Bricklaying robot

A robot and robot body technology, applied in the field of brick masonry construction, can solve the problems of complex masonry quality detection of mobile robots and positioning robots, achieve intelligence and diversity, save labor costs, and improve masonry quality. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

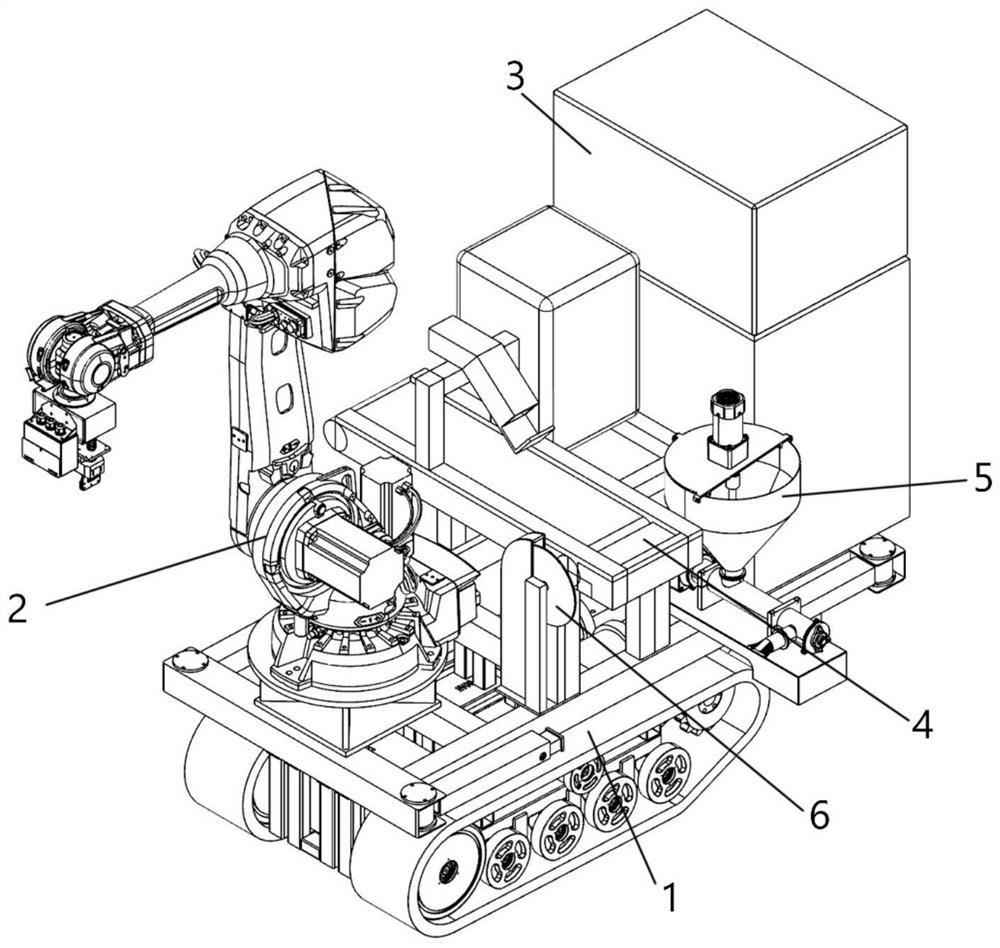

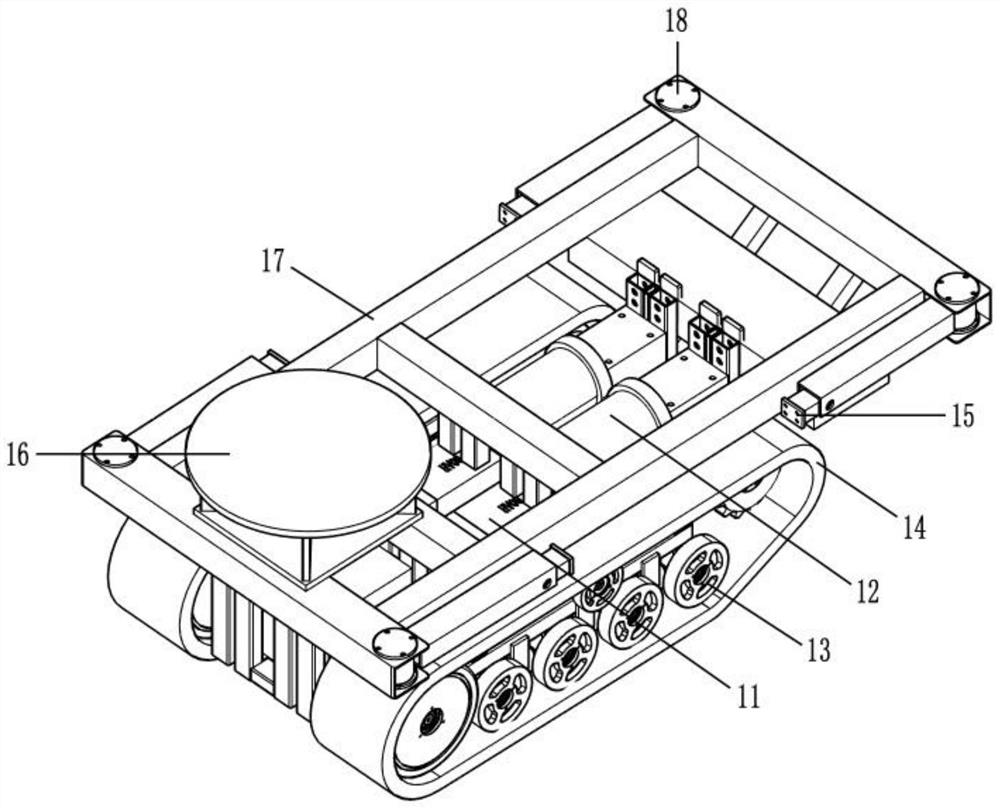

[0044] Such as figure 1 As shown, a bricklaying robot provided by an embodiment of the present invention includes a mobile chassis 1 capable of moving on a construction site, a machine gripper mechanism 2 and a displacement detection device 23 . The machine gripper mechanism 2 includes a six-degree-of-freedom robot body mounted on the mobile chassis 1 at one end and a gripper mechanism connected to the other end of the robot body. Grab and place masonry bricks.

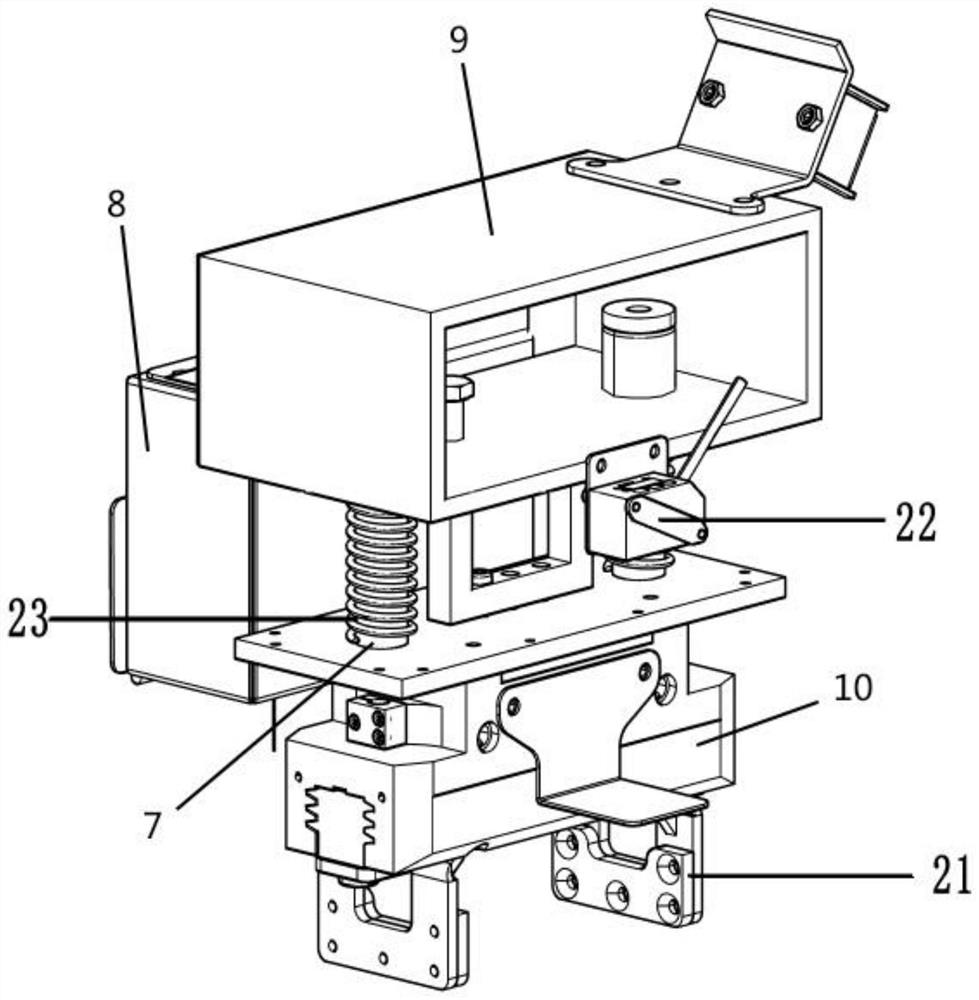

[0045]The gripper mechanism can perform brick pick-and-place operations under the drive of the robot body. As an embodiment of the present invention, a separate drive mechanism, such as a driving cylinder, can be set on the gripper mechanism, and the gripper mechanism can be driven by the drive mechanism. Carry out brick pick and place operations. Specifically, the gripper mechanism includes a mount 8 connected to the robot body and a gripper assembly 21 disposed on the mount 8 and capable of displacement relative t...

Embodiment 2

[0057] Based on the bricklaying robot described in Embodiment 1, the present invention provides a method for using the bricklaying robot, which specifically includes the following steps:

[0058] Step 101, move the chassis 1 to the working position, perform leveling support, and prepare for work;

[0059] Step 102, obtain the position information through the position feedback camera 22, transmit it to the control mechanism 3, and calculate the position of the bricklaying robot;

[0060] Step 103, according to the preset program information of the control mechanism 3, transmit commands and motion data to each mechanism;

[0061] Step 104, the brick feeding mechanism 4 obtains commands and data, and transmits bricks;

[0062] Step 105, the mortar feeding mechanism 5 obtains commands and data, and performs mortar smearing operations on the transported bricks;

[0063] Step 106, the brick cutting mechanism 6 acquires commands and data, and performs cutting operations on the smea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com