimensional mode, a spiral conveyer and a vibratory hammer are fixedly arranged at the tail end of the pouring posture adjusting mechanism, and a feeding mechanical arm is arranged on the steel ladle foundation and is close to the steel ladle. The device brings convenience to automatic building of the steel ladle working lining, effectively relieves labor intensity of the building operation, improves building efficiency, ensures building accuracy of the steel ladle working lining, and prolongs the service life of the steel ladle working lining.

Owner:CHINA FIRST HEAVY IND

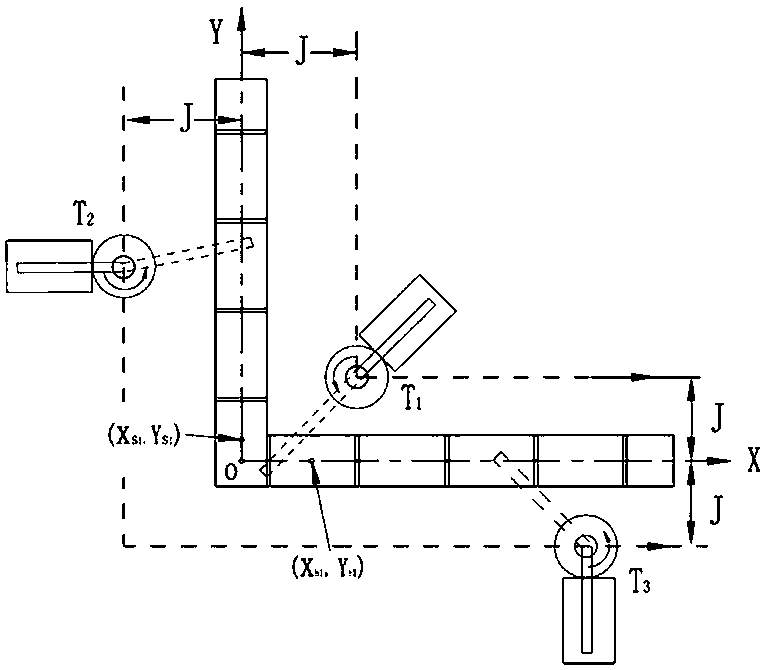

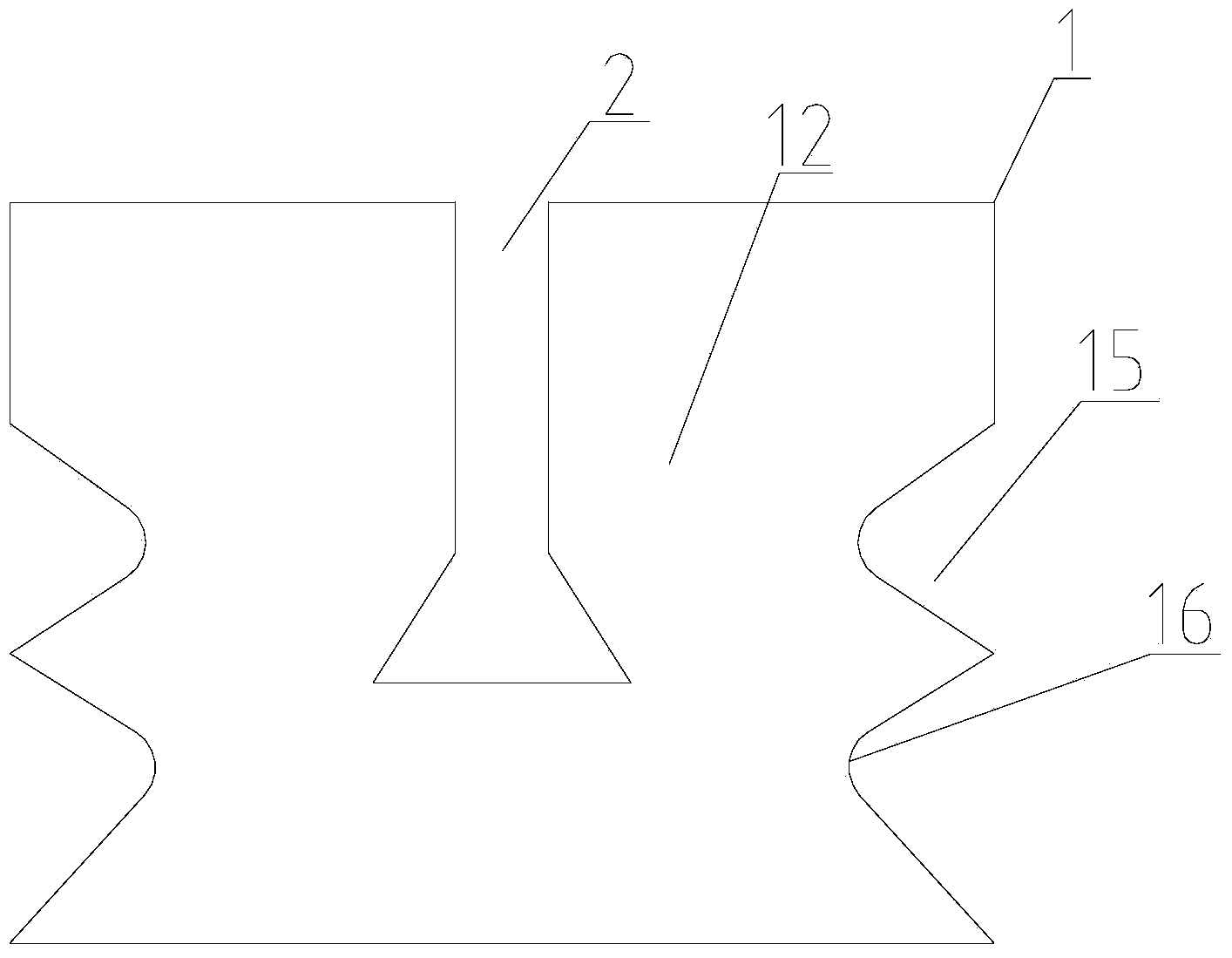

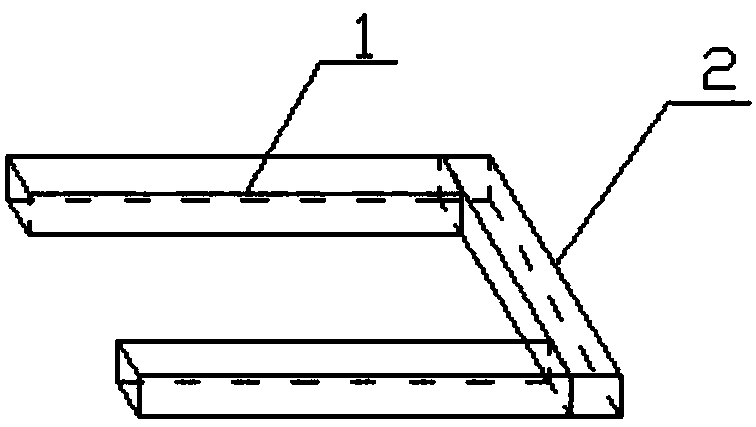

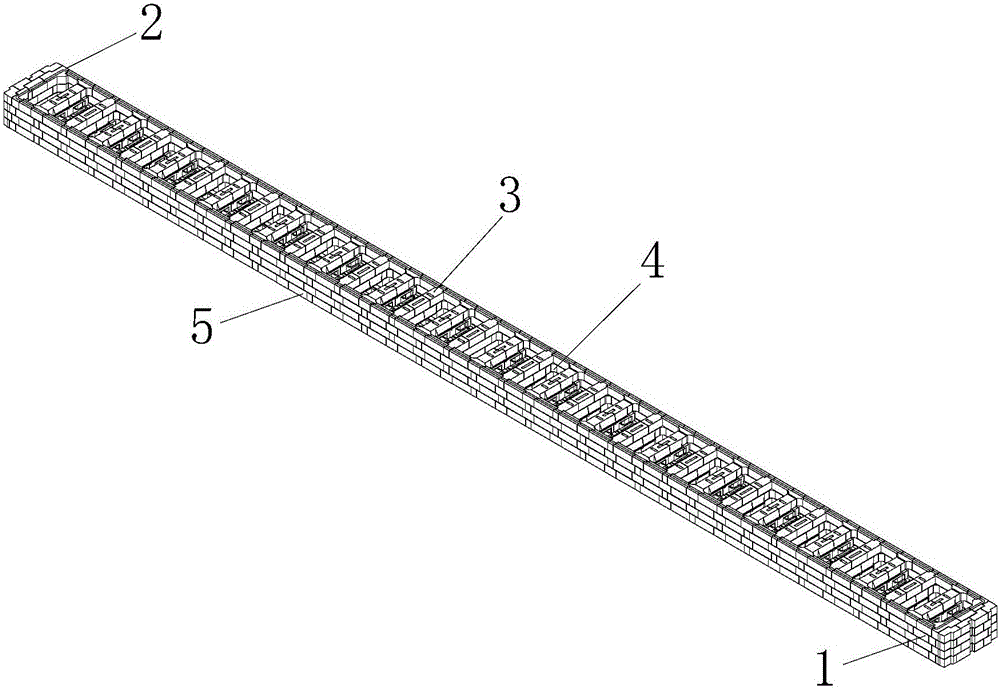

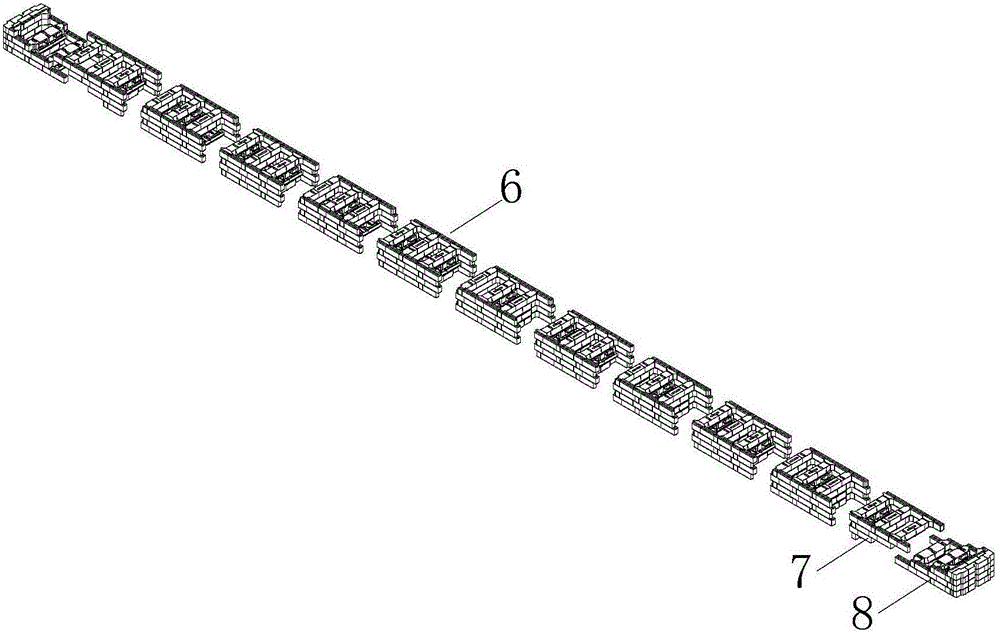

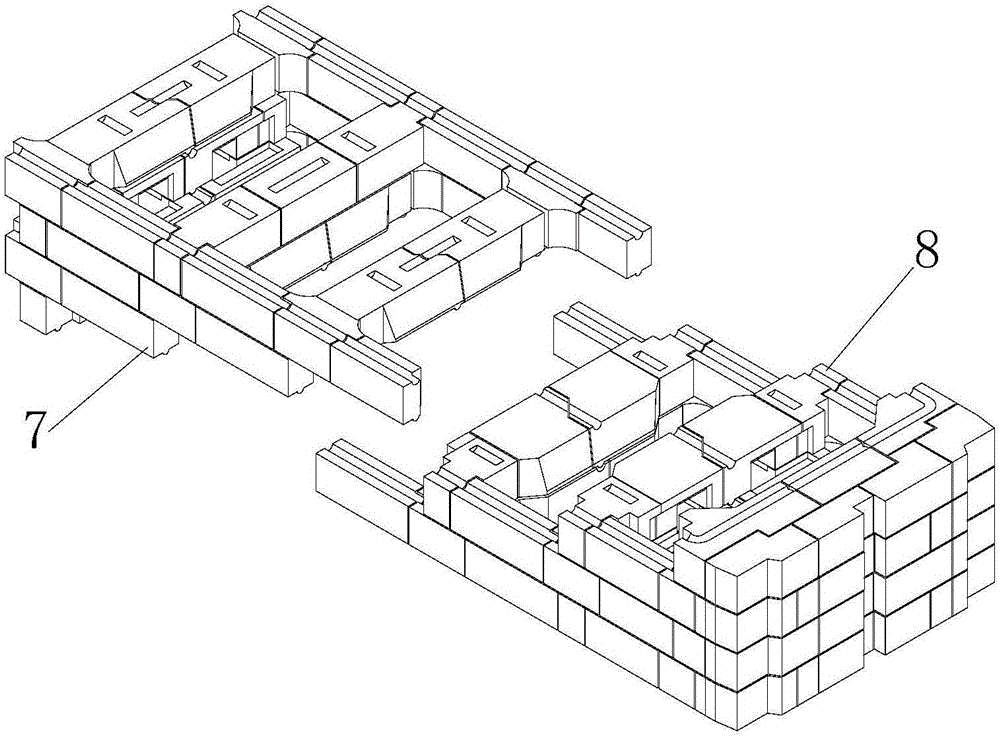

Right-angled wall bricking method of bricking robots

ActiveCN107605167AImprove masonry efficiencyBuilding material handlingStructural engineeringMechanical engineering

The invention discloses a right-angled wall bricking method of bricking robots. The method comprises the following steps that a, a reference coordinate system is determined; b, the number of layers ofbricks is calculated, the arrangement mode of each layer of bricks is simulated, and the coordinate position of each brick is calculated; c, the multiple bricking robots are arranged near a wall; d,the coordinate positions of the bricking robots at the corners, the standing posture of each linear bricking robot and the coordinate position of each standing posture are determined; and e, the action instruction that each bricking robot clamps bricks from the brick fetching position at each position and constructs bricks one by one and layer by layer is created, and sent to a programming controlsystem, so that the robots carry out corresponding actions to brick the right-angled wall. The bricking robots are adopted for bricking of the right-angled wall, the arrangement mode of each layer ofbricks is simulated by establishing the coordinate system, the standing posture position of each bricking robot is determined, and thus the bricking robots automatically brick the right-angled wall according to the control instruction, cross wall engagement bricking is conducted, integrality is high, and the wall is firm.

Owner:HUAWAY IOT TECH

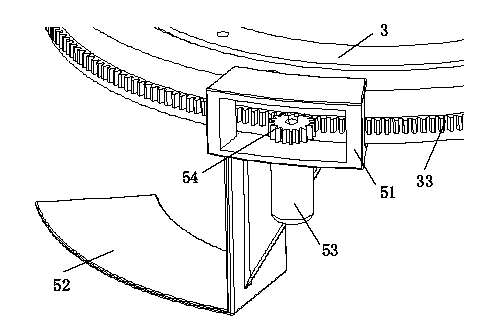

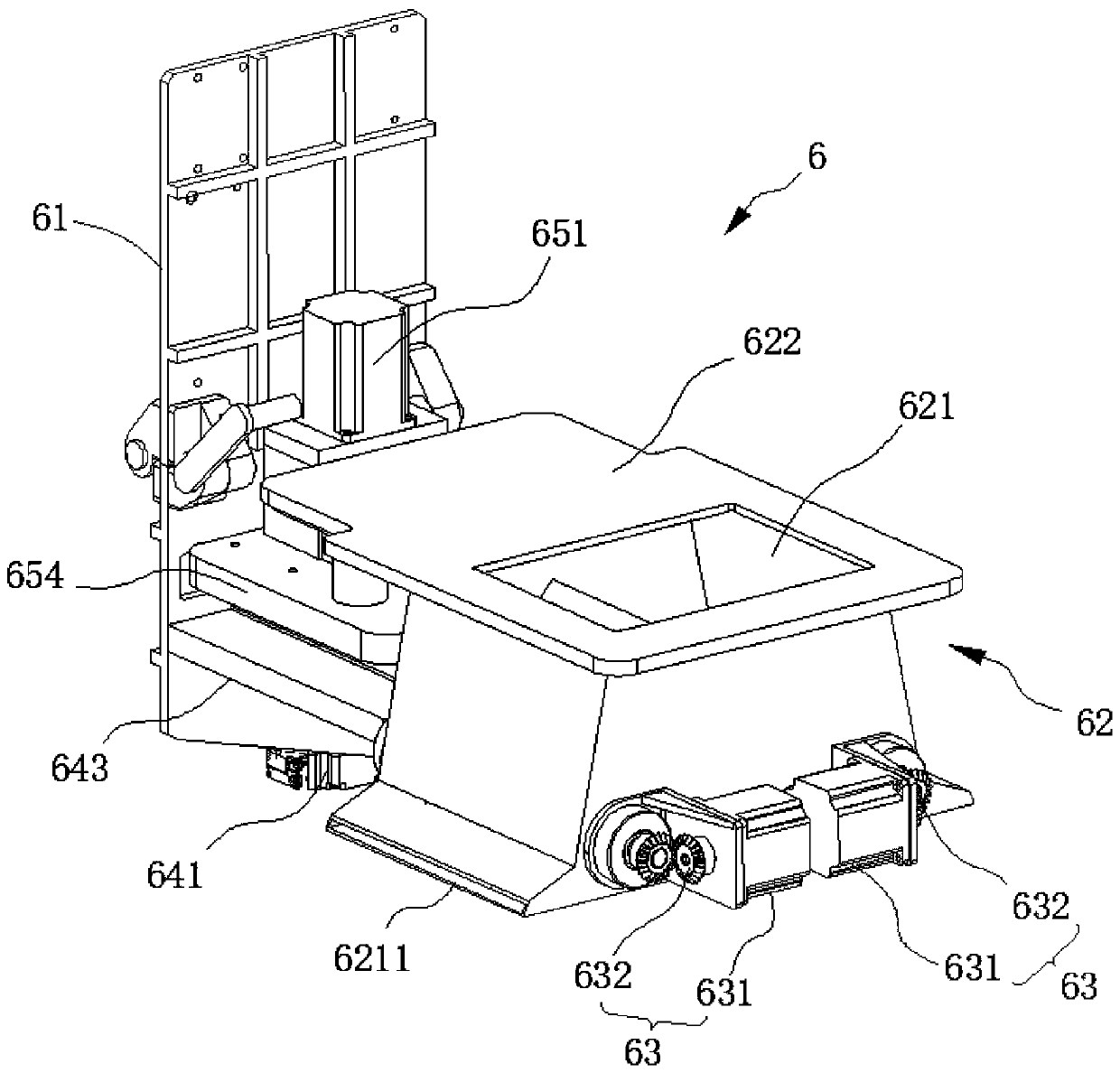

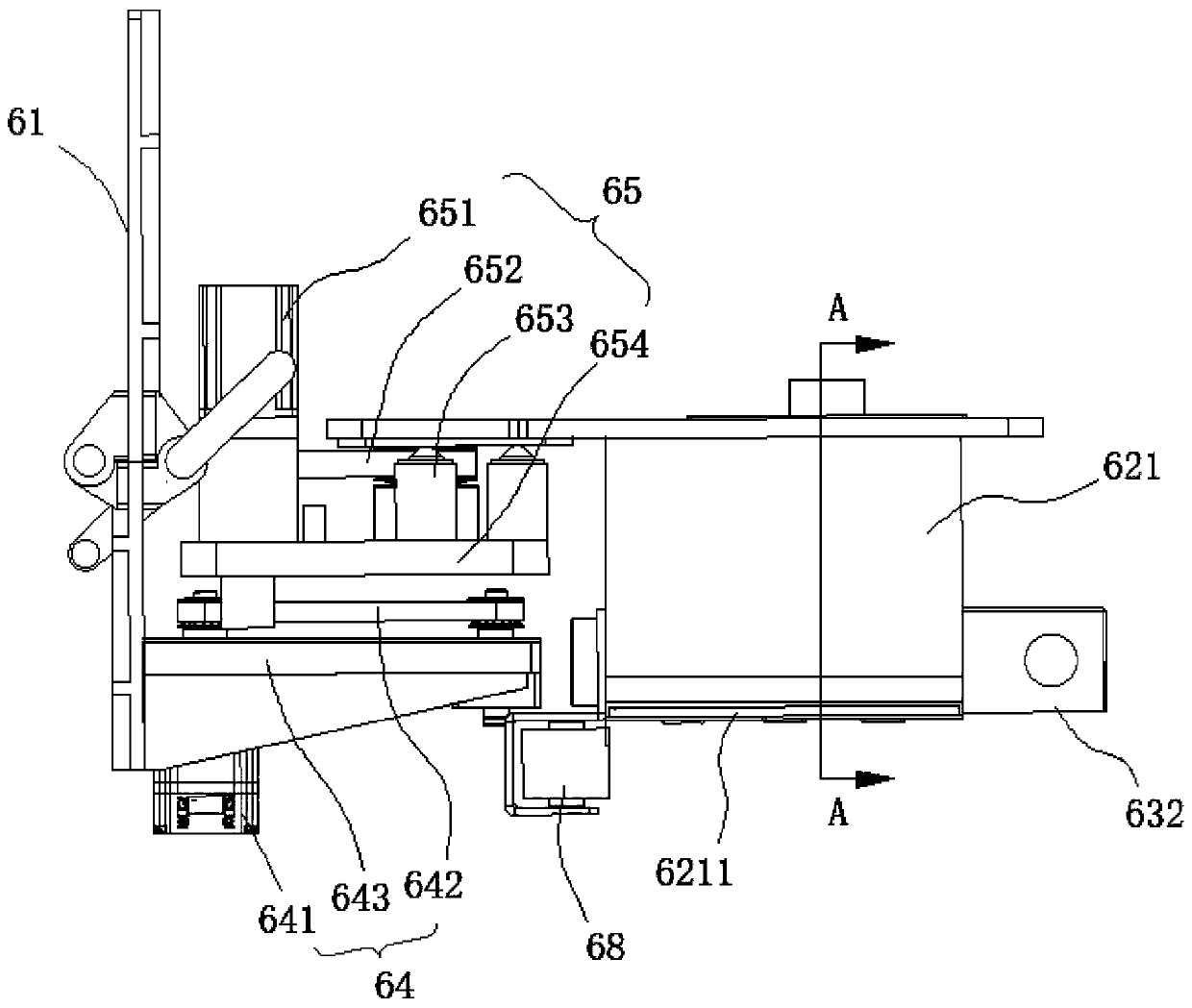

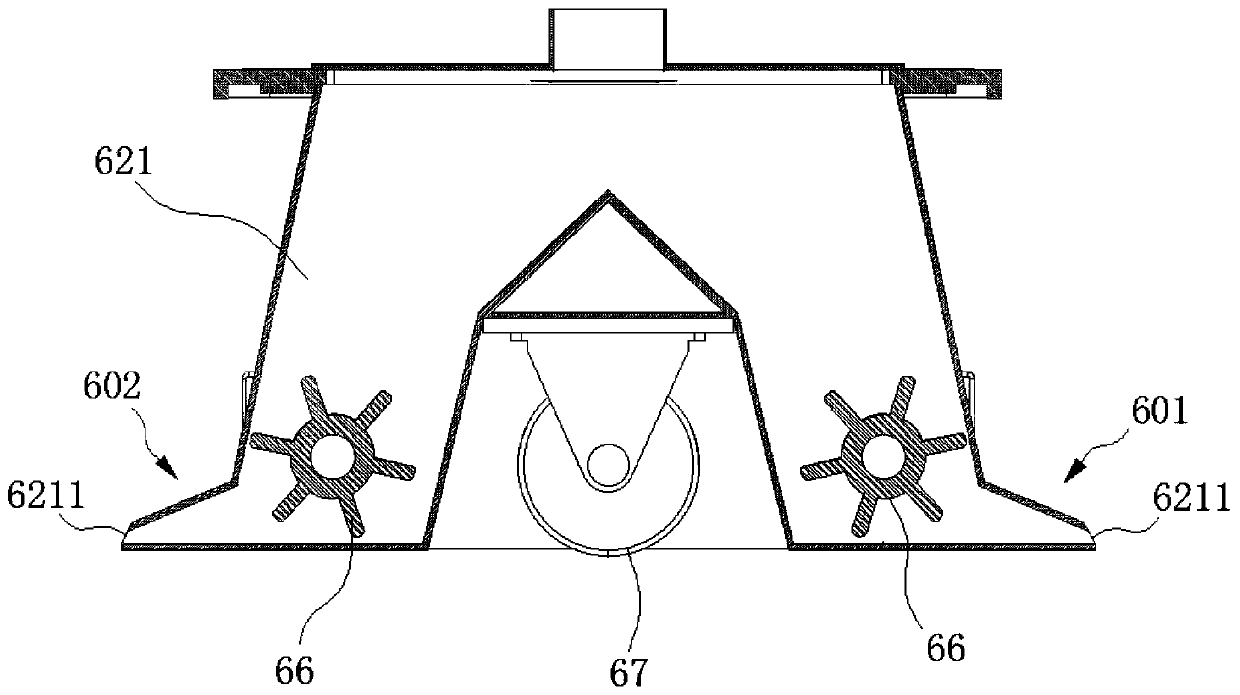

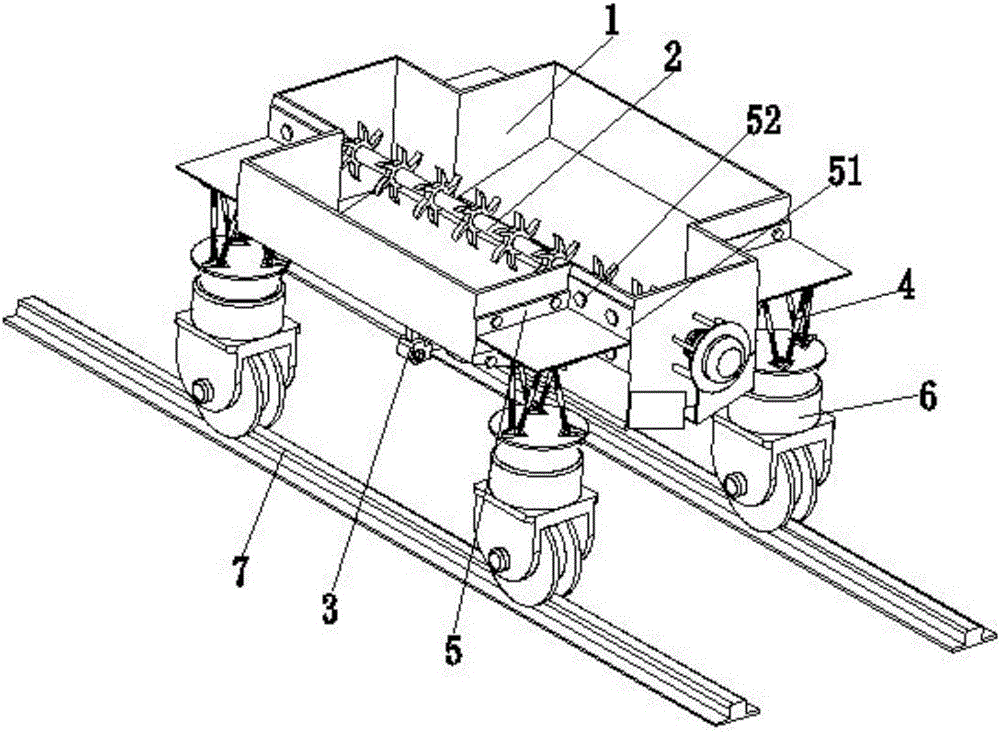

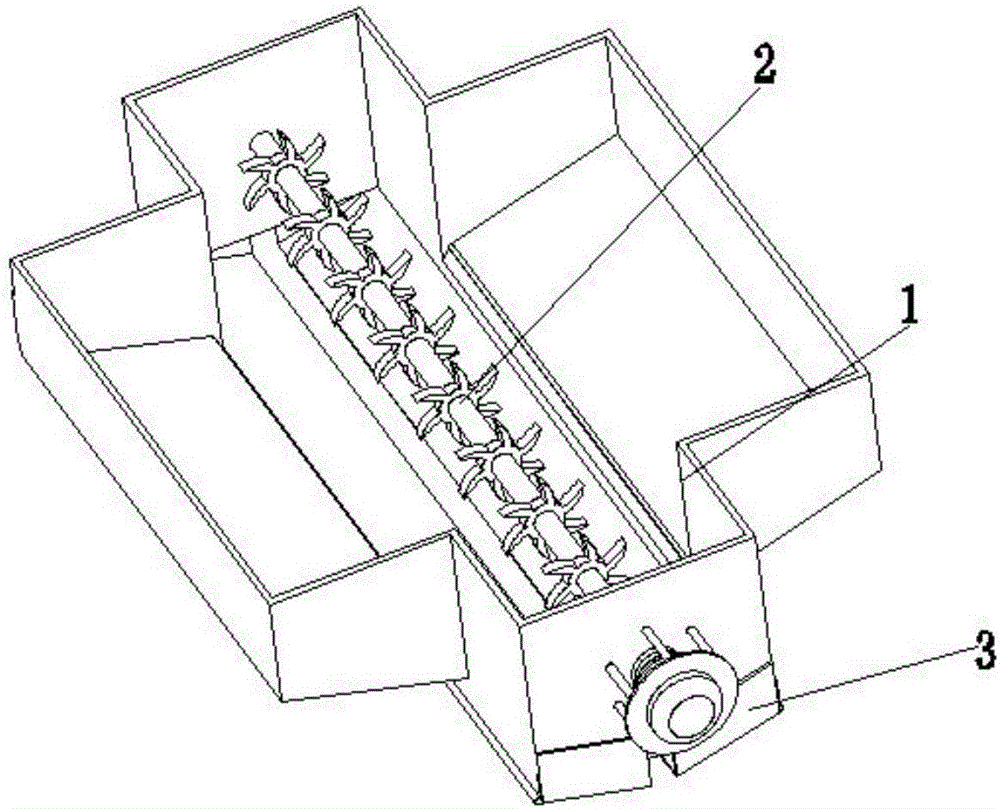

Plastering device, plastering robot and masonry equipment

InactiveCN111287475AEasy to moveAchieve two-way reciprocating slurry effectBuilding material handlingBrickArchitectural engineering

The invention provides a plastering device, a plastering robot and masonry equipment, and relates to the technical field of construction machinery. The plastering device comprises a plastering support, a slurry bin and a support wheel, wherein the slurry bin is mounted on the plastering support, the two opposite ends of the bottom of the slurry bin are each provided with a discharging port, slurryflows to the position to be plastered through the discharging ports, and when the slurry is plastered, one of the two discharging ports is chosen to open; the support wheel is mounted on the slurry bin and disposed between the two discharging ports for supporting the slurry bin. The plastering robot comprises the plastering device. According to the plastering device and the plastering robot, theslurry smearing precision is improved, meanwhile, the two-way reciprocating plastering effect on a masonry wall surface can be achieved, and the plastering uniformity is improved. The masonry equipment comprises a sliding rail assembly, a brick feeding trolley, a masonry robot and the plastering robot used for plastering the masonry wall surface, full-automatic masonry of the wall surface can be achieved, and the masonry efficiency and precision of the wall surface are improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

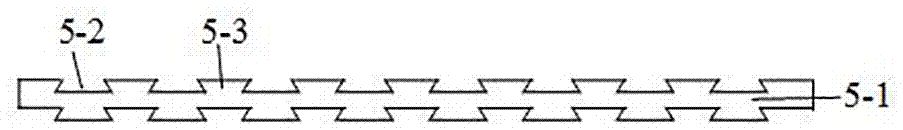

Hanging brick special for kiln covers

ActiveCN103615896AConvenience for masonryImprove masonry efficiencyFurnace componentsBuilding materialMaterials science

The invention relates to cement production equipment accessories, in particular to a hanging brick special for kiln covers. The hanging brick is characterized in that a hanging structure used for preventing building materials from shedding is arranged on a building surface of a brick body, and due to the fact that the building materials used for brick body building have certain viscosity and the building materials enter the hanging structure during brick body building, the building materials are prone to shedding under the action of the hanging structure and the viscosity of the building materials, convenience in brick body building is achieved, and building efficiency of the a refractory layer of a kiln is improved.

Owner:长兴盛华耐火材料有限公司

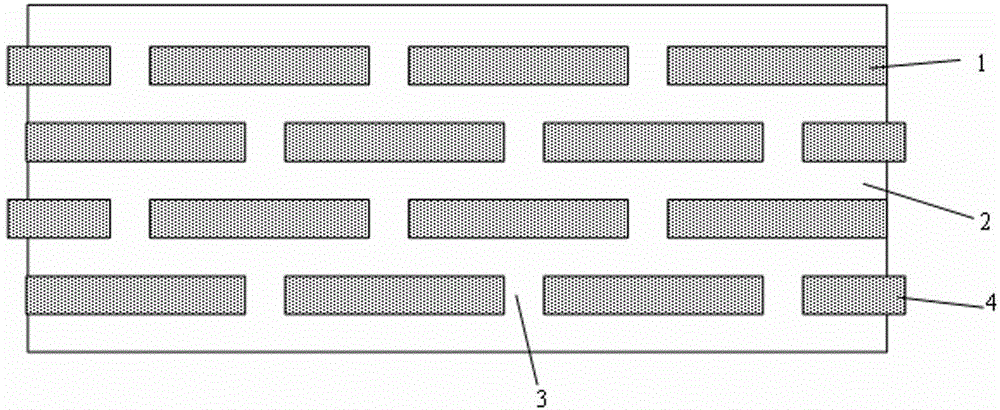

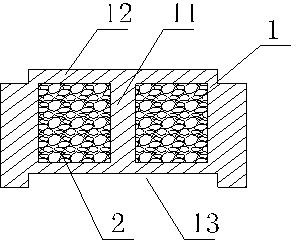

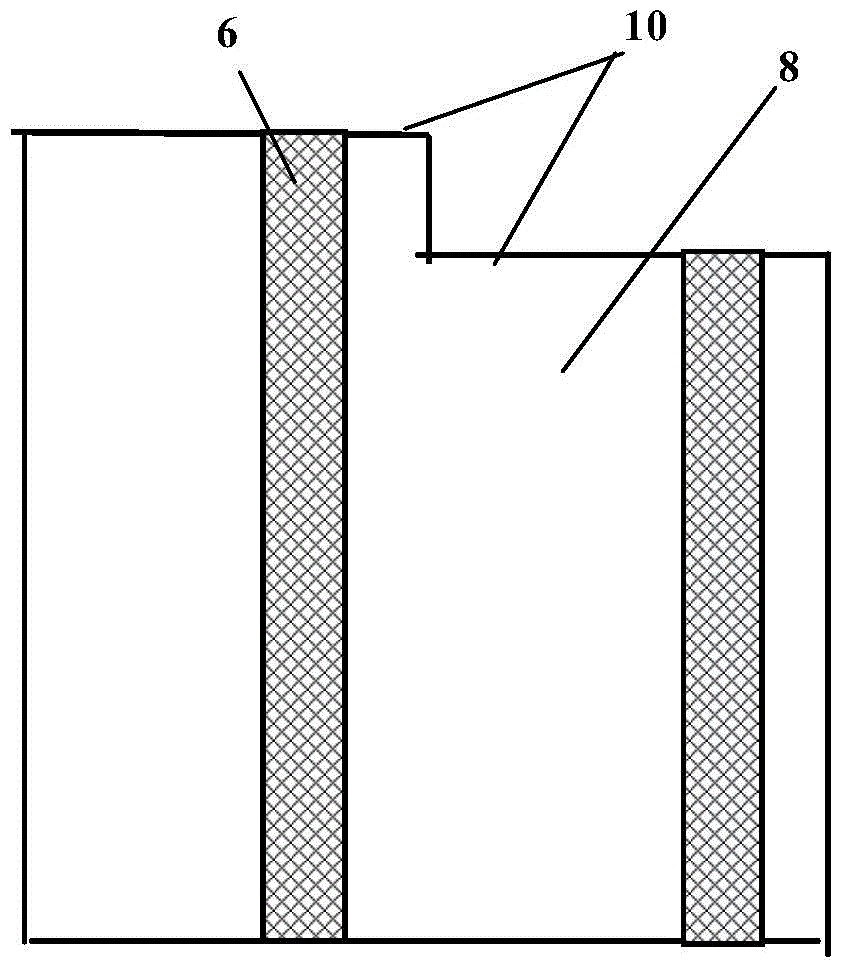

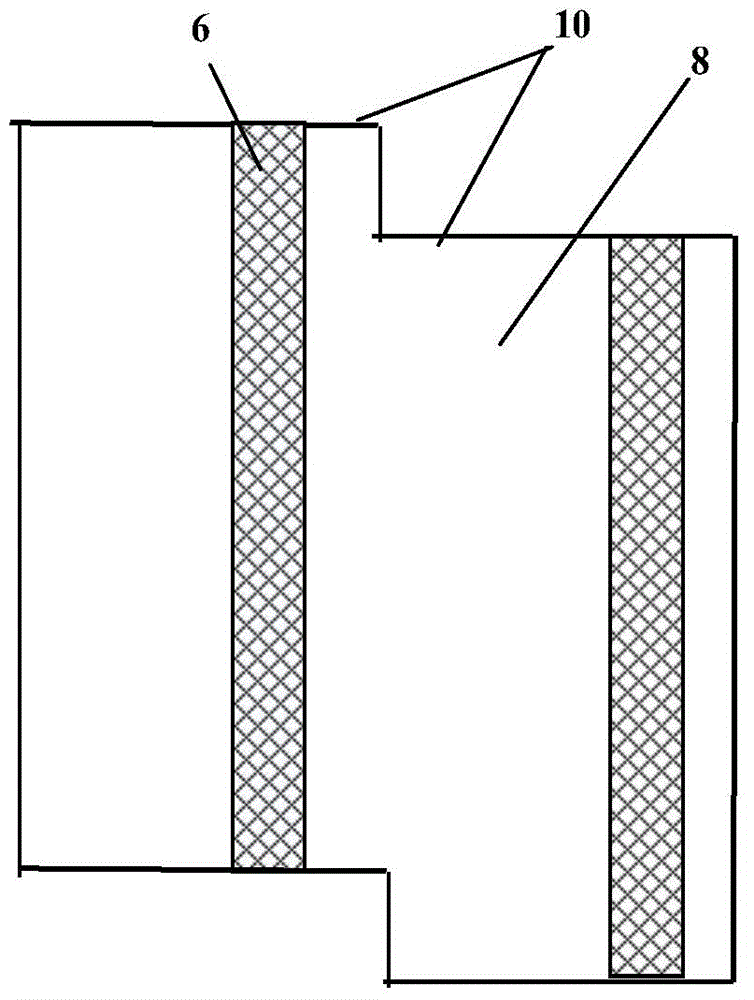

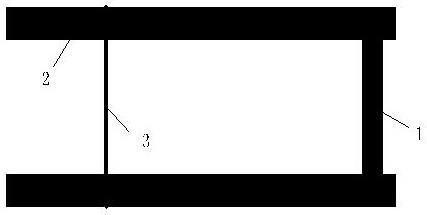

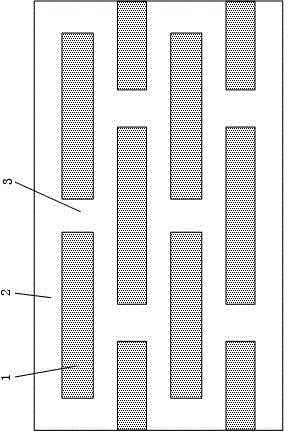

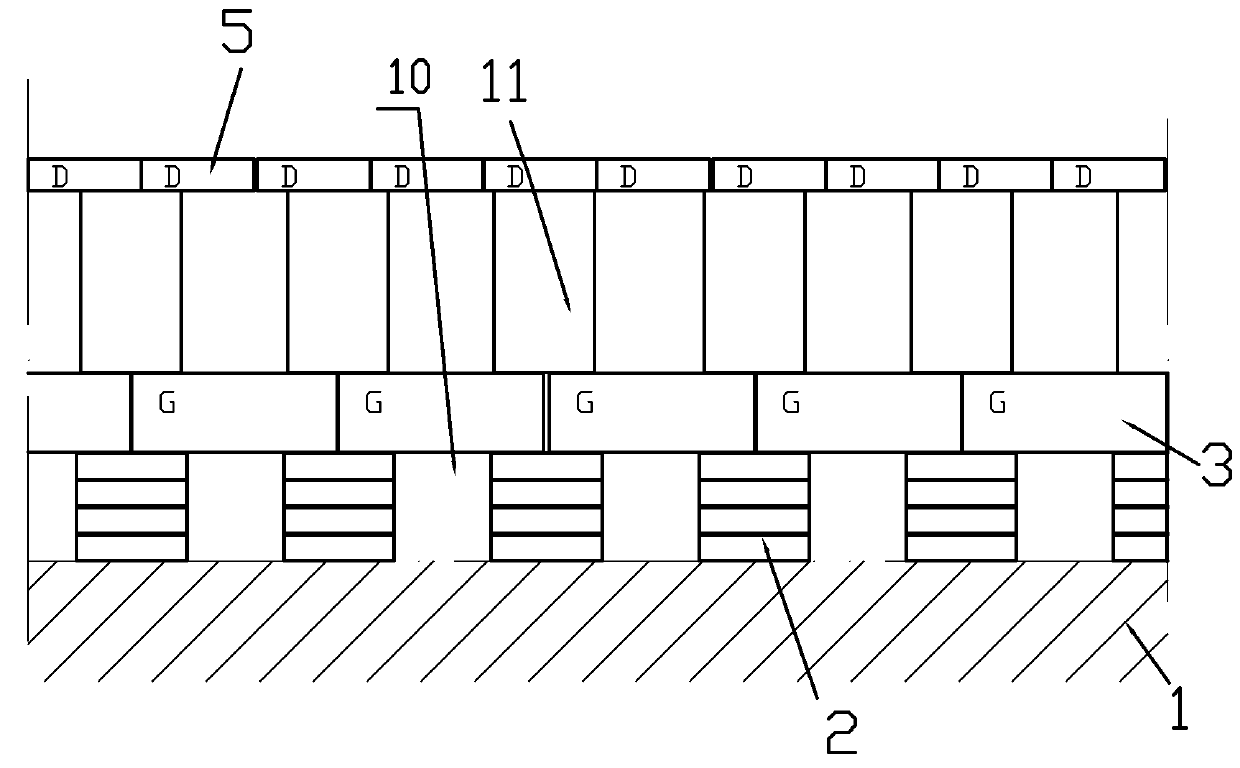

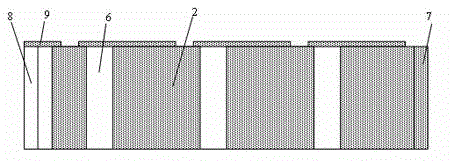

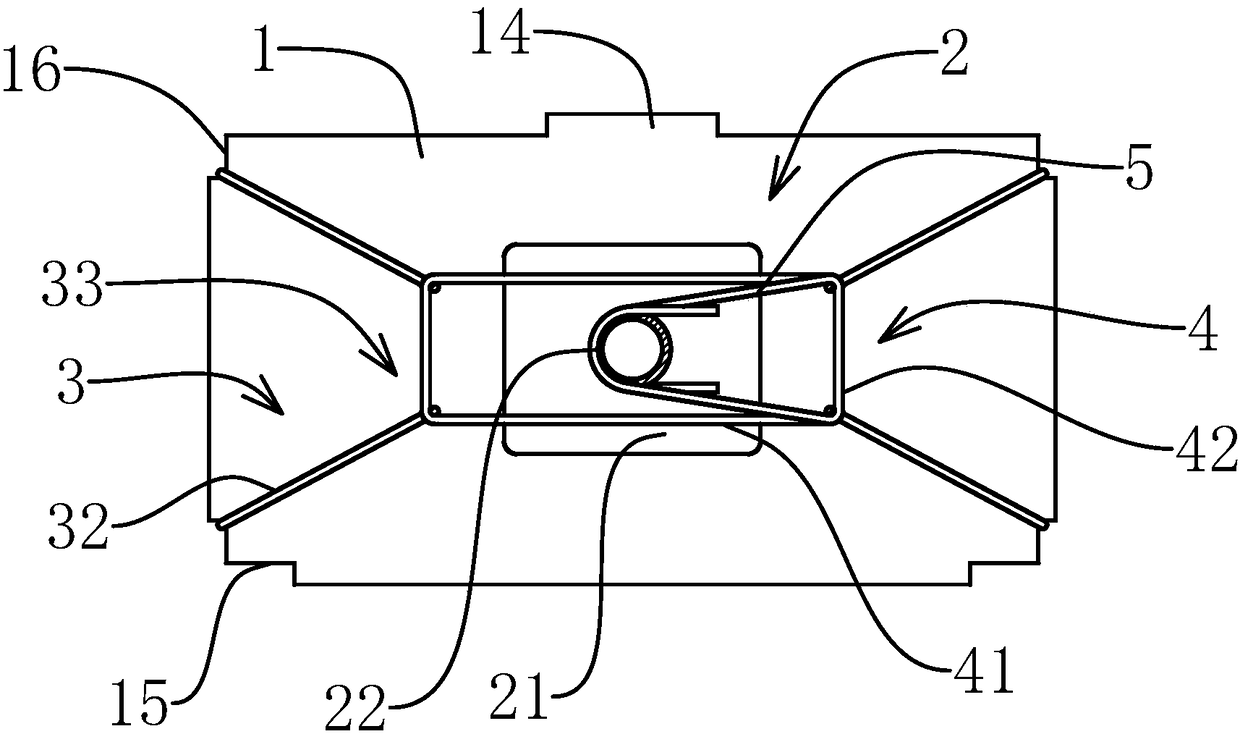

Heat bridge-free self-insulation building block

InactiveCN102912925AAvoid thermal bridgesThermal bridge effectiveConstruction materialInsulation layerThermal bridge

The invention relates to a heat bridge-free self-insulation building block comprising insulation boards and concrete, wherein the insulation boards are arranged in the concrete at intervals in four rows; concrete ribs are formed between adjacent insulation boards in the same row; the concrete ribs and the insulation boards in different rows are staggered; the insulation boards in even layers and odd layers respectively extend out of the left side and the right side of the building block to form outwards-extended insulation boards; and all the insulation boards extend out of the top surface of the building block to form outwards-extended insulation boards. The building block disclosed by the invention has the beneficial effects that the heat bridge effect of non-insulation parts of the building block, masonry mortar joints and the like can be avoided with no need of adopting other insulating layers, so that the energy saving ability of the buildings is greatly increased and the heat insulation effect is enhanced and has the advantages of durable service, safety, fire prevention and effectiveness in sound insulation. According to the invention, the heat preserving layer does not need to be added, therefore, the construction technique is convenient, the speed is high, the building efficiency is increased, the material is saved, the transportation volume is reduced and the construction cost is reduced.

Owner:SHENYANG JIANZHU UNIVERSITY

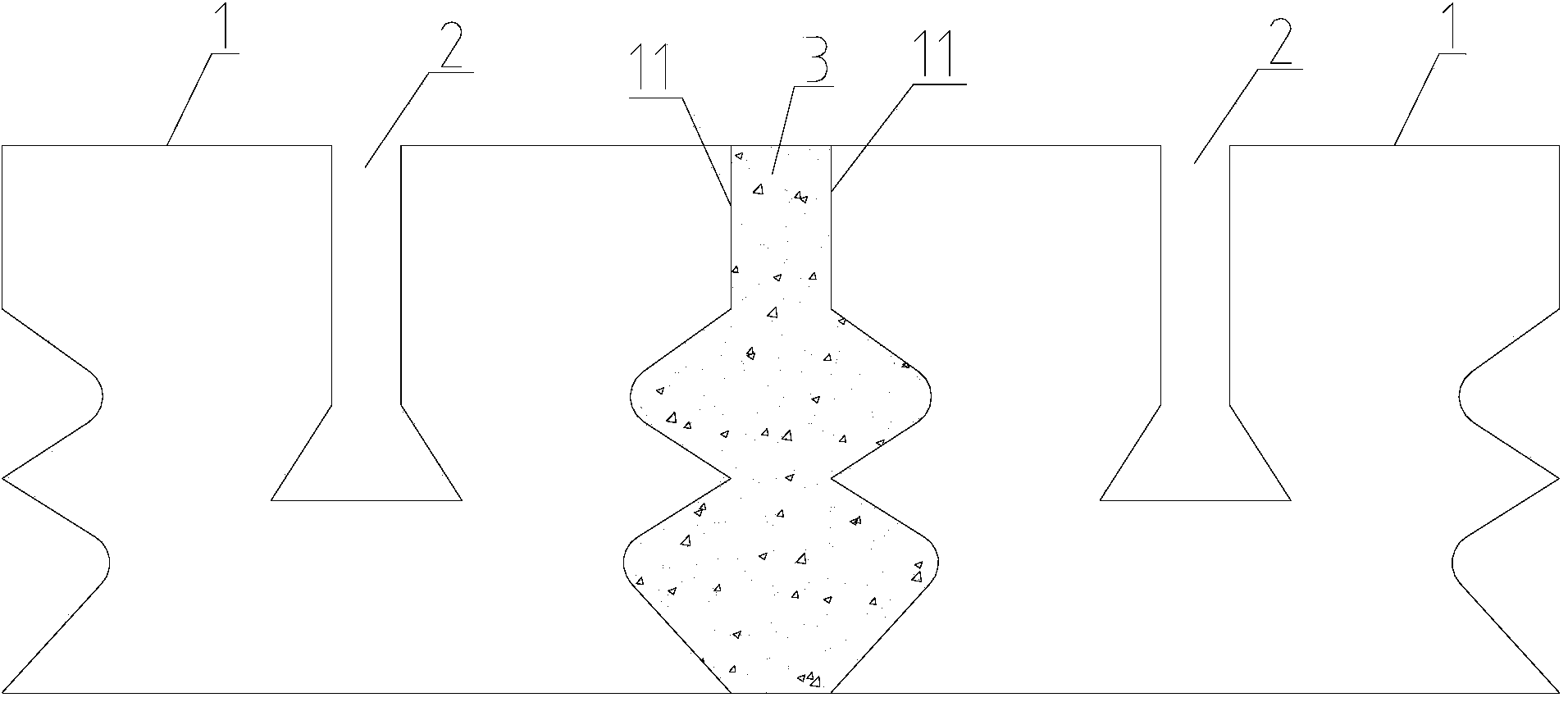

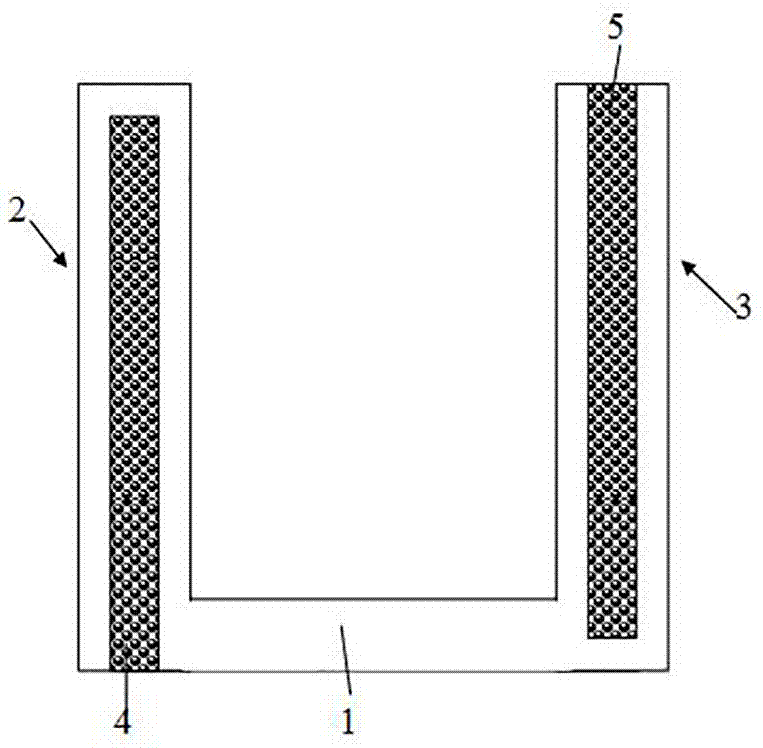

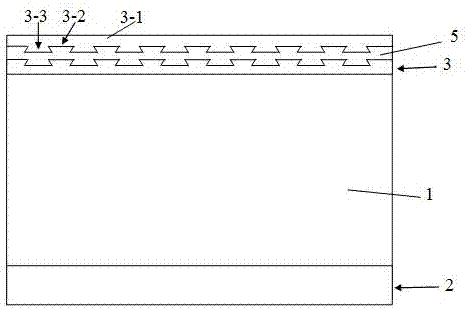

Structure of stone wall constructed by strip stone cut by machine and method thereof

ActiveCN101949182AImprove bindingIncreased shear strength of gray jointsWallsBuilding material handlingStone wallStructure of the Earth

The invention discloses a structure of a stone wall constructed by strip stone cut by a machine and a method thereof. The structure comprises upper strip stone and lower strip stone which are cut by a machine; a lime slot is formed between the constructing interface of the upper strip stone and the constructing interface of the lower strip stone; the lime slot is filled with bonding material used for bonding the upper strip stone and the lower strip stone together; the constructing interface of the upper strip stone and the constructing interface of the lower strip stone are both provided with crossed grooved grains; a plurality of grooves are formed on the constructing interface of one row of strip stone; shear keys are convex externally on the constructing interface of the other row of strip stone; the shear keys correspond to the grooves and are meshed with the grooves; in this way, the upper strip stone and the lower strip stone can be bonded more firmly by the grooved grains arranged on both of the constructing interfaces of the upper strip stone and the lower strip stone and the grooves and the shear keys which are arranged on the two constructing interfaces and are matched; thereby, the shear strength of the lime slot of the stone wall formed by construction is largely enhanced; and the stone wall has excellent seismic performance and compressive load capacity.

Owner:HUAQIAO UNIVERSITY

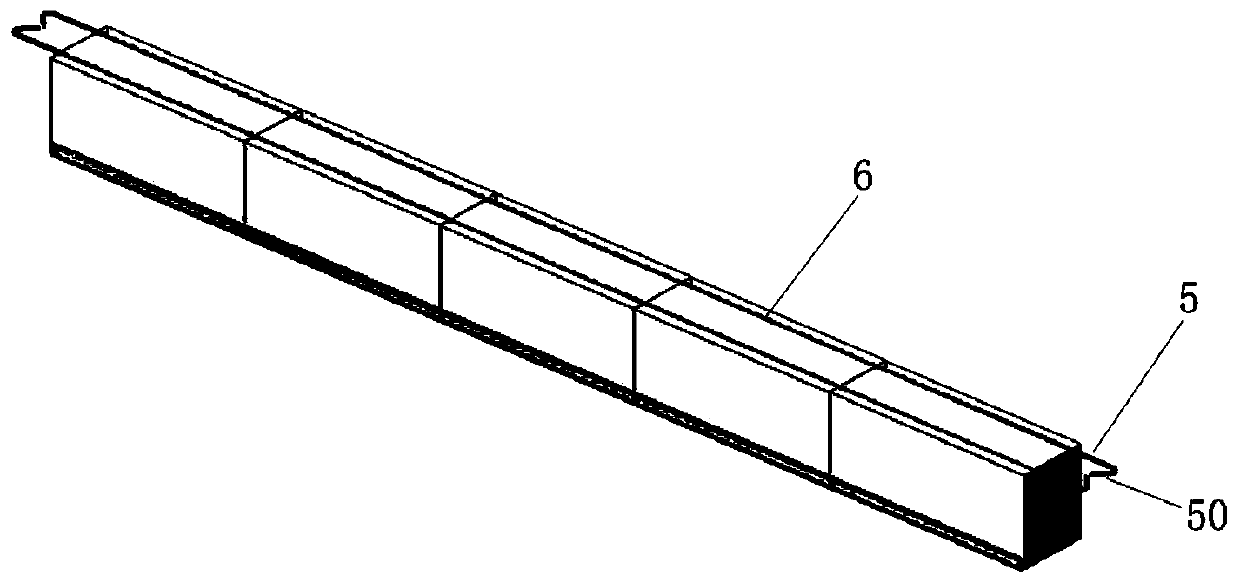

Manufacturing and use method of masonry mortar spreading tool

InactiveCN108265993AQuality assuranceGuaranteed efficiencyBuilding material handlingMaterials preparationMachining

The invention discloses a manufacturing and use method of a masonry mortar spreading tool. The manufacturing method comprises the main technological processes that material preparation is conducted; square pipe machining is conducted; a U-shaped frame is manufactured; a steel plate is machined and welded to the upper portion of the U-shaped frame to manufacture a mortar-leakage-preventing component; the steel plate is manufactured and welded to the lower portion of the U-shaped frame to machine a clamping groove, manufacturing of a masonry mortar spreading device is completed; and the clampinggroove face is placed on the wall body masonry operating face to conduct mortar spreading, and after filling and trowelling, the masonry mortar spreading device slides in the wall body direction to conduct next mortar spreading. The manufacturing and use method has the beneficial effects that manufacturing is convenient, the technology is simple, the applicable and reliable effects are achieved,the construction difficulty is reduced, reuse can be achieved, and the construction cost is saved.

Owner:CHINA MCC17 GRP

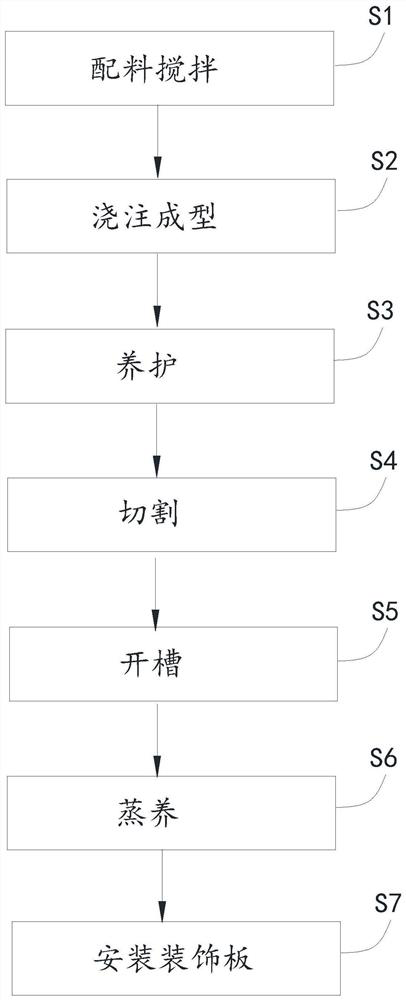

Fabricated autoclaved aerated concrete plate and preparation method thereof

ActiveCN113105199AImprove structural strengthImprove construction efficiencyCeramic shaping apparatusCeramicwareEngineeringSlurry

The invention discloses a fabricated autoclaved aerated concrete plate and a preparation method thereof. The preparation method comprises the following steps: S1, stirring ingredients: uniformly mixing and stirring the ingredients into slurry; S2, performing casting molding: pouring the stirred slurry into a mold; S3, curing: feeding the mold poured with the slurry into a curing chamber for aeration and static curing to obtain an aerated concrete green body; S4, cutting: carrying out transverse cutting and longitudinal cutting on the aerated concrete green body; S5, grooving: forming an assembly female groove and an assembly male groove in the two ends of the aerated concrete plate in the length direction; S6, steam-curing: putting the slotted aerated concrete plate into an autoclave, and performing steam curing to obtain an autoclaved aerated concrete plate; and S7, mounting a decorative plate: fixing the decorative plate on at least one side surface of the autoclaved aerated concrete plate. The efficiency and the quality of the autoclaved aerated concrete plate masonry wall are improved.

Owner:福建厚德节能科技发展有限公司

Concrete block

InactiveCN103388373AConvenient sourceImprove masonry efficiencyConstruction materialNational standardHeat losses

The invention discloses a concrete block. The cross section of the concrete block is square; a rib plate is vertically arranged in the center of the square; the middle part of the upper side of the square is raised; the corresponding part of the lower side of the square is recessed; the height of the raised part and the height of the recess are the same. The concrete block is made of common concrete, high in building efficiency, low in cost and long in service life and can be subjected to dry masonry, the materials are readily available, the strength can reach the current national standard requirements, and the heat loss is low; concrete blocks are meshed and locked to be built from top to bottom, and thus the integrity is high.

Owner:无锡柯马机械有限公司

Z-shaped heat-preservation board heat-free bridge self-heat-preservation building block

InactiveCN104453074AReduce weightSimple construction technologyConstruction materialArchitectural engineeringHeight difference

The invention provides a Z-shaped heat-preservation board heat-free bridge self-heat-preservation building block, belonging to the technical field of construction building blocks. The Z-shaped heat-preservation board heat-free bridge self-heat-preservation building block comprises outer rows of Z-shaped heat-preservation boards, inner rows of Z-shaped heat-preservation boards, a horizontal mortar joint energy transmitting cutting-off ladder, concrete, and continuous ladder energy transmitting concrete extending ribs, wherein the inner and outer rows of Z-shaped heat-preservation boards are arrayed in the concrete in parallel at equal intervals; outer-layer longitudinal plates and inner-layer longitudinal plates of the adjacent Z-shaped heat-preservation boards in the same row are mutually overlapped; the outer-layer longitudinal plates, transverse plates and the inner-layer longitudinal plates of the two rows of Z-shaped heat-preservation boards are used for dividing the concrete into the plurality of continuous ladder energy transmitting concrete extending ribs; the longitudinal plates of two rows of Z-shaped heat-preservation boards at the two ends of a building block stretch out of the building block to form outwards-extending heat preservation boards; and the whole building block is provided with ladder surfaces with height difference on one side or two side surfaces between the two rows of Z-shaped heat-preservation boards, so as to form the horizontal mortar joint energy transmitting cutting-off ladder, and thus the whole L-shaped or Z-shaped building block is formed. According to the Z-shaped heat-preservation board heat-free bridge self-heat-preservation building block, heat bridges at different parts of a wall body are separated so that the energy-saving and heat-preservation effects are improved; and the building block is applied to a plurality of types of self-heat-preservation wall bodies.

Owner:SHENYANG JIANZHU UNIVERSITY

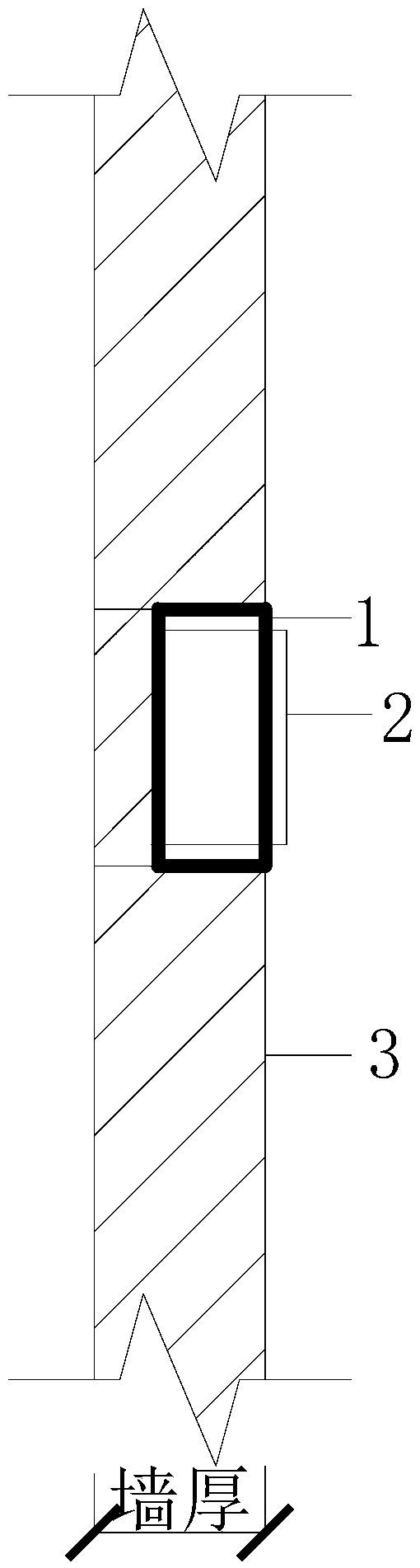

Construction method of concealed distribution box in pre-buried concrete prefabricated frame in brickwork structure

InactiveCN109083414ASimple processEasy to implementBuilding material handlingBuilding constructionBrickwork

The invention discloses a construction method of a concealed distribution box in a pre-buried concrete prefabricated frame in a brickwork structure, and belongs to the technical field of brickwork structures. The method includes the steps of preparing the concrete prefabricated frame of the distribution box, conducting paying-off and positioning, installing the laid prefabricated frame, and fixedly installing the distribution box. The method has the advantages that the process is simple and convenient to implement, the method is widely used for installing the concealed distribution box in thebrickwork structure, the size deviation of a reserved hole of a traditional distribution box is reduced, and the construction progress of the brickwork structure is accelerated.

Owner:BEIJING SHOUGANG CONSTR GROUP

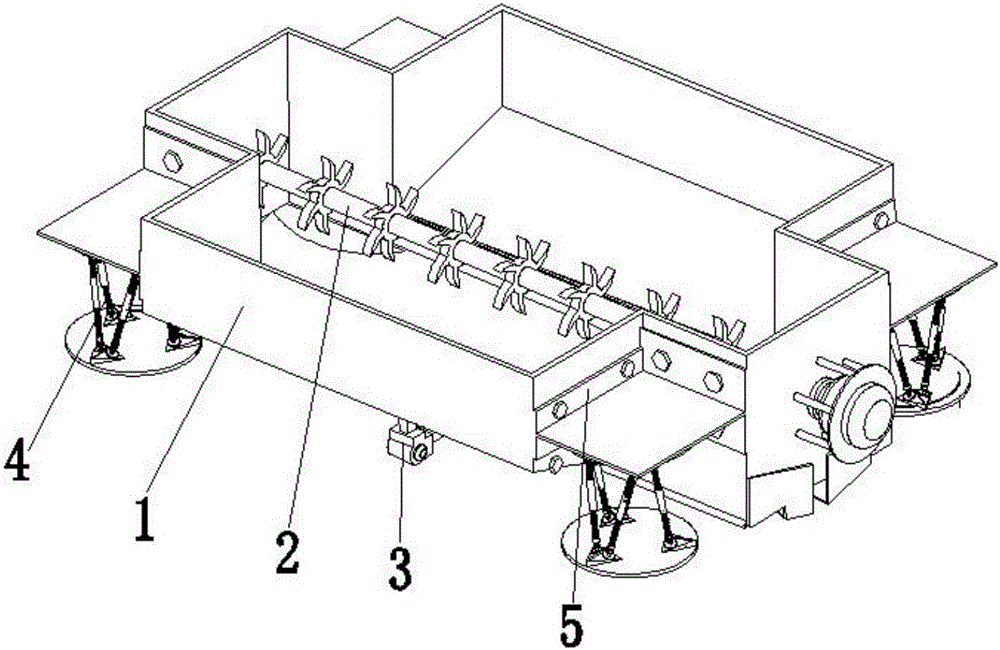

Intelligent robot for laying railway type road borders

ActiveCN106120518AImprove efficiencyQuality improvementRoads maintainenceEngineeringSix degrees of freedom

The invention relates to an intelligent robot for laying railway type road borders. The intelligent robot comprises a material storing tank, a stirring device, an adjustable type discharging device, six-degree-of-freedom parallel connection vibration tables, a fixing device, four walking devices and a railway, wherein the stirring device is located in the material storing tank; the adjustable type discharging devices are located just below a square ventage in the position at the middle part of the lower end of the material storing tank; the six-degree-of-freedom parallel connection vibration tables are respectively located at four vertex angles of the material storing tank, and are mounted on the outer side wall of the material storing tank through the fixing device; and the four walking devices are separately located just below the corresponding six-degree-of-freedom parallel connection vibration table, besides, the upper end of each walking device is connected with the lower end of the corresponding six-degree-of-freedom parallel connection vibration table, and the lower end of each walking device is mounted on the railway. According to the intelligent robot disclosed by the invention, the functions of secondarily stirring concrete, vibrating and mixing, adjustable type discharging and automatic walking are integrated, one machine has multiple functions, besides, the mechanical intelligence degree is high, and the laying efficiency and the laying quality of road borders are effectively improved.

Owner:SHENZHEN MUNICIPAL ENG

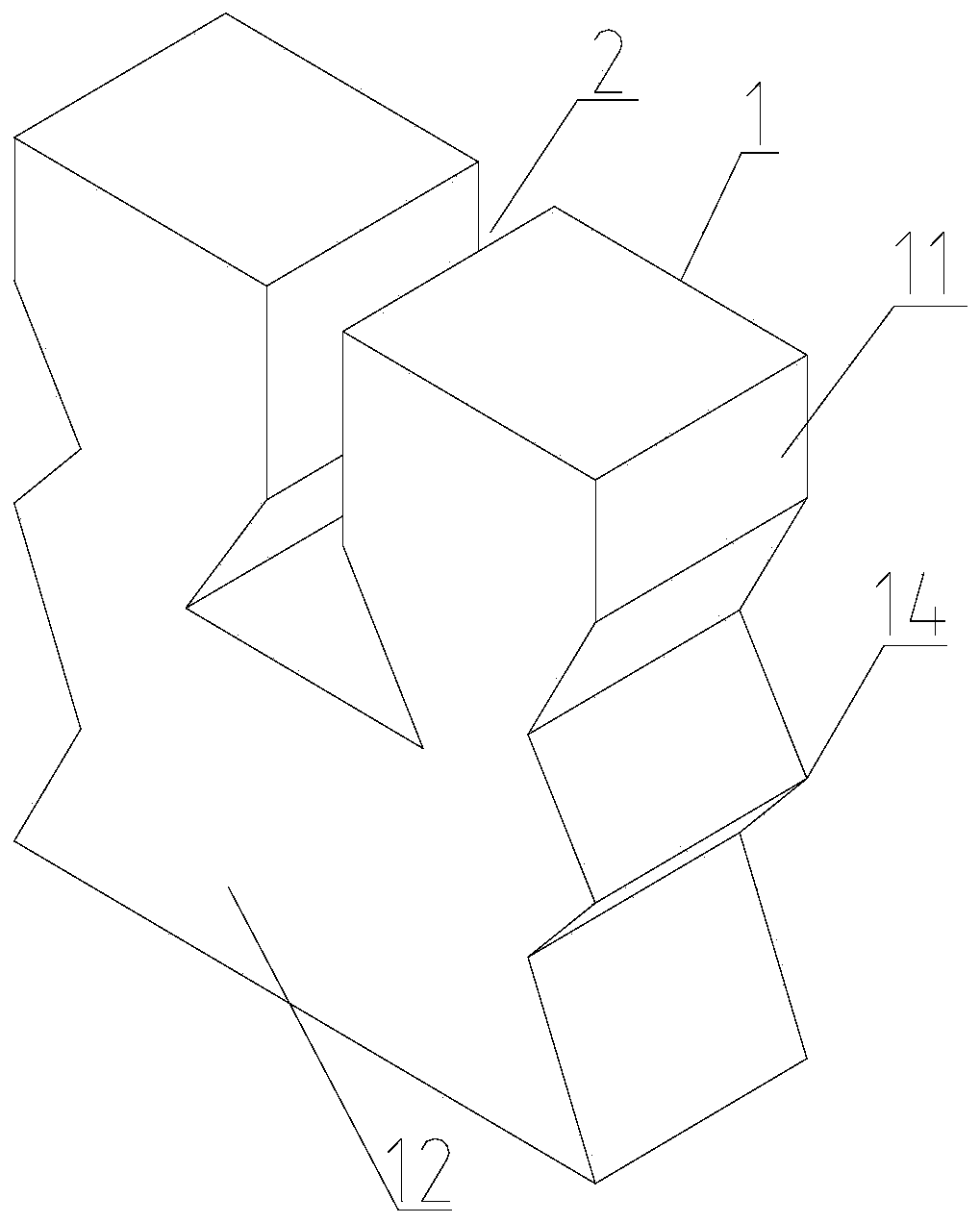

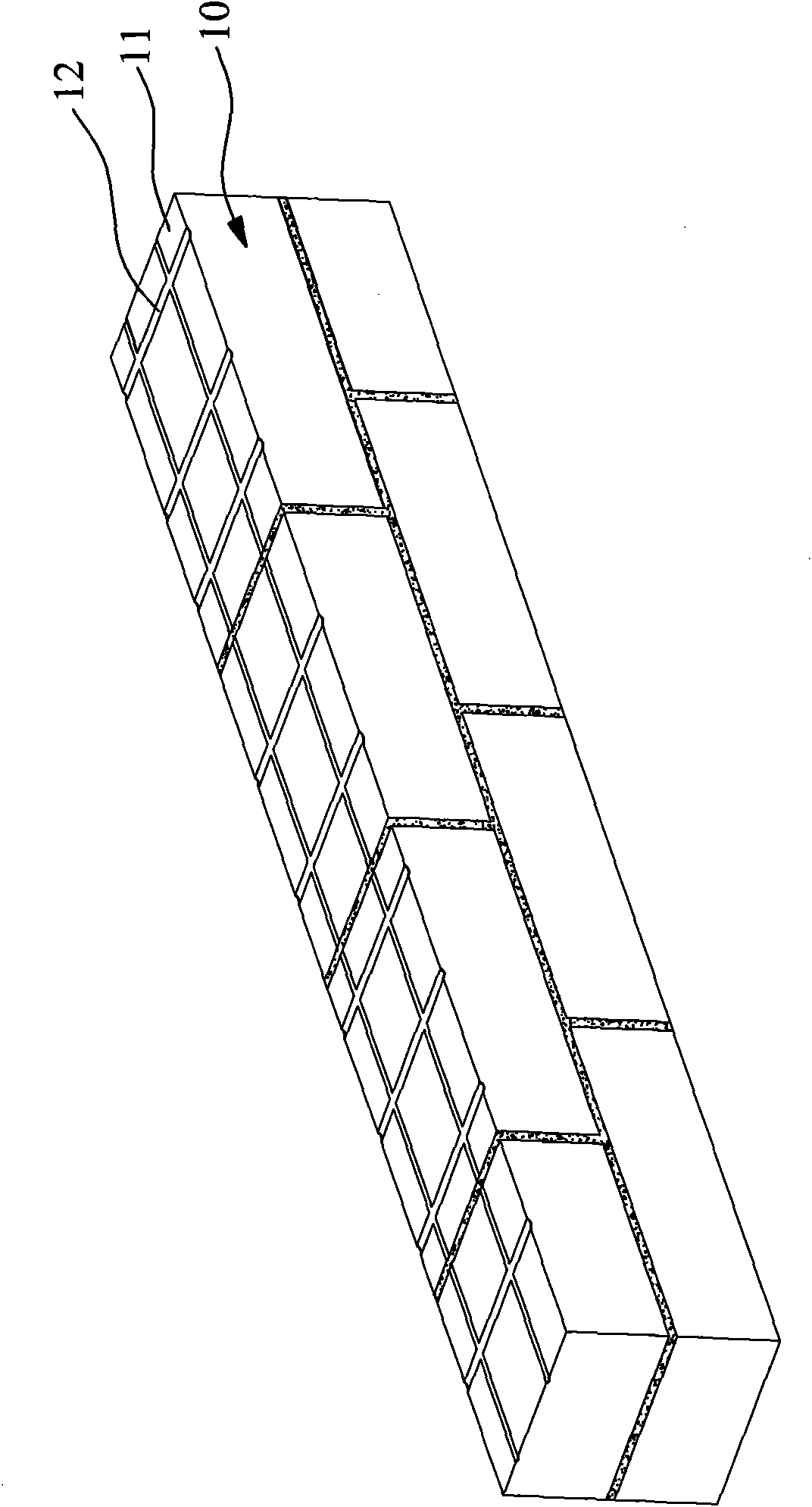

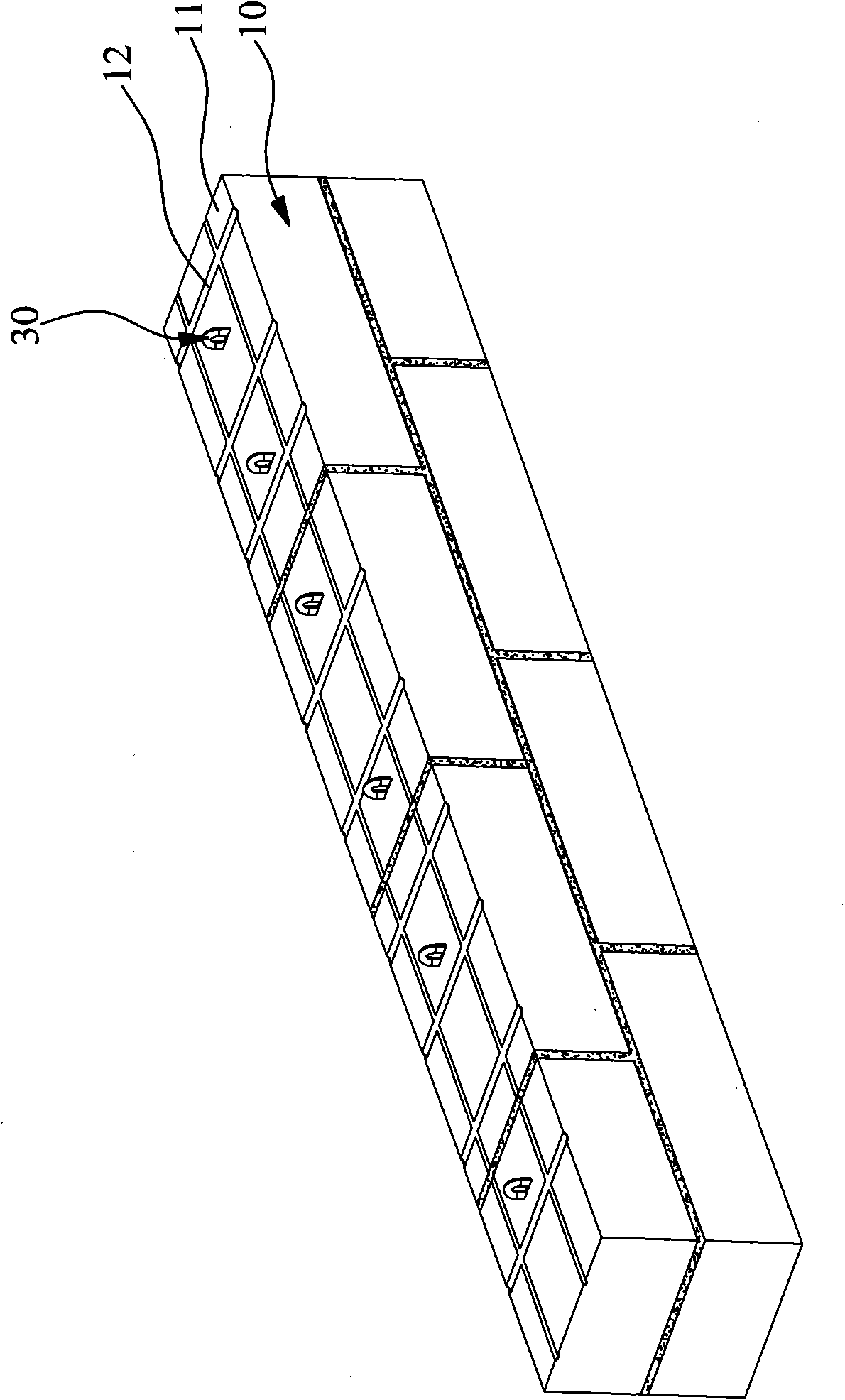

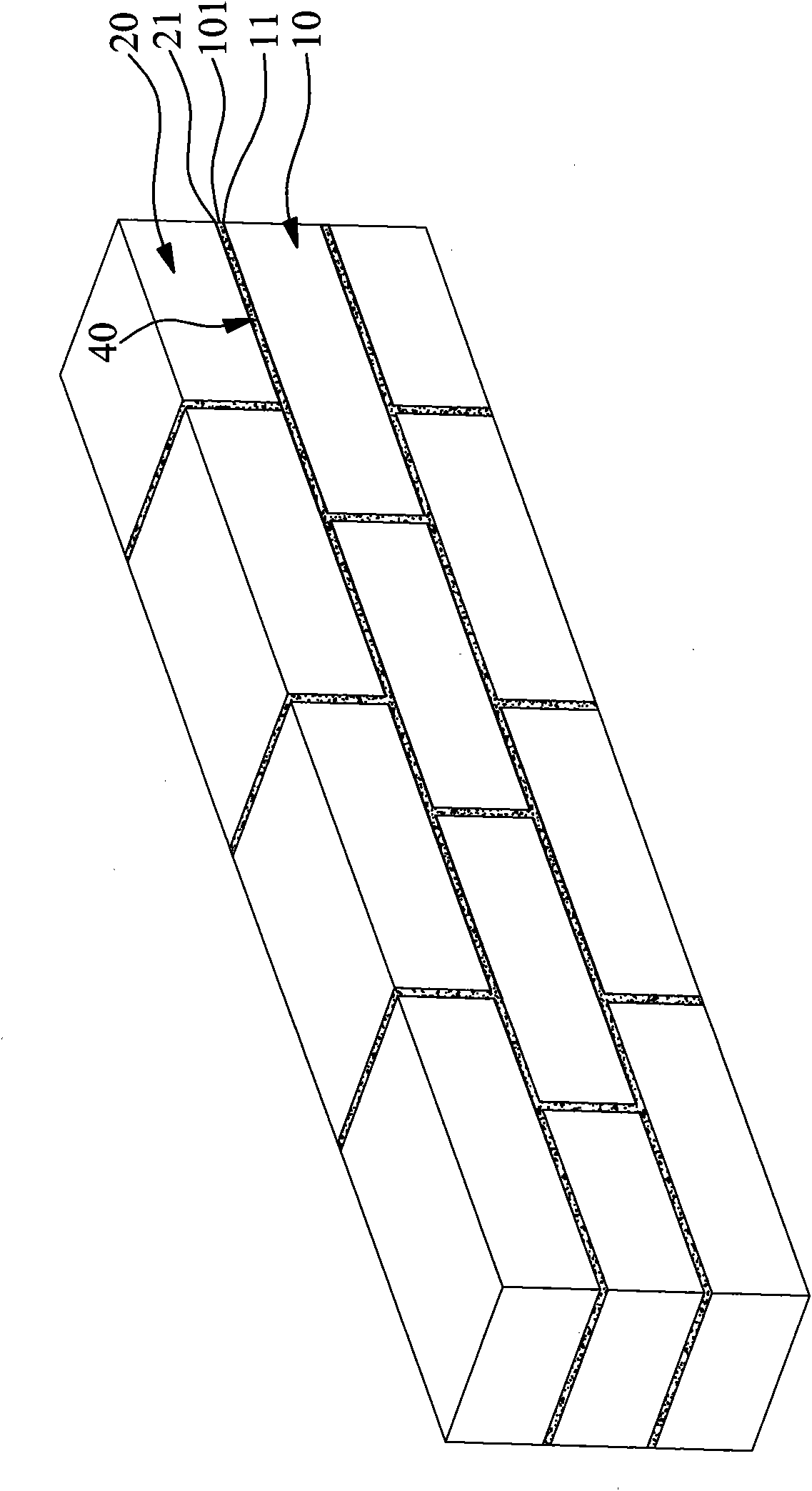

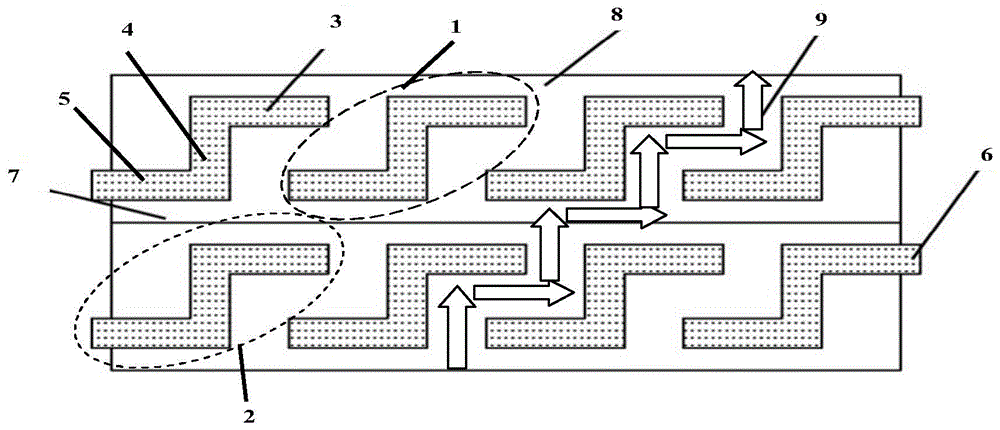

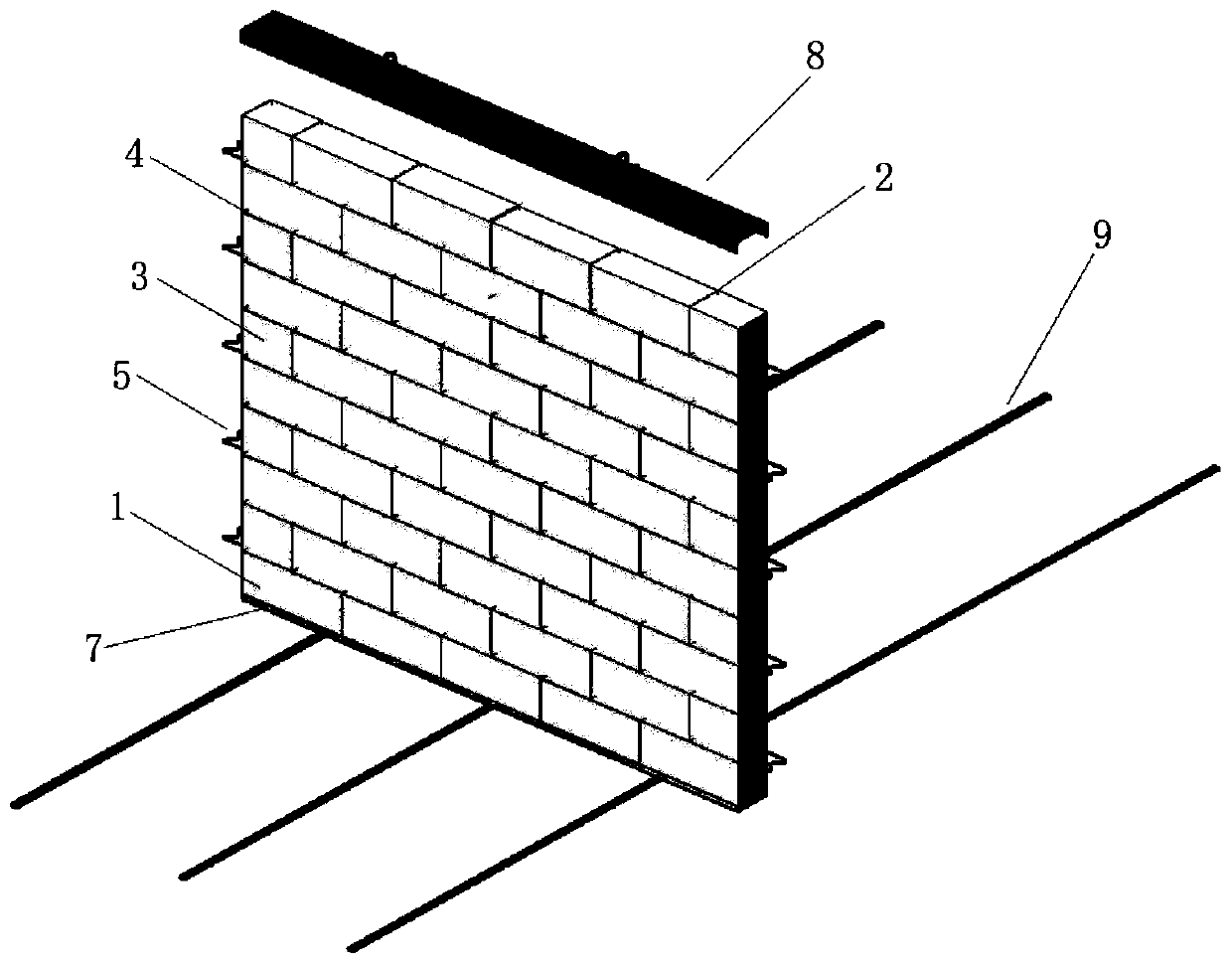

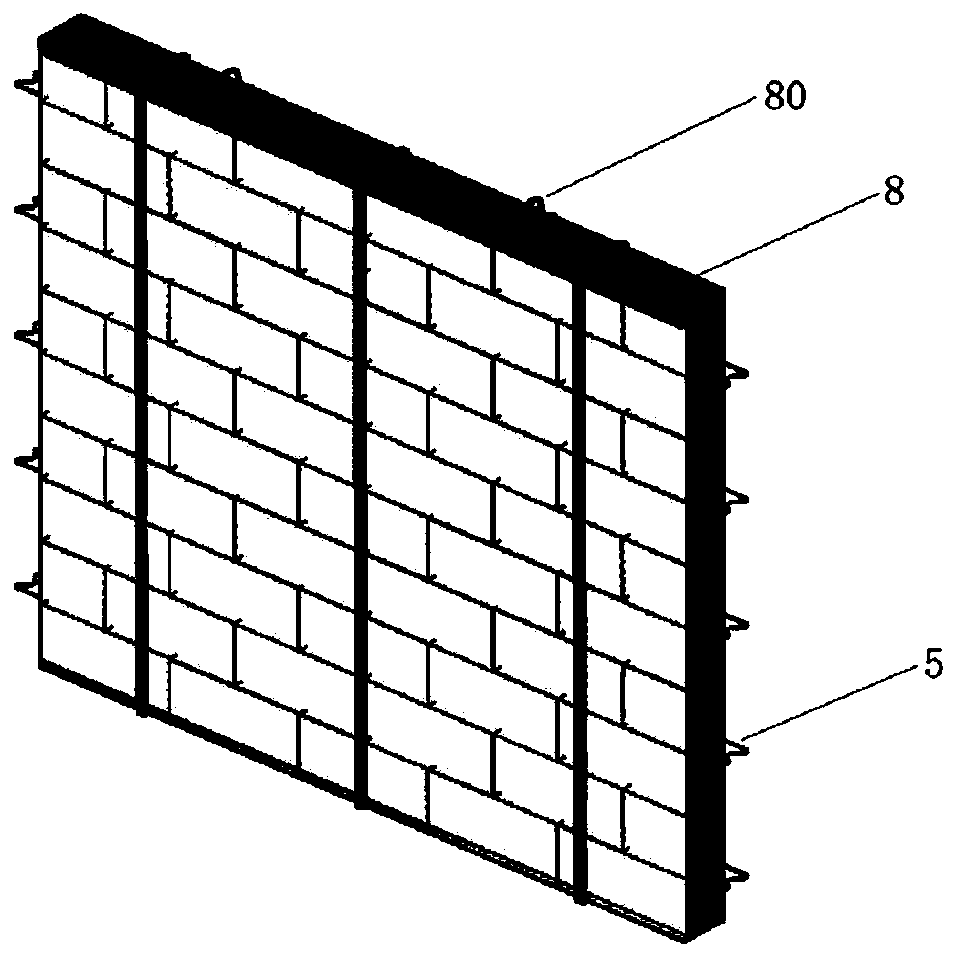

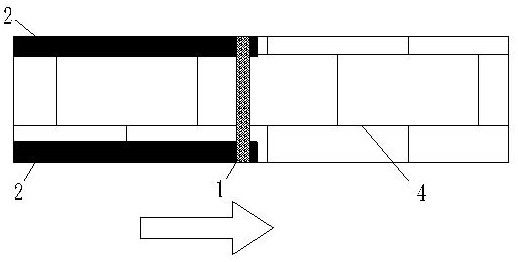

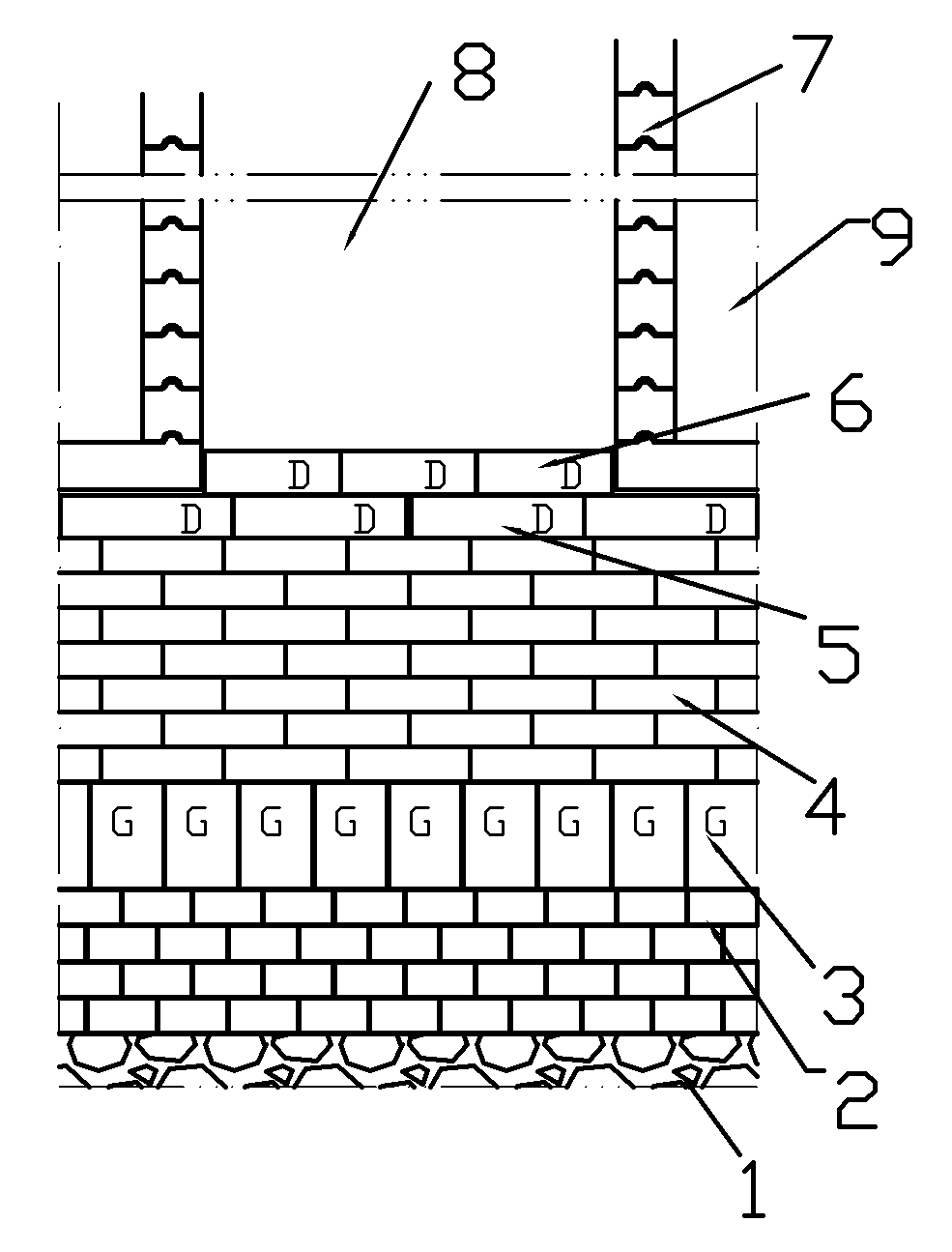

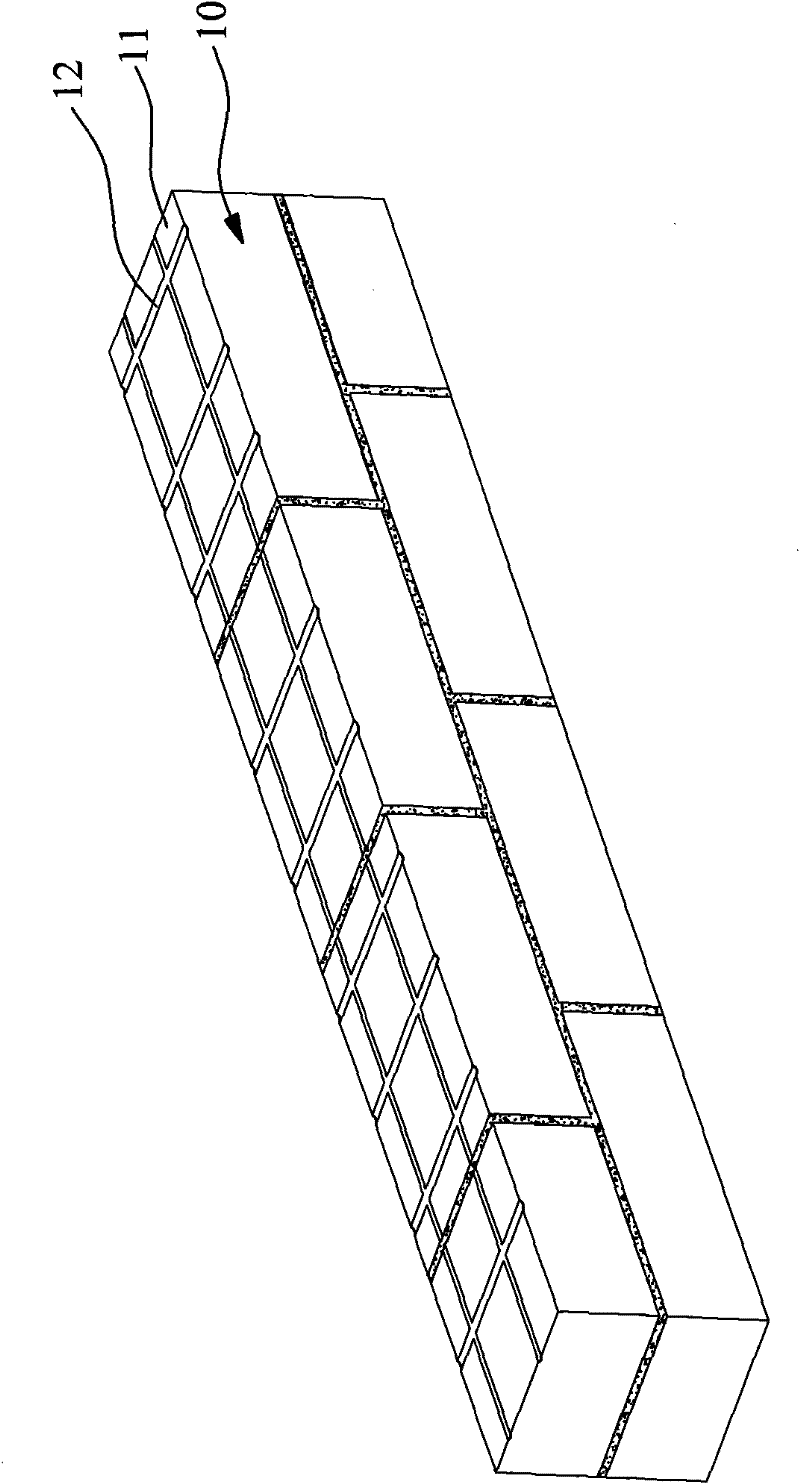

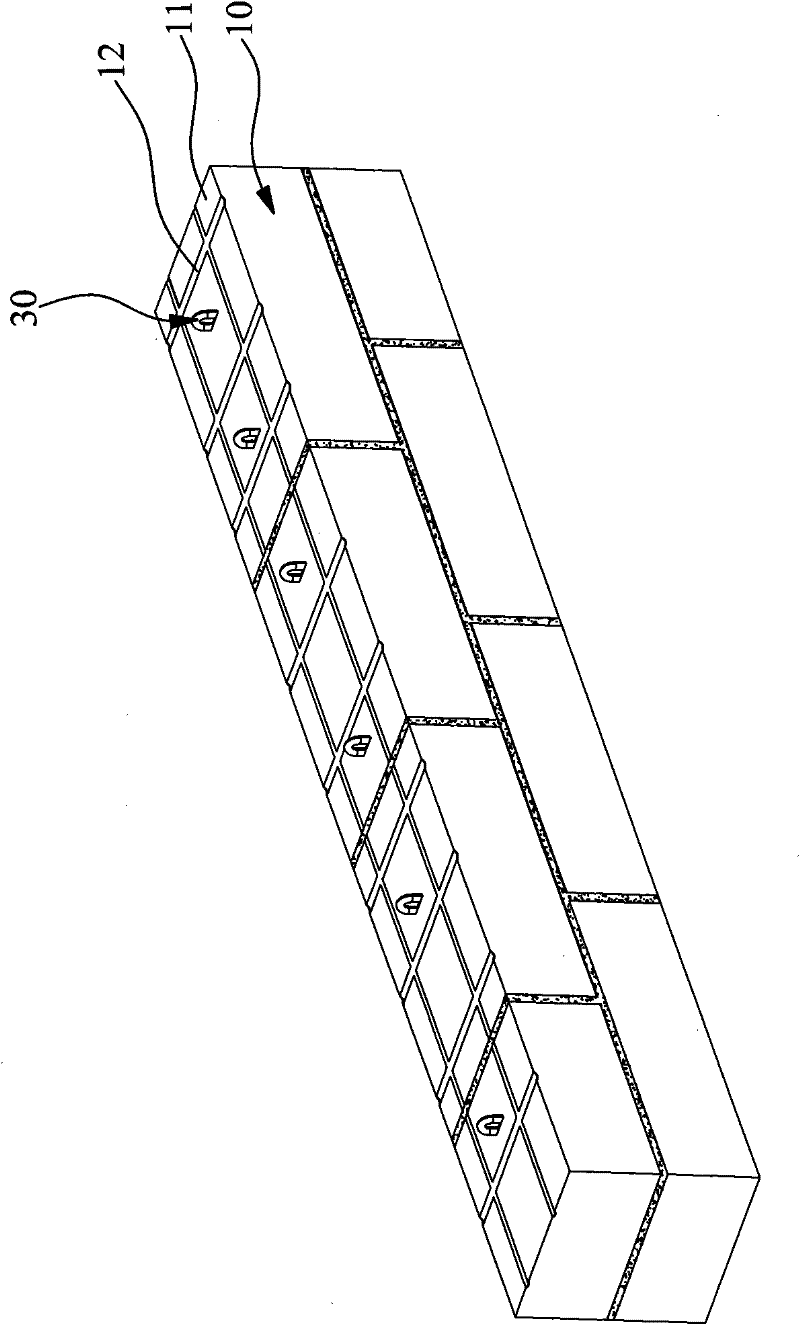

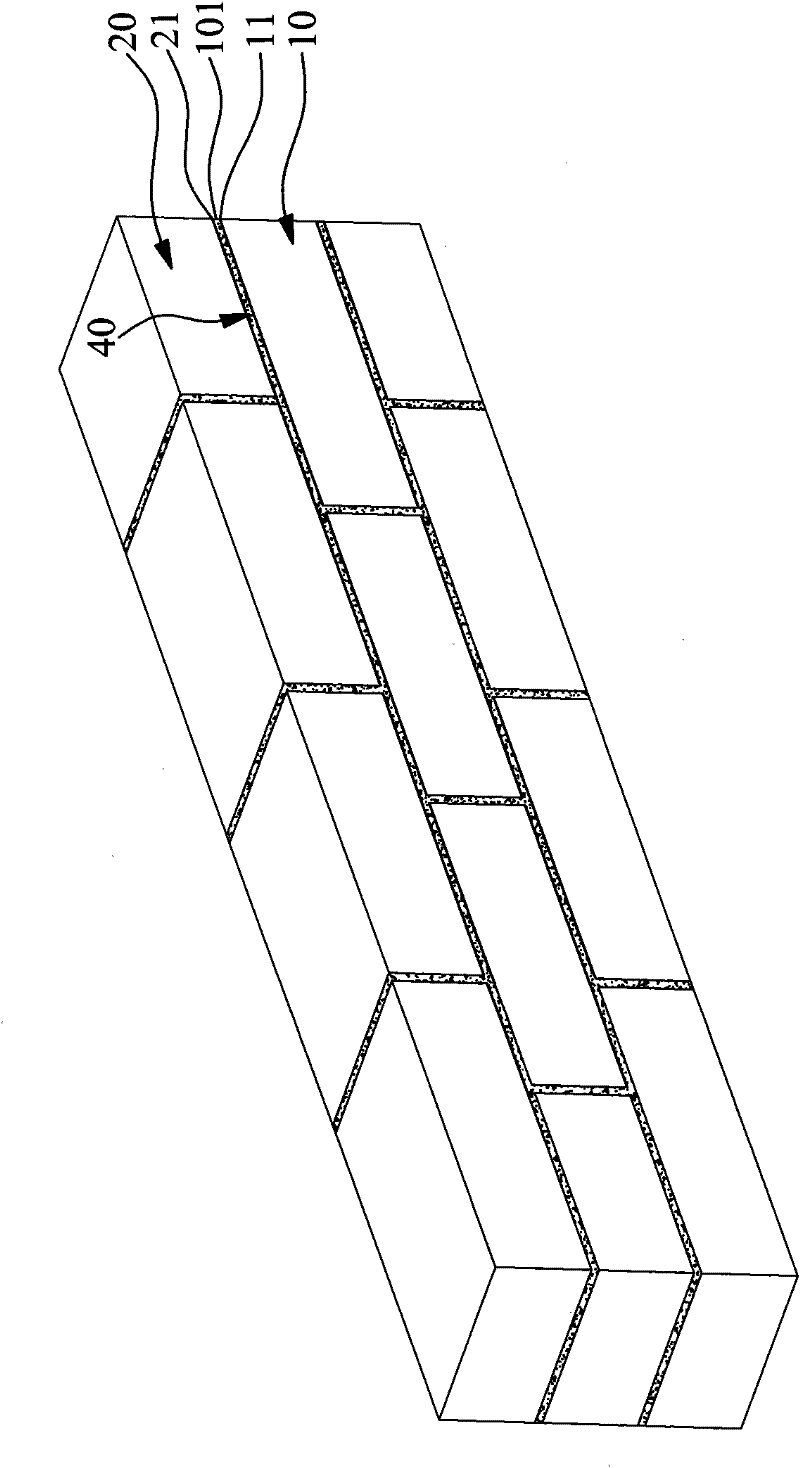

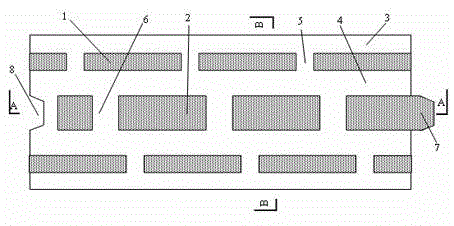

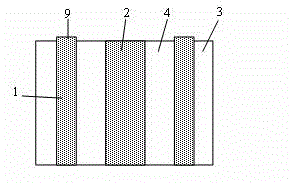

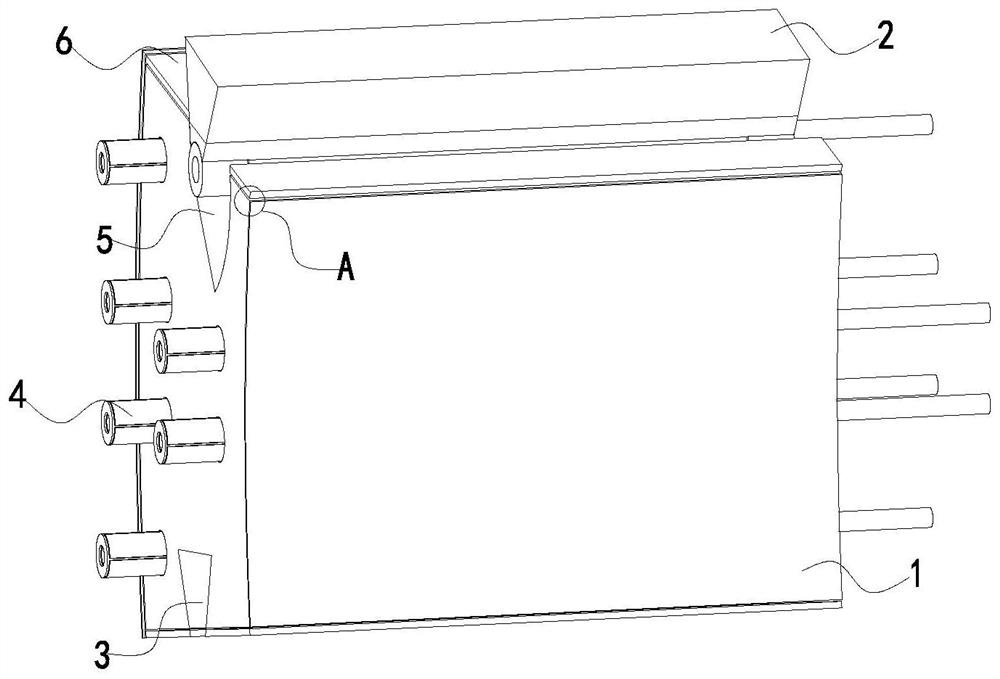

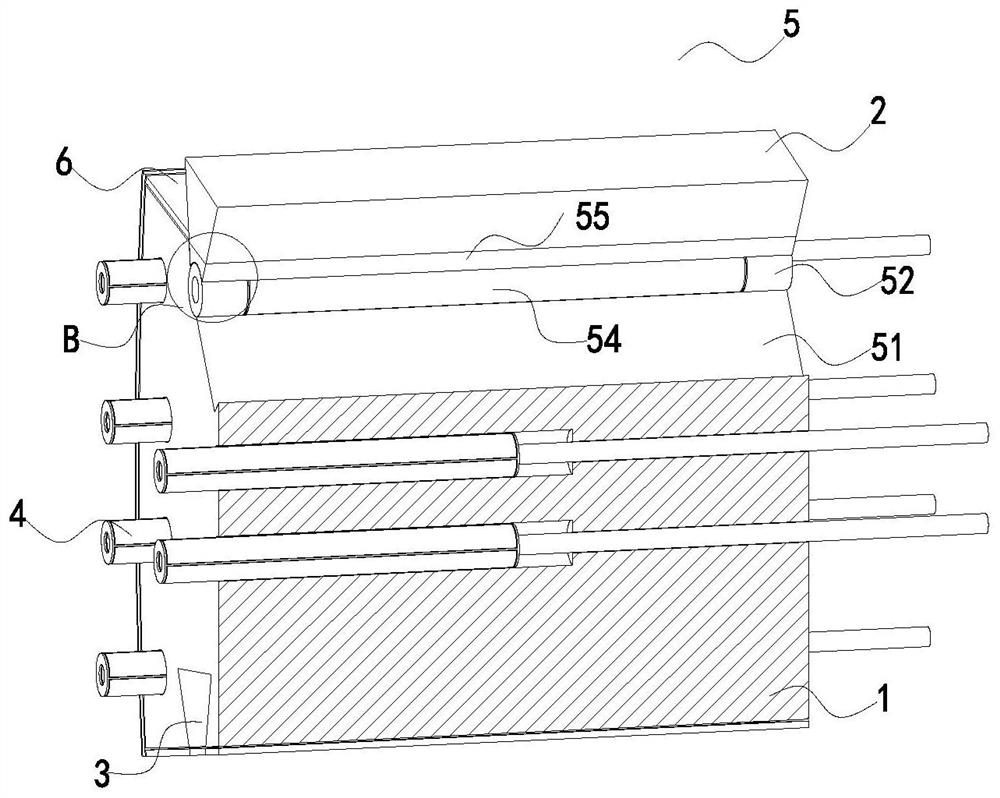

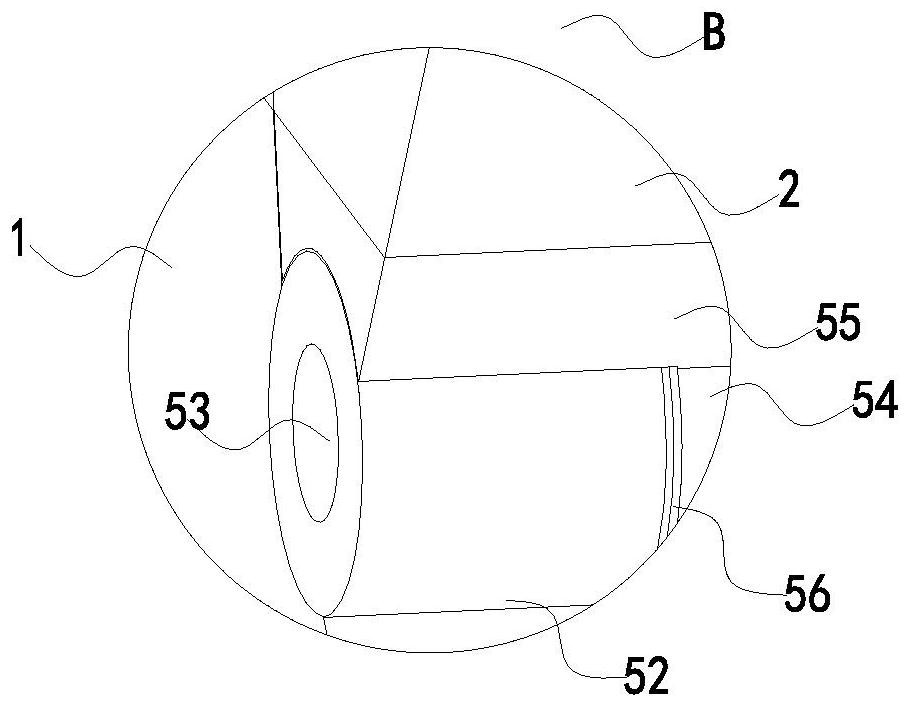

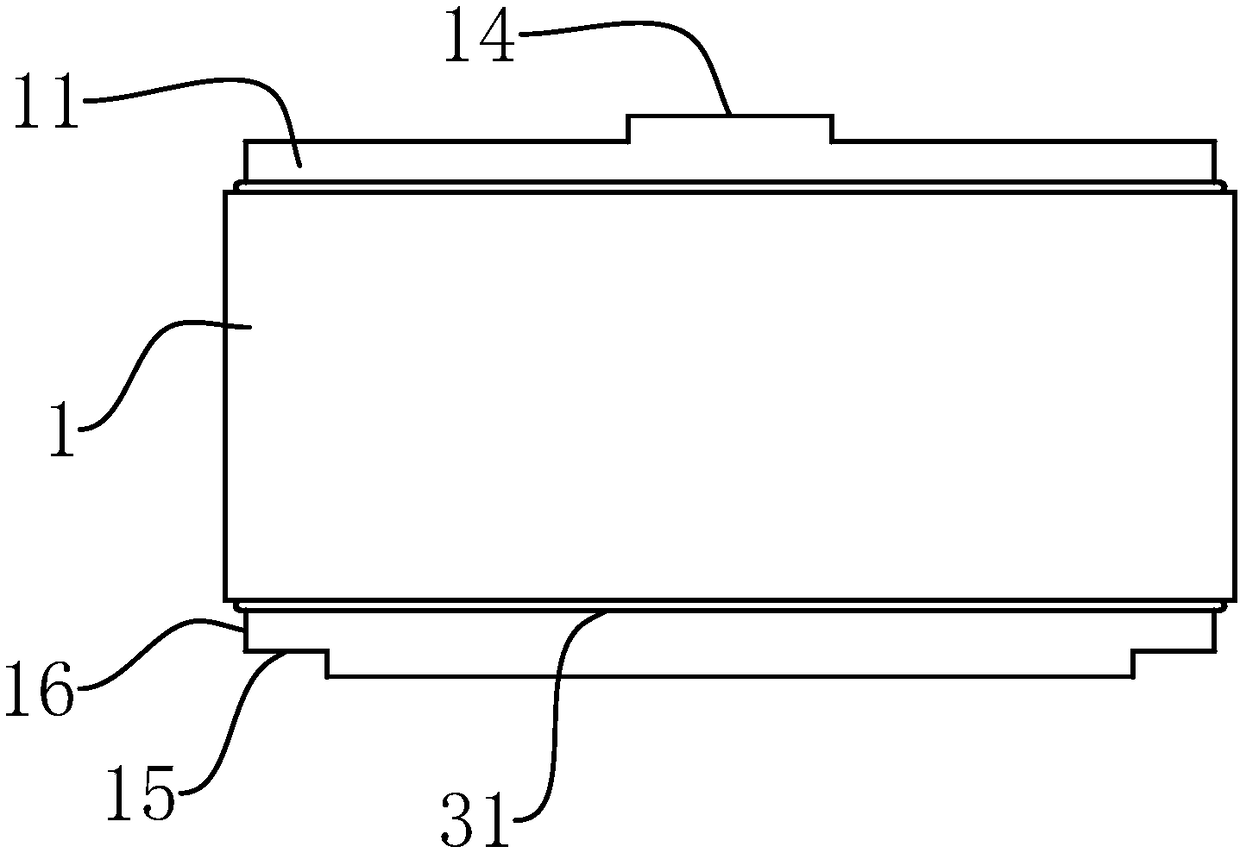

Assembled block wall and hoisting system thereof

PendingCN111101616ASimple masonry structureFacilitate automated masonryWallsBuilding material handlingRebarMechanical engineering

The invention relates to an assembled block wall, which is a multi-layer block layer formed by stacking blocks, wherein the block layer at the bottom layer is sequentially built by N blocks along a length direction, vertical mortar joints are arranged between adjacent blocks, the block layer of the sub-layer adjacent to the bottom layer is composed of a half-length block, a N-1 block and a half-length block in sequence, and the vertical mortar joints are arranged between adjacent blocks; N is a positive integer greater than 1; the structure of the adjacent blocks is the same, and transverse mortar joints are arranged between the adjacent block layers; two horizontally tied steel bars symmetrically distributed along the length of the bottom layer are arranged between the block layer of thebottom layer and the block layer of the sub-layer, the horizontal tied steel bars with 500-600mm spacing are arranged along the wall height of the assembled block in sequence, and the horizontal tie bars are located between the adjacent two block layers and symmetrically arranged along the length direction; and the two ends of the horizontal tie bars protrude from the two sides of the block layerrespectively. According to the invention, the masonry is standardized, the masonry structure is simple, automatic masonry is convenient, and the masonry efficiency is high.

Owner:杭州三丰装配式建筑科技有限公司 +2

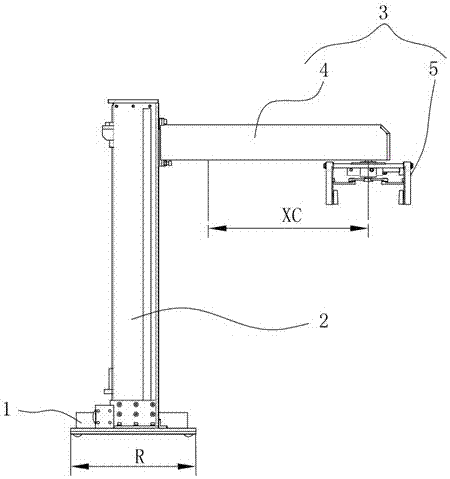

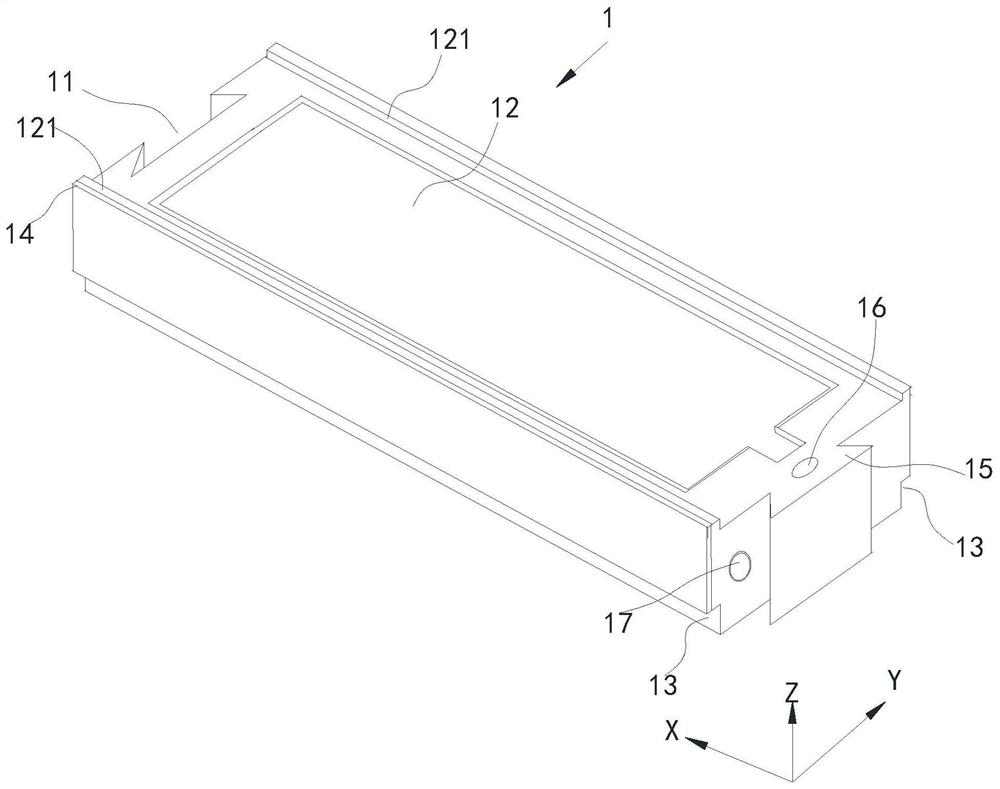

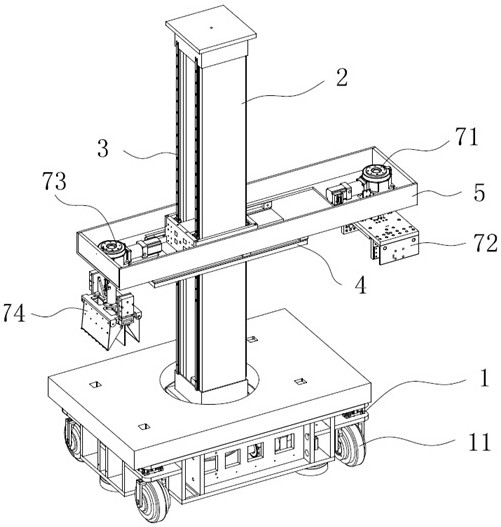

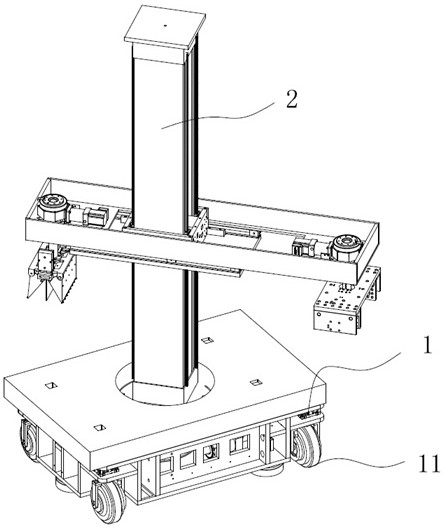

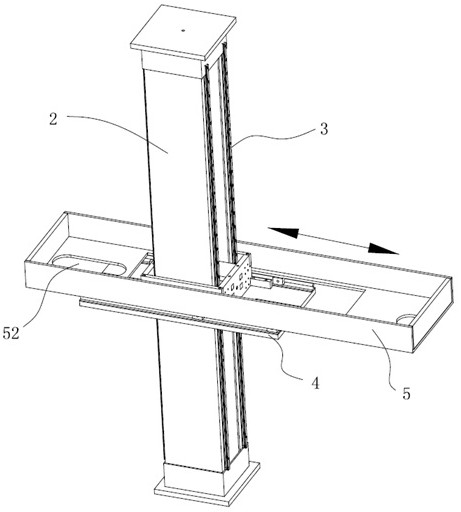

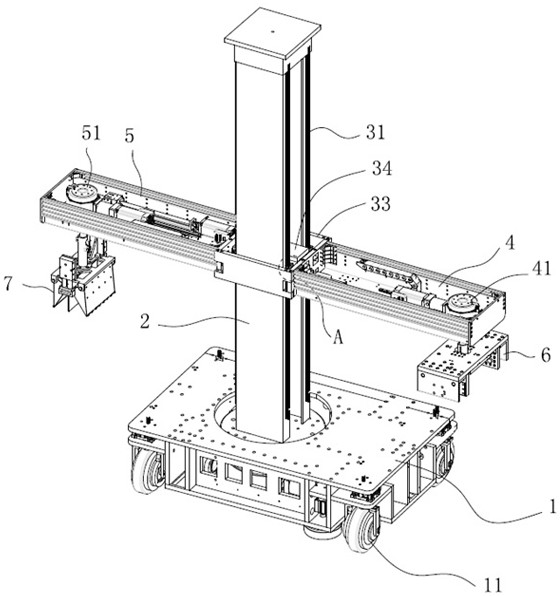

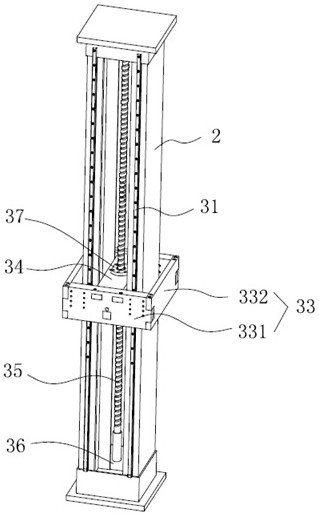

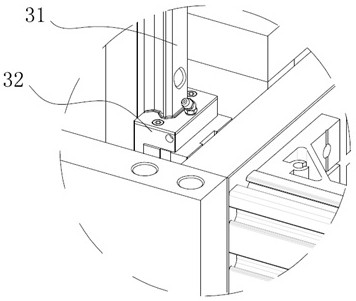

Wall building robot with telescopic arm and wall building method thereof

ActiveCN111910937APrevent solidificationShorten the lengthBuilding material handlingStructural engineeringControl theory

The invention discloses a wall building robot with a telescopic arm. The wall building robot comprises a rotating base, a robot body, a vertical moving module, a platform plate, the telescopic arm, atelescopic power assembly, a clamp assembly and a mortar cup assembly. The vertical moving module, the platform plate, the telescopic arm, the telescopic power assembly, the clamp assembly and the mortar cup assembly are mounted on the robot body, the platform plate is installed on the vertical moving module, and a sliding rail and a rail sliding block arranged along the sliding rail are arrangedon the platform plate; the telescopic arm is fixed above the rail sliding block, the telescopic power assembly is installed in the telescopic arm, and the telescopic power assembly controls the telescopic arm to horizontally move along the sliding rail; and the clamp assembly and the mortar cup assembly are installed at the two side ends of the telescopic arm respectively, the clamp assembly comprises a clamp and a first motor set, and the mortar cup assembly comprises a mortar cup and a second motor set. Through the arrangement of the telescopic arm, the use is more flexible, bricks and mortar can be clamped at the same time, bricklaying can be conducted synchronously after plastering, the bricklaying procedure is simplified, the overall bricklaying efficiency is improved, and the mortaris prevented from being solidified in the bricklaying process.

Owner:HUAWAY IOT TECH

Coke oven refractory material matching board construction method

The invention discloses a coke oven refractory material matching board construction method which comprises the following steps: based on BIM technology, firstly creating a coke oven brick family file and loading into a project for combination; finishing the establishment of the models of all parts of the coke oven masonry; and performing matching board construction of the coke oven masonry according to daily plan, human post determination, brick positioning, matching board positioning and fixed-point building. The method disclosed by the invention has the following beneficial effects: the builders can be helped to accurately and quickly select the brick type, and the building efficiency is improved. Based on the enterprise production quota, the daily workload distribution scheme and brick delivery data of each builder are quickly finished, and the building task is practiced by specific builders while the builders are told about the models in details. The brick sorting time in the oven is saved, and the working efficiency is improved. A coke oven refractory material transport structure effectively prevents excessive wear and collapse of refractory bricks on a brick board caused by jolt.

Owner:CHINA FIRST METALLURGICAL GROUP

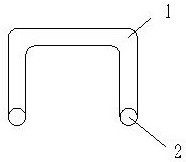

Tool for building and rapidly forming mortar joints

InactiveCN113550610ASimple structureEasy to manufactureBuilding material handlingConstruction engineeringRebar

The invention relates to a tool for building and rapidly forming mortar joints. The tool comprises two reinforcing steel bars and a handle. The tool is characterized in that the two reinforcing steel bars are equal in length with phi 10mm, the handle is an n-shaped handle made of reinforcing steel bars, the width between two supporting legs of the n-shaped handle is matched with the parallel width of the interval of the two reinforcing steel bars, and the two supporting legs of the n-shaped handle are perpendicularly and fixedly welded to one end of the two reinforcing steel bars, so that the tool for forming the mortar joints is formed. The tool for building and rapidly forming the mortar joints has the advantages of the simple structure, convenience in manufacturing, easiness in operation, high applicability, high repeated utilization rate and high mortar joint forming speed, the building efficiency is improved, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Apparatus for Ladle Working Lining Construction

ActiveCN103406527BConvenient automatic masonryGuarantee the accuracy of masonryMelt-holding vesselsBraced frameBrick

The invention discloses a device for building a steel ladle working lining. The bottom face of a supporting framework of the device is arranged on a steel ladle foundation in an erected mode and located above a steel ladle, the top end of a telescopic stand column set is vertically arranged in the center of the top face of the supporting framework and extends into the steel ladle, a rotation lifting platform and a brick lifting disc are arranged on the telescopic stand column set and lift along the telescopic stand column set, the brick lifting disc is arranged at the outer edge of the rotation lifting platform and rotates along the rotation lifting platform, a brick building mechanical arm and a pouring posture adjusting mechanism are fixedly arranged at the outer edge of the rotation lifting platform in a spaced mode, the tail end of the pouring posture adjusting mechanism moves horizontally within a vertical surface in a two-dimensional mode, a spiral conveyer and a vibratory hammer are fixedly arranged at the tail end of the pouring posture adjusting mechanism, and a feeding mechanical arm is arranged on the steel ladle foundation and is close to the steel ladle. The device brings convenience to automatic building of the steel ladle working lining, effectively relieves labor intensity of the building operation, improves building efficiency, ensures building accuracy of the steel ladle working lining, and prolongs the service life of the steel ladle working lining.

Owner:CHINA FIRST HEAVY IND

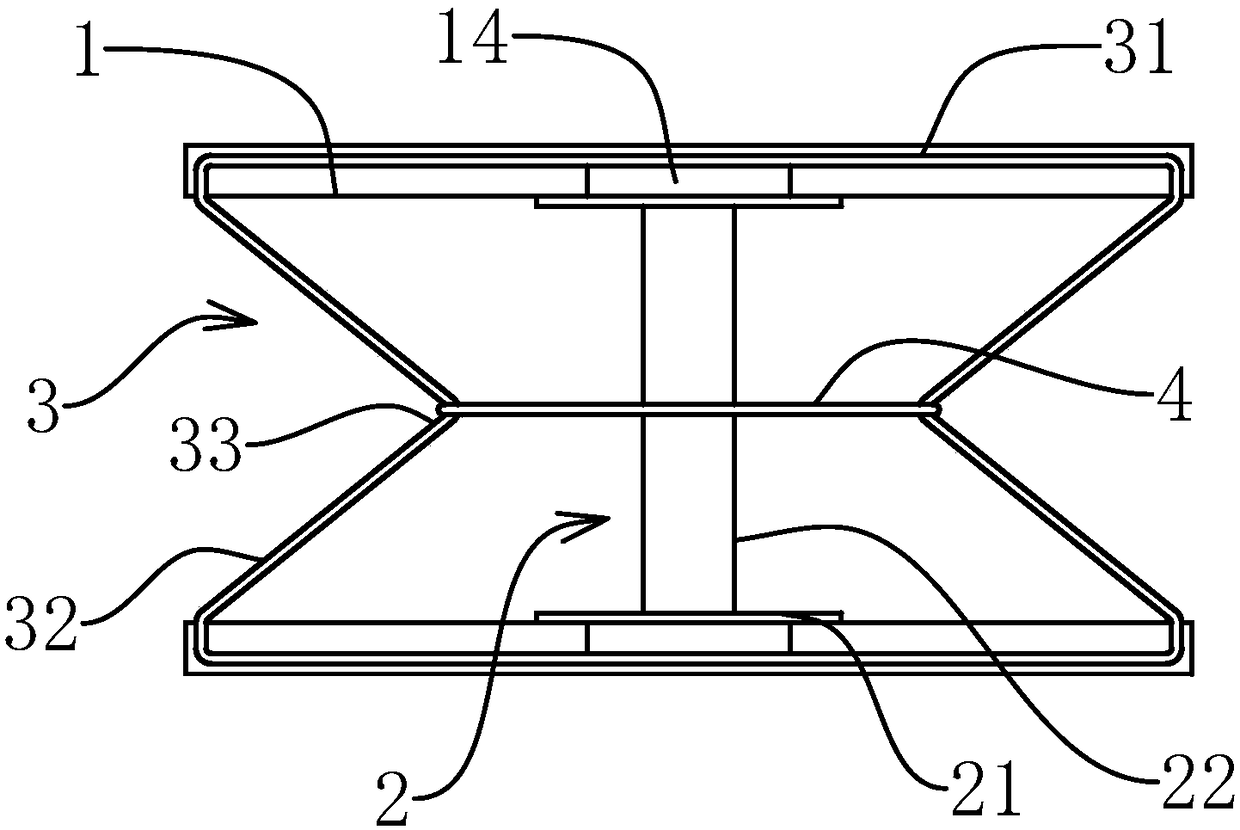

Trellis type sandwiched and heat-bridge free concrete block and preparation method thereof

InactiveCN102912924AAvoid thermal bridgingReduce weightConstruction materialCeramic shaping apparatusThermal insulationFire resistance

The invention discloses a trellis type sandwiched and heat-bridge free concrete block and a preparation method thereof. The trellis type sandwiched and heat-bridge free concrete block includes sandwiched thermal insulation layer trellis type concrete and concrete ribs, and at least four sandwiched thermal insulation layers are arranged in the trellis type concrete; and every two sandwiched thermal insulation layers on each layer are separated by one concrete rib, at least two concrete ribs are arranged on each layer, and the sandwiched thermal insulation layers and the sandwiched thermal insulation layers on the adjacent layers are mutually staggered. The invention has the effects and advantages that the heat bridge effect at the part without thermal insulation of the building block can be prevented without adopting other thermal insulation layers, so that the energy-saving capability of a building is greatly improved, the thermal insulation effect is enhanced, and durability, safety, fire resistance and effective sound insulation can be realized; and the construction technique is convenient, the speed is high, the building efficiency is improved, material is saved, transporting capacity and construction cost are reduced, the building block is light, and the cost of the whole building is low.

Owner:SHENYANG JIANZHU UNIVERSITY

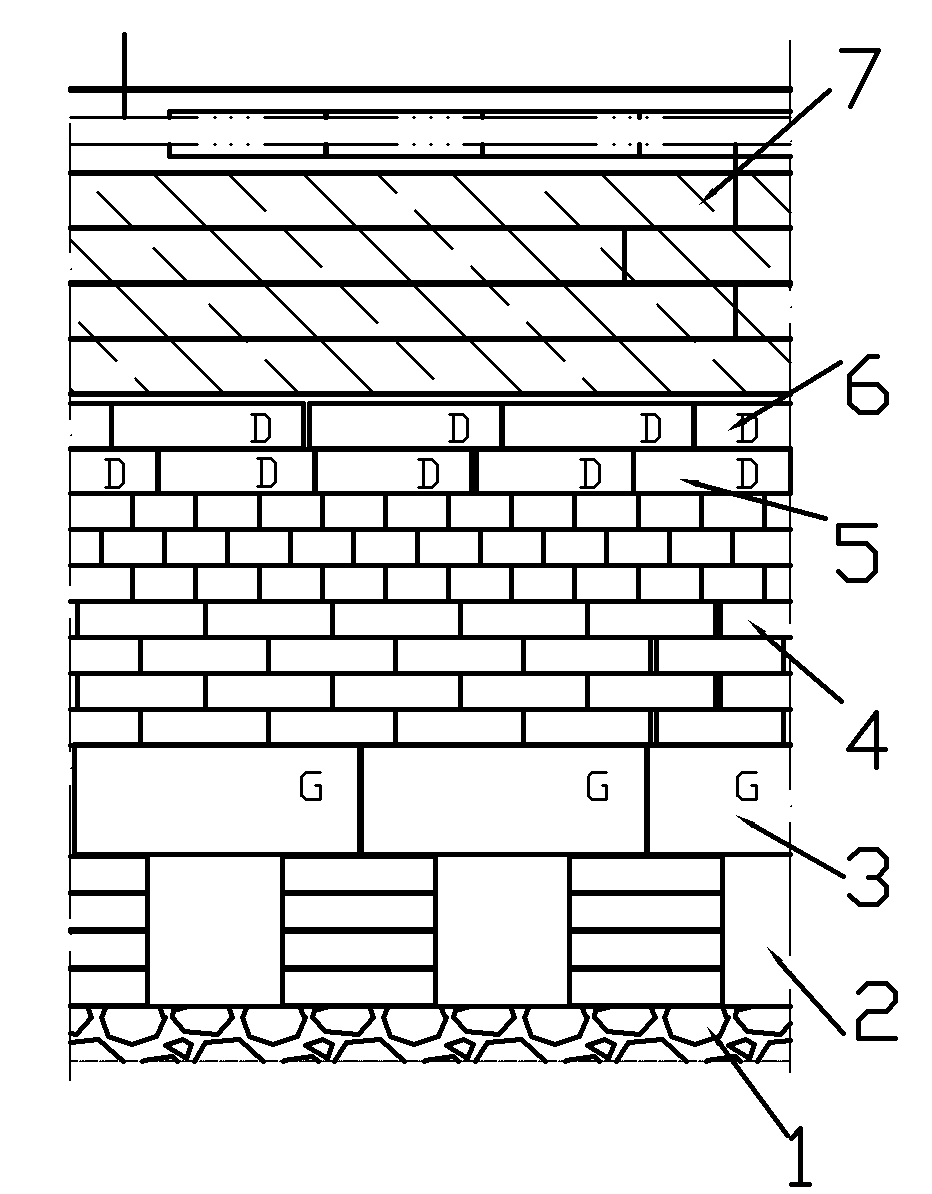

Hearth refractory material structure of carbon roasting furnace

InactiveCN102706159ASolve the problem that the structure is too complex and the efficiency of masonry is lowSolve serious accidents such as sinkingFurnace componentsFire brickRefractory

The invention discloses a hearth refractory material structure of a carbon roasting furnace. The hearth refractory material structure of the carbon roasting furnace comprises hearth heavy refractory materials or concrete, light heat-insulation bricks, hearth blocks and heavy refractory bricks at the bottom of a flame path wall, and the hearth heavy refractory materials or the concrete are connected with the heavy refractory bricks at the bottom of the flame path wall by a plurality of support columns. The hearth refractory material structure in the technical scheme has the advantages that problems that the shapes of bricks are multiple, a hearth structure is over complicated and construction efficiency is low in the prior art are solved, and problems of serious accidents such as that heat-insulation bricks are often broken and a flame path wall is subsided during usage of an existing carbon roasting furnace due to the fact that the hearth light heat-insulation bricks are low in strength and the like are also solved.

Owner:HENAN ANRUI HIGH TEMPERATURE MATERIALS

Structure of stone wall constructed by strip stone cut by machine and method thereof

ActiveCN101949182BImprove bindingIncreased shear strength of gray jointsWallsBuilding material handlingStone wallStructure of the Earth

The invention discloses a structure of a stone wall constructed by strip stone cut by a machine and a method thereof. The structure comprises upper strip stone and lower strip stone which are cut by a machine; a lime slot is formed between the constructing interface of the upper strip stone and the constructing interface of the lower strip stone; the lime slot is filled with bonding material usedfor bonding the upper strip stone and the lower strip stone together; the constructing interface of the upper strip stone and the constructing interface of the lower strip stone are both provided with crossed grooved grains; a plurality of grooves are formed on the constructing interface of one row of strip stone; shear keys are convex externally on the constructing interface of the other row of strip stone; the shear keys correspond to the grooves and are meshed with the grooves; in this way, the upper strip stone and the lower strip stone can be bonded more firmly by the grooved grains arranged on both of the constructing interfaces of the upper strip stone and the lower strip stone and the grooves and the shear keys which are arranged on the two constructing interfaces and are matched;thereby, the shear strength of the lime slot of the stone wall formed by construction is largely enhanced; and the stone wall has excellent seismic performance and compressive load capacity.

Owner:HUAQIAO UNIVERSITY

Double-arm wall building robot and wall building method thereof

ActiveCN111910936APrevent solidificationSimplify the wall-building processBuilding material handlingBrickArchitectural engineering

The invention discloses a double-arm wall building robot. The robot comprises a rotating base, a robot body arranged on the rotating base and capable of rotating along the rotating base, a vertical moving module installed on the robot body, a brick clamping arm and a mortar taking arm, wherein the brick clamping arm and the mortar taking arm are installed on the vertical moving module and capableof moving up and down along the vertical moving module. A first motor set is arranged on the brick clamping arm, a clamp used for clamping bricks is connected to the lower portion of the first motor set, a second motor set is arranged on the mortar taking arm, and a mortar cup used for clamping mortar is connected to the lower portion of the second motor set. The invention further discloses a wallbuilding method of the double-arm wall building robot. The two mechanical arms, namely the brick clamping arm and the mortar taking arm, are arranged, so that the two arms move at the same time to clamp the bricks and the mortar, the mortar can be synchronously applied after brick building, the wall building procedure is simplified, the overall building efficiency is improved, and the mortar is prevented from being solidified in the building process.

Owner:HUAWAY IOT TECH

Industrial waste residue self-insulation raw soil building block without heat bridge and preparation method thereof

InactiveCN102912927AReduce pollutionGood energy saving effectConstruction materialClimate change adaptationInsulation layerThermal bridge

The invention discloses an industrial waste residue self-insulation raw soil building block without a heat bridge. The industrial waste residue self-insulation raw soil building block comprises insulation boards on both sides, wherein a side rib is formed between the adjacent insulation boards on both sides, a middle rib is formed between the middle adjacent insulation boards, the side ribs and the middle ribs in different layers are staggered, the outer sides of the insulation boards on both sides are raw soil protection layers, and raw soil layers are arranged between the insulation boards on both sides and the middle insulation boards; the building block is outwards extended from the middle insulation board on one end of the building block so as to form a vertical mortar joint extension insulation layer, a vertical mortar joint heat bridge blocking groove matched with the vertical mortar joint extension insulation layer is arranged on the other end of the building block, and the insulation boards on both sides and the middle adjacent insulation boards are outwards extended to form a horizontal vertical mortar joint extension insulation layer. According to the invention, a large amount of industrial waste residues can be consumed to produce an energy-saving building wall material, so that the environmental pollution is reduced, vast fertile farmland clay is saved, the waste is changed into wealth, and a large amount of fuel coal is saved. Furthermore, the energy-saving capacity of the building is improved, the thermal insulation effect is enhanced, and the industrial waste residue self-insulation raw soil building block has the advantages of durability, safety and flame resistance, and capability of effectively blocking sound.

Owner:SHENYANG JIANZHU UNIVERSITY

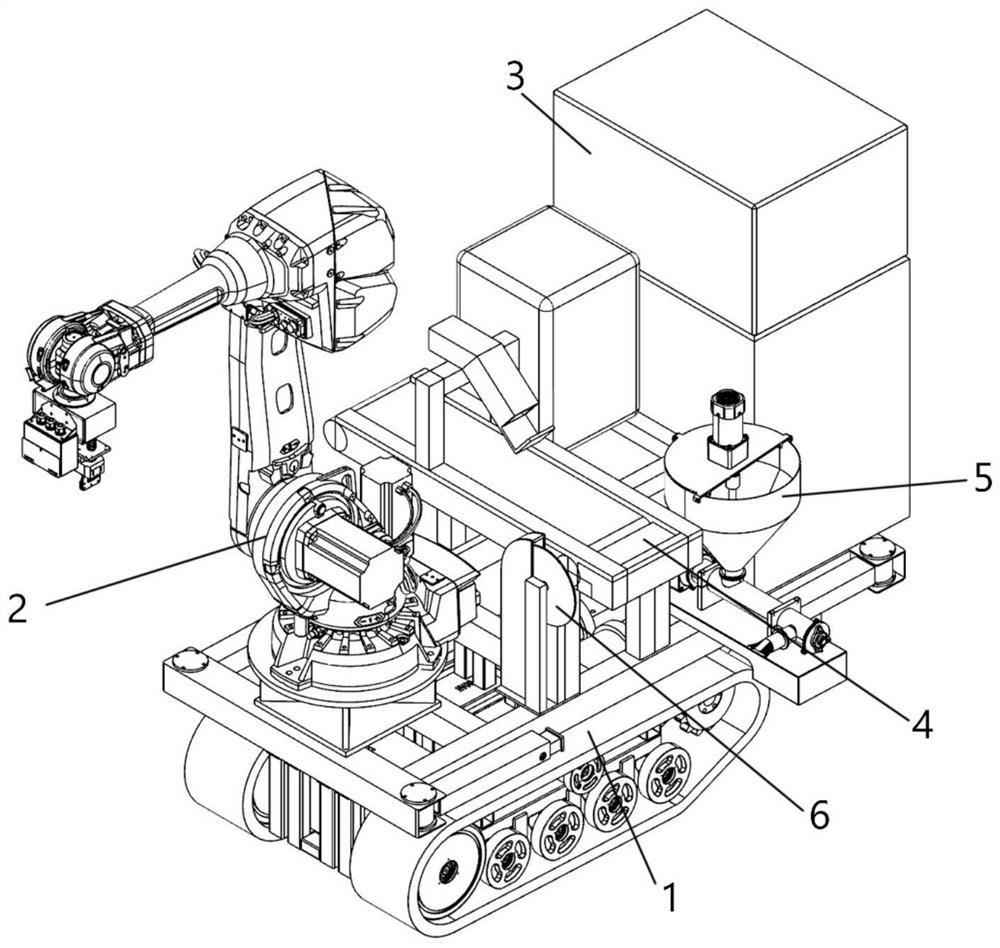

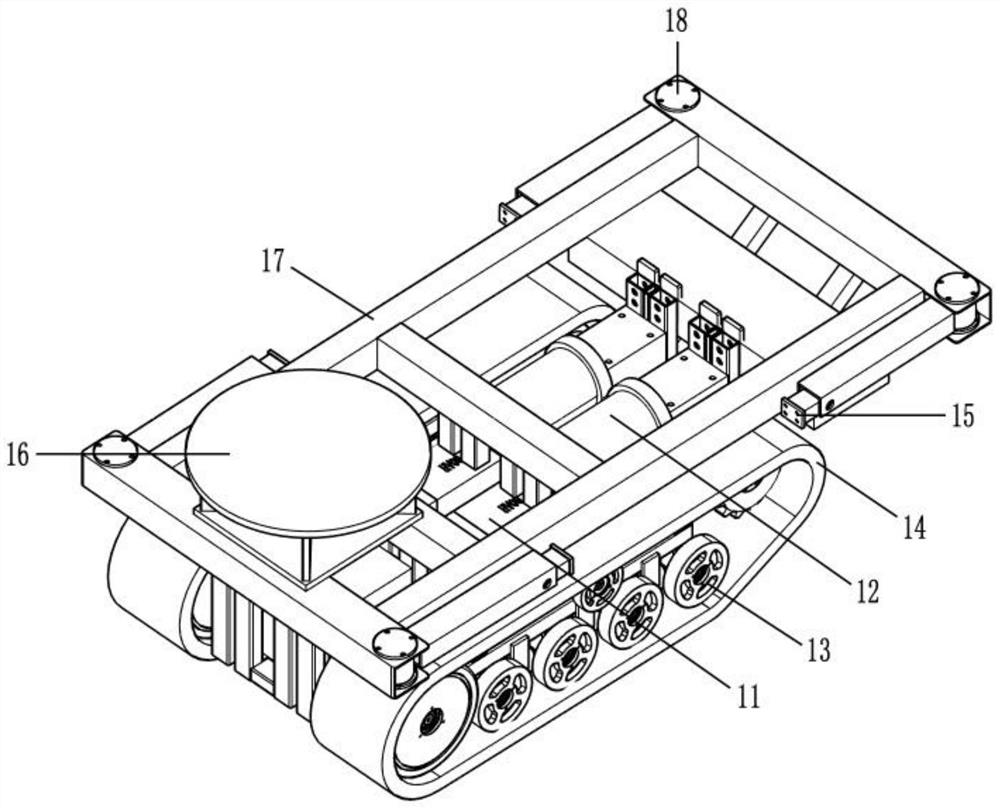

Bricklaying robot

InactiveCN112302356AHigh precisionImprove construction efficiencyBuilding material handlingMechanical measuring arrangementsControl engineeringBrick masonry

The invention provides a bricklaying robot, and belongs to the technical field of brick masonry construction. The bricklaying robot comprises a moving chassis, a mechanical gripper mechanism and a displacement detection device; The mechanical gripper mechanism comprises a six-degree-of-freedom robot body with one end installed on the movable chassis and a gripper mechanism connected with the otherend of the robot body; the gripper mechanism can be driven by the robot body to conduct brick taking and placing operation; the gripper mechanism comprises a mounting base connected with the robot body and a gripper assembly which is arranged on the mounting base and can move relative to the mounting base; and the displacement detection device is arranged on the gripper mechanism and used for detecting the displacement of the gripper assembly. According to the bricklaying robot, the construction precision and the construction efficiency of parameterized brick wall on-site masonry can be improved.

Owner:TONGJI UNIV +1

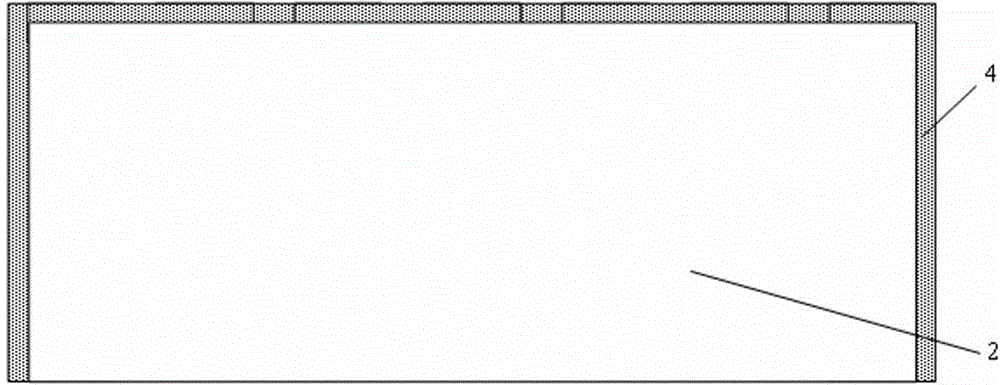

Dismantle-free concrete mold used for pouring insulation foundation

InactiveCN107574832AHigh strengthLow costFoundation engineeringInsulation layerUltimate tensile strength

The invention relates to building foundation pouring templates, in particular to a dismantle-free concrete mold used for pouring an insulation foundation. The cross section of the dismantle-free concrete mold used for pouring the insulation foundation is in a groove shape. A concrete bottom plate is arranged at the bottom of the dismantle-free concrete mold. A bottom communicating insulation concrete side plate and a top communicating insulation concrete side plate are arranged on the two sides of the dismantle-free concrete mold. Insulation layer dovetail grooves in the inner side and the outer side of the top communicating insulation plate are engaged with concrete dovetail joints correspondingly. Insulation layer dovetail joints are engaged with concrete dovetail grooves correspondingly. The dismantle-free concrete mold has the effects and the advantages of being free of dismantling, high in strength, economical, convenient to construct, short in construction period and capable of improving the laying efficiency, saving materials, reducing freight volume and lowering the construction cost. The strength of the concrete grooves is as same as that of post-poured concrete, the goodbonding performance is achieved, and the integrality is good. Insulation layers are arranged in the mold, thus, the poured foundation has the insulation performance, the insulation layers are locatedin a structure, environment erosion is avoided, and the durability, soundness are the like are remarkably improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Self-flow castable for filling back seam of side wall of aluminium electrolytic bath

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Refractory brick for boiler masonry

PendingCN114719285AReduce the chance of breaking downReduce crackingCasings/liningsBrick masonryFire brick

The invention relates to the technical field of refractory bricks, in particular to a refractory brick for boiler masonry. A clamping block is arranged in the middle of the upper surface of the brick body; a clamping groove is formed in the middle of the lower surface of the brick body; a rotating mechanism is arranged at the position, corresponding to the clamping block, of the upper surface of the brick body and comprises a containing groove formed in the position, corresponding to the clamping block, of the upper surface of the brick body. Two fixing rings are symmetrically and fixedly connected to the positions, corresponding to the clamping blocks, of the side wall of the containing groove. A rotating shaft is arranged between the two fixing rings; the outer circle face, located between the two fixing rings, of the rotating shaft is sleeved with a sleeve. The upper end of the outer circle face of the sleeve is fixedly connected with a connecting block. The influence of collision between bricks caused by bumping of a transport vehicle on the clamping blocks can be reduced, the situation that cracks or fractures occur at the joints of the clamping blocks and the brick bodies is reduced, the influence on follow-up refractory brick masonry is reduced, and the refractory brick masonry efficiency is improved.

Owner:方帆

Hollow building block and wall body manufacturing and building method

The invention providers a hollow building block and a wall body manufacturing and building method and belongs to the field of building structures. According to the hollow building block and the wall body manufacturing and building method, the problems that an existing building block is low in strength and low in construction efficiency are solved. The hollow building block comprises two wall plates, a supporting frame and two connecting frames. The supporting frame comprises supporting plates and a supporting pipe, and the two supporting pates are fixed to the two wall plates. Each connectingframe comprises two outer connecting rods and two V-shaped inner connecting rods. Hooked bar parts are arranged in the middles of the inner connecting rods, and two connecting grooves are formed in the outer side face of each wall plate. The two outer connecting rods of one connecting frame are located in the connecting grooves in the positions, close to the upper side edges, of the two wall plates correspondingly, and the two outer connecting rods of the other connecting frame are located in the connecting grooves in the positions, close to the lower side edges, of the two wall plates correspondingly. The hollow building block further comprises a steel bar frame of a rectangular frame structure, and the steel bar frame is arranged around the supporting pipe, and the total four hooked barparts of the two connecting frames are hooked by the four corners of the steel bar frame correspondingly. Manufacturing and building through the building bock are convenient, the structure is stable,and a high-strength wall body structure can be built.

Owner:WENZHOU OULIN ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com