Apparatus for Ladle Working Lining Construction

A technology of working lining and ladle, applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems of high labor intensity, unsuitable for masonry, and inability to masonry the bottom of the ladle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

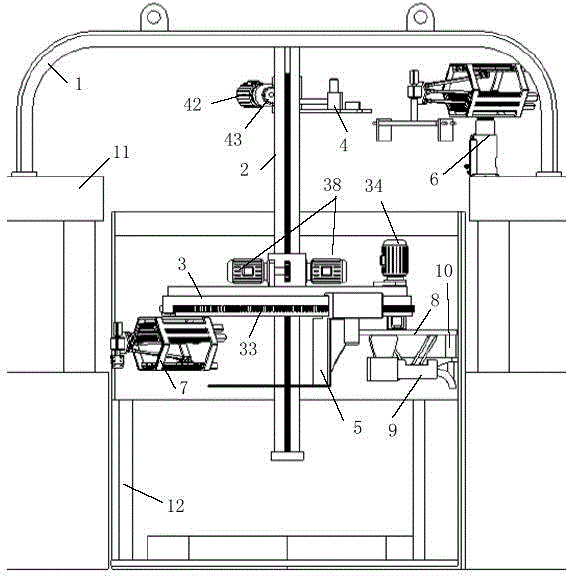

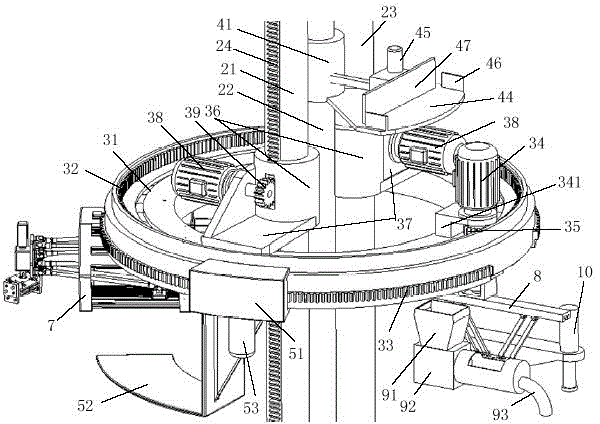

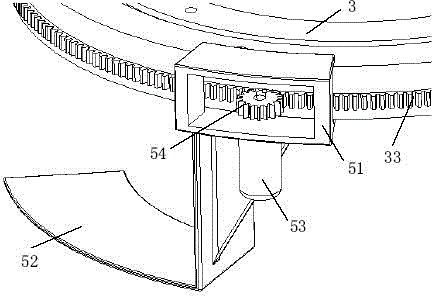

[0017] Such as figure 1 As shown, the device for ladle lining masonry of the present invention includes a support frame 1, a telescopic column group 2, a rotary lifting platform 3, a brick lifting plate 4, a brick rotary plate 5, a bricklaying manipulator 7, and a pouring posture adjustment mechanism 8 , screw conveyor 9, vibrating hammer 10 and feeding manipulator 6, the bottom surface of the support frame 1 is erected on the ladle foundation 11 and is located above the ladle 12, and the top of the telescopic column group 2 is vertically arranged at the center of the top surface of the support frame 1 And extend into the ladle 12, the rotary lifting platform 3 and the brick lifting plate 4 are set on the telescopic column group 2 and lift along the telescopic column group 2, the brick rotary plate 5 is set on the rotary lifting platform 3 The outer edge is rotated along the rotary lifting platform 3. The bricklaying manipulator 7 and the pouring attitude adjustment mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com